Benefits of Using the Right Gauge Wire for Small Electronics

The gauge of wire used in small electronics plays a crucial role in ensuring the efficiency and functionality of these devices. Choosing the right wire gauge can provide several benefits that can improve the overall performance and safety of your small electronics projects. Here are some key advantages of using the right gauge wire:

1. Optimal Performance: Using the correct wire gauge ensures that the electrical current flows smoothly through the circuit without any significant loss or resistance. This leads to better performance and functionality of the device, preventing issues such as voltage drops or overheating.

2. Efficiency: Proper wire gauge selection minimizes power loss during transmission, resulting in efficient energy usage. This not only extends the battery life of portable devices but also reduces electricity consumption in larger electronics, contributing to energy savings.

3. Safety: Choosing the right wire gauge helps maintain safety standards by preventing overheating and reducing the risk of electrical fires. Incorrect wire gauge can lead to excessive heat build-up, which can damage components or even cause electrical short circuits.

4. Ease of Installation: Working with the right wire gauge makes installation and troubleshooting much easier. It ensures the wire is flexible enough to maneuver through tight spaces without breaking or damaging the insulation, saving time and effort in the process.

5. Cost-effective: Using the appropriate wire gauge helps avoid unnecessary expenses. When the wire gauge is too thick, it may be more expensive and difficult to work with. On the other hand, using a gauge that is too thin can result in poor performance and frequent replacements.

