What Is an Electronic Speed Controller (ESC)?

An Electronic Speed Controller (ESC) is a crucial component in the field of remote-controlled vehicles, such as drones, RC cars, and helicopters. It acts as the intermediary between the power source, usually a battery, and the motor, controlling the speed and direction of the vehicle. Essentially, an ESC translates the electronic commands from the receiver into the appropriate power output for the motor.

The primary function of an ESC is to regulate the power flowing from the battery to the motor, ensuring smooth and precise control over the vehicle’s speed. It receives signals from the transmitter, which are then decoded by the receiver. The ESC interprets these signals and adjusts the amount of power being sent to the motor. By varying the power, the ESC enables the operator to control the vehicle’s speed, direction, and even braking.

ESC technology has evolved significantly over the years, improving the overall performance and efficiency of remote-controlled vehicles. Modern ESCs are equipped with advanced microcontrollers and firmware, allowing for more precise and responsive control. They also support various motor types, such as brushed and brushless motors, offering versatility to RC enthusiasts.

Furthermore, ESCs often come with additional features like programmability, integrated BECs (Battery Eliminator Circuits) for powering other electronics, and built-in safety mechanisms to protect against overloading, overheating, and voltage fluctuations.

Overall, an electronic speed controller is an essential device for anyone involved in the world of remote-controlled vehicles. Its ability to manage power delivery and control vehicle speed and direction makes it a critical component for achieving optimal performance and maneuverability in various applications.

How Does an ESC Work?

An Electronic Speed Controller (ESC) operates by taking signals from the receiver and converting them into appropriate power output for the motor. This enables precise control over the speed and direction of a remote-controlled vehicle. Understanding the inner workings of an ESC is crucial for any RC enthusiast or hobbyist.

When the transmitter sends signals to the receiver, those signals are then decoded and processed by the ESC. The ESC contains a microcontroller that interprets the signals and adjusts the power flow accordingly. The controller regulates the amount of voltage and current being delivered to the motor, which directly affects the speed and performance of the vehicle.

An ESC uses Pulse Width Modulation (PWM) to control the power output to the motor. PWM works by rapidly switching the power on and off at varying pulse widths. The length of each pulse determines the amount of power being sent to the motor. A longer pulse width corresponds to more power, resulting in increased motor speed.

The frequency of the PWM signals is typically around 50Hz to 500Hz, but this can vary depending on the ESC model. Higher frequencies provide smoother and more precise control over the motor’s speed.

Inside the ESC, there are multiple electronic components that work together to ensure the smooth operation of the motor. These components include transistors, capacitors, and voltage regulators. The transistors act as switches, turning the power on and off according to the PWM signals. The capacitors help stabilize the power supply, while the voltage regulators ensure that the motor receives a consistent voltage level.

In addition to controlling the motor’s speed, ESCs also handle other functionalities, such as braking, reversing the motor direction, and providing power to other electronics on the RC vehicle. This multi-functionality makes ESCs a versatile component in the world of remote-controlled vehicles.

Overall, an ESC serves as the crucial link between the receiver, motor, and power source. Through the use of PWM signals and advanced electronic components, it translates the commands from the transmitter into precise control over the vehicle’s speed and direction. The ability to fine-tune the power output allows RC enthusiasts to achieve optimal performance and maneuverability with their vehicles.

