Overview of Electronic Suspension Systems

Electronic suspension systems have revolutionized the way vehicles handle and provide a comfortable ride. These systems use advanced technologies and components to automatically adjust the suspension settings based on various factors such as road conditions, vehicle speed, and driving style. By doing so, they improve stability, enhance handling, and increase overall comfort for the driver and passengers.

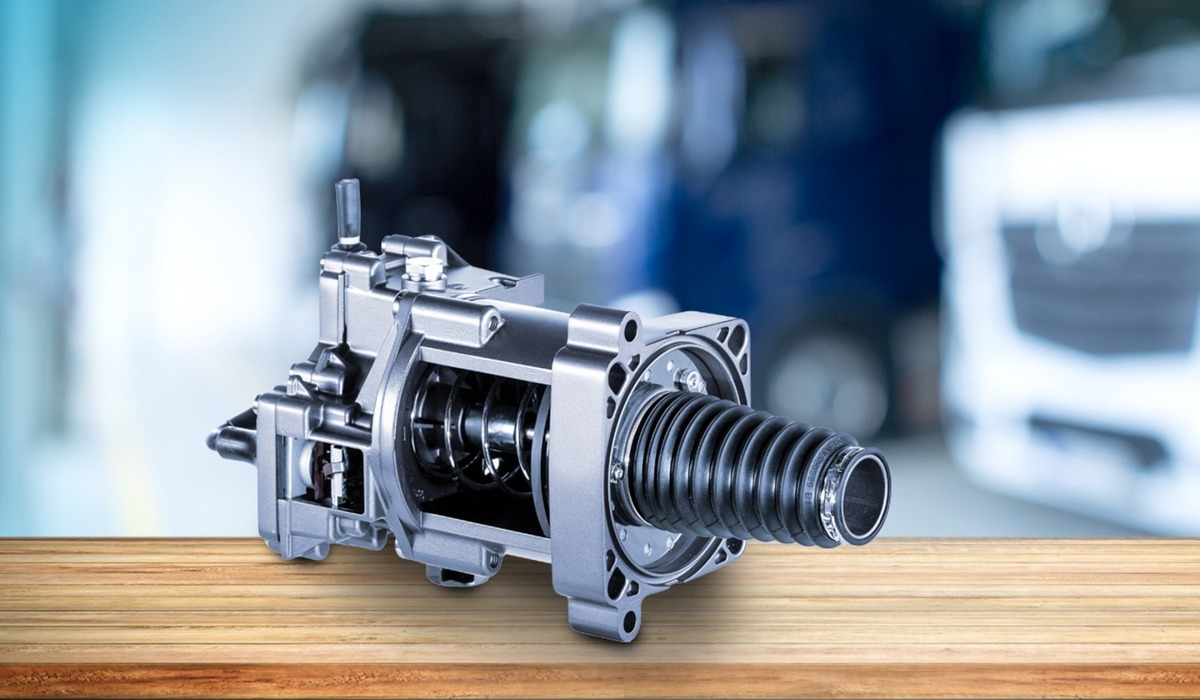

One of the key components of electronic suspension systems is the actuator, which plays a crucial role in controlling the movement and behavior of the suspension. The actuator is responsible for adjusting the damping rates, ride height, and stiffness of the suspension system, allowing it to adapt to different driving conditions and optimize performance.

Electronic suspension systems utilize different types of actuators, including electromagnetic, hydraulic, pneumatic, and electric motor actuators. Each type has its own strengths and weaknesses, and the choice of actuator depends on various factors such as cost, performance requirements, and system complexity.

These systems typically incorporate sensors that monitor inputs such as wheel speed, vehicle body position, acceleration, and steering angle. The sensor data is continuously fed to an electronic control unit (ECU), which analyzes and processes the information to determine the appropriate suspension adjustments. The ECU then sends signals to the actuators, commanding them to make the necessary changes to the suspension settings in real time.

