Choosing the Components

When it comes to making an electronic circuit, choosing the right components is crucial. Each component plays a specific role in the circuit and contributes to its overall functionality. Here are some important factors to consider when selecting the components for your circuit:

1. Purpose of the Circuit: Start by clearly defining the purpose of your circuit. Are you building a simple LED flasher or a complex microcontroller-based project? Understanding the desired functionality will help you determine the components you need.

2. Voltage and Current Requirements: Consider the voltage and current requirements of your circuit. Make sure the components you choose can handle the necessary voltage levels and provide the required current without overheating or malfunctioning.

3. Component Specifications: Pay attention to the specifications of each component, such as resistance values, capacitance values, and voltage ratings. Match these specifications to the requirements of your circuit for optimal performance.

4. Availability and Cost: Check the availability of the components in your local electronics stores or online suppliers. Consider their cost as well, especially if you are on a budget. It’s important to choose components that are easily obtainable and fit within your financial constraints.

5. Quality and Reliability: Opt for components from reputable manufacturers to ensure quality and reliability. Cheap or counterfeit components may lead to unpredictable behavior or premature failure of your circuit.

6. Compatibility: Ensure the compatibility of the components with each other and with your circuit design. Different components may have varying pin configurations or operating specifications, so double-check their compatibility to avoid any issues during assembly.

7. Future Expandability: If you anticipate adding more features or expanding your circuit in the future, consider components that allow for easy integration and scalability. This will make it simpler to modify or upgrade your circuit as needed.

By carefully considering these factors, you can choose the right components for your electronic circuit and set a strong foundation for a successful project. Remember to read datasheets and consult experts if you have any doubts or questions during the selection process.

Understanding Circuit Diagrams

Circuit diagrams are visual representations of electronic circuits that use standardized symbols to depict the components and connections within the circuit. Understanding how to read and interpret these diagrams is crucial for successfully building and troubleshooting electronic circuits. Here are some key points to help you grasp the basics of circuit diagrams:

1. Components and Symbols: Familiarize yourself with the common symbols used in circuit diagrams to represent components such as resistors, capacitors, diodes, transistors, and more. Each symbol represents a specific component and its function within the circuit.

2. Connection Lines: The lines in a circuit diagram represent the connections between components. Straight lines indicate direct connections, while curved lines indicate crossed connections or connections that are not directly connected.

3. Power Sources: Power sources, such as batteries or power supplies, are usually represented by a long vertical line with positive and negative signs. These sources provide the necessary voltage for the circuit to function.

4. Labels and Values: Circuit diagrams often include labels and values to provide additional information about the components. These labels may indicate resistance values, capacitance values, or specific part numbers to aid in component identification.

5. Direction of Current: Arrows or plus (+) and minus (-) signs are used to indicate the direction of current flow within the circuit. It’s essential to follow the correct direction to ensure the circuit functions as intended.

6. Series and Parallel Connections: Circuit diagrams show how components are connected either in series or in parallel. Series connections are represented by components connected one after another, while parallel connections are shown when components share a common connection point.

7. Circuit Paths: Circuit diagrams help visualize the flow of current through different paths within a circuit. By understanding the path of current, you can identify potential areas of resistance or troubleshoot faulty connections.

8. Read and Analyze: Take your time to carefully read and analyze the circuit diagram before starting the actual circuit construction. Pay attention to the interconnections, component values, and the flow of current to gain a clear understanding of how the circuit operates.

With practice and exposure to various circuit diagrams, you’ll become more comfortable and proficient at interpreting them. Remember to always cross-reference circuit diagrams with component datasheets and consult relevant resources or experts for more complex circuit designs.

Gathering Tools and Supplies

Before diving into any electronic circuit project, it’s essential to gather the necessary tools and supplies to ensure a smooth and efficient building process. Having the right tools and supplies at hand will not only make the assembly easier but also contribute to the overall quality of the finished circuit. Here are some key tools and supplies you should consider:

1. Basic Tools: Start by acquiring the essential tools that are commonly used in electronic circuit projects. These include a soldering iron, wire cutters, needle-nose pliers, a multimeter, a breadboard, and a set of screwdrivers. Having these tools readily available will significantly simplify the construction and testing phases.