Types of ESCs

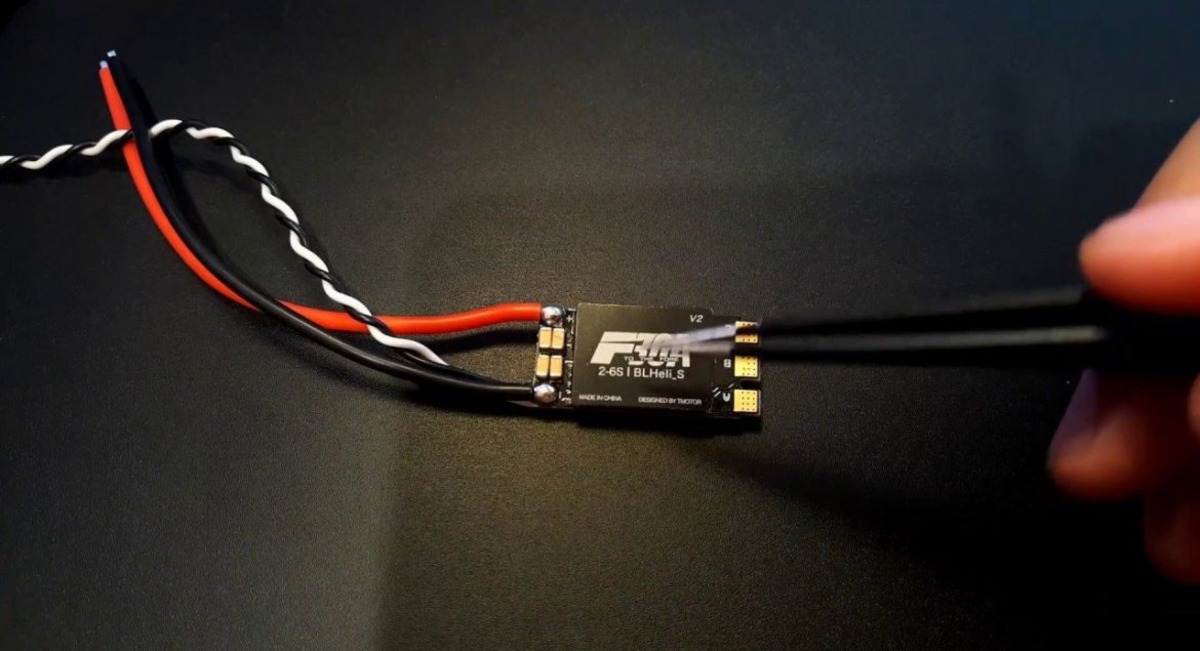

Electronic Speed Controllers (ESCs) come in various types, each designed for specific motor configurations and applications. Understanding the different types of ESCs can help RC enthusiasts choose the right one for their specific needs. Here are the two main types of ESCs:

1. Brushed ESCs

Brushed ESCs are commonly used in vehicles with brushed motors. These motors have a traditional design with brushes and a commutator that transfers power to the rotor. Brushed ESCs work by controlling the polarity and magnitude of the voltage applied to the brushes, thereby dictating the motor’s speed and direction.

Brushed ESCs are relatively straightforward in design and cost-effective compared to their brushless counterparts. They are suitable for beginner-level RC vehicles and other low-power applications. However, they are not as efficient or capable of providing high-speed performance as brushless ESCs.

2. Brushless ESCs

Brushless ESCs are specifically designed to work with brushless motors, which have a more advanced design without brushes or a commutator. These motors rely on electronic commutation, where the ESC controls the timing and voltage phases to power each motor coil. This allows brushless ESCs to provide more precise control and higher efficiency compared to brushed ESCs.

Brushless ESCs are commonly used in high-performance RC vehicles that require faster acceleration, higher speeds, and increased power. They are more complex in design and generally more expensive than brushed ESCs. However, their superior performance and greater longevity make them the preferred choice for experienced RC enthusiasts and professionals.

It’s important to note that both brushed and brushless ESCs have their own set of compatible motors. Brushed ESCs are designed for brushed motors, while brushless ESCs are specifically designed for brushless motors. It is crucial to select an ESC that matches the motor type in order to ensure proper compatibility and optimal performance.

Additionally, ESCs can vary in terms of their capabilities, such as the number of supported cells (battery voltage), current rating (amperage), and programmability features. These variations allow RC enthusiasts to choose ESCs that are tailored to their specific power requirements and customization needs.