The benefits of electronic suspension systems are numerous. Firstly, they improve vehicle stability and handling by automatically adjusting the suspension settings to compensate for body roll, pitch, and yaw. This enhances cornering grip, reduces body sway, and provides a more controlled and responsive driving experience.

Secondly, electronic suspension systems enhance the comfort of the vehicle occupants by actively adapting to road conditions. They can soften the suspension on rough surfaces to absorb bumps and vibrations, and stiffen it on smooth roads for better control and stability.

Furthermore, these systems can help optimize fuel efficiency by reducing aerodynamic drag and minimizing energy losses due to excessive suspension movements. By dynamically adjusting the ride height based on driving conditions, they can improve the vehicle’s overall aerodynamics and reduce fuel consumption.

Importance of Actuators in Electronic Suspension Systems

The actuator is a critical component in electronic suspension systems as it enables the system to dynamically adjust and control the suspension settings. Without actuators, the electronic suspension system would not be able to adapt to changing road conditions and provide the desired level of comfort and performance.

One of the key importance of actuators is their ability to adjust the damping rates of the suspension system. Damping is responsible for controlling the movement of the suspension components, such as the shock absorbers, and provides the necessary level of support and cushioning. By adjusting the damping rates, the actuator helps optimize the suspension’s response to different road conditions, improving both the handling and comfort of the vehicle.

Actuators also play a crucial role in controlling the ride height of the vehicle. Electronic suspension systems can automatically lower the vehicle’s ride height at higher speeds to reduce drag and improve aerodynamics, resulting in better fuel efficiency. Conversely, the ride height can be increased to provide better ground clearance in off-road situations. The actuator is responsible for making these adjustments, ensuring that the vehicle maintains the desired ride height at all times.

Another important function of actuators is the ability to control the stiffness of the suspension system. By adjusting the stiffness, the actuator can provide a softer or firmer ride depending on the driving conditions and preferences of the driver. This can greatly enhance comfort during long highway drives or provide a more sporty and responsive feel during aggressive cornering.

Actuators also contribute to the overall safety of the vehicle. By continuously monitoring and adjusting the suspension settings, they help maintain optimal tire contact with the road surface, improving traction and stability. This can greatly enhance the vehicle’s ability to corner, brake, and maneuver safely, especially in challenging driving conditions.

Basic Principles of Actuators in Electronic Suspension Systems

Actuators in electronic suspension systems work based on the fundamental principles of electromagnetism, hydraulics, pneumatics, or electric motors. These principles drive the movement and adjustability of the suspension system for optimal performance and comfort.

Electromagnetic actuators utilize the principles of electromagnetism to control the suspension settings. They consist of a coil and a magnetic core, which create a magnetic field when an electrical current passes through the coil. By varying the strength of the current, the magnetic field can be adjusted, resulting in changes in damping rates, ride height, or stiffness of the suspension system.

Hydraulic actuators operate on the principle of fluid pressure to control the suspension settings. They utilize a piston and cylinder arrangement in which a hydraulic fluid, usually oil, is compressed or released to adjust the suspension characteristics. By controlling the flow of hydraulic fluid, the actuator can regulate the damping rates, ride height, and stiffness of the suspension system.

Pneumatic actuators operate similarly to hydraulic actuators but use compressed air instead of hydraulic fluid. Compressed air is fed into a chamber with a piston, and by adjusting the air pressure, the actuator can vary the damping rates, ride height, and stiffness of the suspension system. Pneumatic actuators are commonly used in air suspension systems.

Electric motor actuators utilize the rotational motion of an electric motor to adjust the suspension settings. These actuators consist of a motor that drives a mechanism to change the damping rates, ride height, or stiffness of the suspension system. By controlling the speed and direction of the motor, the actuator can modify the suspension settings in real time.

