How Does a Switch Work?

A switch is a fundamental component in electronics that allows for the control of electrical circuits. It acts as a gateway, enabling or disabling the flow of electricity through a circuit. Understanding how a switch works is essential for any electronics enthusiast or professional.

At its core, a switch operates on the principle of interrupting or closing a circuit. When the switch is closed or turned on, it completes the circuit, allowing the flow of electric current. Conversely, when the switch is open or turned off, it breaks the circuit, preventing the flow of current.

In simplest terms, a switch consists of two main components – contacts and an actuator. The contacts, usually made of conductive material such as metal, are responsible for initiating or terminating the flow of electricity. The actuator, which can take various forms such as a button or a lever, controls the position of the contacts.

When the actuator is pressed or toggled, it physically moves the contacts into either contact or non-contact positions. In the contact position, the contacts touch or connect, allowing the current to flow smoothly through the circuit. In the non-contact position, the contacts are separated, breaking the circuit and stopping the current from passing through.

The connection or separation of the contacts is achieved through various mechanisms based on the type of switch. Mechanical switches, for example, utilize physical movement to control the contacts. Electrical switches, on the other hand, make use of electronic components such as transistors to manage the current flow.

In either case, the mechanism of a switch ultimately determines its functionality. Some switches have momentary actions, meaning they are only active when the actuator is pressed or held down. Others have maintained actions, where the switch remains in its toggled position until manually changed.

Overall, understanding how a switch works is crucial for designing and integrating switches into electronic circuits effectively. By grasping the principles behind switches, you can confidently choose the right type of switch for your application and ensure the smooth and controlled operation of your electrical systems.

Types of Switches

Switches come in various types, each designed for specific applications and operating mechanisms. Understanding the different types of switches can help you determine the most suitable one for your needs. Here are some common types of switches found in electronics:

1. Mechanical Switches: These switches use physical movement to control the contacts. They are reliable and commonly found in devices such as keyboards, mice, and remote controls.

2. Push Button Switches: Featuring a button or plunger for actuation, push button switches are often used for momentary actions, such as turning on a flashlight or operating a doorbell.

