Inspecting the Connector

Inspecting the Connector

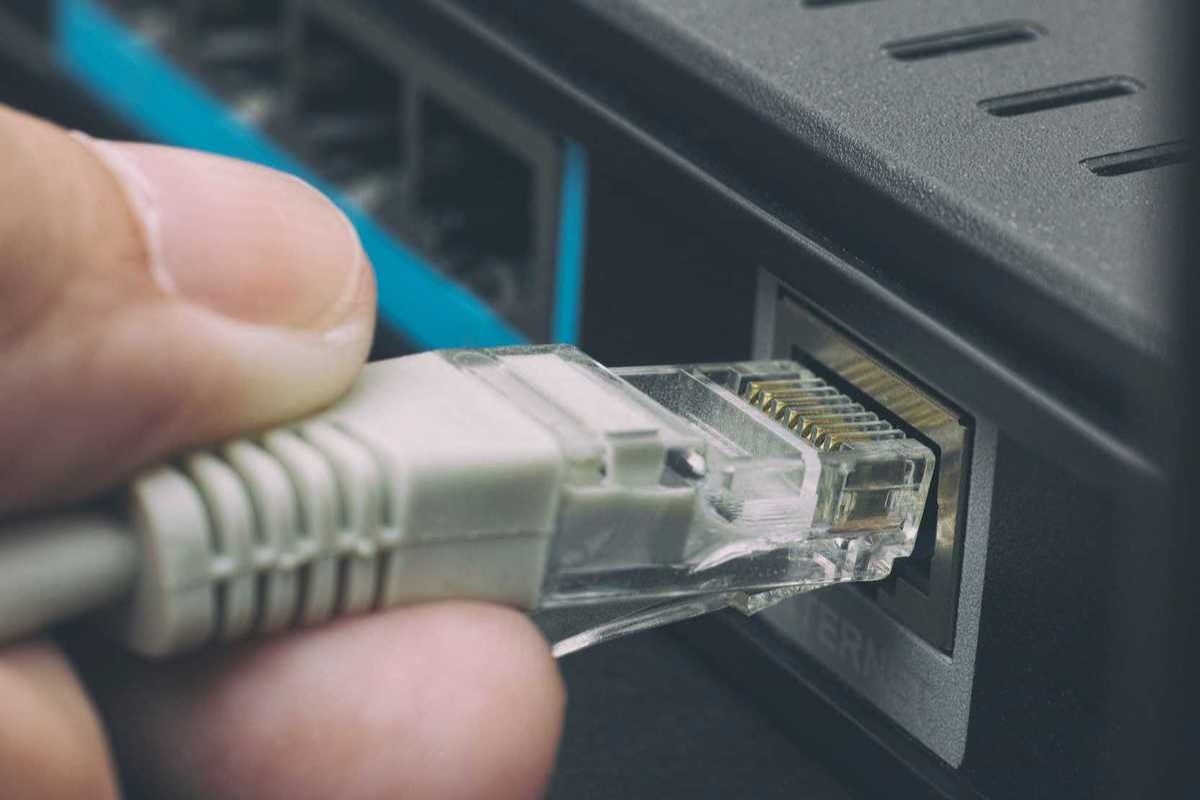

Before embarking on the cleaning process, it’s crucial to thoroughly inspect the Ethernet connector to identify any visible issues. Start by examining the physical condition of the connector, ensuring there are no signs of damage, corrosion, or excessive dirt accumulation. Check for any bent or misaligned pins, as these can interfere with the proper functioning of the connector. Additionally, inspect the surrounding area for any loose or broken components that may impact the connector’s performance.

When inspecting the connector, it’s important to pay attention to any unusual odors emanating from the device, as this could indicate potential overheating or electrical issues. Furthermore, take note of any loose connections or frayed cables that may compromise the integrity of the Ethernet connection. By conducting a comprehensive visual inspection, you can effectively assess the overall condition of the connector and determine the appropriate course of action for cleaning and maintenance.

During the inspection process, it’s advisable to take note of any specific areas that require targeted cleaning or potential repairs. By documenting these findings, you can create a structured approach to addressing the identified issues, ensuring that the cleaning and maintenance efforts are tailored to the connector’s specific requirements.

Using Compressed Air for Dust Removal

When it comes to maintaining an Ethernet connector, one of the most effective methods for removing accumulated dust and debris is utilizing compressed air. Dust particles can easily infiltrate the connector, leading to connectivity issues and potential damage if left unaddressed. Before proceeding with the cleaning process, it’s essential to power off the device and disconnect the Ethernet cable to ensure safety and prevent any potential electrical hazards.