2. Components: Identify and procure the specific electronic components required for your circuit. Make a list of the components mentioned in the circuit diagram, including resistors, capacitors, integrated circuits, transistors, LEDs, and other specialized components. It’s essential to have the correct values and ratings for each component to ensure proper functionality.

3. Breadboard and Jumper Wires: A breadboard is an invaluable tool for prototyping and testing circuits. It allows for easy insertion and removal of components without the need for soldering. Additionally, gather a set of jumper wires of various lengths and colors to connect the components on the breadboard.

4. Prototyping PCB and Perfboard: If you plan to transfer the circuit onto a permanent board, consider getting a prototyping PCB or perfboard. These boards provide a stable platform for soldering the components and creating a more robust and long-lasting circuit.

5. Soldering Supplies: If you intend to solder the components, you’ll need a soldering iron, solder wire, and flux. Opt for a soldering iron with temperature control, as it allows for precise soldering and avoids damaging sensitive components. Remember to use lead-free solder for environmentally friendly and safer results.

6. Safety Equipment: Prioritize your safety by investing in safety equipment such as safety glasses and heat-resistant gloves. Electronic circuits involve working with heat, sharp tools, and potentially hazardous materials, so it’s crucial to protect yourself from accidents or injuries.

7. Storage and Organization: Keep your tools and components organized by having storage solutions in place. Consider getting small plastic containers or storage boxes to keep your components sorted and easily accessible. Labeling the containers will further aid in efficient project management.

8. Reference Materials: A collection of reference books, datasheets, and online resources can be invaluable during the circuit-building process. These references provide detailed information on component specifications, circuit design techniques, and troubleshooting tips.

By gathering the necessary tools and supplies before starting your electronic circuit project, you’ll be well-equipped to handle the construction, testing, and troubleshooting phases. Additionally, having an organized workspace and access to reference materials will enhance your overall efficiency and enjoyment of the circuit-building experience.

Basic Circuit Building Blocks

Understanding the basic building blocks of electronic circuits is essential for constructing functional and reliable circuits. These building blocks, also known as electronic components, serve specific functions within a circuit and can be combined to create complex systems. Here are some of the common basic building blocks found in electronic circuits:

1. Resistors: Resistors are passive components that restrict the flow of electric current in a circuit. They are often used to control voltage levels, limit current flow, or divide voltage in a specific ratio.

2. Capacitors: Capacitors store and release electrical energy. They are used for various purposes such as filtering noise, smoothing voltage, storing energy, and timing circuits.

3. Inductors: Inductors store energy in a magnetic field. They are commonly used in applications involving filtering, energy storage, and impedance matching.

4. Diodes: Diodes are semiconductor devices that allow electrical current to flow in only one direction. They are frequently used in rectification, voltage regulation, and switching circuits.

5. Transistors: Transistors are active components that amplify or switch electronic signals. They are crucial in applications such as amplifiers, oscillators, and digital logic circuits.

6. Integrated Circuits (ICs): Integrated circuits are miniature electronic circuits that are fabricated onto a single chip. They often combine multiple functions, such as amplification, logic operations, or signal processing, into a single component.

7. Operational Amplifiers (Op-Amps): Op-amps are high-gain voltage amplifiers widely used in analog circuits. They are invaluable for tasks such as amplification, signal conditioning, filtering, and mathematical operations.

8. Sensors: Sensors convert physical quantities, such as temperature, light, or motion, into electrical signals. They play a crucial role in various applications, including automation, monitoring, and control systems.

9. Switches and Relays: Switches and relays enable the control of circuit connections. They are used to turn components or circuits on/off, select different input sources, or activate/deactivate specific functions.

10. Power Supplies: Power supplies provide the necessary voltage and current to operate electronic circuits. They can be based on AC-to-DC conversion, batteries, or specialized power sources depending on the specific requirements of the circuit.

