The Importance of Mechanical Drawing

Mechanical drawing is a fundamental skill in the fields of engineering, manufacturing, and design. It involves creating precise and detailed technical illustrations that communicate ideas, concepts, and specifications. While advancements in computer-aided design (CAD) have transformed the way we create technical drawings, the importance of mastering traditional mechanical drawing cannot be overstated. Here are several reasons why mechanical drawing is a crucial skill:

-

Communicating Design Intent:

Mechanical drawings serve as a universal language for designers, engineers, and manufacturers. They provide a clear and accurate representation of the intended design, allowing all stakeholders to visualize and understand the product or component. By effectively communicating design intent, mechanical drawings minimize misunderstandings and ensure that everyone is on the same page.

-

Precise Manufacturing Specifications:

Mechanical drawings provide detailed information about the dimensions, tolerances, materials, and finishes required for manufacturing a product. They help ensure that parts are accurately produced and assembled, reducing errors, rework, and costly production delays. In industries where precision is paramount, such as aerospace and automotive, accurate mechanical drawings are vital for achieving quality and safety standards.

-

Enabling Collaboration:

Mechanical drawings facilitate collaborative efforts among design teams, engineers, and manufacturers. They act as a reference point for discussions, allowing professionals from different disciplines to share ideas and make informed decisions. Moreover, by providing a visual representation, mechanical drawings promote effective communication and problem-solving between team members.

-

Enhancing Creativity and Innovation:

Mechanical drawing is an essential tool for exploring new design ideas and concepts. It allows designers and engineers to quickly sketch and iterate through multiple design iterations, evaluating their feasibility and performance. This iterative process fosters creativity and innovation by enabling a deeper understanding of the design’s functionality and potential improvements.

-

Preserving Intellectual Property:

Creating accurate and detailed mechanical drawings helps protect intellectual property rights. These drawings serve as legal documentation of original designs and inventions, establishing ownership and preventing unauthorized duplication or infringement. By incorporating watermarking or other security measures, mechanical drawings can further safeguard valuable intellectual property.