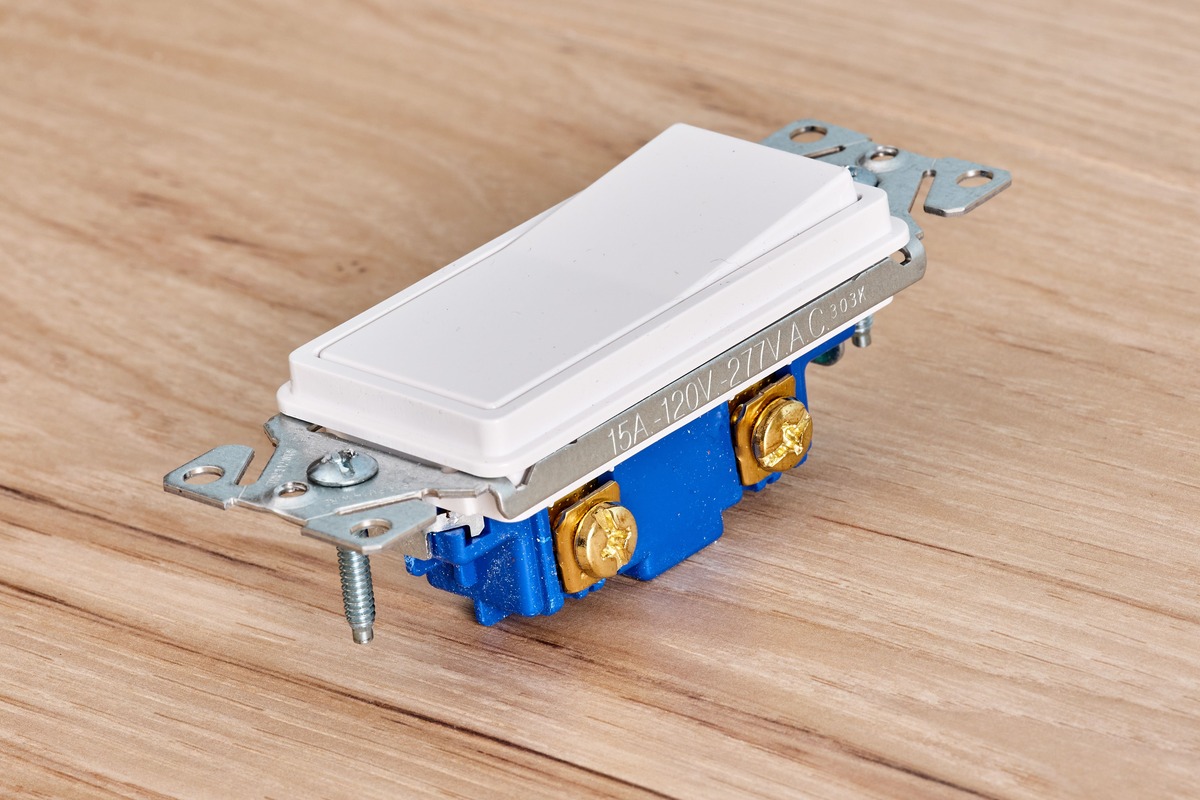

3. Toggle Switches: These switches have a lever or a rocker mechanism that can be flipped up or down to activate or deactivate the circuit. Toggle switches are commonly used in lamps, fans, and home appliances.

4. Rotary Switches: As the name suggests, rotary switches have a rotating mechanism that allows the selection of different positions. They are commonly used in audio equipment to control volume or switch between different audio sources.

5. Slide Switches: Slide switches have a sliding actuator that moves horizontally to open or close the circuit. They are frequently found in portable electronics, such as smartphones and MP3 players, to control power or audio settings.

6. Rocker Switches: Similar to toggle switches, rocker switches have a rocker-shaped actuator that can be rocked back and forth to operate the circuit. They are often used in household appliances and automotive applications.

7. Specialty Switches: These switches are designed for specific purposes and may have unique features. Examples include key switches used in keyboards and micro switches used in gaming controllers.

In addition to these mechanical switches, there are also electrical switches that use electronic components to control the flow of electricity. Examples of electrical switches include electromechnical switches that combine mechanical and electrical systems and solid-state switches that utilize semiconductors for switching operations.

By understanding the different types of switches available, you can choose the one that best fits your application’s requirements in terms of functionality, reliability, and ease of use.

Mechanical Switches

Mechanical switches are a common type of switch that utilize physical movement to control the flow of electricity. They are known for their reliability and robustness, making them suitable for various applications in electronics. Let’s explore how mechanical switches work and where they are commonly used.

Mechanical switches consist of a mechanism that physically moves the contacts to open or close the circuit. When the switch is in the closed or “on” position, the contacts touch or make contact, allowing the flow of current through the circuit. When the switch is in the open or “off” position, the contacts separate, interrupting the flow of current.

One example of a mechanical switch is the classic push-button switch. When the button is pressed, it activates a mechanism that brings the contacts together, allowing the circuit to be closed. Releasing the button causes the contacts to separate, breaking the circuit. This type of mechanical switch is commonly used in devices where momentary actions are required, such as turning on a flashlight or operating a doorbell.

Another common type of mechanical switch is the toggle switch. It features a lever or a rocker that can be flipped up or down to open or close the circuit. Toggle switches are popular in applications where a simple on/off operation is needed, such as lamps, fans, and home appliances.

Rotary switches are also a type of mechanical switch that uses a rotating mechanism to select different positions. These switches are commonly found in audio equipment, such as amplifiers or stereo receivers, where users can switch between different inputs or control the volume.

Slide switches are yet another variant of mechanical switches. They have a sliding actuator that moves horizontally to open or close the circuit. Slide switches are often utilized in portable electronics, such as smartphones and MP3 players, to control power settings, audio options, or other functionalities.