Brushed ESCs

Brushed Electronic Speed Controllers (ESCs) are designed to work with brushed motors, which are commonly found in lower-power remote-controlled vehicles. These ESCs play a crucial role in regulating the speed and direction of the motor by controlling the flow of power.

Brushed motors use a design that includes brushes and a commutator. The brushes make physical contact with the commutator, which acts as a switch, transferring power to different sections of the motor’s armature. The ESC’s primary function is to regulate the voltage and current being delivered to the brushes, thereby controlling the speed and direction of the motor.

Brushed ESCs consist of various components, including a microcontroller, transistors, capacitors, and voltage regulators. The microcontroller decodes the signals received from the transmitter via the receiver and adjusts the power flow accordingly. The transistors act as switches, turning the power on and off to the motor based on the Pulse Width Modulation (PWM) signals. Capacitors help stabilize the power supply, and voltage regulators ensure consistent voltage levels.

One of the advantages of brushed ESCs is their simplicity and cost-effectiveness. They are generally less expensive compared to their brushless counterparts, making them a popular choice for entry-level and budget-oriented RC vehicles. Their straightforward design and operation also make them easier to troubleshoot and repair.

However, brushed ESCs have certain limitations. They are not as efficient as brushless ESCs and can produce more heat due to the constant friction between the brushes and commutator. This heat buildup can lead to reduced motor performance and potentially shorten the lifespan of the motor. Additionally, brushed motors tend to have less overall power and lower maximum speeds compared to brushless motors.

Despite these limitations, brushed ESCs are still widely used in various applications, including toy cars, low-power boats, and certain airplane models. They are suitable for beginners and casual hobbyists who prioritize simplicity and affordability over high performance.

Brushless ESCs

Brushless Electronic Speed Controllers (ESCs) are specifically designed to work with brushless motors, which are known for their high performance and efficiency. These ESCs play a crucial role in controlling the speed, direction, and overall performance of brushless motors in remote-controlled vehicles.

Unlike brushed motors that use physical brushes and a commutator, brushless motors utilize electronic commutation. This means that the ESC controls the timing and voltage phases to power each coil of the motor. By precisely adjusting the voltage and timing, the brushless ESC can provide smoother and more precise control over the motor’s speed and power output.

Brushless ESCs are more complex in design and functionality compared to their brushed counterparts. They contain advanced microcontrollers that decode the signals from the transmitter and adjust the power flow to the motor. These ESCs often support higher frequencies for Pulse Width Modulation (PWM), allowing for more precise control over the motor’s speed and acceleration.

One of the main advantages of brushless ESCs is their higher efficiency and performance. They generate less heat and power loss compared to brushed ESCs, resulting in improved overall efficiency and longer motor life. Brushless motors are capable of providing higher speeds, faster acceleration, and greater torque, making them ideal for high-performance RC vehicles.

Brushless ESCs also offer a range of programmable features, including throttle curve adjustment, braking force control, and motor timing customization. These programmability options allow RC enthusiasts to fine-tune the ESC’s performance to their desired preferences and optimize their vehicle’s performance for different applications, such as racing or aerobatics.

Although brushless ESCs offer superior performance and efficiency, they can be more expensive compared to brushed ESCs. The additional complexity and advanced technology involved in their design contribute to the higher cost. However, for RC enthusiasts who prioritize high-end performance and reliable power delivery, investing in a brushless ESC is often worth the investment.

Due to their versatility and high-performance capabilities, brushless ESCs are commonly used in a wide range of applications, including RC cars, drones, helicopters, and airplanes. They are the go-to choice for experienced RC hobbyists, professional racers, and individuals who want to unlock the full potential of their remote-controlled vehicles.

Programming an ESC

Electronic Speed Controllers (ESCs) often come with programmable features that allow RC enthusiasts to customize various settings to suit their specific needs and preferences. Programming an ESC allows you to fine-tune parameters such as throttle response, braking force, motor timing, and more. Programming options can vary depending on the ESC model, but most allow adjustments through a combination of transmitter inputs, programming cards, or computer interfaces.