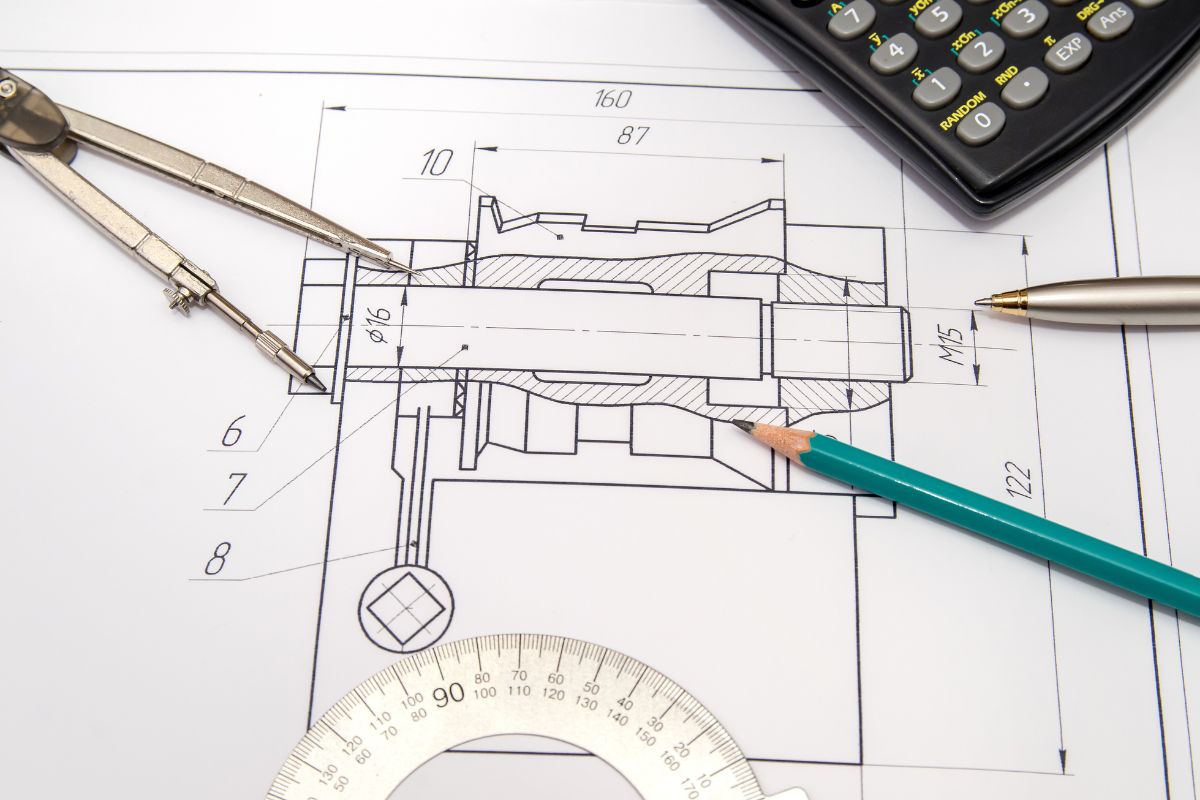

Tools and Materials for Mechanical Drawing

Creating precise and professional mechanical drawings requires the use of specific tools and materials. Whether you’re a beginner or an experienced draftsman, having the right equipment is essential for achieving accurate and high-quality drawings. Here are some of the most commonly used tools and materials in mechanical drawing:

-

Drawing Instruments:

The foundation of mechanical drawing lies in the use of drawing instruments such as compasses, rulers, and protractors. A compass is used to draw circles and arcs, while rulers and protractors are used for measuring and creating accurate angles. Additionally, a drafting triangle or T-square can be used to create straight lines and right angles.

-

Drawing Paper:

The choice of drawing paper is crucial for achieving precise and smudge-free drawings. Traditional drawing paper is typically smooth and heavyweight to prevent ink bleed-through and smudging. Additionally, some professionals prefer using translucent vellum paper for tracing and overlaying drawings.

-

Drawing Pencils:

Drawing pencils with a range of lead hardness, such as HB, 2B, and 4B, are commonly used for mechanical drawing. The different lead hardness allows for various line weights, providing clarity and dimension to the drawings. Mechanical pencils with interchangeable lead sizes are also popular for their precision.

-

Erasers:

Erasers are essential for correcting mistakes and cleaning up drawings. A soft vinyl eraser is commonly used for general erasing, while a kneaded eraser or a precision eraser pen can be used for more delicate erasing tasks. It’s important to choose erasers that don’t leave residue or damage the drawing paper.

-

Inking Tools:

For finalizing the mechanical drawings, a variety of inking tools can be used to create clean and permanent lines. These tools include technical pens, fine-line markers, or disposable drawing pens with different nib sizes. Ink should be chosen carefully to ensure it is waterproof and compatible with the drawing paper.

-

Drafting Software:

With the advancement of technology, many professionals now create mechanical drawings using computer-aided design (CAD) software. CAD programs offer a range of powerful tools and features that simplify and enhance the drawing process. Popular CAD software includes AutoCAD, SolidWorks, and Fusion 360.

Investing in quality tools and materials is essential for creating accurate and professional mechanical drawings. These resources, combined with proper technique and practice, will help you produce high-quality drawings that effectively communicate your design ideas and specifications.

Understanding Different Types of Lines

Lines are the cornerstone of mechanical drawing, conveying various information such as outlines, dimensions, and annotations. Understanding the different types of lines and their meanings is vital for creating clear and accurate drawings. Let’s explore some of the most commonly used lines in mechanical drawing:

-

Visible Lines:

Visible lines represent the edges or boundaries of objects that can be seen in the final product. These lines are typically drawn with a solid, thick line weight. They define the shape and size of the object, providing a clear depiction of its form.