Regardless of the type of actuator, all electronic suspension systems utilize sensors to provide input signals to the control unit. These sensors measure various parameters such as wheel speed, acceleration, steering angle, and vehicle position to determine the appropriate adjustments needed for the suspension system.

The control unit processes these signals and sends commands to the actuators to make the necessary changes to the suspension settings. This continuous monitoring and adjustment process ensures that the suspension system adapts to changing road conditions, providing optimal performance, and comfort.

By understanding the basic principles of actuators in electronic suspension systems, engineers and designers can develop innovative solutions that enhance the performance, safety, and comfort of vehicles.

Electromagnetic Actuators

Electromagnetic actuators are a commonly used type of actuator in electronic suspension systems. These actuators utilize the principles of electromagnetism to control and adjust the suspension settings, providing a dynamic and responsive ride.

Electromagnetic actuators consist of a coil and a magnetic core. When an electrical current passes through the coil, a magnetic field is created, and the magnetic core is either attracted or repelled depending on the polarity of the current. This movement of the core is used to adjust the suspension characteristics.

One of the key advantages of electromagnetic actuators is their ability to provide precise and rapid adjustments to the suspension settings. By varying the strength and polarity of the electrical current, the magnetic field can be controlled with great accuracy. This allows for fine-tuning of damping rates, ride height, and stiffness to optimize the performance and comfort of the vehicle.

Electromagnetic actuators also offer a high degree of flexibility. They can be easily programmed and adjusted, allowing for customization of the suspension settings to suit different driving styles and preferences. This flexibility enables the system to adapt to various road conditions, providing a smooth and controlled ride.

In addition, electromagnetic actuators are known for their reliability and durability. They have a long lifespan and can withstand harsh operating conditions. This makes them ideal for use in automotive applications where reliability is crucial.

However, electromagnetic actuators do have some limitations. They require a power source to operate, usually from the vehicle’s electrical system. This means that if there is a power failure, the actuator may not function properly, resulting in a loss of suspension control. Additionally, electromagnetic actuators can generate heat during operation, which may require a cooling mechanism to maintain optimal performance.

Hydraulic Actuators

Hydraulic actuators are widely used in electronic suspension systems to control and modify the suspension settings. These actuators utilize the principles of fluid pressure to adjust the damping rates, ride height, and stiffness of the suspension system.

Hydraulic actuators consist of a piston and cylinder arrangement filled with hydraulic fluid, usually oil. When the suspension system needs to be adjusted, the actuator modulates the flow of hydraulic fluid into or out of the cylinder, thereby controlling the pressure and position of the piston. This movement of the piston allows for changes in the suspension characteristics.

One of the key advantages of hydraulic actuators is their ability to provide precise and responsive adjustments to the suspension settings. By controlling the flow of hydraulic fluid, the actuator can quickly and accurately modify the damping rates to match the driving conditions. This improves the vehicle’s handling, comfort, and stability.

Hydraulic actuators also offer a wide range of adjustability. The design of the actuator allows for variations in the size of the piston, cylinder, and valve openings, which can alter the stiffness of the suspension system. This adjustability allows for customization of the suspension settings to meet the specific requirements of the vehicle and the driver.

Another advantage of hydraulic actuators is their ability to handle large loads and provide a smooth and consistent ride. The hydraulic fluid acts as a medium that distributes the forces evenly, reducing the impact of bumps and vibrations on the vehicle. This results in a comfortable and controlled ride experience for the passengers.

However, hydraulic actuators also have some limitations. They require regular maintenance and monitoring to ensure proper functioning of the hydraulic system, including checking for leaks, maintaining the fluid levels, and replacing worn-out components. Additionally, hydraulic actuators can be more complex and expensive compared to other types of actuators, adding to the overall cost of the suspension system.

Despite these limitations, hydraulic actuators remain a popular choice in electronic suspension systems due to their ability to provide precise adjustments and deliver a comfortable and responsive ride.

