Choosing the Right LED Lights and Connector

When embarking on a project to illuminate an area with LED lights, it's essential to select the appropriate lights and connectors to ensure a seamless installation process and optimal performance. Here's a step-by-step guide to help you make the right choices:

Researching LED Lights

Before diving into the world of LED lighting, it's crucial to conduct thorough research to understand the different types of LED lights available in the market. LED lights come in various shapes, sizes, colors, and brightness levels. Consider the specific requirements of your project, such as the desired ambiance, the area to be illuminated, and any specific color preferences. Additionally, assess the power consumption and longevity of the LED lights to ensure they align with your project's needs.

Understanding Connector Types

Connectors play a pivotal role in ensuring a secure and efficient electrical connection for LED lights. There are various connector types, such as solderless connectors, snap-on connectors, and screw-on connectors, each designed for specific applications. It's essential to understand the requirements of your project to determine the most suitable connector type. Factors to consider include the ease of installation, the environment in which the lights will be installed, and the level of protection required against moisture and dust.

Compatibility and Voltage Considerations

When choosing LED lights and connectors, it's imperative to consider compatibility and voltage requirements. Ensure that the selected LED lights are compatible with the chosen connector type. Additionally, verify that the voltage ratings of the LED lights and connectors match to prevent potential electrical issues. Understanding the compatibility and voltage requirements will contribute to a seamless and safe installation process.

Quality and Warranty

Prioritize the quality and warranty of the LED lights and connectors. Opt for reputable brands and suppliers known for producing high-quality, durable products. Assess the warranty offered for the LED lights and connectors to safeguard your investment. Quality products and reliable warranties can provide peace of mind and assurance of long-term performance.

Budget and Aesthetics

Consider your budget and the aesthetic appeal of the LED lights and connectors. While it's important to stay within budget constraints, it's equally crucial to select LED lights and connectors that enhance the visual appeal of the illuminated space. Balance cost-effectiveness with aesthetics to achieve a harmonious blend of functionality and visual allure.

By meticulously researching LED lights, understanding connector types, considering compatibility and voltage requirements, prioritizing quality and warranty, and balancing budget with aesthetics, you can make informed decisions when choosing the right LED lights and connectors for your project. This thoughtful approach will set the stage for a successful and visually captivating LED lighting installation.

Preparing the LED Lights and Connector

Once you have carefully selected the appropriate LED lights and connectors for your project, the next crucial step is to prepare them for installation. Proper preparation ensures that the subsequent connection process is smooth and efficient. Here’s a step-by-step guide on how to prepare the LED lights and connectors:

Gathering the Necessary Tools

Before diving into the preparation process, gather the necessary tools and equipment. These may include wire cutters, wire strippers, electrical tape, a voltage tester, and any specific tools recommended by the LED light and connector manufacturers. Having the right tools at hand will streamline the preparation process and contribute to a professional and secure installation.

Inspecting the LED Lights and Connectors

Thoroughly inspect the LED lights and connectors upon receipt to ensure they are free from any defects or damage. Check for any visible signs of wear or manufacturing flaws. It’s essential to address any issues before proceeding with the installation to prevent potential complications down the line. Additionally, familiarize yourself with the specific features and components of the LED lights and connectors to facilitate the preparation process.

Measuring and Cutting the Wires

Measure and cut the wires to the appropriate lengths based on the installation layout and the distance between the LED lights and the power source. Use wire cutters to achieve clean and precise cuts. It’s crucial to follow the manufacturer’s guidelines and any specific instructions provided with the LED lights and connectors to ensure accurate wire lengths and proper fitment during the connection process.

Stripping and Insulating the Wires

After cutting the wires to the required lengths, use wire strippers to carefully strip off the insulation from the wire ends. Take caution to strip off just enough insulation to expose the bare wire without damaging the conductive strands. Once the wires are stripped, insulate the exposed conductors with electrical tape to prevent any potential short circuits or electrical hazards during the connection process.

