Capacitor Basics

A capacitor is a fundamental component in electronics that stores and releases electrical energy. It is widely used in various electronic circuits and systems to perform a range of functions, such as smoothing out voltage fluctuations, filtering noise, and creating time delays. Understanding the basics of capacitors is essential for anyone working with electronics.

At its core, a capacitor consists of two conductive plates separated by a dielectric material. The conductive plates can be made of metal, while the dielectric material can be glass, ceramic, or plastic. When a voltage is applied across the plates, an electric field is formed in the dielectric, causing positive and negative charges to accumulate on the respective plates.

The amount of charge that a capacitor can store is measured in capacitance, which is typically denoted in farads (F). However, capacitors used in most electronic applications have capacitance values ranging from picofarads (pF) to microfarads (µF). The capacitance value determines how much charge the capacitor can store for a given voltage.

One important property of capacitors is their ability to block direct current (DC) while allowing alternating current (AC) to pass through. This is due to the reactive nature of capacitors, which causes them to impede the flow of DC while allowing AC signals to pass. Capacitors are commonly used in conjunction with resistors to create filters and time-dependent circuits.

How Does a Capacitor Work?

To understand how a capacitor works, it’s important to grasp the concept of capacitance. Capacitance is the property of a capacitor that determines its ability to store electrical charge. When a voltage is applied across the conductive plates of a capacitor, it creates an electric field in the dielectric material between the plates. This electric field causes positive charges to accumulate on one plate and negative charges on the other.

The separation of charges creates an electric potential difference, or voltage, between the plates. This stored charge and voltage can be released when needed and used in various electronic applications. When a circuit requires an extra surge of power, the capacitor can discharge its stored charge to meet the demand.

Capacitors also have the ability to influence the flow of electrical current in a circuit. When an AC signal is applied, the capacitor alternately charges and discharges at the frequency of the AC signal. This behavior causes the capacitor to act as a filter, allowing certain frequencies to pass while blocking others. Capacitors are commonly used in filters to remove unwanted noise or to smooth out fluctuations in voltage.

Additionally, capacitors are often used to store energy and release it in a controlled manner. For example, in a flash camera, a capacitor is charged to a high voltage and then discharges rapidly to provide a sudden burst of light. In this case, the high capacitance of the capacitor allows it to store enough energy to produce a powerful flash.

It’s worth noting that capacitors have some limitations. They are not ideal at storing charges for extended periods since they can slowly lose their stored energy over time due to leakage current. The dielectric material used in a capacitor can also affect its performance and stability, as different dielectric materials have different properties and tolerances.

The Structure of a Capacitor

A capacitor consists of several key components that work together to store and release electrical energy. Understanding the structure of a capacitor provides insight into its functionality and performance.

The basic structure of a capacitor includes two conductive plates and a dielectric material. The conductive plates are typically made of metal, such as aluminum or tantalum. These plates provide the surface area for charge accumulation.

The dielectric material is sandwiched between the plates and serves as an insulator. It plays a crucial role in determining the capacitance and other characteristics of the capacitor. Different dielectric materials have varying properties, such as permittivity and breakdown voltage, which affect the capacitor’s performance in different applications.

The plates and dielectric material are then enclosed in a protective casing, often made of a non-conductive material like plastic or ceramic. This casing provides mechanical support and insulation, preventing external influences from affecting the capacitor’s performance.