One advantage of mechanical switches is their tactile feedback, which provides a clear indication of the switch’s position. This tactile sensation helps users confirm whether the switch is in the on or off state, preventing accidental activations or deactivations. Additionally, mechanical switches have a long lifespan and can withstand frequent use without losing their functionality.

Push Button Switches

Push button switches are a type of mechanical switch that is commonly used in various electronic devices. They are designed with a button or plunger that, when pressed, activates the switch’s mechanism to open or close the circuit. Let’s dive deeper into how push button switches work and where they find applications.

Push button switches are typically used for momentary actions, meaning that they are only active as long as the button is pressed or held down. When the button is released, the switch returns to its initial position, breaking the circuit. This characteristic makes push button switches suitable for applications where temporary activations are required, such as turning on a flashlight, operating a doorbell, or triggering a start/stop function in machines.

Inside a push button switch, there are several key components. The button itself is often made of plastic or metal and is designed to be comfortable for users to press. It is connected to a spring-loaded mechanism that provides tactile feedback and ensures the button returns to its original position once released. The contacts inside the switch are responsible for opening and closing the circuit, allowing or preventing the flow of electricity.

When the button is pressed, it activates the mechanism inside the switch, causing the contacts to touch or connect. This completes the circuit and allows the electric current to flow. Releasing the button causes the spring to push the contacts apart, breaking the circuit and stopping the current flow.

There are variations of push button switches, including normally open (NO) and normally closed (NC) configurations. In a normally open push button switch, the contacts are not touching when the button is at rest. Pressing the button brings the contacts together, closing the circuit. In a normally closed push button switch, the contacts are touching when the button is at rest. Pressing the button separates the contacts, opening the circuit.

Push button switches are widely used in consumer electronics, appliances, industrial equipment, and automotive applications. They provide a simple and intuitive way for users to interact with electronic devices, enabling control, activation, or triggering of specific functions.

Toggle Switches

Toggle switches are a type of mechanical switch that features a lever or rocker mechanism for control. They are known for their simplicity and reliability, making them widely used in a variety of electronic and electrical applications. Let’s take a closer look at toggle switches, how they work, and where they are commonly found.

The design of a toggle switch allows for easy on/off operation by flipping the lever or rocker up or down. When the lever is in the upward position, the contacts within the switch are touching, completing the circuit and allowing current to flow. Conversely, when the lever is in the downward position, the contacts separate, breaking the circuit and stopping the current flow.

Toggle switches come in two main types: single-pole, single-throw (SPST) and double-pole, double-throw (DPDT). SPST toggle switches have two terminals and control the connection or disconnection of a single conductor. They are often used for simple on/off functions in applications such as lamps, fans, and household appliances.

On the other hand, DPDT toggle switches have six terminals and enable the connection of two different conductors to different circuits. They are commonly used in more complex electrical systems, allowing for the selection between two different modes or functions. DPDT toggle switches are frequently found in audio equipment, amplifiers, and control panels.

One notable feature of toggle switches is their sturdy construction, which ensures durability and long-lasting performance. They are built to handle repeated flipping without losing functionality. This reliability makes them suitable for applications that require frequent switching, such as industrial machinery, automotive controls, and professional audio systems.

In addition to their functionality, toggle switches also provide a visual indication of their state. The position of the lever or rocker clearly shows whether the switch is on or off, making it easy for users to identify the current status of the circuit.

Toggle switches are highly versatile and can be found in various industries and applications, including electronics, telecommunications, power distribution, and more. Their simple and intuitive operation, combined with their robustness, makes them an excellent choice for controlling electrical circuits in a wide range of devices and systems.

Rotary Switches

Rotary switches are a type of mechanical switch that utilize a rotating mechanism to select different positions or options. They are commonly used in electronic devices and equipment where users need to make multiple selections or adjustments. Let’s explore how rotary switches work, their different configurations, and where they find applications.

A rotary switch consists of a central axis or shaft that can be rotated to various positions, along with a set of contacts arranged in a circular pattern. The rotation of the switch causes a contact arm or wiper to make contact with specific terminals, determining the current path or function of the circuit.