Pneumatic Actuators

Pneumatic actuators are commonly used in electronic suspension systems to control and adjust the suspension settings. These actuators utilize compressed air as the driving mechanism to provide dynamic changes to the damping rates, ride height, and stiffness of the suspension system.

Pneumatic actuators consist of a chamber that contains compressed air and a piston that moves within the chamber. By regulating the air pressure in the chamber, the actuator can control the movement of the piston, thereby adjusting the suspension characteristics. The air pressure is typically controlled by a valve system that allows for precise modulation of the air flow.

One of the key advantages of pneumatic actuators is their ability to provide rapid and responsive adjustments to the suspension settings. The compressed air allows for quick changes in the volume and pressure within the actuator, resulting in immediate adjustments to the suspension. This responsiveness enhances the vehicle’s handling and stability, especially during sudden changes in road conditions.

Pneumatic actuators also offer a high degree of adjustability. By controlling the air pressure, the actuator can effectively change the stiffness of the suspension system. This allows for customization of the ride characteristics to suit the preferences of the driver and the driving conditions. Additionally, pneumatic actuators can be easily integrated with air springs in air suspension systems, further enhancing the comfort and adjustability.

Another advantage of pneumatic actuators is their ability to provide a smoother and more comfortable ride. The air cushioning effect reduces the impact of bumps and vibrations, resulting in a more controlled and enjoyable driving experience. Furthermore, pneumatic actuators can help improve the vehicle’s traction by allowing for precise adjustments to the ride height, optimizing the tire contact with the road surface.

However, pneumatic actuators also have some limitations. They require a reliable and efficient air supply system to operate, which can add complexity and potential maintenance challenges to the overall suspension system. Additionally, they may be more susceptible to air leaks compared to other types of actuators, potentially affecting their performance and reliability.

Despite these limitations, pneumatic actuators remain a popular choice in electronic suspension systems due to their rapid responsiveness, adjustability, and ability to provide a comfortable and controlled ride.

Electric Motor Actuators

Electric motor actuators are a commonly used type of actuator in electronic suspension systems. They utilize the rotational motion of an electric motor to control and adjust the suspension settings, providing precise and customizable ride characteristics.

Electric motor actuators consist of an electric motor that is connected to a mechanism responsible for adjusting the suspension settings. When prompted by the control system, the electric motor rotates and moves the mechanism, which in turn changes the damping rates, ride height, or stiffness of the suspension system.

One of the key advantages of electric motor actuators is their ability to provide accurate and fine-grained adjustments to the suspension settings. The electric motor can be controlled with high precision, allowing for minute changes in the suspension characteristics. This level of control enables the system to adapt rapidly to different driving conditions, providing optimal performance and comfort.

Electric motor actuators also offer a high degree of flexibility and customizability. The control system can program and adjust the motor’s rotational speed, direction, and torque, allowing for tailored suspension responses to various driving situations. This flexibility allows the driver to switch between different suspension modes, such as comfort or sport, to suit their preferences or road conditions.

Another advantage of electric motor actuators is their quiet and efficient operation. The absence of hydraulic or pneumatic systems reduces noise levels, providing a smoother and more serene ride experience for the passengers. Additionally, electric motor actuators can be more energy-efficient compared to other types of actuators, contributing to overall fuel efficiency and reduced environmental impact.

However, electric motor actuators also have some limitations. They require a reliable power supply to operate, which is typically provided by the vehicle’s electrical system. A power failure or electrical malfunction can potentially disrupt the actuator’s functionality. Additionally, electric motor actuators may have higher initial costs compared to other types of actuators, although advancements in technology are gradually reducing this cost disparity.

Despite these limitations, electric motor actuators are widely chosen in electronic suspension systems due to their precise control, customizability, quiet operation, and energy efficiency. They offer a refined and comfortable ride experience, enhancing both the performance and enjoyment of the vehicle.