-

Hidden Lines:

Hidden lines are used to represent edges or boundaries that are not visible in the final product. These lines are drawn using a dashed or dotted line pattern. They help illustrate internal features or components that are obscured by other parts of the object.

-

Centerlines:

Centerlines are used to indicate the center of symmetrical objects or to represent axes and symmetry in drawings. They are drawn using a long dash followed by two short dashes. Centerlines help identify the midpoint and provide a reference for other features in the drawing.

-

Dimension Lines:

Dimension lines are used to indicate the size and measurements of objects or features in the drawing. They have arrowheads at each end and are accompanied by numerical values indicating the distance or size. Dimension lines, together with other annotations, provide crucial information for the manufacturing and assembly process.

-

Extension Lines:

Extension lines are used in conjunction with dimension lines to indicate the boundaries of the dimension being measured. They are drawn as thin lines that extend from the object’s geometry to the dimension line. Extension lines help clarify which part of the object is being measured.

-

Section Lines:

Section lines are used in sectional views to represent the cut surfaces of an object. These lines are drawn at a 45-degree angle and evenly spaced. They provide a visual indication of material and differentiate the solid part from the cutaway section.

-

Phantom Lines:

Phantom lines are used to represent alternative positions, repeated detail, or to illustrate movement in mechanical drawings. These lines are drawn using a combination of long and short dashes. Phantom lines help convey additional information without cluttering the drawing.

-

Break Lines:

Break lines are used to shorten long or repetitive objects in mechanical drawings. They consist of parallel zigzag lines that indicate where the object has been “broken.” Break lines help conserve space in the drawing and make it easier to depict large or complex objects.

Understanding the different types of lines and their usage is essential for accurately communicating design intent in mechanical drawings. By using the appropriate lines and line weights, drafters can create clear and easily understandable representations of objects, facilitating the manufacturing and assembly process.

Basic Geometric Shapes in Mechanical Drawings

Geometric shapes are foundational elements in mechanical drawings, providing a visual representation of objects and components. These shapes serve as building blocks for creating accurate and precise technical illustrations. Understanding the basic geometric shapes used in mechanical drawings is essential for communicating design ideas effectively. Here are some of the most commonly used shapes:

-

Lines:

Lines are the simplest geometric shape used in mechanical drawings. They represent the boundaries, edges, and contours of objects. Lines can be straight, curved, or a combination of both. By varying the length, position, and orientation of lines, drafters can convey specific dimensions, angles, and relationships between different parts of the drawing.

-

Circles:

Circles are widely used in mechanical drawings to represent cylindrical features, holes, and curved surfaces. They can be drawn using compasses or traced around circular objects of a known diameter. Circles are important for accurately depicting dimensions, establishing center points, and ensuring that circular features are symmetrical.

-

Arcs:

Arcs are curved lines that are not complete circles. They are used to represent partial circles or curved features in mechanical drawings. Arcs can be drawn using a compass or by specifying specific radii and angles. They are useful for indicating fillets, chamfers, or any other curved feature that is not a complete circle.

-

Squares and Rectangles:

Squares and rectangles are essential geometric shapes in mechanical drawings. They are used to represent planar surfaces, panels, and many other structural components. Squares have all sides of equal length, while rectangles have two pairs of parallel sides. Accurate depiction of squares and rectangles is critical for maintaining dimensions and ensuring proper fit and alignment in the final product.

-

Triangles:

Triangles are versatile geometric shapes used in mechanical drawings. They can represent structural members, trusses, or any triangular component or feature. Triangles can also be used to depict angles and proportions within the drawing. Understanding the properties and relationships of triangles is essential for accurate representation in mechanical drawings.

-

Polygons:

Polygons are multi-sided shapes that can have three or more sides. They are used to represent irregular or complex features in mechanical drawings. Common polygons include hexagons, pentagons, and octagons. Polygons are essential for accurately representing non-standard or specialized shapes that cannot be easily depicted using simpler geometric shapes.