Depending on the specific design and configuration, rotary switches can have multiple poles and positions. Each pole represents a separate circuit, while the positions indicate the available options or selections. For example, a 2-pole, 4-position rotary switch would have two separate circuits and four different positions that the switch can be set to.

Rotary switches can either have continuous rotation or limited rotation. A continuous rotation rotary switch allows for 360-degree rotation and enables an infinite number of positions. This type of switch is commonly used in applications such as audio equipment to control volume or pan settings.

On the other hand, limited rotation rotary switches have a predetermined number of fixed positions. These switches typically have notches or detents that click into place at each position, providing tactile feedback to the user. Limited rotation rotary switches are commonly found in devices where a limited number of options or functions need to be selected, such as channel selectors on radios.

One advantage of rotary switches is their ability to handle high-power applications and currents. The circular arrangement of the contacts allows for evenly distributed current flow and minimizes voltage drop. This makes rotary switches suitable for applications that require high current ratings, such as power distribution systems and industrial machinery.

Rotary switches are commonly used in audio equipment, industrial controls, test instrumentation, and other devices where multiple selections or adjustments need to be made. Their versatility and ease of use make them a popular choice for applications that require precise and reliable switching.

Overall, rotary switches provide a practical solution for navigating through different options or functions in electronic circuits. Their rotating mechanism and various configurations make them essential components in a wide range of devices and systems.

Slide Switches

Slide switches are a type of mechanical switch that feature a sliding actuator to open or close the circuit. They are commonly found in consumer electronics and portable devices where compactness and ease of use are important factors. Let’s delve into the workings of slide switches, their variations, and the applications they serve.

Slide switches are designed with a rectangular actuator that can be moved horizontally to different positions to control the flow of current. When the actuator is in one position, the switch is open, breaking the circuit and preventing the current from flowing. Sliding the actuator to another position closes the switch, allowing the current to pass through and completing the circuit.

One of the advantages of slide switches is their compact size, which makes them ideal for space-constrained applications. They are commonly used in portable electronic devices, such as smartphones, tablets, MP3 players, and remote controls, where space optimization is crucial.

Slide switches come in various configurations to cater to different requirements. Single-pole, single-throw (SPST) slide switches have two terminals and control a single conductor. They provide a simple on/off functionality and are commonly used for power control in electronic devices.

Double-pole, single-throw (DPST) slide switches have four terminals and allow the control of two separate conductors simultaneously. They are commonly used in applications where multiple circuits need to be switched simultaneously or synchronized.

Slide switches can also come with additional poles and throws, such as double-pole, double-throw (DPDT) configurations. These switches have six terminals and enable the connection of two different conductors to two different circuits. They can be utilized in applications that require alternative selection between two sources or modes.

Slide switches are easy to operate and provide a clear visual indication of their state. The actuator’s position clearly indicates whether the switch is open or closed, enabling users to determine the current status of the circuit at a glance.

Due to their compactness and ease of use, slide switches find applications in a wide range of consumer electronics, home appliances, and portable devices. They are commonly used for functions like power control, audio settings, mode selection, and more.

Rocker Switches

Rocker switches are a type of mechanical switch characterized by their distinctive rocker-shaped actuator. They are widely used in various electronic devices and appliances, offering a convenient and intuitive way to control the flow of electricity. In this section, we will explore how rocker switches work, their different variations, and the applications in which they are commonly found.

Rocker switches are designed with a lever-shaped actuator that can be rocked back and forth to operate the circuit. When the rocker is in one position, the switch is off or open, and the circuit is broken, preventing the flow of current. Rocking the switch to the other position turns it on or closes the switch, enabling the current to flow through the circuit.

One advantage of rocker switches is their ease of use. The large surface area of the rocker actuator makes it convenient for users to press and control the switch. The rocking motion provides a clear tactile feedback, allowing users to discern the switch’s position without visual confirmation.