One common method of programming an ESC is using the transmitter inputs. This involves following a specific sequence of throttle and brake inputs on the transmitter while powering on the ESC. The ESC will enter a programming mode, indicated by a series of LED flashes or audible tones. By manipulating the throttle and brake inputs, you can navigate through the different available programming options and adjust the desired parameters.

Some ESCs offer the convenience of using a programming card. A programming card is a handheld device that plugs directly into the ESC. It typically has an LCD screen and buttons that allow you to navigate through the various programming options and make adjustments easily. The programming card eliminates the need for complex throttle inputs and simplifies the process of customizing the ESC settings.

In addition to transmitter inputs and programming cards, some advanced ESCs can be programmed through a computer interface. This method requires connecting the ESC to a computer using a USB cable and utilizing dedicated software provided by the ESC manufacturer. The software allows for a more detailed and precise adjustment of the ESC parameters, often providing graphical user interfaces and real-time telemetry data.

When programming an ESC, it’s important to refer to the manufacturer’s instructions and documentation to ensure proper configuration. Each ESC model may have specific programming options and limitations. It’s advisable to start with default settings and make gradual changes to avoid unexpected behavior or damage to the ESC or motor.

Programming an ESC allows you to optimize your vehicle’s performance based on your specific requirements. By adjusting parameters such as throttle response, brake strength, and motor timing, you can fine-tune the power delivery and motor performance to achieve the desired speed, acceleration, and handling characteristics.

It’s worth noting that not all ESCs are programmable, especially lower-end models or those intended for basic applications. If customization and fine-tuning options are important to you, it’s recommended to choose an ESC that explicitly states its programmability or compatibility with programming accessories.

ESC Features and Specifications

Electronic Speed Controllers (ESCs) come with a range of features and specifications that determine their capabilities and performance. Understanding these features and specifications is essential when selecting an ESC that meets your specific needs. Here are some common features and specifications to consider:

1. Current Rating

The current rating of an ESC refers to the maximum amount of current it can handle without overheating or getting damaged. It is typically measured in amps (A) and should be compatible with the current requirements of your motor. Choosing an ESC with an appropriate current rating ensures reliable and safe operation of your RC vehicle.

2. Battery Compatibility

ESCs have specific compatibility with the type and number of cells in the battery pack. This compatibility is usually stated as a voltage range, indicating the minimum and maximum number of battery cells that the ESC can handle. It is crucial to select an ESC that supports the voltage range of your battery pack to prevent damage to the ESC and maintain proper performance.

3. BEC (Battery Eliminator Circuit)

Many ESCs include a built-in BEC, which provides power to other electronics such as the receiver, servos, and LED lights. The BEC eliminates the need for a separate battery pack for these components, simplifying the overall setup of the RC vehicle. It is important to consider the BEC voltage and current output when choosing an ESC according to your specific power requirements.

4. Programmability

Some ESCs offer programmable features that allow you to customize settings such as throttle response, braking force, motor timing, and more. The availability and extent of programmability can vary depending on the ESC model. Programmable ESCs provide flexibility to fine-tune your vehicle’s performance to match your preferences and optimize its capabilities for different applications.

5. Built-in Protection Features

ESCs often come with built-in protection features to safeguard against potential issues. These can include over-temperature protection, over-voltage protection, low-voltage cutoff, and motor stall protection. These protection features help prevent damage to the ESC and motor and ensure safe operation under different conditions.

6. Size and Weight

The physical size and weight of the ESC should be taken into consideration, especially if you have limited space in your RC vehicle or need to meet specific weight restrictions. Compact and lightweight ESCs are generally more desirable, but it’s essential to strike a balance between size, weight, and the necessary power requirements for your application.

Keep in mind that the specific features and specifications can vary between different ESC models and brands. It’s crucial to review the manufacturer’s documentation and product descriptions to ensure that the selected ESC meets your specific requirements and is compatible with your RC vehicle and motor.