These basic geometric shapes serve as the foundation for creating accurate and detailed mechanical drawings. Mastering the art of drawing these shapes with precision and consistency is crucial for effectively communicating design concepts, dimensions, and relationships between different parts of the drawing.

How to Create an Isometric Drawing

An isometric drawing is a three-dimensional representation of an object in which all three axes — x, y, and z — are equally foreshortened. It provides a realistic and detailed view of an object and is commonly used in mechanical and technical drawings. Creating an isometric drawing involves a specific process to accurately portray the object’s dimensions and proportions. Here are the steps to create an isometric drawing:

-

Select a Scale:

Determine the scale at which you will be drawing the isometric view. The scale determines the proportion between the actual object’s dimensions and the dimensions of the drawing. It is important to choose a scale that allows for clear and readable drawings.

-

Draw the Isometric Axes:

Start by drawing the isometric axes — the x-axis, y-axis, and z-axis. These axes will help you maintain consistent angles and proportions throughout the drawing. The x-axis is usually drawn at a 30-degree angle to the horizontal, while the y-axis is drawn vertically. The z-axis is drawn diagonally, connecting the intersections of the x and y axes.

-

Sketch the Basic Outline:

Using light, thin lines, sketch the basic outline of the object you want to draw. Start with the overall shape and then add details such as edges, corners, and curves. Focus on capturing the overall proportions and dimensions of the object.

-

Add Depth and Dimension:

To create a three-dimensional effect, add depth and dimension to the isometric drawing. This can be achieved by carefully adding shading, hatching, or crosshatching to indicate areas of the object that are in shadow or recessed. Additionally, consider adding highlights or gradients to emphasize the object’s surfaces and contours.

-

Label and Annotate:

Label and annotate the isometric drawing to provide additional information about the object. Add dimensions, annotations, and callouts to indicate specific measurements, features, or details. Proper labeling and annotation help make the drawing clear and understandable for others.

-

Check for Accuracy:

Review your isometric drawing to ensure accuracy and correctness. Double-check measurements, proportions, and alignments to make sure they align with the intended design. Use drafting aids like rulers or templates to ensure straight and accurate lines throughout the drawing.

-

Finalize the Drawing:

Once you are satisfied with the isometric drawing, darken the lines and erase any unnecessary construction lines. Apply appropriate line weights to distinguish different elements of the drawing and make it visually appealing and clear.

Creating an isometric drawing requires attention to detail, accuracy, and knowledge of perspective. With practice and following these steps, you can create isometric drawings that accurately depict three-dimensional objects in a visually appealing and informative manner.

Exploring 2D and 3D Drawing Techniques

Both 2D and 3D drawing techniques play significant roles in mechanical design and engineering. While 2D drawings provide detailed information about individual components, 3D drawings offer a holistic view of the entire object. Understanding and utilizing these techniques is essential for accurately representing objects and conveying design intent. Let’s explore the differences and applications of 2D and 3D drawing techniques:

2D Drawing Techniques:

2D drawing techniques involve the creation of drawings that represent objects in two dimensions – length and width. These drawings are typically created on a flat surface, such as paper or a computer screen. 2D drawings provide a clear representation of individual components, dimensions, and details. Some common techniques used in 2D drawing include:

- Orthographic Projection: This technique uses multiple 2D views to represent an object, such as front, top, and side views. It provides a comprehensive representation of the object from different angles.

- Sectional Views: Sectional views are created by cutting through an object to reveal its internal features. This technique enhances understanding by showing hidden details that cannot be seen in external views.

- Detail Views: Detail views are used to zoom in on specific areas of an object, providing a magnified and more detailed representation for complex features or intricate geometries.

- Technical Illustration: Technical illustrations combine 2D drawings with text and annotations to provide comprehensive information about an object’s features, assembly, and usage.

3D Drawing Techniques:

3D drawing techniques involve the creation of drawings that represent objects in three dimensions – length, width, and depth. These drawings provide a more realistic and comprehensive view of the object, enabling better visualization and analysis. Common techniques used in 3D drawing include:

- Isometric Drawing: Isometric drawings create a three-dimensional representation of an object using equal foreshortening of the x, y, and z axes. It allows for a realistic visualization of the object from different angles.