By understanding the functions and characteristics of these basic building blocks, you’ll be able to design and construct a wide range of electronic circuits. Remember to consult datasheets and reference materials for specific component specifications and utilize simulation tools to validate circuit designs before implementation.

Soldering Techniques

Soldering is a fundamental skill in electronic circuit construction, allowing components to be securely connected to each other and to the circuit board. Whether you’re a beginner or an experienced electronics enthusiast, mastering soldering techniques is essential for creating reliable and robust circuits. Here are some key soldering techniques to help you achieve successful solder joints:

1. Preparation: Start by preparing your work area. Clean the soldering iron tip using a damp sponge or brass wire, ensuring that it is free from any oxidation or debris. Also, make sure your components and circuit board are clean and free from any contaminants.

2. Heat Control: It’s crucial to have precise control over the temperature of your soldering iron. Use a soldering iron with adjustable temperature settings and set it to the appropriate temperature for the components you are working with. Avoid excessively high temperatures, as they can damage the components or the circuit board.

3. Tinning the Iron: Before soldering, “tin” the soldering iron tip by applying a small amount of solder to the tip. This helps improve heat transfer and ensures better solder flow during the joint creation.

4. Flux Application: Applying flux to the areas to be soldered is essential for achieving clean and reliable joints. Flux helps remove oxidation, improves solder flow, and enhances the wetting of the solder onto the surfaces being joined. Use a flux pen or flux-core solder to apply flux to the components and the soldering pads on the circuit board.

5. Component Placement: Ensure that the components are correctly positioned and aligned on the circuit board before soldering. Use tools such as tweezers to hold small components in place and prevent them from shifting during the soldering process.

6. Soldering technique: Place the soldering iron tip on the joint where the component lead and the pad on the circuit board meet. Heat the joint for a few seconds to ensure proper heat transfer. Then, gently touch the solder wire to the joint, allowing it to melt and flow into the joint. Avoid applying excessive solder, as it can lead to bridging or poor connections.

7. Solder Joint Inspection: After soldering, inspect the joints to ensure they are clean, shiny, and without any solder bridges or cold joints. A good solder joint should have a smooth and concave appearance, indicating proper wetting and adhesion to the surfaces being joined.

8. Post-Soldering Cleaning: Once you have completed the soldering process, clean the circuit board with isopropyl alcohol or a specialized electronics cleaner to remove any flux residue. This helps prevent corrosion and improves the overall aesthetic of the circuit board.

With practice and attention to detail, you can develop proficient soldering skills. Remember to take your time, be patient, and seek guidance or tutorials if you encounter any difficulties. Soldering is a valuable skill that will greatly enhance your ability to build electronic circuits and bring your projects to life.