Comparison of Different Actuator Types

There are various types of actuators used in electronic suspension systems, each with its own strengths and limitations. Understanding the differences between these actuators can help determine the most suitable choice for a specific application.

Electromagnetic actuators provide precise and rapid adjustments to the suspension settings. They offer high flexibility and reliability while allowing for fine-tuning of damping rates, ride height, and stiffness. However, they require a power source and may generate heat during operation.

Hydraulic actuators deliver smooth and consistent ride characteristics. They can handle large loads and offer a wide range of adjustability. However, they require regular maintenance, can be more complex and expensive, and rely on hydraulic fluid for operation.

Pneumatic actuators provide rapid responsiveness and a comfortable ride experience. They offer adjustability and can integrate with air springs in air suspension systems. However, they require a reliable air supply system and may be susceptible to air leaks.

Electric motor actuators offer accurate and customizable adjustments to the suspension settings. They provide quiet and efficient operation while allowing for tailored suspension responses. However, they require a reliable power supply and may have higher initial costs.

When comparing these actuator types, factors such as performance requirements, system complexity, cost considerations, and desired ride characteristics should be taken into account. Electromagnetic and electric motor actuators are often preferred for their precise control and customizability, while hydraulic and pneumatic actuators are commonly chosen for their reliability and smooth ride experience.

It is important to consider the specific needs of the vehicle and the preferences of the driver when selecting the appropriate actuator type. A balance between performance, comfort, reliability, and cost should be achieved to ensure optimal functioning of the electronic suspension system.

Ultimately, the choice of actuator type depends on the desired trade-offs and the specific requirements of the application. Ongoing advancements in actuator technology continue to expand the possibilities and improve the overall performance of electronic suspension systems.

Advantages and Disadvantages of Each Actuator Type

Each type of actuator used in electronic suspension systems offers distinct advantages and disadvantages. Understanding these factors can help in selecting the most suitable actuator for a particular application.

Electromagnetic Actuators:

- Advantages:

- Precise and rapid adjustments to suspension settings

- High level of flexibility and customizability

- Reliable and durable

- Disadvantages:

- Requires a power source for operation

- Potential heat generation during operation

Hydraulic Actuators:

- Advantages:

- Smooth and consistent ride characteristics

- Handling of large loads

- Customizable adjustability

- Disadvantages:

- Requires regular maintenance

- Complex and potentially more expensive

- Relies on hydraulic fluid for operation

Pneumatic Actuators:

- Advantages:

- Rapid responsiveness

- Comfortable ride experience

- Integration with air springs in air suspension systems

- Disadvantages:

- Requires a reliable air supply system

- Potential susceptibility to air leaks

Electric Motor Actuators:

- Advantages:

- Accurate and customizable adjustments

- Quiet and efficient operation

- Flexibility and tailored suspension responses

- Disadvantages:

- Requires a reliable power supply

- Potential higher initial costs

When considering the advantages and disadvantages of each actuator type, factors such as performance requirements, system complexity, cost considerations, and desired ride characteristics should be taken into account. Electric motor and electromagnetic actuators offer precise control and customizability, while hydraulic and pneumatic actuators provide reliability and smooth ride experiences.

Choosing the most suitable actuator type depends on striking a balance between performance, comfort, reliability, and cost to ensure optimal functioning of the electronic suspension system. Ongoing advancements in actuator technology continue to expand possibilities and improve the overall performance of electronic suspension systems.

Considerations for Selecting Actuators in Electronic Suspension Systems

When selecting actuators for electronic suspension systems, several important considerations must be taken into account to ensure optimal performance and functionality. These considerations include:

Performance Requirements:

The specific performance requirements of the vehicle play a crucial role in determining the appropriate actuator type. Factors such as desired handling, ride comfort, and responsiveness should be carefully evaluated to choose an actuator that can meet these requirements effectively.