- Computer-Aided Design (CAD): CAD software enables the creation of detailed and accurate 3D models of objects. These models can be rotated, zoomed, and viewed from various angles to analyze the object’s form and functionality.

- Rendering: Rendering adds texture, lighting, and shading effects to 3D models to create a more photorealistic representation of the object. This technique enhances the visual appeal and realism of the drawing.

- Animation: Animation techniques allow for the creation of dynamic representations of objects, showcasing their motion, assembly process, or functionality. It helps visualize and communicate complex movements or mechanisms more effectively.

Both 2D and 3D drawing techniques are valuable tools in mechanical design, engineering, and manufacturing. While 2D drawings provide detailed information about individual components, 3D drawings offer a more comprehensive visualization of the entire object. Combining both techniques can help communicate design intent, facilitate collaboration, and streamline the manufacturing process.

An Overview of Dimensioning and Scaling

Dimensioning and scaling are critical aspects of mechanical drawing that ensure accurate representation and clear communication of an object’s size and proportions. Proper dimensioning and scaling techniques provide vital information for manufacturing, assembly, and inspection processes. Let’s take a closer look at these important concepts:

Dimensioning:

Dimensioning involves adding numerical values, symbols, and annotations to drawings to define the size, location, and tolerance of objects and features. It provides essential information for fabricators and technicians to manufacture and assemble components accurately. Key points to consider when dimensioning include:

- Dimensions: Dimensions consist of numerical values that indicate the specific size or distance of an object or feature. They are typically accompanied by measurement units and indicated using dimension lines with arrowheads.

- Dimension Lines: Dimension lines are thin lines with arrowheads that extend from the object’s geometry and connect to the dimension values. They indicate the extent of the dimension and provide a clear reference for the measured feature.

- Extension Lines: Extension lines are thin, unbroken lines that extend from the object’s geometry to the dimension lines. They help define which part of the object the dimension applies to.

- Leaders and Text: Leaders and text are used to identify dimensions and provide additional information. Leaders are lines with an arrow or dot that point to the dimension or feature being referenced, while text includes labels, symbols, and notes necessary to describe the dimension.

- Tolerances: Tolerances specify the acceptable deviation from the specified dimension. They ensure the manufacturability and functionality of the part by considering variations in the manufacturing process and materials.

Scaling:

Scaling is the process of proportionally adjusting the size of a drawing to fit within specified limits, such as a specific paper size or predetermined scale. Scaling is often necessary when creating or printing drawings to ensure they are accurately represented in relation to the real-world object. Important considerations for scaling include:

- Scale Ratio: The scale ratio indicates the relationship between the size of the drawing and the size of the actual object. For example, a scale ratio of 1:50 means that one unit of measurement on the drawing corresponds to 50 units of measurement in the real object.

- Standard Scales: Commonly used scales, such as 1:1, 1:10, 1:20, 1:100, and 1:1000, are typically employed in mechanical drawing. These standard scales ensure consistency and ease of comprehension between different drawings and users.

- Scaling Techniques: Scaling can be achieved through manual methods, such as using a ruler or grid system, or by utilizing computer-aided design (CAD) software that automatically scales the drawing based on input parameters.

- Dimension Conversion: When scaling a drawing, it is crucial to ensure that the dimension values are scaled accordingly. For example, if the original drawing represents a length of 10 mm, and the drawing is scaled down by a factor of 10, the dimension value should be adjusted to 1 mm.

Proper dimensioning and scaling are essential to convey accurate information and facilitate effective communication in mechanical drawing. Accurate dimensions provide a clear understanding of an object’s size and features, while scaling ensures that drawings are representative of the real-world object and suitable for various applications.