Building the Circuit on a Breadboard

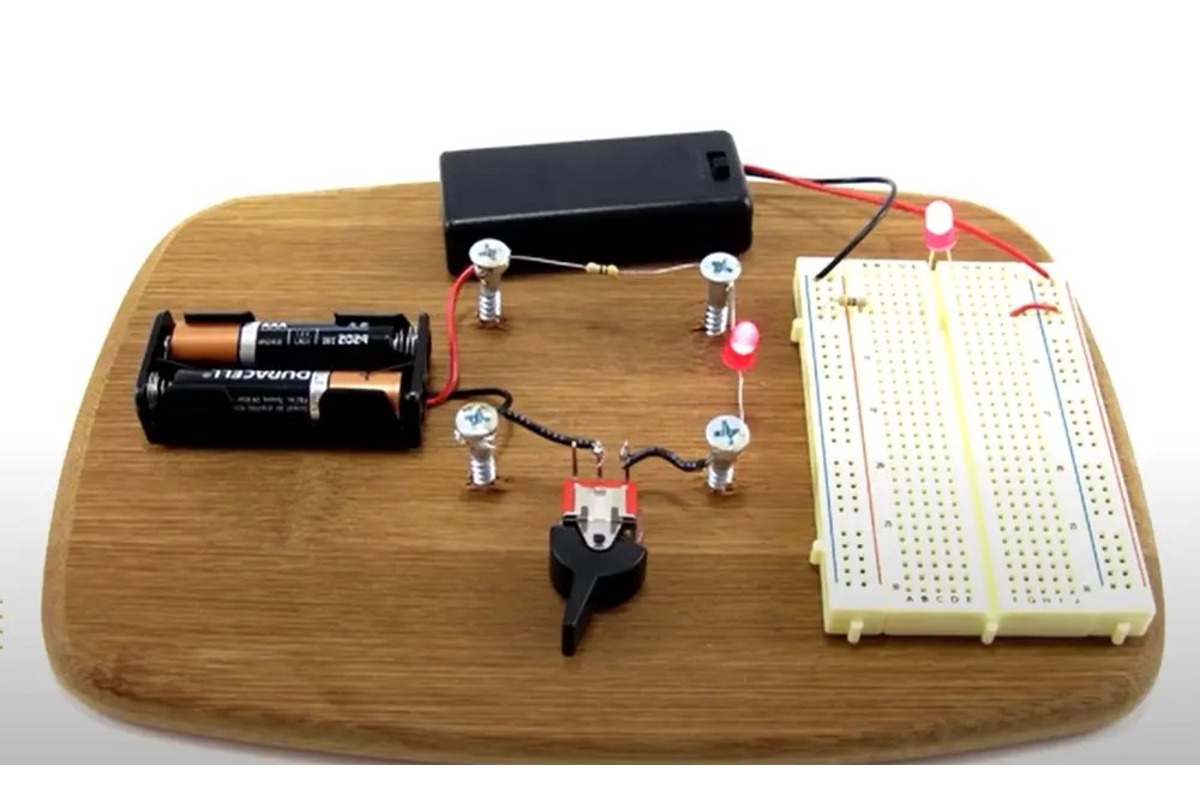

Breadboards are excellent tools for prototyping and testing electronic circuits without the need for soldering. They allow you to quickly and easily connect components together, providing a flexible and reusable platform for circuit construction. Here are the steps to build a circuit on a breadboard:

1. Gather the Components: Start by gathering all the necessary components for your circuit. Refer to the circuit diagram and ensure you have the correct components and values at hand.

2. Familiarize Yourself with the Breadboard: Take a moment to familiarize yourself with the breadboard’s layout. It consists of rows and columns of interconnected metal clips. The clips within each row are electrically connected, while the clips on opposite sides of the breadboard are not connected.

3. Plan the Layout: Examine your circuit diagram and plan the layout on the breadboard. Start by placing the integrated circuits (ICs) and larger components first, keeping in mind the connections between them and the required spacing.

4. Connect the Power Supply: Determine which row or column on the breadboard will be used for the power supply connections. Insert the positive and negative leads of the power supply into the appropriate rows or columns, ensuring they are securely connected.

5. Insert the Components: Insert the components into the breadboard according to your layout plan. Ensure that the component leads make contact with the appropriate metal clips without touching any adjacent clips.

6. Make the Connections: Use jumper wires to make the necessary connections between the component leads and the corresponding metal clips on the breadboard. Use different colors of jumper wires to visually distinguish between different connections.

7. Test and Troubleshoot: Once all the connections are made, double-check your work and ensure there are no loose connections or accidental short circuits. Connect the power supply and test the circuit to verify its functionality. If any issues arise, check for loose connections, misplaced components, or faulty components.

8. Modify and Experiment: Breadboards offer flexibility, allowing you to easily modify or experiment with your circuit. You can add or remove components, change resistor values, and test different configurations without the need for significant modifications.

9. Document Your Circuit: As you build your circuit on the breadboard, it’s helpful to document the connections and component layout. Take notes, draw diagrams, or use circuit simulation software to capture the circuit design for future reference or when transferring the circuit to a more permanent solution.

Building circuits on a breadboard is an excellent way to prototype and test your electronic designs. With practice, you’ll become more efficient at making connections and troubleshooting potential issues. Enjoy the flexibility and experimentation this versatile tool offers as you bring your circuit ideas to life.

