What Is a BEC Electronic Speed Controller?

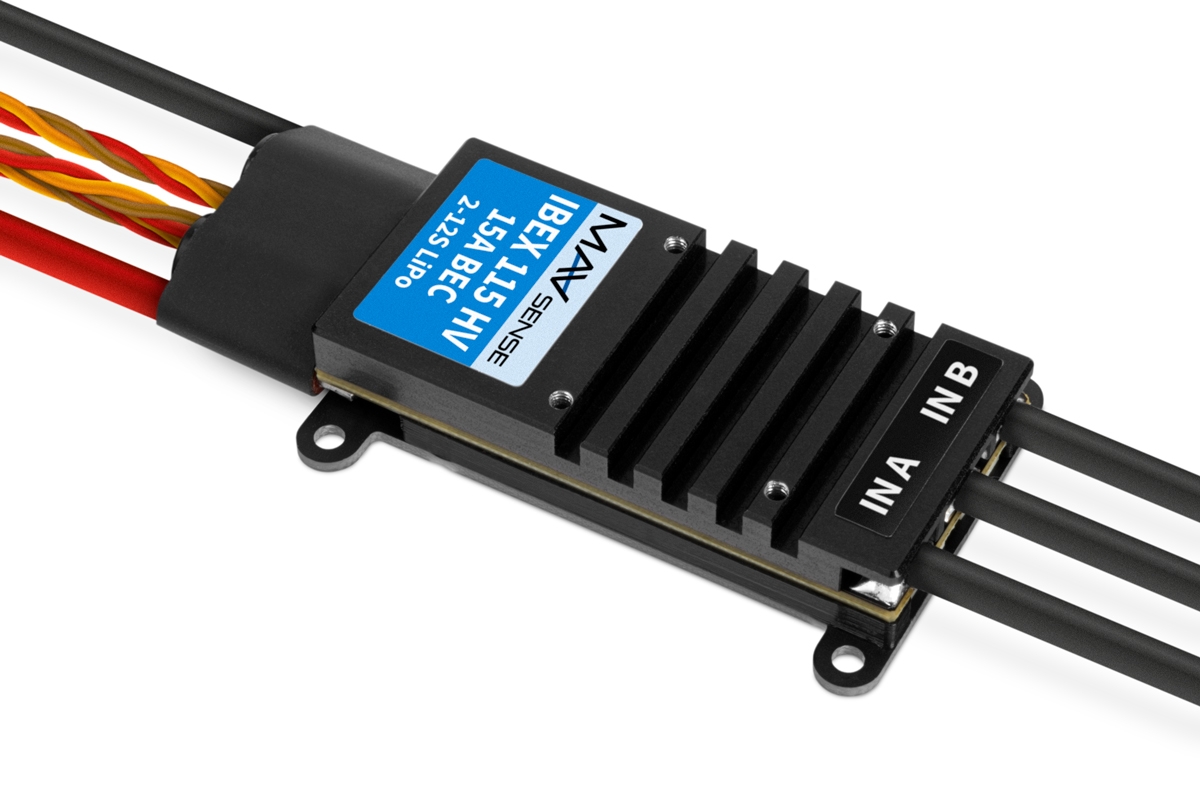

A BEC (Battery Eliminator Circuit) Electronic Speed Controller, commonly referred to as a BEC ESC, is a vital component in the world of remote-controlled vehicles. It plays a crucial role in managing the power supply to the receiver and other electronic devices in the vehicle. The BEC ESC is primarily used in radio-controlled cars, helicopters, drones, and boats to regulate motor speed and direction.

At its core, a BEC ESC is an electronic device that efficiently converts the main battery’s higher voltage into a stable and regulated voltage suitable for powering the receiver, servo, and other onboard electronics. This eliminates the need for a separate receiver battery and simplifies the overall power distribution system in the vehicle.

One of the key functions of a BEC ESC is to provide a constant and reliable power source to the receiver, ensuring uninterrupted control signals. It also powers the servos, which control various mechanical components, such as steering in cars or controlling the pitch angle in helicopters.