Common Drawing Conventions and Symbols

Standardized drawing conventions and symbols are essential in mechanical drawing to ensure clear communication and understanding among designers, engineers, and manufacturers. These conventions provide a visual language that conveys specific information about dimensions, materials, processes, and other important details. Let’s explore some of the most common drawing conventions and symbols used in mechanical drawings:

Line Types:

Different line types are used in mechanical drawings to distinguish between various elements. Here are some commonly used line types:

- Continuous Line: Solid, continuous lines are used for visible edges, boundaries, and outlines.

- Dashed Line: Dashed lines, consisting of evenly spaced dashes, are used for hidden features, break lines, or alternate positions.

- Centerline: The centerline is a long dash followed by two short dashes and indicates the center of symmetry, axes, or reference points.

- Phantom Line: Phantom lines, composed of alternating long and short dashes, are used to represent alternate positions, repeated features, or movement.

- Section Line: Section lines, drawn at a 45-degree angle and evenly spaced, indicate the material cut in sectional views.

Geometric Symbols:

Geometric symbols are used to represent specific shapes, features, or processes. Some common geometric symbols include:

- Circle: Circles are used to represent cylindrical features, holes, or curved surfaces.

- Square or Rectangle: Squares or rectangles represent planar surfaces or panels.

- Triangle: Triangles are used for triangular components, angles, or structural members.

Material and Surface Symbols:

Material and surface symbols provide information about the type of material and surface finish required for a part. Some common symbols include:

- Fillets and Rounds: Fillets and rounds are indicated by placing an arc at the junction of two surfaces, indicating a smooth, rounded transition.

- Roughness: Surface roughness is represented by a series of lines, generally known as roughness symbols, indicating the required surface texture and quality.

Dimension and Annotation Symbols:

Dimension and annotation symbols provide important information about sizes, tolerances, and other details. Some common symbols include:

- Dimension Lines: Dimension lines, accompanied by numerical values, indicate the size or distance of a feature.

- Diameter Symbol: The diameter symbol (Ø) indicates that the given dimension represents the diameter of a circle or cylindrical feature.

- Angle Symbol: The angle symbol (θ) is used to indicate the angle between two lines or surfaces.

- Tolerance Symbols: Tolerance symbols indicate the acceptable deviation from the specified dimension.

- Surface Finish Symbols: Surface finish symbols indicate the required finish quality, such as smoothness or roughness, for a specific surface.

These are just a few examples of the many conventions and symbols used in mechanical drawings. It is essential to consult industry standards and guidelines, such as ISO, ASME, or ANSI, to ensure consistency and accuracy in communicating information through drawings.

Tips for Creating Accurate and Neat Mechanical Drawings

Creating accurate and neat mechanical drawings is crucial for effectively communicating design intent and ensuring the precise manufacturing of components. Here are some valuable tips to help you produce high-quality and professional drawings:

-

Use the Right Tools and Materials:

Invest in quality drawing instruments, such as compasses, rulers, and protractors, to ensure precise measurements and straight lines. Choose appropriate drawing paper that minimizes smudging and bleeding. Utilize pencils with a range of lead hardness for varying line weights.

-

Follow Standard Drawing Practices:

Adhere to industry standards, conventions, and symbols to ensure consistency and ease of understanding for others. Always use proper line types, dimensioning techniques, and symbol representation according to recognized practices.

-

Take Care with Line Quality:

Ensure clear and clean lines by applying appropriate pressure with a steady hand. Avoid shaky or wobbly lines that can lead to confusion or misinterpretation. Practice using a consistent line weight throughout the drawing for a professional appearance.

-

Pay Attention to Proportions and Symmetry:

Maintain accurate proportions and symmetry in your drawings to accurately represent the object. Use construction lines, grids, or guidelines to ensure proper alignment and balanced proportions between different components or features.

-

Check for Accuracy and Errors:

Double-check all dimensions, measurements, and annotations to ensure accuracy. Verify that all lines, symbols, and text are legible, neat, and free from smudges or erasures. Look for any errors or inconsistencies and make appropriate corrections before finalizing the drawing.