Testing and Troubleshooting

Testing and troubleshooting are essential steps in the electronic circuit building process. They help ensure that your circuit functions as intended and identify and resolve any issues or malfunctions. Here are some helpful tips for testing and troubleshooting your electronic circuits:

1. Visual Inspection: Start by visually inspecting the circuit for any obvious issues. Check that all components are in the correct positions, without loose connections or solder bridges. Look for any burnt components or traces on the circuit board that may indicate a problem.

2. Power Supply: Verify that the power supply is connected correctly and provides the appropriate voltage and current for your circuit. Check the polarity of the power supply connections to ensure that you haven’t accidentally flipped them.

3. Oscilloscope and Multimeter: Utilize tools such as an oscilloscope and multimeter to measure voltage levels, current flow, and signal characteristics at various points in your circuit. This allows you to identify any discrepancies between expected values and measured values.

4. Step-by-Step Testing: Test your circuit step-by-step, starting with the individual components and then checking the connections between them. This helps isolate and identify any faulty components or wiring errors.

5. Substituting Components: If you suspect that a component may be faulty, try substituting it with a known working component of the same type. This helps determine if the component is indeed the cause of the problem.

6. Signal Tracing: Trace the flow of signals through your circuit using an oscilloscope or a logic analyzer. This helps identify any points in the circuit where the signal may be weak, distorted, or absent.

7. Rechecking Circuit Design: Double-check your circuit design, component values, and connections against the circuit diagram or schematic. Verify that you have correctly followed the design and that all component values are within the specified tolerances.

8. Breadboard to PCB Transition: If you are transitioning your circuit from a breadboard to a printed circuit board (PCB), recheck all connections and ensure that there are no missing or misaligned components. Use a continuity tester or an ohmmeter to verify the integrity of the PCB traces.

9. Documenting Issues: Keep a record of any issues or challenges you encounter during testing and troubleshooting. Note the symptoms, potential causes, and the steps you have taken to resolve them. This documentation will be helpful if you need to seek assistance or refer back to the troubleshooting process in the future.

10. Seek Help: If you’re unable to identify or resolve an issue, don’t hesitate to seek help from knowledgeable individuals, online forums, or electronics communities. Sometimes, a fresh pair of eyes or expert advice can lead to the discovery of a solution.

Remember, testing and troubleshooting are integral parts of the circuit-building process. By following systematic testing procedures and utilizing the right tools, you can identify and resolve issues, ensuring that your circuit functions properly and reliably.

Transferring the Circuit to a PCB

Transferring your electronic circuit from a breadboard or prototyping board to a printed circuit board (PCB) provides a more permanent and reliable solution. PCBs offer improved durability, compactness, and better electrical performance compared to temporary breadboard setups. Here are the essential steps to transfer your circuit to a PCB:

1. Design the PCB: Begin by designing the PCB layout using software specifically designed for PCB design, such as Eagle, KiCad, or Altium Designer. Create the circuit schematic, place the components, and route the traces to ensure proper connectivity.

2. Acquire the PCB Prototype: Once the design is complete, order a prototype of the PCB from a professional PCB fabrication service or create your own using PCB etching techniques if you have the necessary equipment and expertise.

3. Gather the Required Tools: To transfer the circuit to the PCB, you will need tools such as a soldering iron, wire cutter/stripper, solder wire, flux, and a multimeter to check for continuity and correct connections.

4. Assemble the Components: Place the components onto the PCB, referring to the PCB layout and component placement guide. Ensure that the polarity of the components aligns with the PCB markings, and double-check the correct placement and orientation of each component.

5. Solder the Components: Use the soldering iron to solder the component leads to the designated pads on the PCB. Apply flux to improve solder flow and joint quality, ensuring that each solder joint is clean, secure, and free from solder bridges.

6. Trim Excess Leads: After soldering, trim the excess component leads using a wire cutter or wire stripper. Be careful not to damage any adjacent traces or components during this process.

7. Inspect and Test: Inspect the soldered joints and PCB for any visual defects, such as bridges, cold solder joints, or lifted pads. Use a multimeter to perform continuity checks, especially for critical connections and power supplies.