To achieve this, the BEC ESC takes the high voltage from the main battery (usually a LiPo or NiMH battery) and steps it down to a lower voltage (commonly 5V or 6V) through a voltage regulator. This regulated voltage is then sent to the receiver and other electronic devices via servo connectors.

Additionally, the BEC ESC is equipped with various safety features, such as low-voltage cutoff, thermal protection, and motor timing adjustment. These features help prevent damage to the battery, motors, and other components, ensuring the longevity and optimal performance of the vehicle.

Overall, the BEC ESC serves as a fundamental component in remote-controlled vehicles, ensuring reliable power distribution, precise control, and enhanced safety. Its integration eliminates the need for additional batteries, reduces complexity, and simplifies the overall electrical setup of the vehicle.

How Does a BEC Electronic Speed Controller Work?

Understanding how a BEC (Battery Eliminator Circuit) Electronic Speed Controller works is essential for anyone operating remote-controlled vehicles or devices. The BEC ESC plays a crucial role in managing power distribution and ensuring the smooth operation of motors, servos, and other electronic components.

At its core, a BEC ESC converts the higher voltage from the main battery into a stable and regulated voltage suitable for powering the receiver and other electronic devices. This process involves three main components: the input stage, the power stage, and the control circuit.

The input stage of the BEC ESC is responsible for managing the high-voltage input from the main battery. It typically includes capacitors, which help filter out noise and stabilize the voltage. The input stage also incorporates a voltage regulator, which steps down the voltage to a lower level.

Once the voltage is regulated, it enters the power stage of the BEC ESC. This stage consists of transistors or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), which control the flow of current to the motor. By adjusting the switching frequency of these transistors, the BEC ESC can control the motor’s speed and direction.

The control circuit is the brain of the BEC ESC, responsible for monitoring and managing the entire system. It receives input signals from the receiver and interprets them to adjust the motor speed and direction accordingly. The control circuit also monitors various parameters, such as battery voltage and temperature, to ensure safe operation.

In addition to regulating voltage and controlling motor speed, a BEC ESC often incorporates safety features to protect the battery and electronics. These features may include low-voltage cutoff, which prevents damaging the battery by shutting off power when voltage drops too low, and thermal protection, which safeguards against overheating.

Overall, the BEC ESC works by efficiently converting high-voltage input from the main battery into a stable and regulated voltage suitable for powering the receiver and other electronic devices. It combines input stage components, a power stage with transistors, and a control circuit to enable precise control of motor speed and direction, while also providing safety measures to protect the system components.

Different Types of BEC Electronic Speed Controllers

When it comes to the world of remote-controlled vehicles, there are different types of BEC (Battery Eliminator Circuit) Electronic Speed Controllers available to cater to specific needs and requirements. These different types offer varying features, voltage outputs, and capabilities, allowing users to choose the one that best suits their application.

1. Linear BEC ESC: This is the most common type of BEC ESC and offers a simple and straightforward design. It uses a linear voltage regulator to step down the higher input voltage to a lower, regulated output voltage. Linear BEC ESCs are known for their simplicity and cost-effectiveness but may not be suitable for high-powered applications due to their voltage drop and heat dissipation limitations.

2. Switching BEC ESC: Switching BEC ESCs, also known as Switch-Mode BEC ESCs, overcome the limitations of linear BECs by using a more efficient switching voltage regulator. This type of BEC ESC can handle higher currents and provide a more stable output voltage. Switching BEC ESCs are ideal for high-powered applications, such as large-scale electric cars or high-performance drones.

3. Opto-isolated BEC ESC: Opto-isolated BEC ESCs are designed to provide complete electrical isolation between the power stage and the control circuit. This isolation helps protect the control circuit from electrical noise generated by the motor, ensuring reliable and glitch-free operation. Opto-isolated BEC ESCs are commonly used in professional-grade applications, where noise interference can cause signal loss or system malfunction.

4. Adjustable BEC ESC: Some BEC ESCs offer adjustable output voltage, allowing users to select the desired voltage to power their receivers and servos. This feature is particularly useful when using different types of receivers or servos that have specific voltage requirements. Adjustable BEC ESCs provide flexibility in powering various electronic devices.