Organizing and Labeling

Organize the prepared wires and connectors in a systematic manner to avoid confusion during the installation. Consider labeling the wires and connectors to indicate their respective positions and functions, especially in scenarios where multiple LED lights and connectors are involved. Clear organization and labeling will streamline the connection process and minimize the likelihood of errors.

By gathering the necessary tools, inspecting the LED lights and connectors, measuring and cutting the wires, stripping and insulating the wires, and organizing and labeling the components, you can effectively prepare the LED lights and connectors for a successful installation. This meticulous preparation sets the stage for a seamless and secure connection process, ensuring that the LED lighting system operates at its full potential.

Connecting the Wires to the LED Lights and Connector

With the LED lights and connectors prepared, the next critical step is to connect the wires, establishing a secure and reliable electrical pathway. Properly connecting the wires to the LED lights and connectors is essential for the functionality and safety of the lighting system. Here’s a detailed guide on how to execute this crucial phase of the installation:

Identifying Polarity and Wiring Configuration

Before initiating the connection process, it’s imperative to identify the polarity of the LED lights and the corresponding wiring configuration. LED lights are polarized, meaning they have specific positive and negative terminals. Familiarize yourself with the manufacturer’s documentation or markings on the LED lights to discern the polarity. Additionally, ascertain the wiring configuration of the connectors, ensuring alignment with the polarity of the LED lights for proper electrical flow.

Matching and Securing the Wires

Match the stripped ends of the wires to the corresponding terminals on the LED lights and connectors based on the identified polarity. Ensure a snug and secure fit to establish a reliable electrical connection. Depending on the connector type, follow the manufacturer’s recommended method for securing the wires, whether it involves crimping, soldering, or utilizing specific attachment mechanisms. A secure connection minimizes the risk of electrical fluctuations and potential disconnections.