Understanding Wire Gauge

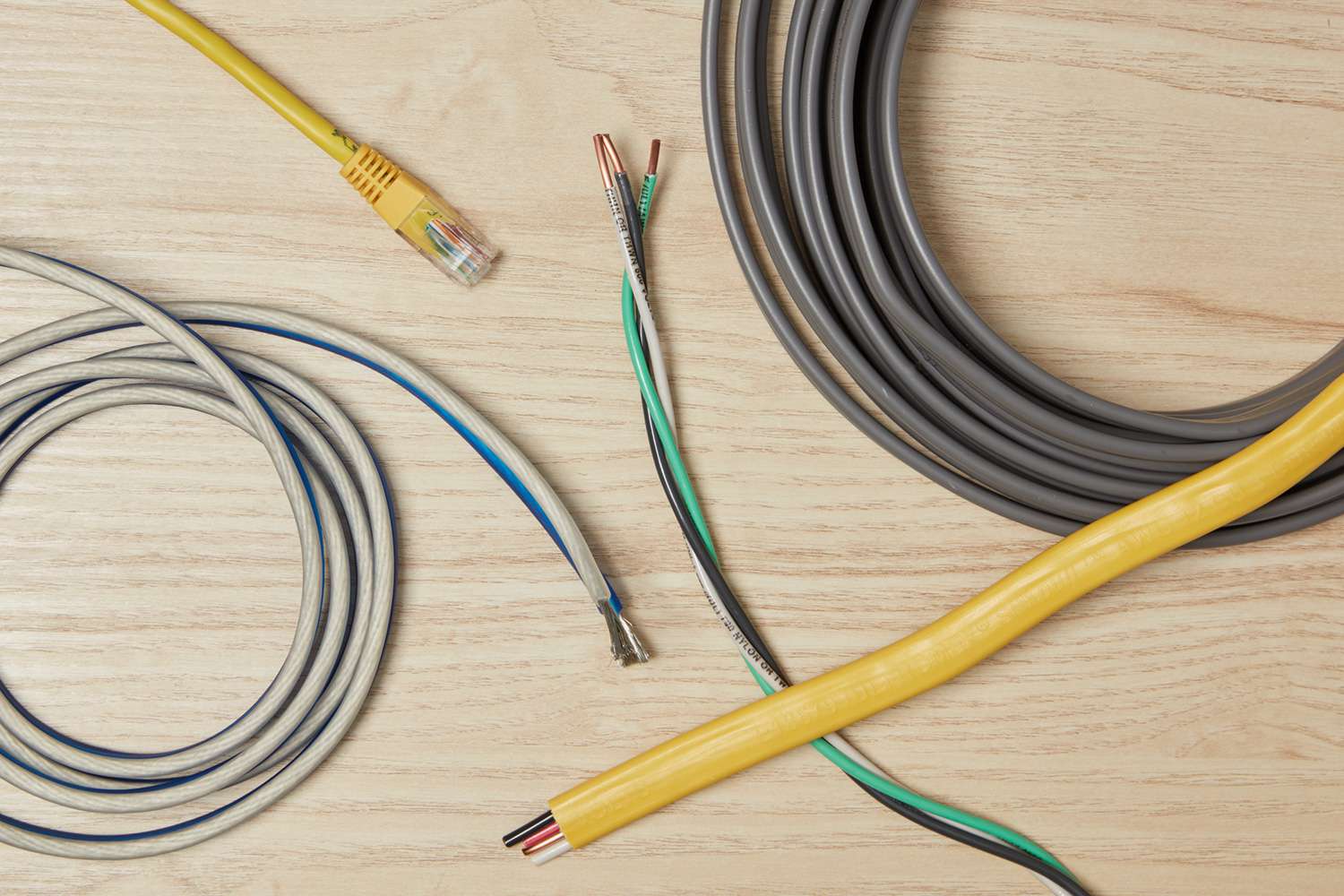

Wire gauge is a term used to determine the size of the wire, specifically its diameter or thickness. It is crucial to understand the concept of wire gauge when working with small electronics. The wire gauge is usually denoted by a number, with smaller numbers indicating thicker wires. Here are some key points to help you understand wire gauge:

1. AWG Standard: The American Wire Gauge (AWG) is the most widely used standard for measuring wire gauge. It assigns a specific number to each wire size, ranging from the thickest (lower numbers) to the thinnest (higher numbers). For example, a 10-gauge wire is thicker than a 24-gauge wire.

2. Wire Diameter: The wire gauge number corresponds to the wire’s diameter. For instance, a 12-gauge wire has a diameter of approximately 2.05 millimeters, while a 22-gauge wire has a diameter of about 0.64 millimeters.

3. Resistance and Current: Wire gauge affects the resistance and current-carrying capacity of the wire. Thicker wires have lower resistance, allowing them to carry larger current loads without excessive voltage drops. Thinner wires, on the other hand, have higher resistance and are suitable for low-power applications.

4. Stranded vs. Solid Wires: Wire gauge is applicable to both stranded and solid wires. Stranded wires are composed of multiple smaller strands twisted together, offering flexibility and better resistance against vibrations. Solid wires, on the other hand, consist of a single solid conductor and are more rigid.

5. Wire Gauge Conversion: In some cases, you may come across wire gauge sizes that are not in the AWG standard. It is essential to convert them to the appropriate AWG size for accurate wire selection and compatibility.

Understanding wire gauge is vital for selecting the right wire size based on the intended application, current requirements, and available space. By familiarizing yourself with wire gauge standards and considerations, you can ensure optimal performance and safety in your small electronics projects.

Factors to Consider When Choosing Wire Gauge for Small Electronics

Choosing the right wire gauge for small electronics projects is crucial to ensure optimal performance, safety, and longevity. Several factors should be considered when selecting the appropriate wire gauge. Here are some key factors to keep in mind:

1. Current Load: Determine the maximum amount of current that will flow through the wire. This information helps in selecting a wire gauge that can handle the required current without overheating. It is important to choose a wire gauge that has a current-carrying capacity greater than the maximum expected current.

2. Length of Wire: The length of the wire affects the amount of resistance in the circuit. Longer wires have higher resistance, leading to voltage drops. To minimize voltage drops, choose a thicker wire gauge for longer wire runs.

3. Space and Flexibility: Consider the available space and the flexibility required for the wire to fit and maneuver within the device or project. Thicker wires take up more space and may be less flexible, making them unsuitable for tight spaces or situations that require flexibility.