5. Dual BEC ESC: Dual BEC ESCs are equipped with two separate BEC circuits, each with its own voltage output. This configuration provides redundancy in power supply and can be useful in critical applications where uninterrupted operation is paramount. Dual BEC ESCs offer an extra layer of reliability and backup for the receiver and other onboard electronics.

Each type of BEC ESC has its own strengths and is suitable for specific applications. It is important to consider factors such as power requirements, voltage needs, and system compatibility when choosing the right BEC ESC for your remote-controlled vehicle or device.

Advantages of Using a BEC Electronic Speed Controller

Using a BEC (Battery Eliminator Circuit) Electronic Speed Controller in your remote-controlled vehicle or device offers numerous advantages that contribute to better performance, increased convenience, and improved safety. Here are some key benefits of utilizing a BEC ESC:

1. Simplified Power System: One of the primary advantages of using a BEC ESC is that it eliminates the need for a separate receiver battery. Traditionally, a receiver battery was required to power the receiver and servos, adding complexity and additional weight to the vehicle. By integrating a BEC ESC, the power can be drawn directly from the main battery, streamlining the power system and reducing the number of batteries that need to be managed.

2. Efficient Voltage Regulation: A BEC ESC ensures a stable and regulated voltage supply to the receiver and other electronic devices. It converts the higher voltage from the main battery into a lower, consistent voltage suitable for powering the receiver and servos. This regulated voltage supply prevents voltage fluctuations and improves the reliability and performance of the vehicle’s electronics.

3. Improved Control Responsiveness: With a BEC ESC, the receiver and servos receive a constant and uninterrupted power supply, ensuring precise control responsiveness. This is crucial for smooth and accurate operation, especially in high-performance applications such as racing drones or competition-level RC cars.

4. Reduced Weight and Size: By eliminating the need for a separate receiver battery, a BEC ESC helps reduce the overall weight and size of the vehicle or device. This weight reduction can have a significant impact on performance, agility, and maneuverability, especially in applications where weight plays a crucial role, such as in aerobatic helicopters or lightweight drones.

5. Enhanced Safety Features: Many BEC ESCs come equipped with built-in safety features, such as low-voltage cutoff and thermal protection. The low-voltage cutoff prevents over-discharging the main battery and protects against potential damage. The thermal protection feature monitors the temperature and shuts down the ESC if it reaches unsafe levels, preventing overheating and potential hazards.

Overall, using a BEC ESC offers a range of advantages, including simplified power systems, efficient voltage regulation, improved control responsiveness, reduced weight and size, and enhanced safety features. These benefits make a BEC ESC an essential component in the world of remote-controlled vehicles and contribute to a better user experience and optimal performance.

Common Applications of BEC Electronic Speed Controllers

BEC (Battery Eliminator Circuit) Electronic Speed Controllers are widely utilized in various remote-controlled vehicles and devices. These versatile components offer reliable power distribution, precise control, and enhanced safety. Here are some common applications where BEC ESCs are frequently used:

1. Remote-Controlled Cars: BEC ESCs are extensively employed in hobby-grade remote-controlled cars. They provide power to the receiver and servos, enabling precise control of steering and throttle. Whether it’s for racing or recreational purposes, BEC ESCs play a vital role in optimizing the performance and responsiveness of these vehicles.

2. Helicopters and Drones: In the world of radio-controlled helicopters and drones, BEC ESCs are essential for managing the power supply to the flight control system, servos, and other electronic components. BEC ESCs boost control accuracy and stability, ensuring smooth flight maneuvers and fast response times. They are crucial for acrobatic flying, aerial photography, and racing applications.

3. Boats: Many remote-controlled boats rely on BEC ESCs to control the propulsion system and other onboard electronics. BEC ESCs provide precise control over motor speed and direction, allowing boaters to navigate in various water conditions. From leisure boating to competitive racing, BEC ESCs play a significant role in enhancing the boating experience.

4. Aircraft: BEC ESCs are widely used in radio-controlled airplanes to power the receiver, servos, and other electronic devices. These ESCs ensure optimal control and responsiveness for ailerons, elevators, rudders, and throttle, contributing to safe and enjoyable flying experiences.

