What is an FPC Connector?

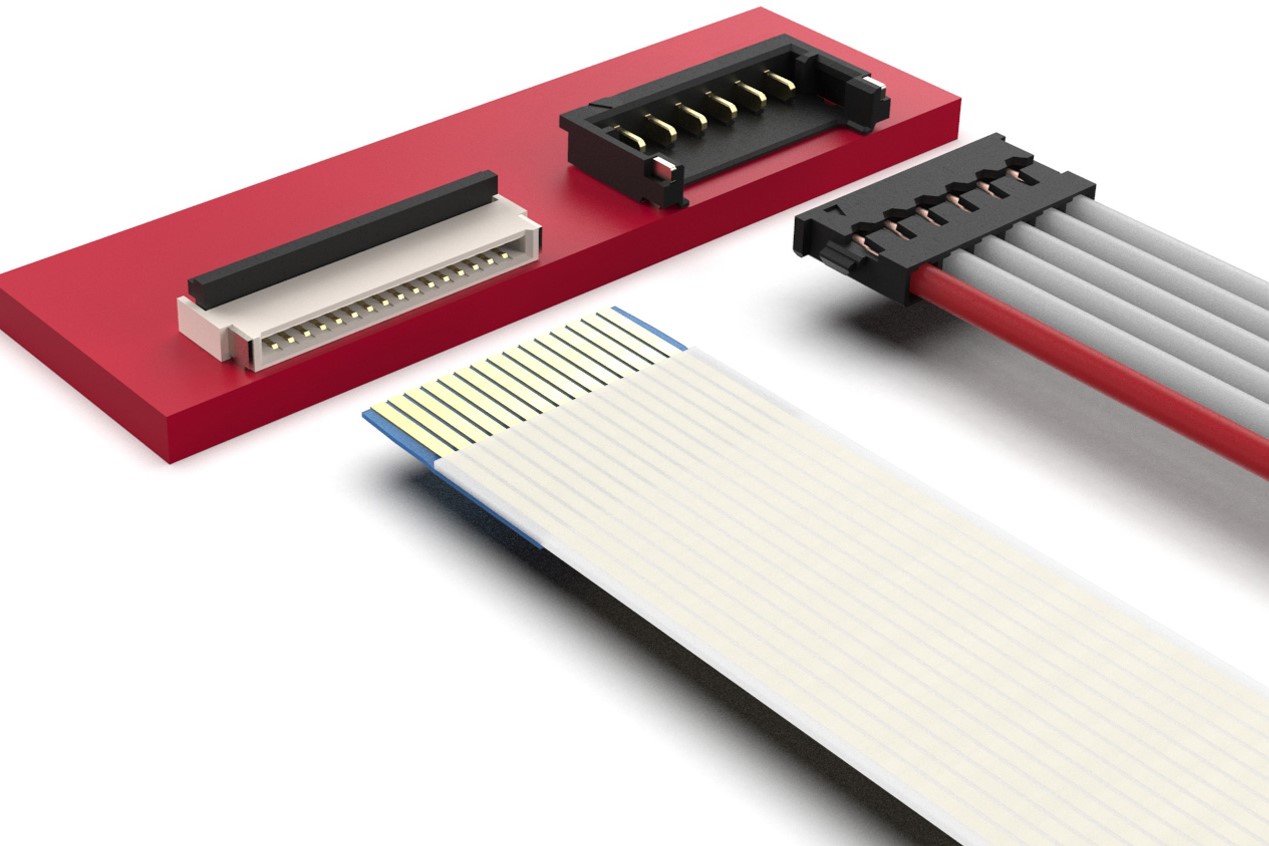

An FPC (Flexible Printed Circuit) connector is a specialized type of connector that is used to connect a flexible printed circuit to another device or to a rigid printed circuit board. It is designed to provide a reliable and secure connection while allowing the flexible circuit to maintain its flexibility and range of motion. FPC connectors are commonly used in electronic devices where space is limited and flexibility is required.

FPC connectors are essential components in the design and manufacture of modern electronic devices. They play a crucial role in enabling the seamless integration of flexible printed circuits into various electronic applications, ranging from consumer electronics to industrial equipment. These connectors are engineered to accommodate the unique characteristics of flexible printed circuits, such as their thin, lightweight, and bendable nature.

FPC connectors come in various configurations to suit different application requirements. They are available in different pitch sizes, contact configurations, and mounting styles, allowing designers to select the most suitable connector for their specific application. Additionally, FPC connectors are designed to withstand the rigors of dynamic flexing and bending, making them ideal for applications where the printed circuit may undergo repeated movements or vibrations.