4. Voltage Rating: Ensure that the wire’s voltage rating matches or exceeds the voltage of the circuit it will be used in. This helps prevent insulation breakdown and potential safety hazards.

5. Temperature: Consider the operating temperature range of the small electronic device. Some wires are better suited for high-temperature environments, while others may become brittle or damaged at extreme temperatures.

6. Device Requirements: Take into account the specific requirements of the small electronic device. Some devices may have specific wire gauge recommendations provided by the manufacturer. Adhering to these recommendations ensures compatibility and optimal performance.

7. Cost: Evaluate the cost implications of using different wire gauges. Thicker wire gauges are generally more expensive, so choose a gauge that meets the necessary requirements without unnecessary overspending.

By considering these factors, you can make an informed decision when selecting the appropriate wire gauge for your small electronics projects. It is vital to maintain a balance between the wire’s current-carrying capacity, space limitations, and device requirements to ensure reliable and efficient operation.

Common Wire Gauges Used in Small Electronics

Small electronics projects require the use of various wire gauges depending on the specific application and requirements. Understanding the common wire gauges used in small electronics can help you make informed decisions when selecting the appropriate wire for your projects. Here are some of the most commonly used wire gauges in small electronics:

1. 30 AWG: This is an extremely thin wire gauge commonly used for small signal and data transmission applications. It is suitable for low-current, low-voltage circuits and is often found in applications such as communication devices and small sensors.

2. 26 AWG: The 26 AWG wire gauge is a versatile option commonly used in small electronics projects. It is thicker than the 30 AWG wire and can handle slightly higher currents. This gauge is often found in applications like PCB wiring, breadboard prototyping, and small module connections.

3. 22 AWG: This wire gauge is thicker and can handle higher current loads. It is commonly used in power supply connections, motor wiring, and other applications where moderate to high currents are expected. The 22 AWG wire provides a good balance between size, flexibility, and current-carrying capacity.

4. 18 AWG: The 18 AWG wire gauge is even thicker and can handle higher currents than the previously mentioned gauges. It is suitable for applications where substantial power flows through the wire, such as battery connections, high-power LEDs, or larger motors.

5. 12 AWG: This wire gauge is considerably thicker and is typically used in small electronics projects that require significant current-carrying capacity, such as power distribution within a circuit board or connecting high-powered components. It is less common in typical small electronics projects but may be necessary for specific applications.

It’s important to note that these are just a few of the commonly used wire gauges in small electronics, and the appropriate gauge will vary depending on the specific project requirements. Factors such as current load, voltage, space limitations, and device specifications should be considered when selecting the appropriate wire gauge.

By understanding the characteristics and common uses of different wire gauges, you can make informed decisions and ensure that your small electronics projects are equipped with the right wire gauge to meet their specific electrical and mechanical needs.

Choosing the Right Wire Gauge for Specific Small Electronics Projects

When it comes to small electronics projects, selecting the right wire gauge is crucial to ensure optimal performance and safety. Different projects may have varying requirements, and understanding how to choose the appropriate wire gauge for specific applications is essential. Here are some guidelines to help you select the right wire gauge for different small electronics projects:

1. Low-Power or Signal Transmission: For applications involving low-power signals or data transmission, such as sensors or communication devices, thinner wire gauges like 30 AWG or 26 AWG are suitable. These fine gauges offer low resistance and flexibility, facilitating efficient signal transfer.

2. PCB Wiring and Breadboard Prototyping: When working with printed circuit boards (PCBs) or breadboard prototyping, a common choice is 26 AWG wire. This gauge strikes a balance between size and current-carrying capacity, making it suitable for most small electronics projects.

3. Power Distribution within a Circuit Board: For projects that involve power distribution within a circuit board, thicker wire gauges like 18 AWG or 22 AWG may be necessary. These gauges can handle higher current loads and minimize voltage drops, ensuring efficient power delivery.