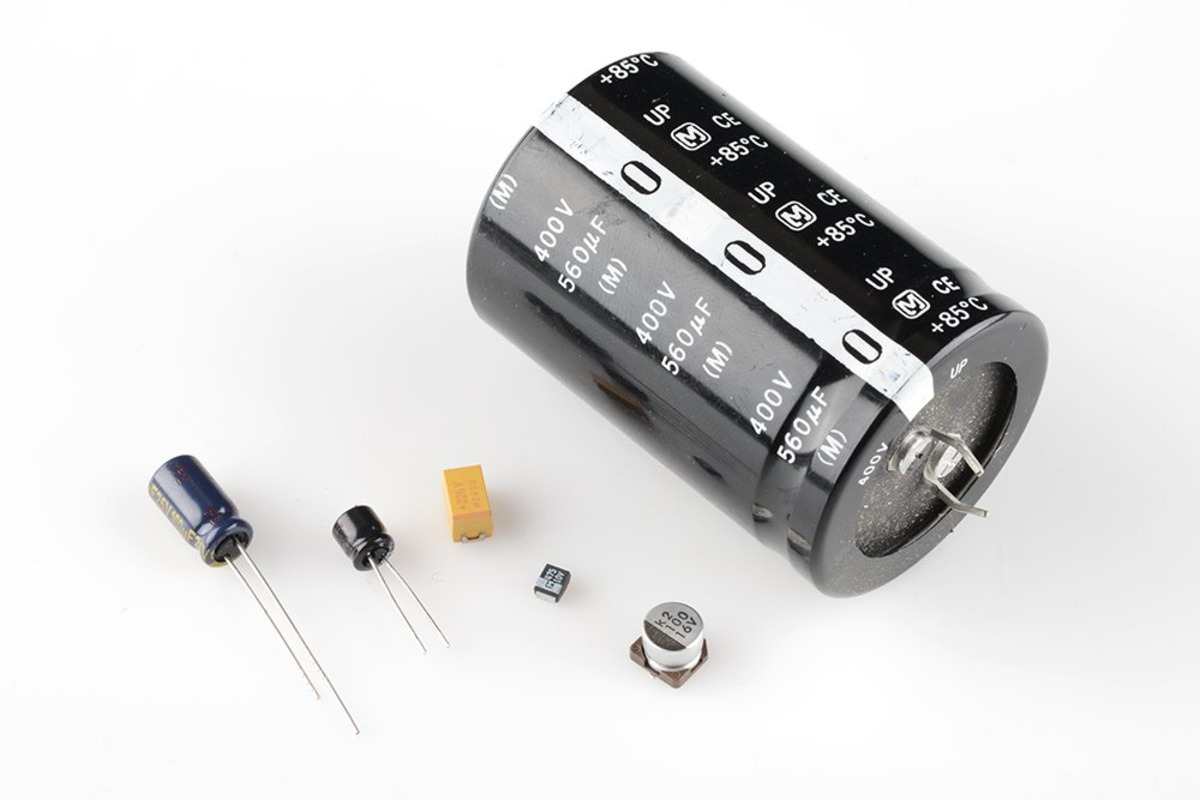

Capacitors can be manufactured in various forms depending on the application. Some common types include ceramic capacitors, electrolytic capacitors, film capacitors, and tantalum capacitors.

Ceramic capacitors are widely used due to their small size, high capacitance, and low cost. They are commonly found in consumer electronics. Electrolytic capacitors, on the other hand, have higher capacitance values but are limited in terms of voltage rating and size. They are commonly used in power supply circuits due to their ability to handle higher voltage levels.

Film capacitors are known for their stability and low losses, making them suitable for applications that require high precision and reliability. Tantalum capacitors, made with tantalum metal as the plate material, have high capacitance and are commonly used in electronic devices with limited space.

The structure of a capacitor directly influences its electrical characteristics, such as capacitance, voltage rating, and temperature stability. Different structures and materials are chosen based on the specific requirements of the application, considering factors like size, performance, and cost.

Capacitor Types and Their Uses

Capacitors come in various types, each with its own unique characteristics, making them suitable for specific applications. Understanding the different types of capacitors and their uses is essential for selecting the right capacitor for a particular electronic circuit.

1. Ceramic Capacitors: Ceramic capacitors are commonly used due to their small size, high capacitance, and low cost. They are ideal for decoupling, bypass, and filtering applications in electronic circuits. Ceramic capacitors are found in consumer electronics, power supplies, and telecommunications equipment.

2. Electrolytic Capacitors: Electrolytic capacitors are known for their high capacitance values. They are commonly used in power supply circuits due to their ability to handle higher voltage levels. Electrolytic capacitors are utilized in audio systems, computer motherboards, and industrial machinery.

3. Film Capacitors: Film capacitors are valued for their stability, low losses, and long lifespan. They are suitable for applications that require high precision and reliability, such as in timing circuits, audio amplifiers, and radio frequency filters.

4. Tantalum Capacitors: Tantalum capacitors are made with tantalum metal as the plate material. They have high capacitance and are commonly used in electronic devices with limited space. Tantalum capacitors are found in mobile phones, laptops, and medical devices.

5. Aluminum Electrolytic Capacitors: Aluminum electrolytic capacitors are designed for high capacitance values and are cost-effective. They are commonly used in power electronics, motor drives, and inverter applications.