The design of FPC connectors takes into account the need for a reliable electrical connection while preserving the flexibility and durability of the flexible printed circuit. This is achieved through the use of specialized contact materials and construction techniques that ensure consistent electrical performance without compromising the mechanical integrity of the flexible circuit.

Overall, FPC connectors serve as the vital link between flexible printed circuits and the rest of the electronic system, enabling seamless connectivity and functionality in a wide range of devices.

In summary, FPC connectors are specialized connectors designed to facilitate the integration of flexible printed circuits into electronic devices. They are engineered to provide reliable electrical connections while accommodating the unique characteristics of flexible circuits, making them essential components in modern electronic design and manufacturing.

Types of FPC Connectors

FPC connectors come in various types, each designed to meet specific application requirements and accommodate different types of flexible printed circuits. Understanding the different types of FPC connectors is essential for selecting the most suitable connector for a particular application. Here are some common types of FPC connectors:

- Top Contact FPC Connectors: These connectors feature contacts on the top side, allowing the flexible printed circuit to be inserted from the top of the connector. They are suitable for applications where space is limited and where the flexible circuit needs to be easily accessible for insertion and removal.

- Bottom Contact FPC Connectors: In contrast to top contact connectors, bottom contact FPC connectors have contacts on the bottom side, enabling the flexible printed circuit to be inserted from the bottom of the connector. These connectors are often used in applications where the flexible circuit needs to be mounted on a surface and where space constraints dictate a bottom-entry approach.

- Slider FPC Connectors: Slider connectors are designed to accommodate the sliding insertion of the flexible printed circuit, allowing for easy and secure connection. They are commonly used in devices where the flexible circuit needs to be inserted and removed in a sliding motion, such as in compact consumer electronics.

- ZIF (Zero Insertion Force) FPC Connectors: ZIF connectors feature a mechanism that allows the flexible printed circuit to be inserted with minimal force, reducing the risk of damage to the circuit during installation. These connectors are ideal for applications where delicate flexible circuits require gentle handling during connection.

- Hinged FPC Connectors: Hinged connectors enable the flexible printed circuit to be folded or hinged during installation, making them suitable for applications where the circuit needs to be routed in tight spaces or folded to accommodate complex device designs.

These are just a few examples of the diverse range of FPC connectors available to accommodate the unique requirements of flexible printed circuits in various electronic applications. By understanding the characteristics and advantages of each type, designers and engineers can make informed decisions when selecting the most appropriate FPC connector for their specific design needs.

Function of an FPC Connector

The primary function of an FPC (Flexible Printed Circuit) connector is to establish a reliable and secure electrical connection between a flexible printed circuit and another electronic device or a rigid printed circuit board. This connection facilitates the transmission of signals, power, and data between the flexible circuit and the rest of the electronic system, enabling seamless functionality and integration.

Specifically, the function of an FPC connector can be outlined as follows:

- Electrical Connection: FPC connectors serve as the interface for establishing electrical connections between the conductive traces on a flexible printed circuit and the corresponding contacts within the connector. This enables the transfer of electrical signals and power between the flexible circuit and the host device, ensuring proper functionality.

- Mechanical Support: In addition to facilitating electrical connections, FPC connectors provide mechanical support to the flexible printed circuit, ensuring that it remains securely attached to the electronic device or the printed circuit board. This support helps prevent damage to the circuit and maintains its position during operation.

- Flexibility Preservation: FPC connectors are designed to accommodate the inherent flexibility of the printed circuit, allowing it to bend, flex, or move as needed while maintaining a reliable electrical connection. This feature is essential for applications where the flexible circuit undergoes dynamic movements or where space constraints require flexibility.

- Ease of Installation and Removal: FPC connectors are engineered to facilitate the easy and secure insertion and removal of flexible printed circuits, enabling efficient assembly and maintenance processes. The design of the connector ensures that the flexible circuit can be installed and replaced without compromising the integrity of the connection.

- Environmental Protection: Some FPC connectors incorporate features that provide environmental protection, such as shielding against electromagnetic interference (EMI) or offering resistance to moisture and contaminants. These protective elements help safeguard the electrical connection and the flexible circuit from external factors that could impact performance.

Overall, the function of an FPC connector is integral to the seamless integration of flexible printed circuits into electronic devices, providing both electrical and mechanical connectivity while preserving the unique characteristics of flexible circuits.