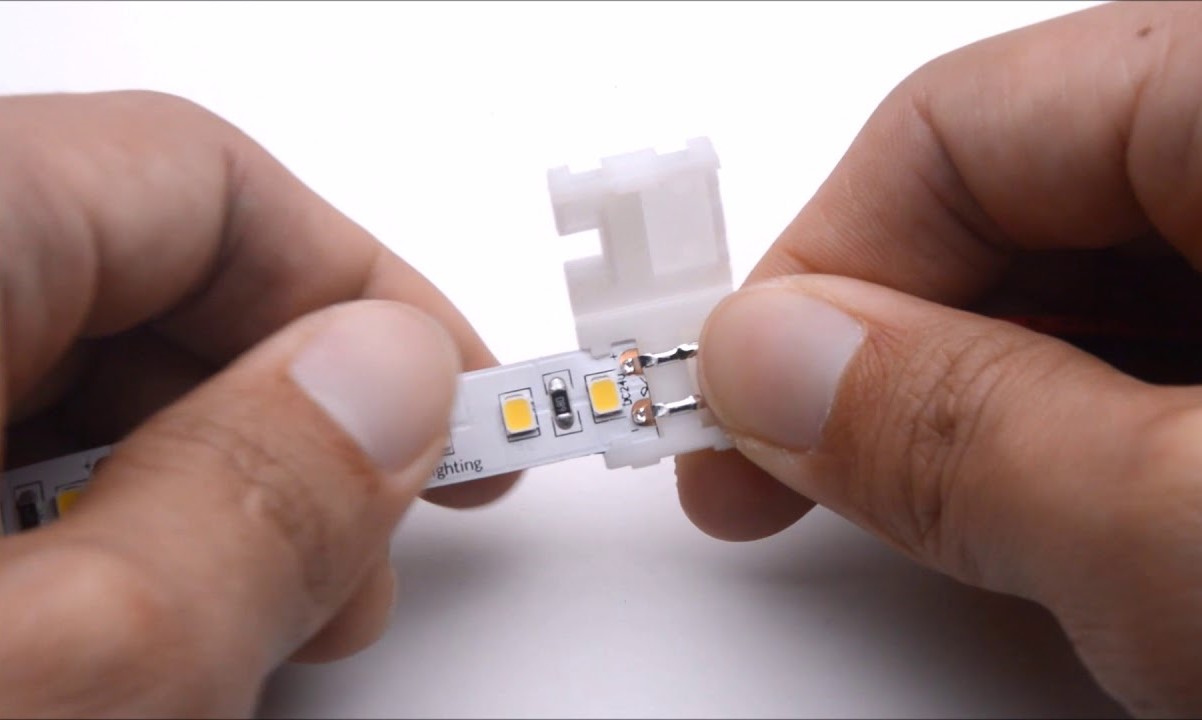

Utilizing Solderless Connectors

If employing solderless connectors, carefully insert the stripped wire ends into the designated slots within the connector, following the prescribed polarity. Apply firm pressure to ensure the wires are fully seated in the connector. Verify that the connection points are secure and free from any exposed conductors. Solderless connectors offer a convenient and efficient means of establishing solid electrical connections without the need for soldering equipment.

Applying Insulation and Protection

Upon completing the wire connections, apply electrical tape or heat-shrink tubing to insulate and protect the exposed connection points. Insulation serves to safeguard the connections from moisture, dust, and accidental contact, reducing the risk of electrical hazards. Additionally, verify that the insulated connections fit comfortably within the designated housing or enclosure, ensuring a tidy and organized installation.

Testing the Electrical Continuity

After securing the wire connections, utilize a voltage tester to verify the electrical continuity of the LED lights and connectors. Confirm that the electrical flow is consistent and uniform, indicating successful wire connections and proper polarity alignment. Testing the electrical continuity provides assurance of a well-established electrical pathway, setting the stage for the subsequent stages of the installation process.

By identifying polarity and wiring configuration, matching and securing the wires, utilizing solderless connectors, applying insulation and protection, and testing the electrical continuity, you can effectively connect the wires to the LED lights and connectors. This meticulous process ensures a secure and reliable electrical pathway, laying the foundation for a fully functional and safe LED lighting system.

Securing the Connection and Testing the LED Lights

After connecting the wires to the LED lights and connectors, the final steps involve securing the connections and conducting comprehensive testing to ensure the proper functionality of the LED lighting system. Here’s a detailed guide on how to secure the connections and carry out thorough testing:

Securing the Connections

Once the wire connections are established, it’s essential to secure them to prevent any inadvertent dislodging or loosening. Depending on the specific connector type and installation environment, utilize appropriate securing mechanisms recommended by the manufacturer. This may involve fastening the connectors within designated enclosures, utilizing cable ties for bundling and organizing the wires, or employing strain relief components to mitigate any undue stress on the connections.

Verifying Physical Stability

Inspect the physical stability of the connected components, ensuring that the LED lights, connectors, and associated wiring are securely positioned and free from any undue movement. Verify that the connections are not subjected to excessive tension or bending, as this can compromise the integrity of the electrical pathway. Physical stability is crucial for the long-term reliability and performance of the LED lighting system.

Conducting Functional Testing

Before finalizing the installation, conduct comprehensive functional testing to validate the proper operation of the LED lights. Activate the power source and observe the functionality of each LED light, ensuring that they illuminate as intended. Verify that the brightness levels are consistent and that there are no flickering or irregularities in the lighting output. Functional testing provides assurance of a successful connection and enables early detection of any potential issues.

Assessing Voltage and Current

Utilize a voltage and current measuring device to assess the electrical parameters of the LED lighting system. Confirm that the voltage levels are within the specified range for the LED lights and connectors. Additionally, measure the current flow to ensure that it aligns with the rated specifications. Monitoring the voltage and current parameters provides valuable insight into the operational health of the LED lighting system.

Verifying Environmental Resilience

Assess the environmental resilience of the installed LED lights and connectors, especially in outdoor or challenging settings. Verify that the connections are adequately protected against moisture, dust, and other environmental factors that may compromise their performance. Additionally, consider conducting testing under varying environmental conditions to assess the resilience and durability of the installed components.

By securing the connections, verifying physical stability, conducting functional testing, assessing voltage and current, and verifying environmental resilience, you can ensure the robustness and reliability of the LED lighting system. These meticulous steps culminate in a thoroughly tested and securely installed LED lighting setup, ready to deliver efficient illumination and lasting performance.