Factors that Determine Soldering Iron Wattage

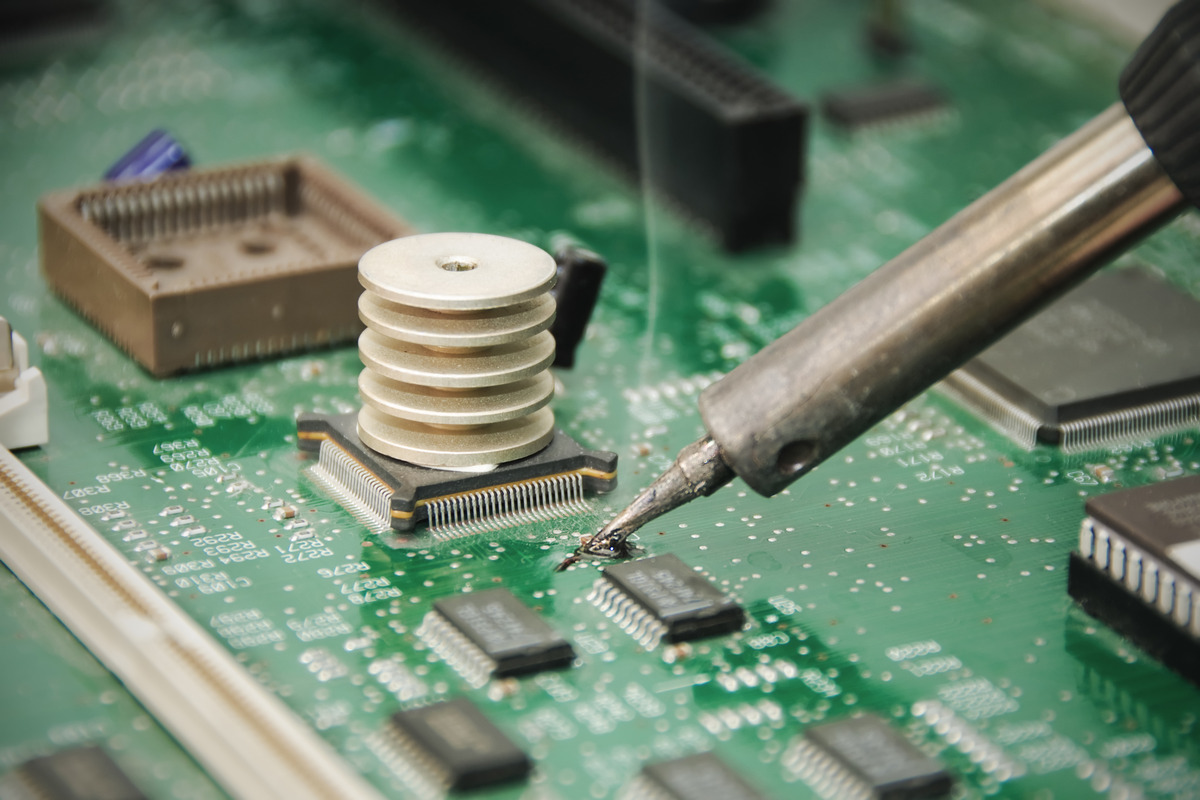

When it comes to soldering electronic components, the wattage of the soldering iron plays a crucial role in achieving optimal results. The right wattage ensures efficient heat transfer and effectively melts the solder, allowing for precise and reliable connections. However, determining the appropriate wattage for a soldering iron depends on several factors. Let’s take a closer look at these factors:

- Component Size and Thermal Mass: The size and thermal mass of the components being soldered directly influence the required wattage. Larger or heat sinked components may require higher wattage to generate enough heat for proper soldering.

- Soldering Task: Different soldering tasks have different wattage requirements. Basic solder joints on small components might only require low wattage, while more complex tasks like desoldering or working on larger boards may demand higher wattage.

- Soldering Environment: The ambient temperature and airflow in the workspace also affect the wattage needed. Cold environments or areas with significant airflow may necessitate higher wattage to compensate for heat loss.

- Soldering Iron Tip: The heat transfer efficiency of the soldering iron tip is influenced by its material, shape, and size. A well-maintained and high-quality tip can enhance heat transfer, allowing for efficient soldering at lower wattages.

- User Skill Level: The skill level of the person performing the soldering task is a crucial factor. Novice solderers may find it easier to handle lower wattage irons, whereas experienced professionals may require higher wattage for faster and more precise soldering.