-

Organize and Label the Drawing:

Ensure your drawing is well-organized and easy to understand. Use appropriate labels, headers, and titles to identify different sections or components. Incorporate a legend or key to explain symbols, abbreviations, or special notations used in the drawing.

-

Maintain Proper Scale and Projections:

Ensure that your drawing is correctly scaled and that the dimensions reflect the intended size of the object. Consistently use the same projection system (orthographic, isometric, etc.) throughout the drawing to avoid confusions and inconsistencies.

-

Practice and Seek Feedback:

Regular practice is key to improving your drawing skills. Experiment with different techniques and learn from experienced drafters. Seek feedback from peers, mentors, or instructors to identify areas for improvement and gain valuable insights into producing accurate and neat drawings.

By following these tips and continuously honing your skills, you can create accurate, professional, and visually appealing mechanical drawings that effectively convey design intent and facilitate the manufacturing process.

Using CAD Software for Mechanical Drawing

Computer-aided design (CAD) software has revolutionized the field of mechanical drawing, allowing for more efficient and precise creation of technical illustrations. CAD software offers a wide range of powerful tools and features that simplify the drawing process and enhance productivity. Here are some key benefits and uses of CAD software for mechanical drawing:

Increased Accuracy and Precision:

CAD software enables precise and accurate measurements, alignments, and annotations. The software automatically enforces design constraints, ensuring that drawings adhere to specified dimensions, tolerances, and other requirements. This eliminates human error and significantly improves accuracy in the design and manufacturing process.

Efficiency and Time Savings:

CAD software offers a variety of time-saving features, such as copy and paste, parametric modeling, and dynamic blocks. These tools help streamline the drawing process and eliminate repetitive tasks. Rapid changes and modifications can be made efficiently, reducing the time required to revise designs and drawings.

Visualizations and Simulations:

CAD software allows for the creation of detailed 3D models that provide a realistic representation of the object. These 3D models can be easily manipulated to visualize different viewpoints, exploded views, or cross-sections. Virtual simulations and analyses can be performed to evaluate factors such as stress, airflow, or motion, facilitating design optimization and problem-solving.

Collaboration and Revision Control:

CAD software fosters collaboration among designers, engineers, and stakeholders. Multiple team members can work on the same drawing concurrently, eliminating version control issues. Changes made by one person are automatically updated for others, ensuring everyone is working on the latest version. This streamlines communication and reduces potential errors resulting from miscommunication.

Documentation and Data Management:

CAD software provides efficient documentation and data management capabilities. Drawings can be easily organized, stored, and retrieved, reducing the risk of lost or misplaced files. Additionally, CAD software allows for the integration of design data with other systems, such as bill of materials (BOM) or enterprise resource planning (ERP) systems, further enhancing data management and accessibility.

Printing and Presentation:

CAD software offers flexible printing options, allowing for precise scaling, layout arrangement, and plotting. Drawings can be printed in various formats, such as PDF or DWG, ensuring compatibility with different systems and stakeholders. Additionally, CAD software provides tools for creating professional presentations with rendered images, animations, or exploded views for client or management review.

Overall, CAD software has become an integral tool in mechanical drawing, providing numerous benefits that enhance productivity, accuracy, and collaboration. Familiarity with CAD software and its features is essential for modern-day mechanical drafters and designers, allowing them to produce efficient, highly accurate, and visually compelling drawings.

Applying Mechanical Drawing Skills in Real-World Applications

Mechanical drawing skills have a wide range of real-world applications in various industries. Whether it’s engineering, manufacturing, architecture, or product design, the ability to create accurate and detailed technical illustrations is invaluable. Here are some ways in which mechanical drawing skills are applied in real-world scenarios:

Product Design and Development:

Mechanical drawings are crucial in the product design and development process. They communicate design intent and serve as a reference for engineers, manufacturers, and stakeholders. Mechanical drawings ensure consistency across different phases of product development, from concept sketches to detailed 2D and 3D drawings, aiding in the manufacturing, assembly, and quality control processes.