6. Supercapacitors: Supercapacitors, also known as ultracapacitors, have very high capacitance compared to traditional capacitors. They are used for energy storage in applications requiring rapid discharge and high power delivery, such as in hybrid vehicles, wind turbines, and energy harvesting systems.

7. Variable Capacitors: Variable capacitors have adjustable capacitance values, allowing for tuning or frequency adjustments in radio and tuning circuits.

Each type of capacitor offers specific advantages and limitations. Choosing the right capacitor type involves considering factors such as capacitance, voltage rating, size, frequency response, and cost, based on the requirements of the electronic circuit or system.

Capacitor Capacity and Voltage Rating

When selecting a capacitor for a specific application, it is crucial to consider the capacitor’s capacity and voltage rating. These two specifications determine the capacitor’s performance and suitability for the desired circuit or system.

Capacitor capacity, measured in farads (F), indicates how much charge a capacitor can store. However, in most electronic applications, capacitance values range from picofarads (pF) to microfarads (µF). The capacitance value determines the amount of charge the capacitor can store for a given voltage. Generally, higher capacitance values provide the ability to store more charge, while lower capacitance values are suitable for applications requiring fast charge and discharge cycles.

Voltage rating, measured in volts (V), represents the maximum voltage that a capacitor can safely handle. Exceeding the voltage rating can lead to capacitor failure, such as leakage or even explosion. It is crucial to choose a capacitor with a voltage rating higher than the maximum voltage present in the circuit. For safety and reliability, it is recommended to have a voltage rating with a margin to handle any unexpected voltage spikes or fluctuations.

It is important to note that the capacity and voltage rating of a capacitor are interconnected. Capacitors with higher capacitance values often have lower voltage ratings, while capacitors with higher voltage ratings typically have lower capacitance values. This trade-off occurs due to the physical limitations of the capacitor’s design and the dielectric material used.

The capacity and voltage rating requirements for a specific application depend on various factors, including the required charge storage, voltage levels present in the circuit, and size constraints. Choosing a capacitor with the appropriate capacity and voltage rating helps ensure optimal performance, reliability, and longevity of the circuit or system.

How to Read Capacitor Values

Reading and understanding capacitor values is essential for selecting the correct capacitor for a specific electronic application. Capacitor values are typically represented using alphanumeric codes or standardized markings. Here are some key guidelines on how to read capacitor values:

1. Capacitance Value: Capacitance is denoted by a numerical value followed by a unit of measurement such as picofarads (pF), nanofarads (nF), or microfarads (µF). For example, a capacitor marked with “10n” indicates a capacitance of 10 nanofarads.

2. Tolerance Rating: The tolerance rating represents the maximum allowable deviation from the specified capacitance value. It is usually indicated as a percentage, such as ±5% or ±10%. For instance, a capacitor with a specified value of 100nF and a tolerance of ±10% can have a capacitance ranging from 90nF to 110nF.

3. Voltage Rating: The voltage rating indicates the maximum voltage that the capacitor can safely handle. It is typically written in volts (V) or kilovolts (KV) and must be higher than the maximum voltage in the circuit. For example, a capacitor with a voltage rating of 25V is suitable for circuits with voltage levels up to 25 volts.

4. Temperature Coefficient: Some capacitors have a temperature coefficient specification, denoted by a three-digit code. This code represents the percentage change in capacitance over a specified temperature range. It helps to ensure that the capacitance remains stable across varying temperatures.

5. Polarization: Certain types of capacitors, such as electrolytic capacitors, are polarized and have specific markings to indicate their polarity. The positive terminal is marked with a plus sign (+) or a longer lead, while the negative terminal is marked with a minus sign (-) or a shorter lead.

It is important to note that different capacitor types may have variations in marking conventions and codes. Referring to datasheets, manufacturer specifications, or reference guides can provide additional information on decoding specific capacitor markings.

When selecting a capacitor for a specific application, it is essential to consider the required capacitance value, voltage rating, tolerance, and any other specifications that align with the circuit’s needs. This ensures optimal performance and reliability of the electronic system.

How to Test a Capacitor

Testing a capacitor is important to ensure its functionality and determine whether it needs to be replaced. Here are some methods to test a capacitor:

1. Visual Inspection: Start by inspecting the capacitor for any physical damage, such as bulging, leaking electrolyte (for electrolytic capacitors), or broken leads. Any visible damage indicates that the capacitor needs replacement.