Advantages of Using FPC Connectors

Utilizing FPC (Flexible Printed Circuit) connectors offers a multitude of advantages, making them a preferred choice in various electronic applications. These advantages stem from the unique characteristics and design features of FPC connectors, which contribute to enhanced performance, reliability, and flexibility in electronic designs. The key advantages of using FPC connectors include:

- Space Efficiency: FPC connectors enable compact and space-efficient designs, particularly in devices where traditional rigid connectors may not be practical. The flexibility and thin profile of FPCs, combined with the compact form factor of FPC connectors, allow for efficient use of space within electronic assemblies.

- Flexibility and Durability: FPC connectors preserve the inherent flexibility and durability of flexible printed circuits, ensuring that the circuits can bend, twist, or flex without compromising the integrity of the electrical connection. This flexibility is crucial in applications where the circuit undergoes repeated movements or where space constraints demand a flexible form factor.

- Weight Reduction: The lightweight nature of FPC connectors, coupled with the minimal weight of flexible printed circuits, contributes to overall weight reduction in electronic devices. This is particularly advantageous in portable and handheld devices where weight is a critical factor in design considerations.

- Reliable Electrical Performance: FPC connectors are engineered to provide consistent and reliable electrical performance, ensuring secure transmission of signals and power between the flexible circuit and the host device. The design of the connectors minimizes signal loss and impedance variations, contributing to stable electrical connections.

- Versatile Mounting Options: FPC connectors offer versatile mounting options, allowing for surface mounting, through-hole mounting, or other customized mounting configurations based on the specific requirements of the application. This flexibility in mounting facilitates seamless integration into diverse electronic designs.

- Customization and Adaptability: FPC connectors can be customized to accommodate unique design requirements, such as specific pitch sizes, contact arrangements, and environmental protection features. This adaptability allows for tailored solutions that align with the needs of different electronic applications.

- Cost-Effective Assembly: The use of FPC connectors can contribute to cost-effective assembly processes, as they enable efficient installation and replacement of flexible printed circuits. This can lead to streamlined manufacturing and maintenance procedures, reducing overall production costs.

These advantages collectively position FPC connectors as indispensable components in modern electronic design, offering a versatile and reliable solution for integrating flexible printed circuits into a wide range of electronic devices.

Applications of FPC Connectors

FPC (Flexible Printed Circuit) connectors find extensive application across various industries, playing a crucial role in enabling the integration of flexible circuits into electronic devices and systems. The unique characteristics and design flexibility of FPC connectors make them well-suited for a diverse range of applications, including:

- Consumer Electronics: FPC connectors are widely used in consumer electronic devices, such as smartphones, tablets, digital cameras, and wearable technology. Their compact form factor, flexibility, and space-saving attributes make them ideal for compact and portable consumer electronics where space and weight considerations are paramount.

- Automotive Electronics: In the automotive industry, FPC connectors are employed in various electronic systems, including infotainment systems, dashboard displays, electronic control units (ECUs), and interior lighting. Their ability to withstand vibrations, temperature variations, and space constraints makes them suitable for automotive applications.

- Medical Devices: FPC connectors play a vital role in medical devices and equipment, where flexibility, miniaturization, and reliability are essential. They are utilized in devices such as medical imaging equipment, patient monitoring systems, wearable medical devices, and diagnostic instruments, contributing to the compact and lightweight design of medical electronics.

- Industrial Automation: In industrial automation and control systems, FPC connectors are utilized in electronic interfaces, control panels, and sensor modules. Their ability to withstand harsh industrial environments, including temperature fluctuations and mechanical stress, makes them suitable for industrial applications where reliability and durability are paramount.

- Aerospace and Defense: FPC connectors are employed in aerospace and defense applications, including avionics, military communication systems, and unmanned aerial vehicles (UAVs). Their lightweight construction, resistance to environmental factors, and ability to accommodate complex routing requirements make them valuable in aerospace and defense electronics.

- Wearable Technology: The growing market for wearable technology, including smartwatches, fitness trackers, and augmented reality devices, relies on FPC connectors to enable flexible and compact electronic designs that conform to the contours of the human body while maintaining reliable electrical connections.

- IoT (Internet of Things) Devices: FPC connectors play a role in IoT devices, where compact, low-profile connectors are needed to facilitate connectivity and sensor integration in smart home devices, industrial IoT applications, and connected consumer products.

These applications represent just a fraction of the diverse industries and sectors that benefit from the unique capabilities of FPC connectors. Their versatility, reliability, and adaptability make them indispensable in enabling the seamless integration of flexible printed circuits into an ever-expanding array of electronic devices and systems.