Importance of Cleaning Electronic Boards

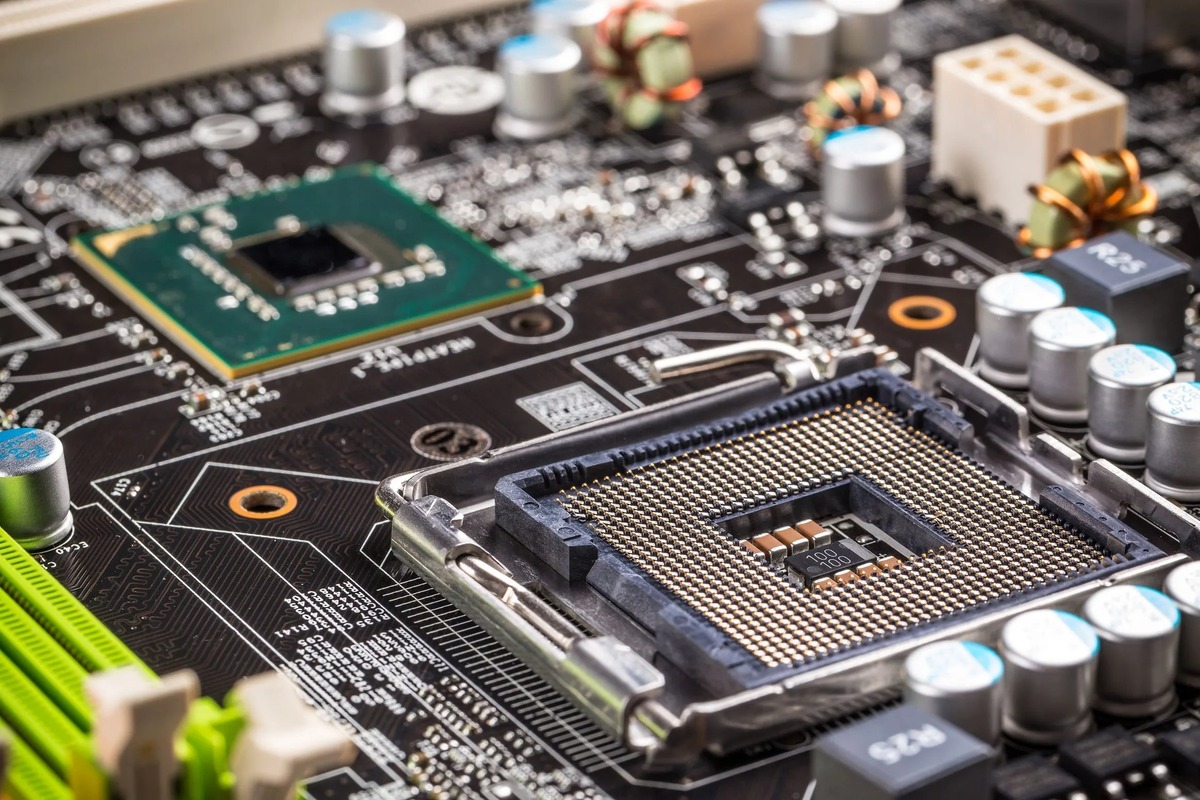

Electronic boards are the backbone of many electronic devices, from computers and smartphones to household appliances and industrial machinery. These boards are comprised of intricate circuitry and components that allow the device to function properly. Over time, dust, debris, and other contaminants can accumulate on the surface of electronic boards, leading to potential performance issues and even device failure.

Regularly cleaning electronic boards is essential for maintaining their optimal functionality and prolonging their lifespan. Here are a few reasons why cleaning electronic boards is of utmost importance:

- Preventing overheating: Dust and debris deposited on electronic boards can act as an insulator, impeding the dissipation of heat generated by the components. This can lead to overheating, which not only affects the performance of the device but also shortens its lifespan.

- Ensuring proper electrical connection: Contaminants on electronic boards can cause poor electrical contact between the board and its various components. This can result in signal loss, intermittent connections, and malfunctions, impacting the overall performance and reliability of the device.

- Preventing corrosion: Some contaminants, such as moisture or corrosive substances, can lead to corrosion on the surface of electronic boards. Corrosion can damage the circuitry and components, leading to irreparable malfunction or failure of the device.