To begin, gently position the Ethernet connector in a stable and secure manner, ensuring that it is not susceptible to unnecessary movement during the cleaning process. With the help of a can of compressed air equipped with a thin nozzle attachment, carefully direct the airflow into the connector. It’s crucial to maintain a consistent distance and angle to avoid causing damage to the internal components while effectively dislodging the trapped dust particles.

As you administer the compressed air, pay close attention to any visible debris being expelled from the connector. Ensure that the airflow reaches all corners of the connector to guarantee comprehensive dust removal. Additionally, exercise caution to prevent the dispersal of dislodged dust particles into the surrounding environment, as this can lead to further contamination and potential reaccumulation within the connector.

By utilizing compressed air for dust removal, you can effectively dislodge and expel trapped particles without the need for direct physical contact, minimizing the risk of damaging the delicate components within the connector. This method offers a non-invasive yet highly efficient approach to preserving the integrity and functionality of the Ethernet connector, ultimately contributing to sustained performance and reliability.

Using Isopropyl Alcohol for Cleaning

When it comes to maintaining the cleanliness of an Ethernet connector, utilizing isopropyl alcohol is a highly effective method for removing stubborn residues and contaminants. Isopropyl alcohol, also known as rubbing alcohol, is renowned for its ability to dissolve and evaporate various types of grime and residue without leaving behind any harmful byproducts.

Before commencing the cleaning process, it is imperative to ensure that the connector is completely disconnected from any power source and that the surrounding area is well-ventilated. Begin by dampening a lint-free cloth or swab with a small amount of isopropyl alcohol, ensuring that it is not excessively saturated to prevent any liquid from seeping into the connector’s internal components.

Gently and methodically wipe the external surfaces of the connector with the isopropyl alcohol-dampened cloth, paying particular attention to areas where dirt, grease, or other contaminants may have accumulated. It is crucial to exercise caution and precision during this process to avoid causing damage to the connector or its intricate components. Additionally, refrain from using excessive force to prevent inadvertently dislodging any internal elements.

For hard-to-reach areas and intricate crevices, consider using a cotton swab lightly moistened with isopropyl alcohol to meticulously clean these areas. This meticulous approach ensures that even the most secluded areas of the connector are thoroughly cleansed, promoting optimal performance and longevity.

Following the application of isopropyl alcohol, allow the connector to thoroughly air-dry before reconnecting it to the network. This crucial step ensures that any residual alcohol evaporates completely, leaving the connector free of moisture and ready for seamless functionality.

By incorporating isopropyl alcohol into the cleaning regimen for Ethernet connectors, you can effectively eliminate persistent residues and contaminants, thereby safeguarding the connector’s performance and prolonging its operational lifespan.

Using a Soft Brush for Debris Removal

When addressing debris and particulate matter that has accumulated within an Ethernet connector, employing a soft brush is a valuable and non-invasive method for effectively dislodging and removing such contaminants. The use of a soft brush enables meticulous cleaning without risking damage to the delicate internal components of the connector.

Prior to utilizing the soft brush, it is imperative to ensure that the connector is disconnected from any power source and that the surrounding area is free from excessive dust and debris. This precautionary measure minimizes the risk of introducing additional contaminants into the connector during the cleaning process.

Select a soft-bristled brush specifically designed for delicate electronic components, ensuring that the bristles are fine and pliable to prevent scratching or damaging the connector’s surfaces. Gently and methodically brush the exterior and interior of the connector, focusing on areas where debris and particulate matter are visibly present. Exercise patience and precision to effectively dislodge the contaminants without exerting excessive force on the connector.

When using the soft brush, it is essential to adopt a systematic approach, ensuring that all accessible areas of the connector are thoroughly addressed. Pay particular attention to the connector’s ports and crevices, as these areas are prone to accumulating debris and may require targeted cleaning to restore optimal functionality.

Throughout the cleaning process, periodically inspect the brush to ensure that dislodged debris is not reintroduced into the connector. If necessary, gently tap the brush against a clean surface to dislodge any accumulated particles, thereby preventing their reentry into the connector.

Following the removal of debris with the soft brush, visually inspect the connector to ascertain the effectiveness of the cleaning process. If any stubborn residues persist, consider complementing the soft brush method with isopropyl alcohol or compressed air to achieve comprehensive cleanliness and ensure the connector’s optimal performance.

By incorporating a soft brush into the maintenance routine for Ethernet connectors, you can effectively address debris and particulate matter, thereby promoting sustained functionality and minimizing the risk of connectivity issues arising from contamination.

Avoiding Harsh Cleaning Chemicals

When undertaking the cleaning and maintenance of Ethernet connectors, it is imperative to exercise caution and refrain from using harsh cleaning chemicals that may potentially compromise the integrity of the connector. While it may be tempting to resort to strong solvents or abrasive cleaners to expedite the cleaning process, such substances can pose significant risks to the connector’s delicate components and overall functionality.