5. Robotics: BEC ESCs are also employed in robotics projects and applications. They provide a regulated power source to motor controllers, servos, and other control systems, enabling precise and coordinated movements. BEC ESCs play a crucial role in various robotic projects, from complex automated systems to educational robotics kits.

6. DIY Electronics: BEC ESCs find applications beyond the realm of remote-controlled vehicles. Hobbyists and electronics enthusiasts often utilize BEC ESCs in DIY electronic projects, such as motorized mechanisms, automated systems, and robotics prototypes. Their compact size, efficiency, and voltage regulation capabilities make them versatile and adaptable for various creative endeavors.

These are just a few examples of the common applications where BEC ESCs are widely used. The reliability, stability, and control enhancement offered by BEC ESCs make them indispensable for a diverse range of remote-controlled vehicles, aerial systems, watercraft, robotics, and DIY electronics projects.

Troubleshooting and Maintenance Tips for BEC Electronic Speed Controllers

While BEC (Battery Eliminator Circuit) Electronic Speed Controllers are designed to be reliable and perform optimally, occasional issues or maintenance needs may arise. Here are some troubleshooting and maintenance tips to ensure the smooth operation of your BEC ESC:

1. Check Wiring Connections: If you experience any issues with your BEC ESC, start by checking the wiring connections. Ensure that all connections are secure and properly plugged in. Loose or damaged connections can cause power loss or intermittent operation. If necessary, re-solder or replace any faulty connectors.

2. Inspect Power Source: Check the power source, which is typically the main battery. Ensure that the battery is fully charged and in good condition. Low battery voltage can lead to a drop in power and performance. If you suspect a faulty battery, replace it with a fully charged one that meets the recommended specifications for your BEC ESC.

3. Calibrate the ESC: Proper ESC calibration is essential for accurate and responsive control. Follow the manufacturer’s instructions to calibrate the ESC with your transmitter and receiver system. This ensures that the ESC interprets the control inputs correctly and that the throttle range is properly configured.

4. Keep ESC Cool: Overheating can affect the performance and longevity of your BEC ESC. Ensure that the ESC is adequately cooled during operation. Install a heat sink or fan if necessary, and avoid enclosing the ESC in tight spaces with limited ventilation. Proper heat dissipation helps prevent thermal shutdown and ensures stable operation.

5. Monitor Motor Timing: Adjusting the motor timing can optimize the performance of your BEC ESC. Experiment with different timing settings to find the best balance between power, efficiency, and motor response. Keep in mind that higher timing settings may generate more heat, so monitor temperature and adjust accordingly.

6. Follow ESC Protection Features: BEC ESCs often incorporate safety features like low-voltage cutoff and thermal protection. Familiarize yourself with these features and set them up correctly. The low-voltage cutoff prevents over-discharging the battery, while thermal protection safeguards against overheating. Enable and customize these features to protect your components and ensure safe operation.

7. Regularly Inspect and Clean: Periodically inspect your BEC ESC for any signs of dirt, debris, or moisture buildup. Clean the ESC using compressed air or a soft brush, taking care not to damage any components. Moisture or foreign objects can cause electrical shorts or signal interference.

By following these troubleshooting and maintenance tips, you can address common issues and ensure the longevity and optimal performance of your BEC ESC. Regular inspections, proper adjustments, and attention to power sources and connections will help keep your remote-controlled vehicle or device running smoothly.

Choosing the Right BEC Electronic Speed Controller for Your Needs

When selecting a BEC (Battery Eliminator Circuit) Electronic Speed Controller for your remote-controlled vehicle or device, it’s crucial to consider several factors to ensure optimal performance and compatibility. Here are some key considerations when choosing the right BEC ESC:

1. Voltage Output: Determine the voltage requirements of your receiver and servos. Most BEC ESCs offer a fixed output voltage of either 5V or 6V, which is suitable for the majority of applications. Make sure the BEC ESC you choose provides the appropriate voltage to power your electronic components.

2. Current Capacity: Consider the current requirements of your system, including the receiver, servos, and any additional electronics. Ensure that the BEC ESC can handle the total current draw. It’s better to choose a BEC ESC with a higher current capacity to have a safety margin and prevent overloading.