Considering these factors, it is essential to choose a soldering iron with the appropriate wattage for your specific needs. Using a soldering iron with insufficient wattage can result in inadequate heat, leading to unsatisfactory joints. On the other hand, using a soldering iron with excessive wattage may risk damaging delicate components or creating overheated joints.

Now that we understand the factors that determine soldering iron wattage, let’s dive deeper into the various wattage options available in the market.

Low Wattage Soldering Irons

Low wattage soldering irons generally range from around 15 to 30 watts. These irons are commonly used for delicate soldering tasks on small electronic components such as surface mount devices (SMD) or thin wires. Here are some key characteristics and applications of low wattage soldering irons:

- Precision Soldering: Low wattage soldering irons excel at providing precise control over heat transfer, making them ideal for intricate soldering jobs where overheating can damage components.

- Energy Efficiency: With lower wattage, these soldering irons consume less power, making them cost-effective and environmentally friendly.

- Battery-Powered Options: Some low wattage soldering irons are designed to operate on battery power, allowing for increased portability and convenience.

- Small Component Soldering: These irons are well-suited for soldering small electronic components, such as resistors, capacitors, and diodes, which require lower heat levels.

- Entry-Level Soldering: Low wattage soldering irons are often recommended for beginners or hobbyists who are new to soldering and want to practice their skills without the risk of damaging components.

While low wattage soldering irons may not deliver the same heat output as higher wattage alternatives, they are sufficient for many common electronic soldering tasks that don’t require excessive heat. It is important to note that low wattage soldering irons may take longer to heat up and may struggle to maintain consistent temperatures when soldering larger components or through-hole connections.

When considering a low wattage soldering iron, be sure to check for a temperature control feature. This will allow you to adjust the heat output to match the specific requirements of your soldering task. Additionally, investing in a soldering iron with interchangeable tips can provide versatility for different soldering applications.

In the next section, we will explore the medium wattage range and its applications in electronic soldering.

Medium Wattage Soldering Irons

Medium wattage soldering irons typically have wattage ratings ranging from 40 to 80 watts. These irons offer a balance between precision and power, making them suitable for a wide range of electronic soldering applications. Here’s what you need to know about medium wattage soldering irons:

- Versatile Power Output: Medium wattage soldering irons provide enough heat for soldering both small and medium-sized components, making them a popular choice for general electronics work.

- Faster Heat-Up Time: Compared to low wattage irons, medium wattage irons heat up more quickly, reducing the waiting time before you can start soldering.

- Suitable for Through-Hole Soldering: Medium wattage irons are commonly used for soldering through-hole components such as transistors, ICs, and connectors, which require slightly higher temperatures and more heat transfer.

- Improved Thermal Recovery: With medium wattage, these irons have better thermal recovery, allowing them to quickly regain heat during the soldering process, ensuring consistent and efficient soldering.

- Desoldering Capabilities: Medium wattage soldering irons can often be used for desoldering as well, making them a versatile tool for both soldering and rework tasks.

Medium wattage soldering irons strike a balance between the precision of low wattage irons and the power of high wattage irons. They are commonly used by hobbyists, DIY enthusiasts, and professionals working on various electronic projects. However, it’s important to note that although medium wattage irons offer more power, they may not be suitable for soldering extremely large components or applications that require very high heat output.

When selecting a medium wattage soldering iron, ensure it has a temperature control feature, allowing you to adjust the heat as needed. Additionally, consider choosing a soldering iron with interchangeable tips to accommodate different soldering tasks and ensure compatibility with your specific projects.

Next, let’s take a look at high wattage soldering irons and their applications in electronic soldering.

High Wattage Soldering Irons

High wattage soldering irons are the heavy-duty workhorses of electronic soldering, typically ranging from 100 to 250 watts. These robust irons provide the power needed for demanding soldering applications that involve large components, thick wires, or extensive soldering tasks. Here’s what you should know about high wattage soldering irons:

- Quick Heat Transfer: High wattage soldering irons deliver rapid heat transfer, allowing for efficient soldering even on large or heat-sinked components. This reduces the time spent waiting for the iron to heat up and speeds up the overall soldering process.

- Heavy-Duty Soldering: These irons are well-suited for heavy-duty soldering tasks that require higher heat levels, such as soldering thick gauge wires, soldering onto large ground planes, or applying solder to metal contacts with high thermal mass.

- Durable and Long-Lasting: High wattage soldering irons are built to withstand frequent and intensive use. They often have robust construction, including durable heating elements and heat-resistant handles, ensuring longevity in demanding soldering environments.

- Effective Heat Recovery: With the ability to supply a high amount of power, high wattage irons have excellent heat recovery, maintaining constant temperature during prolonged soldering sessions.