Engineering and Manufacturing:

In the fields of engineering and manufacturing, mechanical drawings are used to specify dimensions, tolerances, materials, and manufacturing processes. They provide instructions for fabricators and technicians, ensuring that components are accurately produced, assembled, and tested according to design specifications. Mechanical drawings facilitate efficient communication between design teams and the production floor, reducing errors, rework, and production delays.

Architecture and Construction:

In architecture and construction, mechanical drawings are used to convey design ideas, construction details, and specifications. They help architects, contractors, and other stakeholders visualize the final structure, plan the layout of components, and make critical decisions regarding materials, safety, and functionality. Mechanical drawings are essential for obtaining building permits, coordinating different trades, and ensuring compliance with building codes and regulations.

Prototype Development and 3D Printing:

Mechanical drawings are a precursor to the prototyping and 3D printing process. These drawings are used to create virtual 3D models, validate designs, and simulate functionality. The data from the mechanical drawings is often used to generate 3D printable files, enabling the creation of physical prototypes for testing, verification, and refinement before mass production.

Documentation and Maintenance:

Mechanical drawings play a crucial role in equipment and machinery maintenance. They serve as a reference for technicians during installation, troubleshooting, and repair tasks. Mechanical drawings provide vital information about parts identification, assembly procedures, and recommended maintenance schedules. Accurate and up-to-date drawings are essential for maintaining the reliability and safety of machinery in various industrial settings.

These are just a few examples of the real-world applications of mechanical drawing skills. Whether it’s bringing innovative products to market or maintaining existing machinery, the ability to create and interpret accurate technical illustrations is essential across numerous industries, ensuring efficiency, accuracy, and safety in various applications.

Resources for Further Learning and Practice

If you’re looking to improve your mechanical drawing skills or expand your knowledge in the field, there are plenty of resources available that can help you learn, practice, and hone your abilities. Here are some valuable resources to consider:

Online Tutorials and Courses:

Explore online platforms that offer tutorials and courses specifically focused on mechanical drawing. Websites like Udemy, Coursera, and LinkedIn Learning provide a wide range of courses that cover topics such as drafting techniques, CAD software, dimensioning, and scaling. These courses often include video lessons, practical exercises, and quizzes to reinforce your understanding.

Books and Reference Guides:

There are numerous books available that cover mechanical drawing techniques, principles, and best practices. Some recommended titles include “Technical Drawing with Engineering Graphics” by Frederick E. Giesecke and “Engineering Drawing and Design” by David A. Madsen. These books provide in-depth explanations, examples, and exercises to help you develop essential skills.

Industry Standards and Guidelines:

Reference industry standards and guidelines to ensure proper application of mechanical drawing principles. Organizations such as the International Organization for Standardization (ISO), American Society of Mechanical Engineers (ASME), and American National Standards Institute (ANSI) publish standards that dictate drawing practices and symbols. Consulting these standards will ensure consistency and accuracy in your drawings.

Networking and Mentorship:

Connect with professionals in the field who have expertise in mechanical drawing. Join industry forums, participate in online communities, or attend networking events to meet fellow drafters and designers. Engaging with experienced individuals can provide valuable insights, guidance, and feedback as you continue to improve your skills.

Practice Exercises and Projects:

Practice is crucial for developing proficiency in mechanical drawing. Look for practice exercises and projects that allow you to apply the concepts and techniques you have learned. You can find sample exercises in books, online tutorials, or even create your own by replicating and dimensioning existing objects or components.

Continued Learning and Professional Development:

Stay updated with the latest advancements in mechanical drawing by attending workshops, seminars, or webinars related to the field. These events provide opportunities to learn from experts and gain insights into emerging technologies, software updates, and industry trends. Engaging in continuous learning and professional development ensures you stay current and competitive in the ever-evolving field of mechanical drawing.

Utilize these resources to deepen your understanding, refine your skills, and stay engaged in the world of mechanical drawing. Remember, consistent practice and a thirst for knowledge are key to becoming a proficient and successful drafter or designer.