3. Size and Mounting: Consider the physical size and mounting options of the BEC ESC. Ensure that it can fit securely within your vehicle or device without interfering with other components. Pay attention to the weight as well, especially in weight-sensitive applications such as drones or lightweight vehicles.

4. Compatibility: Ensure that the BEC ESC is compatible with your radio system and receiver. Check for compatibility with the specific brand and model of your transmitter and receiver. Some ESCs may have a proprietary communication protocol or require additional hardware for compatibility.

5. Application-Specific Features: Consider any specific features or requirements for your application. For example, if you’re using your vehicle for competitive racing, look for a BEC ESC with advanced programming options for fine-tuning motor performance. If you’re using it for aerial photography, consider an ESC with excellent throttle response and smooth acceleration.

6. Brand Reputation and Reviews: Research and read reviews about the brand and model of the BEC ESC you’re considering. Look for reliable and reputable brands known for producing high-quality ESCs. Reviews can provide valuable insights into performance, reliability, and customer satisfaction.

7. Budget: Determine your budget for a BEC ESC and consider the options available within that range. While it’s important to invest in a quality ESC, there are often options available at different price points that offer suitable performance for your needs.

By considering these factors and evaluating your specific requirements, you can choose the right BEC ESC that meets your performance needs, fits your vehicle or device, and ensures compatibility with your radio system. Investing time in research and consideration will help you make an informed decision and enjoy optimal performance from your remote-controlled vehicle or device.

Frequently Asked Questions about BEC Electronic Speed Controllers

Here are some common questions and answers regarding BEC (Battery Eliminator Circuit) Electronic Speed Controllers:

Q: What is the purpose of a BEC ESC?

A: The primary purpose of a BEC ESC is to regulate the voltage from the main battery and provide a stable power supply for the receiver and other electronic devices in remote-controlled vehicles or devices.

Q: Do all ESCs have a BEC?

A: No, not all ESCs have a BEC. Some ESCs are designed to be used with an external receiver battery or utilize alternate power sources for the receiver and servos.

Q: Can I use a BEC ESC with a separate receiver battery?

A: It is generally not recommended to use a BEC ESC with a separate receiver battery. The BEC ESC is designed to eliminate the need for a separate battery and simplify the power distribution system in the vehicle.

Q: Can I adjust the output voltage of a BEC ESC?

A: Some BEC ESCs offer adjustable output voltage options, allowing users to match the voltage requirements of their specific receivers and servos. However, it is important to ensure that the adjusted voltage remains within the acceptable range for the electronic components being powered.

Q: Can I use a BEC ESC in high-powered applications?

A: Depending on the specific BEC ESC, it may or may not be suitable for high-powered applications. Switching BEC ESCs are often recommended for high-powered applications as they can handle higher currents and offer more efficient voltage regulation.

Q: How do I calibrate a BEC ESC?

A: Calibration processes may vary depending on the specific ESC model. It typically involves following the manufacturer’s instructions to throttle up and down the motor, which allows the ESC to recognize the full range of throttle inputs and adjust the corresponding output accordingly.

Q: What safety features are included in a BEC ESC?

A: Common safety features in BEC ESCs include low-voltage cutoff, which prevents over-discharging the battery, and thermal protection, which shuts down the ESC if it reaches a certain temperature threshold. These features help protect the battery, ESC, and other components from damage.

Q: How do I maintain a BEC ESC?

A: To maintain a BEC ESC, periodically inspect the wiring connections for any loose or damaged connections. Keep the ESC clean and free from debris or moisture. Follow the manufacturer’s guidelines for any recommended maintenance procedures. Regularly monitor the motor temperature and voltage to ensure optimal performance.

Q: Can I use a BEC ESC in non-RC applications?

A: Yes, BEC ESCs can be used in non-RC applications, such as DIY electronics projects or robotics. They provide a convenient and regulated power source for various electronic devices that require a stable voltage supply.

These are some frequently asked questions about BEC Electronic Speed Controllers. If you have any specific concerns or queries, it is recommended to consult the manufacturer’s documentation or seek guidance from knowledgeable enthusiasts or professionals in the field.