Harsh cleaning chemicals, including strong solvents, acids, and alkalis, can corrode the metal contacts within the connector, leading to diminished conductivity and potential long-term damage. Additionally, these chemicals may adversely affect the insulating materials surrounding the connector, compromising their structural integrity and electrical insulation properties.

Furthermore, the use of abrasive cleaners or scouring pads can result in physical damage to the connector’s surfaces, potentially causing scratches, abrasions, or the removal of protective coatings. Such damage not only detracts from the connector’s aesthetic appeal but also creates potential entry points for dust, debris, and moisture, further exacerbating the risk of connectivity issues and electrical malfunctions.

To safeguard the longevity and performance of Ethernet connectors, it is essential to prioritize the use of gentle cleaning agents and non-abrasive tools. Lint-free cloths, soft brushes, and isopropyl alcohol are recommended for their effectiveness in removing contaminants without posing harm to the connector’s intricate components.

By avoiding harsh cleaning chemicals and opting for milder, electronics-safe cleaning solutions, you can uphold the structural integrity and operational efficiency of Ethernet connectors, thereby mitigating the risk of premature deterioration and connectivity issues.

Checking for Bent or Damaged Pins

One of the critical aspects of maintaining an Ethernet connector involves inspecting the integrity of its pins to ensure optimal connectivity and functionality. The pins within the connector play a pivotal role in establishing secure and reliable electrical connections, making it essential to routinely assess their condition and alignment.

To begin the examination, carefully position the connector under adequate lighting to facilitate a thorough visual inspection. Using a magnifying glass can further aid in scrutinizing the intricate details of the pins, enabling the detection of subtle deformities or damage that may elude the naked eye.

During the assessment, pay close attention to the alignment of the pins, ensuring that they are uniformly positioned and free from any signs of bending, warping, or breakage. Bent or misaligned pins can impede the proper insertion of Ethernet cables, resulting in connectivity issues and potential damage to the connector and the connected devices.

Furthermore, inspect the pins for any indications of corrosion, oxidation, or tarnishing, as these forms of degradation can hinder electrical conductivity and compromise the overall performance of the connector. If any of these issues are observed, prompt remedial action is necessary to rectify the underlying causes and restore the connector to optimal working condition.

In the event that bent or damaged pins are identified, it is crucial to exercise caution and precision when attempting to realign or repair them. Utilizing specialized tools designed for pin straightening or seeking professional assistance can help mitigate the risk of exacerbating the damage and ensure that the corrective measures are carried out effectively.

Regularly checking for bent or damaged pins is instrumental in preemptively addressing potential connectivity issues and safeguarding the long-term functionality of Ethernet connectors. By incorporating this proactive approach into the maintenance regimen, you can uphold the reliability and performance of the connectors within your network infrastructure.

Replacing the Connector if Necessary

Despite diligent maintenance efforts, there may arise situations where the condition of an Ethernet connector necessitates replacement to ensure uninterrupted network connectivity and optimal performance. Recognizing the signs that indicate the need for a new connector is crucial in preemptively addressing potential issues and minimizing disruptions within the network infrastructure.

When considering the replacement of an Ethernet connector, it is essential to first assess the severity of any identified issues, such as extensive physical damage, irreparable corrosion, or persistent connectivity issues that persist despite cleaning and troubleshooting efforts. Additionally, if the connector exhibits signs of wear and degradation that compromise its structural integrity and electrical conductivity, replacement becomes a viable and prudent course of action.

Before embarking on the replacement process, it is imperative to power down the associated devices and disconnect the Ethernet cable to ensure safety and prevent any potential electrical hazards. Carefully remove the existing connector, taking note of its orientation and the arrangement of the internal wires to facilitate the seamless installation of the replacement unit.

When selecting a replacement connector, prioritize obtaining a high-quality, industry-standard component that aligns with the specifications and compatibility requirements of the network infrastructure. Opting for a reputable and reliable connector ensures optimal performance, durability, and compatibility with the existing network setup, thereby mitigating the risk of compatibility issues or subpar connectivity.

During the installation of the replacement connector, meticulous attention to detail is paramount to ensure proper alignment, secure attachment, and accurate termination of the internal wires. Adhering to the manufacturer’s guidelines and best practices for connector installation is instrumental in achieving a reliable and enduring connection that upholds the network’s performance standards.

By promptly replacing a compromised or deteriorated Ethernet connector, you can effectively restore the integrity and functionality of the network, mitigating the risk of connectivity issues, data loss, and compromised network security. Embracing a proactive approach to connector replacement contributes to the sustained reliability and efficiency of the network infrastructure.