Rocker switches are available in different configurations to suit various application requirements. Single-pole, single-throw (SPST) rocker switches have two terminals and control a single conductor, offering a simple on/off functionality. They are commonly used to control power in devices like lamps, fans, and home appliances.

Double-pole, single-throw (DPST) rocker switches consist of four terminals and can control two separate circuits simultaneously. They are useful in applications that require the synchronization of two circuits, such as certain lighting systems or motor controls.

Rocker switches can also have double-pole, double-throw (DPDT) configurations, featuring six terminals. These switches allow for alternative selection between two different modes or sources, making them useful in devices where users need to switch between different functionalities or inputs.

Rocker switches are extensively used in household appliances, automotive controls, machinery, and power distribution systems. They are commonly found in devices like ovens, refrigerators, power tools, and control panels due to their reliable and robust design.

In addition to their functionality, rocker switches often feature illuminated versions, where an indicator or LED is integrated into the switch to provide visual feedback. This is especially useful in low-light environments or to indicate the status of the switch at a glance.

Overall, rocker switches offer a user-friendly and dependable solution for controlling the flow of electricity in various electronic devices and applications. Their simple operation, tactile feedback, and versatility have made them a popular choice in the world of electrical switches.

Specialty Switches

Specialty switches are a category of switches that are designed for specific purposes and often feature unique characteristics or functionalities. These switches serve niche applications and provide tailored solutions for specialized needs in various industries. Let’s explore some common types of specialty switches and the applications in which they are commonly found.

One example of a specialty switch is the key switch, which is commonly used in keyboards and security systems. Key switches are designed specifically for input devices and provide a tactile feedback when a key is pressed. They ensure accurate typing and are durable to withstand repetitive keystrokes.

Micro switches are another type of specialty switch that is widely used in gaming controllers, vending machines, and industrial applications. These switches are characterized by their small size and spring-loaded mechanism, which provides precise feedback and allows for quick actuation with minimal force.

Pressure switches are specialty switches that are sensitive to pressure changes and are commonly used in hydraulic and pneumatic systems. They are designed to actuate based on specific pressure thresholds, triggering actions such as pump activation or safety alarms in response to pressure fluctuations.

Tactile switches, also known as tactile push buttons, have a distinct tactile feedback mechanism. They provide a pronounced physical response when pressed, making them suitable for applications that require confirmation of button actuation, such as in medical devices, control panels, and gaming controllers.

Limit switches are specialty switches often used in industrial automation and robotics. They are designed to detect the presence or absence of an object within a defined range. When the object interacts with the switch, it triggers a response or action, ensuring precise positioning or safety in machinery and equipment.

Proximity switches are specialty switches that can detect the presence or absence of objects without physical contact. These switches use magnetic, capacitive, or inductive principles to sense nearby objects. Proximity switches are commonly used in automated industrial processes, such as material handling systems and assembly lines.

Emergency stop switches, also known as e-stop switches or mushroom switches, are designed to provide a quick and easily accessible means to stop equipment or machinery in emergency situations. They feature a large, prominently placed actuator that can be activated by pushing or twisting, instantly halting the operation of the system.

In addition to these examples, there are numerous other specialty switches available, each tailored to specific applications and industries. These switches often feature unique characteristics such as waterproofing, high-temperature resistance, or explosion-proofing to fulfill specific environmental requirements.

Specialty switches provide customized solutions for applications with specific needs or constraints. Their design and functionality make them crucial components in various industries, aiding in the efficient and reliable operation of specialized equipment and systems.

Electrical Switches

Electrical switches are a category of switches that utilize electronic components to control the flow of electricity. These switches are widely used in a variety of electronic devices and systems, offering precise and efficient switching capabilities. Let’s explore the different types of electrical switches and their applications.

Electromechanical Switches: Electromechanical switches combine mechanical and electrical systems to control the flow of current. They often feature an actuator that initiates the mechanical movement while utilizing electronic components to enable or disable the circuit. Electromechanical switches are commonly found in industrial controls, home appliances, and automotive applications.