System Complexity:

The complexity of the electronic suspension system should be considered when selecting actuators. Some actuator types may require additional components or complex control systems, adding complexity and potential maintenance challenges. The overall system complexity should be balanced with performance requirements and cost considerations.

Cost Considerations:

The cost of the actuators, including installation and maintenance costs, is an important consideration. Some actuator types may have higher initial costs or require more extensive maintenance, which should be weighed against the benefits they offer. It is essential to find a balance between cost-effectiveness and desired performance.

System Integration:

The compatibility of the actuator with other components of the electronic suspension system is crucial. Proper integration and communication between the actuator, control unit, sensors, and other system components are essential for smooth and reliable operation. Compatibility and ease of integration should be carefully evaluated during the selection process.

Reliability and Durability:

The reliability and durability of the actuators are critical considerations for ensuring the long-term performance of the electronic suspension system. Actuators that can withstand harsh operating conditions, resist wear and tear, and require minimal maintenance are preferred for enhanced reliability and overall system longevity.

Future Scalability:

Considering future scalability and upgradability is important when selecting actuators. The chosen actuator type should allow for potential system expansions or upgrades, allowing for the integration of new technologies or functionalities as needed. This ensures that the electronic suspension system remains adaptable to future advancements.

By carefully considering these factors, automotive engineers and designers can select the most appropriate actuator type that meets the specific requirements of the electronic suspension system. Striking the right balance between performance, system complexity, cost, integration, reliability, and future scalability is crucial to achieving a well-functioning and efficient suspension system.

Future Trends in Actuator Technology for Electronic Suspension Systems

The field of actuator technology for electronic suspension systems is continuously evolving, driven by advancements in material science, control systems, and electric powertrain technology. Several future trends are emerging, paving the way for enhanced performance and functionality in electronic suspension systems.

Electromagnetic Actuators:

Electromagnetic actuators are expected to undergo further refinement and improvement. Future advancements may focus on reducing heat generation, enhancing efficiency, and miniaturizing the size of electromagnetic actuators. This could lead to more compact and lightweight suspension systems without compromising their functionality or performance.

Smart Materials:

Developments in smart materials, such as magnetorheological fluids and piezoelectric materials, hold promise for future actuator technology. These materials can change their viscosity or shape in response to an external stimulus, allowing for adaptive and adjustable suspension characteristics. Smart materials could enhance the responsiveness and adaptability of actuators, providing even greater control over the suspension system.

Active Vibration Control:

Active vibration control is an emerging trend that aims to improve ride comfort further. Actuators could be combined with advanced control algorithms and sensors to actively cancel out vibrations and noise from the road surface. This technology could significantly reduce the transfer of road-induced vibrations to the cabin, resulting in a smoother and more refined ride experience.

Integrated Sensor Systems:

The integration of sensor systems directly into the actuators is another future trend in actuator technology. By incorporating sensors within the actuator assembly, real-time feedback on suspension behavior can be obtained, enabling even more precise and responsive adjustments. This integration could lead to enhanced suspension control and improved overall system performance.

Digital Control Systems:

Digital control systems are expected to play a significant role in future actuator technology. Advanced control algorithms, artificial intelligence, and machine learning techniques could be used to optimize suspension performance based on various parameters such as road conditions, driver preferences, and vehicle dynamics. This could result in highly adaptive and intelligent suspension systems that can continuously learn and improve their response.

Electrification and Hybridization:

The ongoing trend towards vehicle electrification and hybridization is expected to impact actuator technology in electronic suspension systems. With the increasing use of electric powertrains, actuators could be designed to leverage the electrical system of the vehicle, leading to improved integration, efficiency, and performance of the suspension system.

These future trends in actuator technology for electronic suspension systems hold great potential for enhancing ride comfort, handling, and overall driving experience. As advancements continue, actuator technology will play a pivotal role in the evolution of electronic suspension systems, paving the way for more intelligent, efficient, and adaptable vehicle suspensions in the future.