- Reducing electromagnetic interference: Dust and debris can interfere with the proper functioning of sensitive electronic components, leading to electromagnetic interference (EMI). EMI can disrupt the signals and communications within the device, causing a loss of data or malfunction.

- Maintaining optimal performance: By cleaning electronic boards regularly, you can ensure that the device continues to perform at its best. Clean boards allow for the efficient flow of electrical signals and prevent any external factors from hindering its functionality.

Given the importance of clean electronic boards for the smooth operation of electronic devices, it is crucial to incorporate regular cleaning as part of device maintenance. Taking the time to clean and maintain electronic boards can significantly extend their lifespan and improve overall performance.

Tools Needed for Cleaning Electronic Boards

Properly cleaning electronic boards requires the use of specific tools to ensure the removal of contaminants without causing any damage. Here are the essential tools you will need for cleaning electronic boards:

- Isopropyl Alcohol: Isopropyl alcohol, also known as rubbing alcohol, is a common cleaning agent used for electronic components. It effectively removes dirt, grease, and other residues from the surface of electronic boards without leaving any residue behind.

- Lint-Free Microfiber Cloth: A lint-free microfiber cloth is ideal for wiping the surface of electronic boards. It is soft and will not scratch the delicate components. The lint-free nature of the cloth ensures that no fibers are left behind, preventing any potential damage or interference.

- Soft Bristle Brush: A soft bristle brush, such as a small paintbrush or a dedicated electronics brush, is useful for removing dust and debris from hard-to-reach areas of the board. It allows for gentle cleaning without causing any damage to the delicate components.

- Compressed Air Duster: A can of compressed air or an electronic duster is handy for blowing away loose particles and dust from the electronic board. It provides a burst of high-pressure air, effectively dislodging stubborn contaminants from the surface and crevices of the board.

- Cotton Swabs: Cotton swabs, commonly known as Q-tips, are useful for applying small amounts of isopropyl alcohol to specific areas that need extra cleaning attention. The soft cotton tips allow for precise cleaning without leaving behind any fibers.

- Anti-Static Gloves: Anti-static gloves or wrist straps are essential when handling electronic boards to prevent electrostatic discharge (ESD). ESD can damage sensitive components and affect the functionality of the board. These gloves help to discharge any static electricity from the body and ensure safe handling.

- Protective Eyewear: It is crucial to protect your eyes when working with electronic boards. Safety goggles or protective eyewear should be worn to shield your eyes from any potential debris or chemicals that may be dislodged during the cleaning process.

Having these tools on hand will enable you to safely and effectively clean your electronic boards. Remember to use caution and follow proper procedures to avoid mishandling or damaging the sensitive components of the board.

Precautions to Take Before Cleaning Electronic Boards

Before attempting to clean electronic boards, it is crucial to take certain precautions to ensure the safety of both the board and the person performing the cleaning. Here are some essential precautions to follow:

- Power Off: Before starting the cleaning process, make sure to power off and unplug the electronic device. This prevents any electrical shocks and protects the components from accidental damage.

- Ground Yourself: Static electricity can cause damage to electronic boards. To prevent electrostatic discharge (ESD), which can harm sensitive components, it is important to ground yourself. Use an anti-static wrist strap or touch a grounded metal object before handling the board.

- Work in a Controlled Area: Ideally, clean electronic boards in a clean and well-ventilated area to minimize the risk of dust and debris. Avoid working in areas with excessive humidity or static buildup, as these can be detrimental to the board and affect the cleaning process.

- Use Proper Tools: Ensure that you have the right tools for the job, as mentioned in the previous section. Using improper tools can damage the board and result in costly repairs or replacement.

- Be Gentle: When cleaning the board, use gentle and steady movements. Avoid applying excessive pressure or scrubbing vigorously, as this can damage the delicate components or leave scratches on the board’s surface.

- Avoid Excessive Moisture: While isopropyl alcohol is a common cleaning agent, it is important to use it sparingly. Excessive moisture can seep into the components or connectors and cause damage. Apply the alcohol to a lint-free cloth or cotton swab rather than directly on the board.

- Allow Sufficient Drying Time: After cleaning, ensure that the board is completely dry before reassembling the device or applying power. Moisture on the board can lead to short circuits and damage the components. Use compressed air or allow the board to air dry in a clean and dust-free environment.

- Consult Manufacturer’s Guidelines: If the electronic device or board has specific cleaning instructions from the manufacturer, it is advisable to follow those guidelines to ensure proper cleaning and avoid any voiding of warranties.