8. Power On and Verify: Once you are confident in the assembly, power on the circuit and verify its functionality. Sequence through different modes or test different inputs and outputs to ensure that all components are working as expected on the PCB.

9. Troubleshoot if Necessary: If any issues arise during testing, use troubleshooting techniques outlined earlier to identify and resolve the problem. Check for loose connections, incorrect component values or orientations, and faulty components.

10. Document and Iterate: Document any changes or improvements made during the process and consider iterations or upgrades for future versions of the circuit. This documentation will be valuable when referring back to the design or when making modifications in the future.

Transferring your circuit to a PCB provides a more professional and reliable solution. Proper planning, careful assembly, and meticulous testing will ensure a successful transition from a breadboard to a fully functional PCB.

Powering the Circuit

Properly powering your electronic circuit is crucial for its successful operation. Choosing the right power supply and implementing appropriate power management techniques ensures that your circuit receives the correct voltage and current to function optimally. Here are some key considerations when powering your circuit:

1. Determine Power Requirements: Start by determining the voltage and current requirements of your circuit. Consult the datasheets of the components in your circuit to identify their operating voltage range and current consumption.

2. Select the Power Supply: Choose a power supply suitable for your circuit’s requirements. Consider factors such as the required voltage output, current capacity, and stability. Options include batteries, wall adapters, or dedicated DC power supplies.

3. Voltage Regulation: Incorporate voltage regulation techniques to ensure a steady and reliable power supply. Voltage regulators, such as linear regulators or switching regulators, can maintain a constant voltage output despite fluctuations in the input voltage or load variations.

4. Current Limiting: Implement current limiting measures to protect your circuit from excessive current flow. This can be achieved through the use of current-limiting resistors, current-limiting ICs, or current protection devices, depending on the specific requirements of your circuit.

5. Power Distribution: Plan and design the distribution of power throughout your circuit. Ensure that power is appropriately distributed to each component while keeping in mind power dissipation and potential heat generation.

6. Decoupling Capacitors: Place decoupling capacitors near power-hungry components, such as microcontrollers or integrated circuits. These capacitors act as localized energy storage, reducing noise and fluctuations in the power supply and stabilizing the voltage at each component.

7. Wire Gauge: Consider the wire gauge for connecting power to your circuit. Choose a wire gauge that can handle the expected current without excessive voltage drops or heating. Thicker wires generally have a lower resistance and are better suited for power distribution.

8. Grounding: Establish proper grounding in your circuit to maintain signal integrity and mitigate noise interference. Connect the ground terminals of all components to a common ground plane, ensuring low impedance and minimizing voltage differentials.

9. Power-On Sequencing: Implement power-on sequencing if your circuit contains multiple subsystems or sensitive components. Properly sequencing the power supply can prevent issues such as inrush currents or component damage due to voltage spikes.

10. Protection Circuits: Consider incorporating protection circuits, such as overvoltage protection, overcurrent protection, or reverse polarity protection, depending on the nature of your circuit and the criticality of the components involved.

By paying attention to the power requirements of your circuit and applying appropriate power management techniques, you ensure stable and reliable operation. Remember to test the power supply and monitor your circuit’s power consumption during operation to ensure continuous and efficient power delivery.

Adding Additional Components

As you develop your electronic circuit, you may find the need to add additional components to enhance functionality, expand capabilities, or implement specific features. The process of adding new components requires careful consideration to ensure they integrate seamlessly with the existing circuit. Here are some key points to consider when adding additional components:

1. Assessing Circuit Compatibility: Consider whether the additional component is compatible with your existing circuit. Review the datasheets of the new component and evaluate its electrical specifications, pin configuration, and operating requirements. Ensure that the new component can be integrated without causing issues or conflicts.

2. Identifying Circuit Modifications: Determine if any modifications are required in the circuit to accommodate the new component. Assess whether additional connections need to be made or existing connections need to be altered. Plan and document the necessary circuit changes to ensure a clear understanding of the modifications.