Popular Brands of ESCs

When it comes to Electronic Speed Controllers (ESCs), there are several reputable brands known for producing high-quality and reliable ESCs for remote-controlled vehicles. These brands are trusted by RC enthusiasts and professionals alike. Here are some popular brands known for their ESCs:

1. Hobbywing

Hobbywing is a well-known brand that offers a wide range of ESCs for various applications, including cars, drones, boats, and airplanes. They are renowned for their advanced technology, high-performance ESCs, and reliable power delivery. Hobbywing ESCs often come equipped with programmable features, built-in protection mechanisms, and excellent heat dissipation capabilities.

2. Castle Creations

Castle Creations is a leading brand in the RC industry, specializing in high-performance ESCs for a wide range of applications, including cars, trucks, boats, and aircraft. Castle Creations ESCs are known for their durability, smooth control, and advanced programmability. They offer a range of options, catering to both casual hobbyists and professional racers.

3. Traxxas

Traxxas is a well-established brand that manufactures a variety of RC products, including ESCs for their popular line of RC cars and trucks. Traxxas ESCs are known for their reliability, ease of use, and seamless integration with Traxxas vehicles. They offer a range of ESC options, from entry-level to high-performance models, catering to different skill levels and applications.

4. Tekin

Tekin is a respected brand in the RC racing community, renowned for its high-performance ESCs and motors. Tekin ESCs are designed for maximum performance, providing precise control, exceptional power delivery, and advanced programmability options. They are popular among competitive racers who demand top-of-the-line performance and customization capabilities.

5. Speed Passion

Speed Passion is a brand that focuses on producing high-quality ESCs primarily for the competitive racing scene. Speed Passion ESCs are known for their reliability, smooth control, and advanced features. They offer various ESC options tailored to different racing classes and have a reputation for delivering consistent performance on the track.

These are just a few examples of popular brands known for their ESCs. Other notable brands include LRP, Futaba, Team Orion, and Yeah Racing, each with its own unique features and strengths. It’s important to consider factors such as compatibility, performance, and customer support when choosing an ESC, as these factors can vary between brands and models.

Ultimately, the choice of ESC brand depends on individual preferences, budget, and specific requirements for your RC vehicle. Reading reviews, seeking input from experienced RC enthusiasts, and considering the brand reputation can help you make an informed decision and select an ESC that will enhance the performance and enjoyment of your remote-controlled vehicle.

ESC Safety and Precautions

When using Electronic Speed Controllers (ESCs) in remote-controlled vehicles, it is important to prioritize safety and take necessary precautions to prevent accidents and damage. Here are some essential safety tips and precautions to keep in mind when working with ESCs:

1. Read the Manual

Before using an ESC, thoroughly read and understand the manufacturer’s instructions and safety guidelines. The manual provides important information specific to the ESC model, including installation procedures, programming options, and recommended operating parameters.

2. Proper Battery Connection

Ensure that you correctly connect the battery to the ESC, paying attention to the polarity and battery type. Failure to connect the battery properly can lead to electrical damage or even explosions. Be meticulous in following the instructions and double-check the connections before powering on the ESC.

3. Prevent Overheating

ESCs generate heat during operation, especially under heavy loads and prolonged use. To prevent overheating, make sure the ESC is adequately ventilated and avoid covering or obstructing it. Additionally, monitor the temperature of the ESC during use and take breaks if necessary to allow it to cool down.

4. Avoid Water Exposure

Most ESCs are not designed to be waterproof or water-resistant. Keep the ESC and its connections dry and avoid exposing them to water or excessive moisture. Water ingress can damage the ESC and potentially lead to a short circuit or malfunction.

5. Proper Wiring and Connections

When connecting the ESC to the motor and receiver, ensure proper wiring and secure connections. Loose or incorrect wiring can cause signal loss, reduced power delivery, or even damage to the components. Use high-quality connectors, solder connections when necessary, and secure all wires to prevent them from coming loose during operation.