By taking these precautions, you can minimize the risk of damaging the electronic board during the cleaning process. Remember to handle the board with care and follow best practices to maintain the integrity and functionality of the device.

Cleaning Process for Electronic Boards

Cleaning electronic boards requires a systematic approach to ensure effective removal of contaminants without damaging the delicate components. Here is a step-by-step process for cleaning electronic boards:

- Power off and disconnect the device: Before starting the cleaning process, turn off and unplug the electronic device to prevent any electrical accidents or damage to the board.

- Prepare the cleaning area: Find a clean, well-ventilated workspace to perform the cleaning process. Remove any dust or debris from the area to minimize the risk of contamination.

- Wear proper protective gear: Put on anti-static gloves and safety goggles to protect yourself from electrostatic discharge (ESD) and potential debris during the cleaning process.

- Remove loose dust and debris: Use a soft bristle brush or compressed air canister to gently remove any loose dust and debris from the surface of the electronic board. Be careful not to blow dust or debris further into the device.

- Prepare the cleaning solution: Dilute isopropyl alcohol with distilled water in a 1:1 ratio. Alternatively, use an electronics-specific cleaning solution as recommended by the manufacturer.

- Clean the surface: Dampen a lint-free microfiber cloth or cotton swab with the cleaning solution. Gently wipe the surface of the electronic board, taking care not to apply excessive pressure. Pay close attention to areas with visible dirt or residues.

- Clean connectors and ports: Dip a cotton swab into the cleaning solution and use it to carefully clean the connectors and ports on the board. Wipe away any debris or buildup that may affect connectivity.

- Clean soldered areas: If there are visible residues or flux on soldered areas of the electronic board, use a small brush or cotton swab lightly dipped in the cleaning solution to clean them. Be cautious not to disturb any delicate solder joints or components.

- Dry the board: Allow the board to air dry in a clean and dust-free environment. Alternatively, use compressed air or a lint-free cloth to gently dry the board. Ensure that no moisture remains on the board before proceeding.

- Reassemble and test: Once the board is completely dry, reassemble the device and reconnect all necessary components. Power on the device and test its functionality to ensure that the cleaning process did not cause any issues.

Following this cleaning process will help remove contaminants from the electronic board and maintain its optimal performance. Remember to exercise caution and patience during the cleaning process to avoid damaging the delicate components.

Removing Dust and Debris from Electronic Boards

Dust and debris accumulation on electronic boards can hinder their performance and potentially lead to device failure. It is crucial to remove these contaminants regularly to maintain the board’s functionality. Here are some effective methods for removing dust and debris from electronic boards:

- Use Compressed Air: A can of compressed air or an electronic duster is an excellent tool for blowing away loose particles from the surface of the board. Hold the can at a slight angle and use short bursts of air to dislodge the dust. Be cautious not to blow the dust deeper into the device.

- Brush with Soft Bristles: Utilize a soft bristle brush, such as a small paintbrush or a dedicated electronics brush, to gently sweep away dust and debris from the board’s surface. Ensure the brush is clean and free from any abrasive materials that could scratch or damage the board.

- Vacuum with ESD-Safe Attachment: If the dust and debris are persistent or difficult to remove, consider using a vacuum cleaner with an ESD (Electrostatic Discharge)-safe attachment. ESD-safe attachments prevent the build-up of static electricity that could damage sensitive components.

- Wipe with Lint-Free Cloth: Dampen a lint-free microfiber cloth with isopropyl alcohol or an electronics-specific cleaning solution. Gently wipe the surface of the board, ensuring the cloth is slightly damp but not dripping wet. This method helps to remove loose dust and debris that may be clinging to the board.

- Inspect for Stubborn Debris: After using the above methods, carefully inspect the board for any remaining stubborn debris or residue. Use a dry, lint-free cloth or cotton swab to target these areas and gently remove the remaining contaminants.

- Repeat if Necessary: Depending on the degree of dust and debris buildup, it may be necessary to repeat the cleaning process multiple times to ensure a thorough removal. Take your time and be patient to achieve the desired cleanliness.

Ensuring the removal of dust and debris from electronic boards will help maintain their optimal performance and prevent any potential issues. Remember to handle the board with care during the cleaning process and avoid using excess force that could cause damage. By regularly removing dust and debris, you can extend the lifespan and functionality of the electronic board.