Solid-State Switches: Solid-state switches differ from electromechanical switches in that they do not have any moving parts. Instead, they rely on electronic components, such as transistors or thyristors, to control the flow of electricity. Solid-state switches offer fast switching speeds, high reliability, and precise control, making them ideal for applications where frequent switching, energy efficiency, and compactness are required. They are commonly used in power electronics, automation systems, and electronic devices like LED lighting.

Both electromechanical switches and solid-state switches have their advantages and are utilized in various industries based on the specific requirements of the application. Electromechanical switches offer robustness and versatility, while solid-state switches provide faster switching speeds, higher durability, and better control over the current flow.

Electrical switches, regardless of the type, play a crucial role in regulating the flow of electricity within circuits. They facilitate the control of various functions and enable the efficient operation of electronic systems. Whether it’s turning on a light, adjusting the volume of an audio system, or activating complex industrial processes, electrical switches form an integral part of the electronics we use in our daily lives.

When choosing electrical switches for a specific application, factors such as voltage rating, current capacity, switching speed, reliability, and environmental considerations must be taken into account. Proper selection ensures the switch’s compatibility with the system and guarantees optimal performance and safety.

Overall, electrical switches offer precise and reliable control over electrical circuits, contributing to the smooth operation of electronic devices and systems. They play a vital role in various industries, from consumer electronics to industrial automation, where efficient and accurate switching is essential to meet specific application requirements.

Electromechanical Switches

Electromechanical switches are a type of electrical switch that combines mechanical and electrical components to control the flow of current. They offer a reliable and versatile solution for various applications where precise switching is required. Let’s explore how electromechanical switches work, their different variations, and the applications they serve.

At their core, electromechanical switches utilize physical movement to control the electrical circuit. They typically feature an actuator, such as a button or lever, that, when activated, initiates the movement of internal mechanical parts. This movement, in turn, opens or closes the switch contacts, allowing or interrupting the flow of electric current.

One common example of an electromechanical switch is the relay. Relays use an electromagnet to control the position of switch contacts. When the coil of the relay is energized, it generates a magnetic field that attracts or repels the switch contacts, either opening or closing the circuit. Relays are often used in control and automation systems to interface between low-power electronic signals and high-power electrical devices.

Another example of an electromechanical switch is the solenoid switch. Solenoids use an electromagnetic coil to create a magnetic field that moves a plunger. This plunger, when activated, physically opens or closes the switch contacts, allowing or breaking the flow of current. Solenoid switches find applications in door locks, valves, and automotive systems, among others.

Electromechanical switches come in various configurations to suit different needs. Single-pole, single-throw (SPST) switches have two positions – open or closed – and control a single conductor. They are commonly used for simple on/off applications.

Double-pole, single-throw (DPST) switches feature two independent sets of contacts that are simultaneously opened or closed. This configuration is useful when two circuits need to be controlled in unison.

A specialized type of electromechanical switch is the rotary switch. Rotary switches have multiple positions and contacts arranged in a circular pattern. Rotating the actuator selects a particular position, connecting or disconnecting the associated contacts. Rotary switches are commonly used in electronics, audio equipment, and industrial controls.

Electromechanical switches are prized for their reliability and capability to handle high current and voltage ratings. They are often used in industrial controls, home appliances, automotive systems, and other applications where robustness and versatility are crucial.

When selecting an electromechanical switch, factors such as the required current and voltage ratings, contact material, switching speed, and mechanical durability should be considered to ensure compatibility with the intended application.

Solid-State Switches

Solid-state switches are a type of electrical switch that rely on electronic components, such as transistors or thyristors, to control the flow of current. Unlike electromechanical switches, solid-state switches do not have any moving parts, offering advantages such as faster switching speeds, enhanced reliability, and precise control. Let’s explore how solid-state switches work, their variations, and the applications in which they excel.

The operation of solid-state switches is based on the principles of semiconductors. These switches use electronic components like transistors (such as MOSFETs) or thyristors (such as SCRs or TRIACs) to control the current flow in a circuit. By turning these components on and off, solid-state switches can effectively regulate the flow of electricity.