6. Be Mindful of High Currents

ESCs can handle high currents, so it’s essential to use appropriate gauge wires that can handle the current draw. Using wires that are too thin can cause voltage drops, overheating, and potential damage to the ESC. Always refer to the manufacturer’s recommendations for wire gauge and current carrying capacity.

7. Regular Maintenance and Inspection

Perform regular maintenance and inspections on your ESC to ensure it remains in good working condition. Check for any loose connections, damaged wires, or signs of wear. Clean the ESC periodically to remove dirt and debris that can affect its performance or cause overheating.

8. Consult the Manufacturer or Experts

If you have any questions or concerns about your ESC, don’t hesitate to reach out to the manufacturer or consult experienced RC hobbyists or professionals. They can provide valuable advice, troubleshooting tips, and recommendations to help ensure the safe and proper use of your ESC.

By following these safety tips and precautions, you can minimize the risk of accidents, protect your RC vehicle, and enhance the overall enjoyment and longevity of your ESC.

Troubleshooting ESCs

Electronic Speed Controllers (ESCs) can sometimes encounter issues that affect their performance or functionality. Troubleshooting these issues is an important skill for RC enthusiasts to ensure their ESCs operate smoothly. Here are some common troubleshooting steps to help identify and resolve ESC-related problems:

1. Check Power Connections

Ensure that all power connections, including the battery, ESC, and motor, are properly connected and secure. Loose or faulty connections can result in intermittent power supply or loss of signal. Check for any damaged wires, connectors, or loose solder joints, and address any issues promptly.

2. Verify Receiver and Transmitter Signals

Confirm that the receiver is receiving the proper signal from the transmitter. Check the transmitter batteries, signal range, and channel assignment. If the ESC does not respond to commands, recalibrating the transmitter and receiver may be necessary.

3. Calibrate the ESC

If the ESC does not arm or respond correctly, it may need to be recalibrated. Follow the manufacturer’s instructions on how to calibrate the ESC, which typically involves a specific sequence of throttle and brake inputs on the transmitter while powering on the ESC.

4. Check ESC Temperature

If the ESC becomes excessively hot during operation, it may be a sign of an overheating issue. Ensure that the ESC is adequately ventilated and not covered or obstructed. Consider reducing the load or adjusting the programming settings to prevent overheating.

5. Test with Different Motor and Battery

If possible, swap out the motor or battery with known working components to eliminate potential issues with those components. This can help determine whether the problem lies with the ESC or elsewhere in the system.

6. Firmware Update

Check if a firmware update is available for your ESC model. Manufacturers may release updates that address known issues or improve performance. Follow the instructions provided by the manufacturer to update the ESC firmware properly.

7. Seek Expert Advice

If troubleshooting steps do not resolve the issue, reaching out to experienced RC hobbyists, online forums, or contacting the manufacturer’s technical support can be helpful. They can provide insights, specific solutions, or recommend further troubleshooting steps.

Remember, troubleshooting ESC issues requires patience and systematic troubleshooting steps. It is essential to follow the manufacturer’s instructions, be cautious while working with electrical components, and seek guidance from knowledgeable sources when necessary. By effectively diagnosing and resolving ESC-related problems, you can ensure optimal performance and extend the lifespan of your ESC.

Upgrading and Replacing an ESC

As RC enthusiasts gain more experience and seek improved performance from their vehicles, upgrading or replacing the Electronic Speed Controller (ESC) becomes a viable option. Upgrading an ESC can provide enhanced power delivery, advanced features, and improved overall performance. Here are some important considerations when upgrading or replacing an ESC:

1. Motor Compatibility

Ensure that the new ESC is compatible with the motor you intend to use. Match the motor type (brushed or brushless) and the specific motor specifications (kV rating, number of poles, etc.) to the capabilities of the new ESC. Mismatched ESC and motor specifications can result in poor performance or damage to the components.