2. Capacitance Testing: Use a multimeter with a capacitance measurement function to measure the capacitance of the capacitor. Ensure that the capacitor is discharged before testing. Connect the multimeter leads to the capacitor terminals and set the multimeter to capacitance mode. Compare the measured capacitance with the specified value. If the measured capacitance deviates significantly from the specified value or if it reads as “open” or “short,” the capacitor may be defective and should be replaced.

3. Leakage and ESR Testing: Electrolytic capacitors may suffer from high leakage or increased Equivalent Series Resistance (ESR), leading to degraded performance. Specialized equipment, such as an ESR meter, can be used to measure the ESR of the capacitor. If the measured ESR is significantly higher than the acceptable range or the leakage is excessive, it indicates a faulty capacitor that requires replacement.

4. Functionality Testing: Capacitors in specific circuit applications may affect the overall functionality. For example, capacitors used in timing circuits or filter applications can be tested by analyzing the performance of the circuit. If the circuit exhibits abnormal behavior or does not function as intended, it may indicate a faulty capacitor.

5. Substitution Testing: In some cases, if a replacement capacitor is available, swapping it with the suspected faulty capacitor can help determine if the original capacitor is the issue. If the circuit operates correctly with the substituted capacitor, it confirms that the original capacitor is defective.

Always exercise caution while handling capacitors, ensuring they are properly discharged and taking necessary safety measures. If you are uncertain about testing or lack the proper equipment, consult a professional or consider replacing the capacitor to avoid potential risks or further damage to the circuit.

Capacitor Applications in Electronics

Capacitors play a vital role in various electronic circuits and systems, contributing to their functionality and performance. Here are some common applications of capacitors in electronics:

1. Power Supply Regulation: Capacitors are used in power supply circuits to smooth out voltage fluctuations and reduce noise. They act as reservoirs, storing energy during high-demand periods and releasing it during low-demand periods to ensure a stable and consistent power supply.

2. Timing Circuits: Capacitors, in conjunction with resistors, are used in timing circuits to create specific time delays. By adjusting the capacitance and resistance values, precise timing intervals can be achieved, which are crucial in applications like pulse generators, oscillators, and timers.

3. Filtering: Capacitors are employed in various filtering applications, such as low-pass, high-pass, and band-pass filters, to remove unwanted frequencies. They allow certain frequencies to pass through while blocking others, ensuring a clean and accurate signal in audio systems, radio communication, and data transmission.

4. Coupling and Decoupling: Capacitors are used for coupling audio or AC signals between different stages of an electronic circuit. They block the DC component while allowing the AC component to pass through. Capacitors are also used for decoupling, which involves isolating different parts of a circuit to prevent interference and ensure stable operation.

5. Energy Storage: Capacitors with high capacitance values, such as supercapacitors, are used to store and deliver a substantial amount of energy in a short duration. They are used in applications where large surges of power are required, such as electric vehicles, renewable energy systems, and flash cameras.

6. Motor Start and Run Capacitors: Capacitors are utilized in motor circuits to provide starting torque and maintain optimal performance during the running phase. Start capacitors provide extra voltage for starting a motor, while run capacitors help improve the motor’s efficiency and power factor.

7. Voltage Compensation: Capacitors are used to compensate for voltage drops and maintain a stable voltage level across electronic components or systems. They help regulate voltage during sudden changes in load or power fluctuations, ensuring the proper operation of sensitive equipment.

These are just a few examples of the numerous applications for capacitors in the field of electronics. Capacitors’ versatile characteristics make them indispensable in a wide range of electronic devices, from your smartphone and computer to complex industrial machinery and power systems.

Common Issues with Capacitors

While capacitors are essential components in electronics, they can experience certain issues that can affect their performance and reliability. Here are some common issues encountered with capacitors:

1. Capacitor Aging: Over time, capacitors can deteriorate due to factors such as temperature, voltage stress, and usage. Aging capacitors can lead to changes in capacitance values, increased leakage current, and reduced overall performance. It is important to monitor and replace aged capacitors to maintain proper functionality in electronic systems.

2. Overheating: Excessive heat can negatively impact capacitors, leading to reduced capacitance, increased leakage current, and even catastrophic failure. High ambient temperatures, overvoltage conditions, or inadequate cooling can contribute to overheating. Proper heat dissipation and ensuring that capacitors are rated for the operating temperature are necessary to prevent overheating issues.