4. Battery Connections: When connecting batteries to small electronics, consider the current demands of the device. For low-power applications, a wire gauge like 26 AWG may be sufficient. However, for higher-power devices or applications, consider using a thicker gauge like 18 AWG to handle the increased current.

5. Motor Wiring: Motors typically require wires capable of handling higher current loads. Depending on the motor’s power requirements, wire gauges between 18 AWG and 12 AWG may be suitable. Ensure the selected gauge can safely carry the required current without overheating.

6. High-Power LEDs or Heating Elements: Projects involving high-power LEDs or heating elements require wires capable of handling substantial current. Wire gauges like 18 AWG or larger may be necessary to minimize resistance and prevent overheating.

Remember to consider other factors such as device specifications, space limitations, and acceptable voltage drops when choosing the right wire gauge. It’s recommended to consult technical specifications, manufacturer guidelines, or seek advice from experienced electronics enthusiasts to ensure the best wire gauge selection for your specific project.

By selecting the appropriate wire gauge for your small electronics projects, you can ensure reliable performance, minimize power loss, and maintain the safety and efficiency of your electronic devices.

Tips for Working with Different Wire Gauges

Working with different wire gauges in small electronics projects can present various challenges. Each wire gauge has its own characteristics and considerations. Here are some useful tips to help you work effectively with different wire gauges:

1. Use the Right Tools: Invest in a good set of wire strippers or cutters that are specifically designed for the wire gauges you plan to work with. This ensures clean and precise cuts without damaging the wire.

2. Be Gentle: Thinner wire gauges, such as 30 AWG or 26 AWG, are delicate and can easily break if handled roughly. Handle them with care, especially when stripping insulation or making connections.

3. Choose the Right Connector: Use connectors that are compatible with the wire gauge you are working with. Improperly sized connectors can result in loose connections or even damage the wire, impacting performance and safety.

4. Strain Relief: Provide proper strain relief by securing the wire near the connection point or using cable ties to prevent tension or pulling on the wire. This helps protect the wire from damage and improves the longevity of the connection.

5. Twisting Stranded Wires: For stranded wires, twist the exposed strands in a clockwise direction before inserting them into connectors or soldering them. This helps create a tight connection and improves conductivity.

6. Consider Soldering: If you are working with thicker wire gauges or need a more secure and permanent connection, consider soldering the wire ends. Proper soldering techniques ensure a strong joint and prevent unwanted voltage drops or intermittent connections.

7. Test Continuity: After making connections, always test continuity with a multimeter or a similar device to ensure that the wire connections are solid and there are no breaks or shorts.

8. Label and Organize: When working with multiple wire gauges in a project, label them or use color-coded sleeves to easily identify their thickness and purpose. This helps prevent confusion and mistakes during installation and troubleshooting.

9. Practice Proper Insulation: Make sure to use appropriate insulation, such as heat-shrink tubing or electrical tape, to protect and insulate the exposed wire ends. This reduces the risk of short circuits or accidental contact with other components.

10. Consult Resources: When in doubt, refer to wiring and connection guides, online resources, or seek advice from experienced individuals in the field. Learning from others’ experiences can provide valuable insight and help you overcome any challenges you may encounter.

By following these tips, you can ensure that your work with different wire gauges in small electronics projects is efficient, safe, and yields reliable connections. Adapting your techniques to the specific wire gauge you are working with will enhance the overall quality and performance of your projects.

Safety Precautions When Working with Different Wire Gauges

Working with different wire gauges in small electronics projects requires careful attention to safety to prevent accidents and ensure the well-being of yourself and others. Here are some important safety precautions to keep in mind when working with different wire gauges:

1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and a lab coat or apron, to protect yourself from potential hazards like sharp wire ends, soldering fumes, or accidental contact with electricity.

2. Inspect Wires: Before using any wire, inspect it for any signs of damage, such as frayed insulation or exposed conductors. Do not use wires that are worn out or damaged, as they may pose a safety risk.