- Industrial and Professional Use: High wattage soldering irons are commonly used in industrial settings and by professional electronics technicians who work on complex projects or require the additional power for consistent results.

It’s important to note that high wattage soldering irons are not recommended for small-scale or delicate soldering tasks. The intense heat output can easily damage sensitive components or circuit traces if not used with caution. Additionally, due to their high power consumption, using high wattage irons for extended periods may require monitoring and precautions to avoid overloading electrical circuits or causing overheating.

When selecting a high wattage soldering iron, it is crucial to prioritize safety features such as heat-resistant handles, reliable temperature control, and a stable base or stand to prevent accidents or damage.

In the next section, we will discuss recommended wattage ranges for different electronic applications to help you choose the right soldering iron for your specific needs.

Wattage Recommendations for Different Electronic Applications

Choosing the appropriate soldering iron wattage is crucial to ensure successful soldering for different electronic applications. While the specific wattage requirements can vary depending on the factors we discussed earlier, here are some general recommendations for common electronic soldering tasks:

- Low Wattage (15-30 Watts): Ideal for soldering small components, surface mount devices (SMD), and thin wires. This wattage range is suitable for delicate soldering tasks that require precise control over heat transfer.

- Medium Wattage (40-80 Watts): Suitable for a wide range of general electronics work, including soldering through-hole components, desoldering, and medium-sized component soldering. These irons strike a balance between precision and power.

- High Wattage (100-250 Watts): Recommended for heavy-duty soldering tasks that involve large or heat-sinked components, thick wires, or applications that require high heat levels. These soldering irons provide rapid heat transfer and are commonly used in industrial or professional settings.

When selecting the appropriate wattage for your specific application, consider the factors we previously discussed, including component size, soldering task complexity, soldering environment, and your skill level. It’s always a good practice to consult the manufacturer’s recommendations for the specific components and soldering materials you will be working with.

Remember that wattage is not the only factor to consider when choosing a soldering iron. Other features, such as temperature control, heat-up time, thermal recovery, and tip compatibility, also play a crucial role in achieving optimal soldering results.

Additionally, it’s important to practice proper soldering techniques, regardless of the wattage of your soldering iron. This includes using the appropriate soldering flux, ensuring proper solder flow, and maintaining a clean and well-tinned soldering iron tip.

By selecting the right wattage and employing proper soldering techniques, you can ensure successful soldering connections and avoid potential damage to electronic components.

Next, let’s recap the importance of choosing the right wattage soldering iron and the impact it can have on your soldering results.

Importance of Choosing the Right Wattage Soldering Iron

The choice of soldering iron wattage significantly impacts the quality and success of your soldering projects. It is important to select the right wattage soldering iron to ensure optimal heat transfer, proper solder melting, and reliable connections. Let’s explore the importance of choosing the right wattage soldering iron:

- Efficient Heat Transfer: The right wattage ensures that the soldering iron delivers sufficient heat to melt the solder and create reliable bonds between components. Insufficient wattage can result in incomplete melting, weak joints, or rework due to cold soldering. On the other hand, excessive wattage can lead to overheating, damaging delicate components or causing excessive thermal stress on the circuit board.

- Component Protection: Different electronic components have specific heat tolerance levels. Choosing the appropriate wattage helps prevent overheating and potential damage to sensitive components, ensuring their longevity and functionality.

- Precision and Control: Selecting the right wattage allows for precise and controlled soldering. Lower wattage irons provide more control when working on intricate or small-scale soldering tasks, while higher wattage irons deliver the power needed for larger components or more demanding soldering applications.

- Safety: Using a soldering iron with the correct wattage reduces the risk of accidents and injuries. Excessive wattage can lead to burns or electrical hazards, while inadequate wattage may require prolonged contact with the solder joint, increasing the risk of accidental contact with hot components.

- Energy Efficiency: By choosing the appropriate wattage, you can optimize power consumption and reduce energy waste. This is particularly important in environments where multiple soldering irons are in use or when working on projects with extended soldering durations.

Ultimately, selecting the right wattage soldering iron ensures that you can achieve successful soldering connections that are reliable, durable, and efficient. It allows you to work confidently and effectively on a wide range of electronic applications while preserving the integrity of the components being soldered.

Consider the specific requirements of your soldering projects, the size of the components, and the complexity of the soldering tasks when choosing the wattage. It is always recommended to consult manufacturer guidelines and expert recommendations for the specific materials and components you will be working with.

By understanding the importance of choosing the right wattage soldering iron and considering the factors involved, you can enhance your soldering skills and achieve optimal results in your electronic projects.