3. Electrolyte Leakage: Electrolytic capacitors are prone to electrolyte leakage, especially when subjected to voltage stress, prolonged use, or high temperatures. Leakage can cause a decrease in capacitance, increased ESR, and potential damage to the surrounding components. Visual inspection and replacement of leaking electrolytic capacitors are crucial to prevent further issues.

4. Dielectric Failure: The dielectric material in capacitors can fail due to factors such as excessive voltage, overvoltage spikes, or manufacturing defects. Dielectric failure can result in a short circuit, increased leakage current, or complete loss of capacitance. Proper voltage ratings and choosing capacitors from reputable manufacturers can help minimize dielectric failure issues.

5. ESR Increase: Equivalent Series Resistance (ESR) is an inherent resistance associated with capacitors. Over time, ESR can increase due to aging or environmental conditions. Increased ESR can lead to reduced capacitance, higher power dissipation, and decreased filtering effectiveness. Regular testing and replacement of capacitors with high ESR values are necessary in critical applications.

6. Voltage Derating: Exceeding a capacitor’s voltage rating can lead to catastrophic failure, such as rupture or explosion. Voltage derating, which involves operating capacitors at a lower voltage than their rated value, is essential to ensure reliability and prevent voltage stress-related issues.

7. Incorrect Installation or PCB Layout: Improper installation, such as reverse polarity or incorrect soldering, can lead to capacitor failure. Additionally, poor PCB layout, such as inadequate spacing, inadequate soldering pads, or inadequate trace widths, can cause heat buildup or electrical issues that can affect capacitor performance. Following proper installation guidelines and designing an appropriate PCB layout can help mitigate these issues.

Regular inspection, proper selection, and maintenance of capacitors are crucial to identify and address these common issues. By ensuring capacitors are well-maintained and used within their specified parameters, the overall performance and reliability of electronic systems can be enhanced.

Capacitor Maintenance and Replacement

Maintaining and replacing capacitors is important to ensure the proper functioning of electronic circuits and systems. Here are some guidelines for capacitor maintenance and replacement:

1. Regular Inspection: Conduct periodic visual inspections of capacitors to check for any signs of physical damage, such as bulging, leakage, or broken leads. Inspect the PCB for any signs of capacitor-related issues, such as discoloration, heat damage, or corrosion. Promptly replace any damaged or faulty capacitors to prevent potential circuit failures.

2. Monitoring Capacitance: If possible, periodically measure the capacitance of critical capacitors using a multimeter. Compare the measured capacitance with the specified capacitance. If the measured capacitance deviates significantly from the specified value, it may indicate a faulty capacitor that requires replacement.

3. Voltage Rating Considerations: Ensure that capacitors are operated within their specified voltage ratings. Avoid subjecting capacitors to voltage spikes or prolonged exposure to voltages close to their maximum rating. If operating conditions exceed the capacitor’s voltage rating, consider using capacitors with higher voltage ratings or implementing voltage derating to prolong their lifespan.

4. Temperature Considerations: Take into account the operating temperature range of capacitors and ensure they are not subjected to temperatures beyond their specified limits. Capacitors are sensitive to heat, and excessive temperatures can lead to accelerated aging, increased leakage, and decreased performance. Proper cooling and thermal management are essential to maintain capacitor reliability.

5. Replacing Aged Capacitors: Over time, capacitors can deteriorate and experience decreased performance or increased failure rates. It is advisable to proactively replace aged capacitors, especially electrolytic ones, to prevent potential issues. Consider the estimated lifespan and the application’s criticality when determining the replacement interval for capacitors in long-term installations.

6. Sourcing Capacitors: When replacing capacitors, ensure that the replacements meet the required specifications in terms of capacitance, voltage rating, tolerance, and ESR. Use capacitors from reputable manufacturers or trusted suppliers to ensure reliability and performance.

7. ESD Precautions: When handling capacitors, follow proper electrostatic discharge (ESD) precautions to prevent damage from static electricity. Use ESD-safe tools, work on an ESD-safe surface, and wear ESD wrist straps or gloves if necessary. Capacitors are sensitive to ESD, and mishandling can lead to premature failure.

By following these maintenance practices and promptly replacing faulty capacitors, you can ensure the continued operation and reliability of electronic circuits and systems.