3. Circuit Analysis: Analyze the impact of adding the new component on the overall circuit behavior. Consider how the new component will affect voltage levels, current flow, timing, or any other important circuit parameters. Perform simulation or testing to assess the anticipated performance of the modified circuit.

4. Power Requirements: Evaluate the power requirements of the additional component. Ensure that the power supply can handle the increased load and that there is no significant impact on voltage regulation, current limitations, or power distribution throughout the circuit. Adjust the power delivery system if necessary.

5. Physical Placement: Determine the optimal physical placement of the new component within the circuit layout. Consider factors such as space availability on the circuit board, proximity to related components, and potential signal interference. Optimize the component placement for efficient circuit operation and ease of assembly.

6. Signal and Data Flow: Evaluate the impact of the new component on the signal and data flow of the circuit. Ensure that the new component integrates smoothly into the overall signal path and data exchange. Consider any necessary changes in signal routing or additional signal conditioning required.

7. Circuit Testing: After adding the new component, thoroughly test the modified circuit to verify its functionality and performance. Conduct functional tests, monitor signal integrity, and validate the expected behavior under different operating conditions. Address any issues through troubleshooting and make adjustments as required.

8. Documentation: Document the addition of the new component in the circuit design documentation. Include details on the modifications made, connections, and any specific considerations or limitations related to the new component. This documentation will be helpful for future reference, troubleshooting, or replication of the circuit.

Adding additional components to your electronic circuit can provide exciting opportunities for enhancements and expanded capabilities. However, careful consideration of compatibility, power requirements, and circuit modifications is essential to ensure a seamless integration and the desired performance of the modified circuit.

Safety Tips and Best Practices

When working with electronic circuits, it is essential to prioritize safety to protect yourself, your equipment, and also to ensure the proper functioning of your circuits. Here are some important safety tips and best practices to keep in mind:

1. Power Off: Always ensure that the power is switched off and disconnected before working on any circuit. This helps reduce the risk of electric shock and prevents accidental damage to components or short circuits.

2. ESD Protection: Electrostatic discharge (ESD) can damage sensitive electronic components. Use proper ESD protection measures, such as wearing an anti-static wrist strap and working on an anti-static mat, to safely handle and protect your components from ESD damage.

3. Eye and Skin Protection: Wear safety glasses to protect your eyes from debris, solder splatter, or potential component breakage. Additionally, consider using heat-resistant gloves when soldering or handling hot components to prevent burns or injuries.

4. Proper Ventilation: Provide adequate ventilation in your workspace to dissipate fumes and minimize exposure to potentially harmful solder flux or other chemicals. Use a fume hood or work in a well-ventilated area to prevent inhalation of toxic fumes.

5. Proper Tool Usage: Use tools and equipment properly and only for their intended purposes. Read and follow the manufacturer’s instructions for each tool or equipment to ensure safe operation and avoid accidents or damage.

6. Heat Management: Be cautious of the heat generated during soldering or when handling circuits that may become hot. Avoid touching hot components and use heat-resistant surfaces or tools to prevent burns or damage to your workspace.

7. Component Identification: Handle components carefully and ensure proper identification. Read the datasheets and markings on the components to understand their ratings, pin configurations, and specifications before connecting them to the circuit. Using incorrect components can lead to circuit malfunction or damage.

8. Good Wiring Practices: Follow good wiring practices when connecting components, such as using appropriate wire gauges, proper insulation, and secure connections. Avoid using damaged or frayed wires and ensure that all connections are tight to prevent electrical hazards or intermittent operation.

9. Test Equipment Safety: Ensure that any test equipment you use is properly grounded and meets safety standards. Regularly inspect and maintain your equipment to identify any potential safety hazards or malfunctions.

10. Learning and Continuous Improvement: Stay updated on safe practices for working with electronic circuits through research, training, and continued learning. Stay informed about new safety guidelines and industry best practices to ensure that your work environment remains safe and productive.

Remember, safety should be a top priority when working with electronic circuits. By following these safety tips and best practices, you can minimize risks, protect yourself and your equipment, and confidently work on your circuits with peace of mind.