Cleaning the Surface of Electronic Boards

The surface of electronic boards can become dirty with fingerprints, oils, residues, and other contaminants that may affect their performance. Regularly cleaning the surface of electronic boards is essential for their proper functioning. Here are some effective methods for cleaning the surface of electronic boards:

- Isopropyl Alcohol: Isopropyl alcohol, also known as rubbing alcohol, is a common and effective cleaning agent for electronic boards. Dampen a lint-free microfiber cloth with isopropyl alcohol and gently wipe the surface of the board. The alcohol helps to dissolve and remove oils, fingerprints, and other residues.

- Electronics-Specific Cleaning Solution: There are commercial cleaning solutions specifically designed for electronic components and boards. Follow the manufacturer’s instructions and apply the solution to a lint-free cloth. Wipe the surface of the board gently to remove any contaminants.

- Cotton Swabs: For more precise cleaning, use a cotton swab dipped in isopropyl alcohol or an electronics-specific cleaning solution. Target any areas that may have stubborn residues, such as connectors or edges of components. Be careful not to leave behind any cotton fibers that could cause interference.

- Avoid Excess Moisture: When using cleaning solutions or isopropyl alcohol, it is important to dampen the cloth or cotton swab rather than saturating it. Excess moisture can seep into components or connectors and potentially cause damage. Apply the cleaning solution sparingly.

- Be Gentle: Use gentle, circular motions when cleaning the surface of the board to avoid applying excessive pressure. Scrubbing too hard or using abrasive materials can damage delicate components or scratch the surface of the board. Take your time and use a light touch.

- Dry the Board: After cleaning, allow the board to air dry in a clean and dust-free area. Alternatively, use a lint-free cloth to gently dry the board. Ensure that no moisture remains on the surface before reassembling or applying power to the device.

Regularly cleaning the surface of electronic boards helps maintain their appearance and functionality. By using the appropriate cleaning agents and techniques, you can remove residues and contaminants that might hinder the performance of the board. Take care to follow the recommended cleaning methods while treating the board delicately to ensure its longevity and optimal performance.

Cleaning Circuitry and Components on Electronic Boards

The circuitry and components on electronic boards are susceptible to dust, dirt, and other contaminants that can affect their performance and longevity. It is vital to clean these areas regularly to maintain the optimal functionality of the board. Here are some effective methods for cleaning the circuitry and components on electronic boards:

- Isopropyl Alcohol: Dampen a lint-free cloth or cotton swab with isopropyl alcohol. Gently wipe the circuitry and components on the board to remove any dust or residues. Be careful not to apply excessive pressure or leave behind any excess moisture that could damage the components.

- Cleaning Solution for Electronics: If available, use a dedicated electronics cleaning solution recommended by the manufacturer for cleaning circuitry and components. Apply the solution to a lint-free cloth or cotton swab and wipe the areas carefully. Follow the manufacturer’s instructions for proper usage.

- Soft Bristle Brush: Use a soft bristle brush, such as a small paintbrush or an electronics-specific brush, to gently remove any loose dust or debris from the circuitry and components. Brush in a light, sweeping motion to avoid damaging any sensitive parts.

- Cotton Swabs: Dip a cotton swab into isopropyl alcohol or electronics cleaning solution as necessary. Use the dampened swab to target specific areas of the circuitry or components that may require extra cleaning attention. Take caution to avoid excess moisture and be mindful of delicate components.

- Avoid Excessive Heat: When applying cleaning solutions or isopropyl alcohol to the circuitry and components, ensure that the board is at room temperature or cool. Excessive heat can cause the cleaning agents to evaporate too quickly, potentially leaving behind residue or damaging the board.

- Check for Residues: After cleaning, inspect the circuitry and components for any visible residues or debris. Use a lint-free cloth or cotton swab to gently wipe away any remaining contaminants. Take care not to scratch or dislodge any delicate components.

- Dry the Board: Allow the board to air dry in a clean and dust-free environment. Use a lint-free cloth or compressed air to gently dry any remaining moisture. Ensure that the board is completely dry before reassembling or applying power.

By following these methods for cleaning the circuitry and components of electronic boards, you can maintain their optimal performance and extend their lifespan. Take your time, be gentle, and exercise caution to prevent any damage to the delicate circuitry and components during the cleaning process.