3. Power Off: When making connections, ensure that the power source is turned off or disconnected to prevent accidental electric shock or short circuits.

4. Trace Live Wires: If you need to work with live wires, use appropriate voltage testers or multimeters to confirm that the wire or circuit is not energized. Handling live wires without proper precautions can be extremely dangerous.

5. Heat Protection: When soldering or working with heat-producing tools, be cautious of potential burns. Use heat-resistant mats or work surfaces to protect your work area and yourself from accidental burns.

6. Avoid Overloading: Be mindful of the maximum current-carrying capacity of the wire gauge you are working with. Overloading the wire can result in overheating, insulation breakdown, or even fires. Consult proper current rating guidelines for the specific wire gauge.

7. Proper Insulation: Ensure that all wire connections are properly insulated using heat-shrink tubing, electrical tape, or appropriate connectors. This minimizes the risk of electrical shocks, short circuits, and accidental contact.

8. Work in a Well-Ventilated Area: When soldering or heating wires, make sure you are in a well-ventilated space or use fume extraction equipment to avoid inhaling potentially harmful fumes.

9. Handle Tools Safely: Use tools designed for the specific wire gauge you are working with. Improper tools can cause damage to the wire or result in accidents. Keep tools in good condition and store them safely when not in use.

10. Educate Yourself: Stay informed about best practices, safety guidelines, and any specific precautions related to the wire gauge and project you are working on. Educating yourself will help you make informed decisions and work with confidence.

Remember to exercise caution and take these safety precautions seriously when working with different wire gauges in small electronics projects. Prioritizing safety ensures a secure working environment and minimizes the risk of accidents or injuries.

FAQs about Wire Gauge for Small Electronics

Here are some frequently asked questions about wire gauge in the context of small electronics:

1. What is wire gauge?

Wire gauge refers to the measurement of the diameter or thickness of a wire. It is typically denoted by a numerical value, with smaller numbers indicating thicker wires.

2. How does wire gauge affect current capacity?

Thicker wire gauges have a larger cross-sectional area, which allows them to carry more current without overheating. Thinner wire gauges have higher resistance and are suitable for low-power applications.

3. What wire gauge should I use for small signal or low-power applications?

For small signal or low-power applications, thin wire gauges like 30 AWG or 26 AWG are commonly used. These gauges offer low resistance and flexibility, making them suitable for transmitting small currents or signals.

4. What wire gauge should I use for power connections?

For power connections, the appropriate wire gauge depends on the current load. Thicker wire gauges like 18 AWG or 22 AWG are often used for small electronics projects where significant power flows through the wire.

5. How do I determine the right wire gauge for my project?

To determine the right wire gauge, consider factors such as the maximum current load, length of the wire, available space, voltage rating, and specific device requirements. Consulting wiring and connection guides or seeking advice from experienced individuals can also be helpful.

6. Can I use a thicker wire gauge than recommended?

Using a thicker wire gauge than recommended may not cause any immediate issues. However, it can take up more space and be more expensive. It’s important to strike a balance between the wire’s current-carrying capacity and the requirements of the project.

7. Can I mix different wire gauges within the same project?

Yes, it is common to use different wire gauges within the same project based on specific requirements. However, ensure that the connectors and components used are compatible with the respective wire gauges to ensure reliable connections.

8. What is the AWG standard?

The American Wire Gauge (AWG) is the most widely used standard for wire gauge measurement in the United States. It assigns specific numerical values to wire sizes, ranging from the thickest (lower numbers) to the thinnest (higher numbers) wires.

9. Can wire gauge be converted to metric sizes?

Yes, wire gauge can be converted to metric sizes. Conversion charts are available that provide the equivalent metric diameter for each wire gauge.

10. Are there any safety considerations when working with different wire gauges?

Absolutely. It’s crucial to follow safety precautions when working with different wire gauges, such as wearing appropriate personal protective equipment, ensuring proper insulation, and handling tools safely. Following safety guidelines minimizes the risk of accidents or injuries.