One key advantage of solid-state switches is their ability to switch rapidly, often in nanoseconds or microseconds. This rapid switching capability makes them suitable for applications that require precise control or high-frequency switching, such as power converters, motor control, and switching power supplies.

Another advantage of solid-state switches is their enhanced reliability compared to mechanical switches. Since they do not have any moving parts, there is no wear and tear or mechanical degradation. This absence of physical contact allows solid-state switches to have a longer operational life, making them ideal for applications where frequent switching occurs.

There are several variations of solid-state switches available, each with its specific characteristics and applications. MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are commonly used as solid-state switches for low-power applications. They provide low on-resistance, fast switching, and efficient control of current flow.

Thyristors, such as SCRs (Silicon-Controlled Rectifiers) or TRIACs (Triode for Alternating Current), are solid-state switches suitable for high-power AC applications. They can handle high current and voltage levels and are often used in applications like lighting control, motor control, and power regulation.

Solid-state relays (SSRs) are another type of solid-state switch that provides an isolated interface between low-voltage control signals and high-voltage loads. SSRs offer advantages such as fast response times, low power consumption, and galvanic isolation, making them suitable for applications that require precise and reliable switching, such as in industrial automation or control systems.

Overall, solid-state switches offer improved performance, reliability, and efficiency compared to mechanical switches in various electronic and electrical applications. They find wide usage in power electronics, telecommunications, automotive systems, and control systems where rapid switching, precise control, and minimal maintenance are essential.

When selecting a solid-state switch, factors such as voltage and current ratings, switching speed, heat dissipation, and protection features should be considered to ensure optimal performance and compatibility with the specific application requirements.

Advantages of Using Switches

Switches play a crucial role in electronics and electrical systems, offering numerous advantages that contribute to the efficient operation and control of circuits. Let’s explore the benefits of using switches in various applications.

Control and Functionality: Perhaps the most significant advantage of using switches is the control they provide over electrical circuits. Switches allow users to turn devices on or off, select different options or modes, adjust settings, and trigger specific functions. Whether it’s a light switch in a room or a toggle switch on a device, switches put control at our fingertips.

Flexibility and Versatility: Switches come in a wide range of types, configurations, and sizes to accommodate different applications and requirements. From simple on/off switches to multi-position rotary switches, switches offer versatility in controlling electrical circuits. This flexibility allows for customization and adaptation to different devices, systems, and environments.

Efficient Power Management: Switches enable energy efficiency by providing the ability to cut off the flow of electricity when not needed. By turning off devices or circuits when not in use, switches help conserve power and reduce energy consumption, leading to cost savings and environmental benefits.

Safety: Switches contribute to safety in electrical systems by providing a means to isolate power sources or devices from the circuit. They allow for quick and easy shutdown or disconnection in emergency situations, preventing equipment damage, electrical hazards, and the risk of fire or electrocution.

Convenience and User-Friendliness: Switches offer convenience and ease of use for both professional and everyday applications. They provide a straightforward and intuitive method of controlling electrical circuits, allowing users to interact with devices, adjust settings, and initiate actions effortlessly.

Reliability and Longevity: Many switches are built to withstand rigorous use and maintain their functionality over time. Mechanical switches, in particular, are known for their robustness and durability, withstanding frequent actuation without wearing out. Solid-state switches, on the other hand, offer enhanced reliability with no moving parts that could degrade over time.

Responsive Feedback: Switches often provide tactile or visual feedback, giving users a clear indication of their state. Whether it’s the click of a button, the toggle of a lever, or the illumination of an indicator, responsive feedback helps users confirm their actions and ensures accurate control over electrical circuits.

Overall, the advantages of using switches in electronics and electrical systems are significant. They provide control, flexibility, power management, safety, convenience, reliability, and user-friendly operation. By utilizing switches effectively, users can optimize the performance, efficiency, and safety of their devices, systems, and applications.