Cleaning Connectors and Ports on Electronic Boards

Connectors and ports on electronic boards serve as vital interfaces for connectivity and data transfer. Over time, these areas can accumulate dust, debris, and oxidized residues, causing connection issues and signal degradation. Regularly cleaning connectors and ports is crucial for maintaining optimal performance. Here are some effective methods for cleaning connectors and ports on electronic boards:

- Inspection: Before cleaning, visually inspect the connectors and ports on the board. Look for visible dirt, debris, or oxidation that may be affecting the connections. Identify any areas that require attention during the cleaning process.

- Compressed Air: Use compressed air or an electronic duster to blow away loose particles and debris from the connectors and ports. Hold the canister at a distance and apply short bursts of air to dislodge the contaminants. Avoid blowing the debris further into the device or applying excessive force that could damage the connectors.

- Isopropyl Alcohol: Dampen a lint-free cloth or a cotton swab with isopropyl alcohol. Gently clean the connectors and ports by wiping them with the damp cloth or swab. Be careful not to apply excessive pressure or allow any excess moisture to enter the connectors.

- Cleaning Solution: If preferred, use an electronics-specific cleaning solution specifically designed for connectors and ports. Apply the solution to a lint-free cloth or cotton swab, and gently clean the connectors and ports. Follow the manufacturer’s instructions for proper usage and ensure that no residue is left behind.

- Small Brush or Toothbrush: For hard-to-reach areas or stubborn residues, use a small brush or toothbrush with soft bristles. Gently scrub the connectors and ports in a circular motion to remove any dirt or oxidation. Take care not to damage the connectors or dislodge any delicate components.

- Inspect for Residues: After cleaning, inspect the connectors and ports closely. Look for any remaining residues or debris. If necessary, use a lint-free cloth or cotton swab dipped in isopropyl alcohol to remove any leftover contaminants, ensuring that the connectors and ports are clean and free from any obstructions.

- Dry the Contacts: Once the connectors and ports are clean, allow them to air dry naturally. Alternatively, use compressed air or a lint-free cloth to gently dry any remaining moisture. Ensure that the contacts are completely dry before reassembling or reconnecting cables to prevent any potential damage from moisture.

Regularly cleaning connectors and ports on electronic boards helps maintain reliable connections and optimal performance. Follow these methods carefully, taking precautions to avoid damaging the connectors or other delicate components on the board. By keeping connectors and ports clean, you can ensure seamless data transfer and prevent connectivity issues.

Cleaning Soldered Areas on Electronic Boards

The soldered areas on electronic boards play a critical role in ensuring proper electrical connections and signal flow. Over time, these areas can accumulate flux residues, oxidation, and other contaminants that can hinder their performance. Regularly cleaning soldered areas is important for maintaining the integrity and functionality of the board. Here are some effective methods for cleaning soldered areas on electronic boards:

- Visual Inspection: Before cleaning, visually inspect the soldered areas on the board. Look for any visible flux residues, oxidation, or debris that may be affecting the solder joints. Identify the areas that require attention during the cleaning process.

- Isopropyl Alcohol: Dampen a lint-free cloth or cotton swab with isopropyl alcohol. Gently clean the soldered areas by wiping them with the damp cloth or swab. The alcohol helps dissolve and remove flux residues and other contaminants. Be careful not to apply excessive pressure, which can dislodge or damage the solder joints.

- Cleaning Solution for Electronics: If available, use an electronics-specific cleaning solution designed for soldered areas. Apply the solution to a lint-free cloth or cotton swab, and gently clean the soldered areas. Follow the manufacturer’s instructions for proper usage and ensure that no residue is left behind after cleaning.

- Soft Bristle Brush: If there are stubborn residues or oxidation on the soldered areas, you can use a soft bristle brush to lightly scrub the affected areas. Be gentle and avoid applying excessive force, as this can damage the solder joints or components.

- Cotton Swabs: Dip a cotton swab into isopropyl alcohol or electronics cleaning solution as necessary. Use the dampened swab to target specific soldered areas that require extra cleaning attention. Be cautious not to leave behind any cotton fibers on the solder joints.

- Inspect for Residues: After cleaning, closely inspect the soldered areas for any remaining residues or debris. Use a magnifying glass if necessary. If any residues are found, use a lint-free cloth or cotton swab dipped in isopropyl alcohol to gently remove the remaining contaminants.