2. ESC Specifications

Consider the specifications of the new ESC, such as current rating, battery compatibility, and programmability. Choose an ESC with suitable specifications for your specific RC vehicle and desired performance goals. A higher current rating, for example, may be necessary for more powerful motors or applications that demand higher currents.

3. Size and Mounting

Check the physical dimensions of the new ESC to ensure it fits within the available space in your RC vehicle. Consider the mounting options and compatibility with existing mounting points or brackets. Proper placement and secure mounting are crucial to prevent damage to the ESC and ensure reliable operation.

4. Programming and Features

If you desire advanced programmability or additional features, carefully compare the programming options of different ESCs. Determine whether the new ESC offers the specific features you are looking for, such as advanced throttle curve settings, braking force control, or custom motor timing adjustments.

5. Budget

Consider your budget when upgrading or replacing an ESC. Prices for ESCs can vary significantly depending on the brand, features, and performance. Determine your budget range and research ESCs within that range that offer the desired performance and capabilities.

6. Installation and Setup

Follow the manufacturer’s instructions and guidelines during the installation and setup process of the new ESC. Ensure that all connections, wires, and solder joints are secure and properly insulated. Pay attention to any specific setup procedures, such as throttle calibration or programming, to achieve optimal performance.

7. Safety and Testing

After installing the new ESC, thoroughly test the setup before pushing your RC vehicle to its limits. Verify proper operation, observe motor and ESC temperatures, and ensure that the vehicle responds correctly to throttle inputs. This will help identify any potential issues before engaging in high-speed or high-performance runs.

Ultimately, upgrading or replacing an ESC can significantly enhance the performance and enjoyment of your RC vehicle. By carefully considering motor compatibility, ESC specifications, size, programming, budget, and proper installation, you can select and install an ESC that aligns with your specific needs and takes your RC experience to new heights.

ESCs in Different Applications

Electronic Speed Controllers (ESCs) find applications in various remote-controlled vehicles and other electronic devices. They play a crucial role in powering, controlling, and regulating motor speed in these applications. Here are some areas where ESCs are commonly used:

1. RC Cars and Trucks

ESCs are integral components of RC cars and trucks, controlling the speed, acceleration, and braking. Whether it’s for racing or recreational purposes, ESCs allow precise control over the vehicle’s performance and responsiveness. They enable RC enthusiasts to experience the thrill of high-speed drives and navigate different terrains with ease.

2. Drones

Drones heavily rely on ESCs to control the motor speed of their propellers. ESCs play a vital role in maintaining stability, ensuring smooth flight, and maneuverability. The precise control offered by ESCs allows drones to perform aerial tricks, execute complex flight patterns, and respond quickly to pilot inputs.

3. Airplanes and Gliders

ESCs play a crucial role in powering the motors of RC airplanes and gliders, controlling their speed, thrust, and climb rate. They allow pilots to adjust the motor output to achieve the desired level of lift, speed, and maneuverability. ESCs are especially important in electric-powered aircraft, providing reliable and efficient power delivery.

4. Boats and Watercraft

ESCs find applications in RC boats and watercraft, controlling the speed and direction of the motors that power their propulsion systems. Whether it’s for racing, cruising, or navigating challenging waters, ESCs ensure smooth control and precise response on the water.

5. Robotics

In the field of robotics, ESCs are utilized to control the motors of robotic arms, legged robots, and other mobile robots. They enable precise control over the movements and speeds of the robot, facilitating tasks such as grasping objects, walking, or navigating complex environments. ESCs contribute to the overall efficiency and performance of robotic systems.

6. Electronic Toys

ESCs are commonly found in various electronic toys, such as remote-controlled cars, helicopters, and boats. They provide the power and control necessary for smooth and enjoyable playtime. ESCs in electronic toys offer simplified operation and safety features, catering to younger users and beginners in the RC hobby.

These are just a few examples of how ESCs are utilized in different applications. Their versatility, precise control, and ability to regulate motor speed make them an essential component in the world of remote-controlled vehicles, drones, robotics, and electronic toys.