Applications of Switches in Electronics

Switches play a vital role in a wide range of electronic devices and systems, enabling control, functionality, and user interaction. Let’s explore some common applications of switches in the field of electronics.

Consumer Electronics: Switches are extensively used in consumer electronics, such as smartphones, laptops, televisions, and gaming consoles. They facilitate power control, volume adjustments, input selection, and navigation through various functions and menus.

Home Appliances: Switches are found in numerous household appliances, including refrigerators, ovens, washing machines, and air conditioners. They enable power control, mode selection, timer settings, and other operational adjustments.

Audio Equipment: Switches are essential in audio equipment, such as amplifiers, speakers, and headphones. They enable functions like power control, input selection, volume adjustment, tone control, and channel switching.

Computer Peripherals: Switches are integral to computer peripherals like keyboards, mice, and trackpads. They allow for the input of keystrokes, cursor movements, and navigation through computer interfaces.

Industrial Controls: Switches find extensive use in industrial control systems and automation. They enable power control, switching of electrical circuits, and actuation of machinery in manufacturing plants, process control systems, and robotics.

Telecommunications: Switches are crucial components in telecommunications systems, including telephones, intercoms, and communication networks. They enable call control, mute functions, hold features, and line switching.

Automotive Systems: Switches play a significant role in automotive applications, such as in-car control panels, dashboard functions, lighting systems, and power window controls. They facilitate various operations, including power control, setting adjustments, and safety functions.

Medical Devices: Switches are utilized in medical devices, such as patient monitors, diagnostic equipment, and surgical instruments. They enable power control, menu navigation, parameter adjustments, and setting customization.

Security Systems: Switches are critical elements in security systems, including alarm systems, access control panels, and surveillance devices. They facilitate arming and disarming, sensor activation, and mode selection.

Aerospace and Defense: Switches have crucial applications in aerospace and defense industries, including cockpit controls, avionics panels, communications equipment, and missile systems. They enable system activation, mode switching, and precise control in critical environments.

These are just a few examples of how switches are integrated into various electronics applications. The versatility and functionality of switches make them indispensable components in modern technology, providing control, interactivity, and enhancing the overall user experience.

Choosing the Right Switch

When it comes to selecting a switch for a specific application, careful consideration must be given to ensure optimal performance and compatibility. Here are some key factors to consider when choosing the right switch:

Functionality: Determine the specific functions and operations that the switch needs to perform. Consider whether an on/off switch is sufficient or if additional features like multiple positions, momentary action, or toggle functionality are required.

Type of Switch: Select the appropriate type of switch based on the application’s needs. Consider factors such as mechanical switches for tactile feedback, solid-state switches for high-frequency switching, or specialty switches designed for specific purposes.

Current and Voltage Ratings: Ensure that the switch can handle the electrical load and voltage of the application. Consider the maximum current that the switch needs to support without overheating or voltage drop.

Switching Speed: Evaluate whether the application requires fast or slow switching speeds. Some switches can handle rapid switching, making them suitable for applications that require precise control or high-frequency operation.

Environmental Considerations: Assess the operating environment, including factors such as temperature, humidity, vibration, and exposure to dust or moisture. Choose switches that are specifically designed to withstand these conditions, ensuring durability and reliability.

Mounting Options: Consider the available space and the preferred method of mounting the switch. Evaluate whether a panel mount, PCB mount, or solderless breadboard-compatible switch is needed.

Safety Requirements: Determine if there are any specific safety considerations. Some applications may necessitate switches with features like IP ratings for water or dust resistance, flame retardancy, or compliance with specific safety standards.

Cost: Consider the budget and overall cost requirement for the project. Evaluate the trade-offs between quality, features, and cost to find a switch that offers the right balance for the application.

Reliability: Look for switches from reputable manufacturers that have a proven track record of reliability and durability. Read user reviews and ratings to gauge the experiences of others with a particular brand or model of switch.

By carefully considering these factors, one can choose the right switch that meets the specific requirements of the application. Ensuring compatibility and functionality will result in a more efficient and reliable operation of the electronic system or device.