- Drying: Allow the board to air dry in a clean and dust-free environment. Ensure that the soldered areas are completely dry before reassembling or applying power to the device. Excess moisture can lead to short circuits or corrosion.

Regularly cleaning soldered areas on electronic boards helps maintain the integrity of the solder joints and ensures proper electrical connections. Take care to follow these methods cautiously, ensuring that no excessive force is applied to the delicate components or solder joints. By keeping soldered areas clean, you can help extend the lifespan and performance of the electronic board.

Drying and Reassembling Electronic Boards

After the cleaning process, it is vital to ensure that the electronic board is completely dry before reassembling the device and applying power. Proper drying is crucial to prevent any moisture-related issues and ensure the optimal functionality of the board. Here are the steps to effectively dry and reassemble electronic boards:

- Air Drying: Place the cleaned electronic board in a clean and well-ventilated area, away from any sources of moisture. Allow the board to air dry naturally, ensuring that all moisture has evaporated. The drying time may vary depending on the size of the board and the ambient humidity.

- Compressed Air: If necessary, use compressed air or an electronic duster to gently blow away any remaining moisture from hard-to-reach areas or connectors. Ensure that the air pressure is not too high, as it may damage the board or dislodge components.

- Lint-Free Cloth: To remove any remaining moisture, gently pat the board with a lint-free cloth. Ensure that the cloth is clean and free from any lint or debris that could potentially cause damage or leave residue on the board.

- Reassemble with Care: Once the board is completely dry, carefully reassemble the device, following the manufacturer’s instructions. Check that all connectors and cables are securely attached, ensuring that no loose connections or obstructions are present.

- Inspect for Damaged Components: Before applying power, conduct a visual inspection to ensure that no components were dislodged or damaged during the cleaning or reassembly process. Look for any signs of physical damage, such as bent pins, broken solder joints, or loose components.

- Powering on the Device: Once the board and the device are fully dry and reassembled, reconnect the power source and switch on the device. Monitor the device closely for any abnormalities, such as unusual noises, overheating, or malfunctions.

- Perform Functional Testing: To verify that the cleaning process has not caused any issues, perform functional testing on the device. Test all the essential features and functions to ensure that the board is functioning as expected.

Properly drying and reassembling electronic boards following the cleaning process is crucial to maintain their optimal functionality. Take the necessary time to ensure that the board is completely dry before reassembling and applying power. By following these steps, you can mitigate the potential risks of moisture-related damage and promote the longevity of the electronic board.

Testing the Functionality of Electronic Boards after Cleaning

Once an electronic board has been cleaned and reassembled, it is essential to perform thorough functional testing to ensure that it is operating correctly. Testing the functionality of the board after cleaning helps to identify any potential issues that may have arisen during the cleaning process. Here are some key steps to consider when testing the functionality of electronic boards:

- Power on the Device: Connect the power source and turn on the device. Ensure that the board receives power correctly and that all indicators, lights, and displays illuminate as expected.

- Check System Initialization: Observe the device during the startup process to ensure that the electronic board initializes properly. Look for any error messages or unusual behavior.

- Test Input and Output: Verify that all input functionalities, such as buttons, switches, and touchscreens, are working correctly. Test the corresponding output functionalities, such as displays, speakers, and LEDs, to ensure they are operating as intended.

- Monitor Performance: Pay close attention to the performance of the device. Check for any signs of sluggishness, lag, or unusual behavior, which may indicate underlying issues with the electronic board.

- Connectivity Testing: Test the various connectivity options of the device, such as Wi-Fi, Bluetooth, and USB ports. Ensure that these features are functioning properly and that data transfer and communication are working as expected.

- Perform Stress Tests (if applicable): If the device is designed for intensive use or specific tasks, consider performing stress tests to assess its stability and performance under heavy load. This can include running demanding applications or performing complex operations.

- Validate Data Integrity: If the device processes or stores data, ensure that the data integrity remains intact after the cleaning process. Validate that the board accurately records and processes the data without any corruption or loss.

- Perform Specialized Tests (if applicable): Depending on the nature of the device and the specific functionalities it offers, conduct any specialized tests recommended by the manufacturer or as per the device’s intended use.

Thoroughly testing the functionality of electronic boards after cleaning is crucial to ensure that the board is functioning properly. By identifying any potential issues early on, you can address them promptly and prevent further damage or performance degradation. It is essential to follow the specific testing guidelines provided by the manufacturer or consult a professional if needed.