Factors Affecting Precision

Precision is a crucial factor when it comes to the performance of an electronic balance. It refers to the degree of consistency and reproducibility of the measurements it provides. Several factors can influence the precision of an electronic balance, and understanding these factors is essential for obtaining accurate and reliable results.

The first factor that affects the precision of an electronic balance is the quality of the instrument itself. High-quality, well-calibrated balances tend to provide more precise measurements compared to lower-grade instruments. It is crucial to invest in a reputable brand and ensure regular calibration to maintain optimal precision.

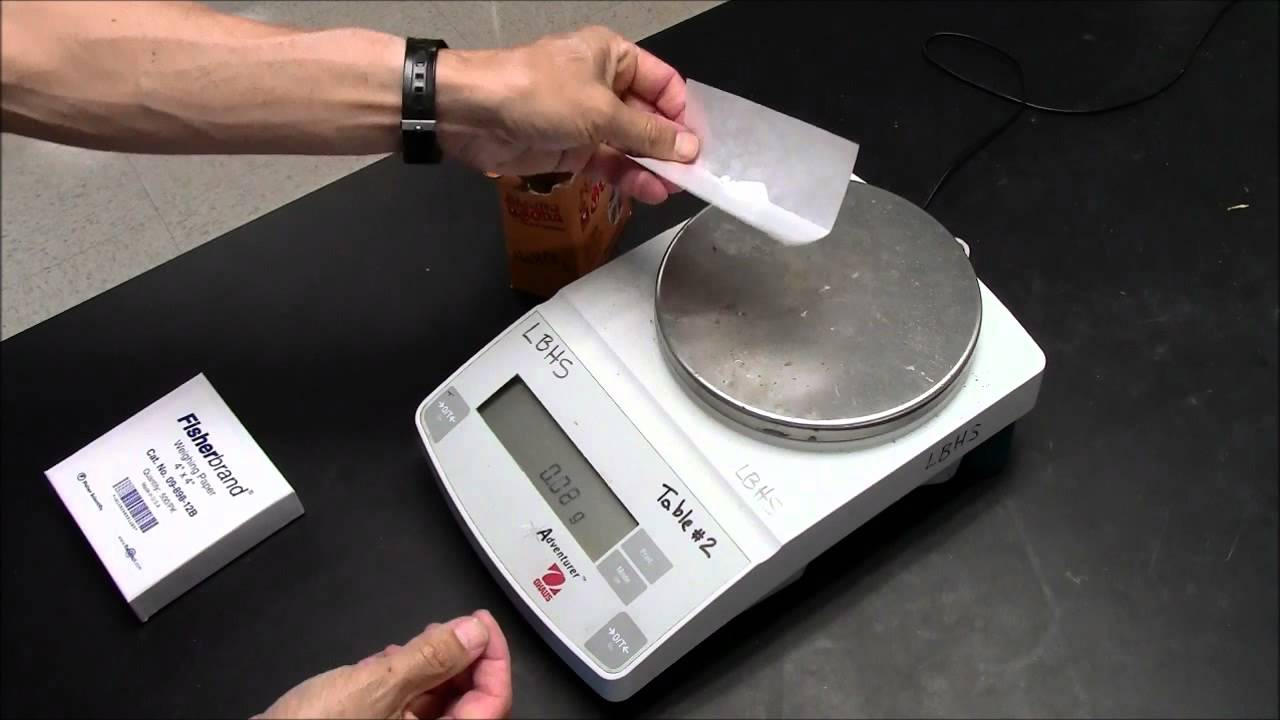

Another factor is the handling and technique employed while using the balance. Users must be trained in proper sample placement, avoiding unnecessary vibrations, and gentle handling of the equipment. Accurate weighing techniques like taring the balance before measurements can significantly improve precision.

The type of sample being weighed also plays a role in precision. Highly reactive or volatile substances can introduce errors and affect the balance’s performance. It is crucial to choose the appropriate sample holder or container and follow recommended procedures to minimize these effects.

Environmental conditions can also impact precision. Temperature fluctuations, humidity, and air currents can cause variations in the measurements. Maintaining a controlled environment with stable conditions, such as using a dedicated weighing area or a draft-free room, can reduce these external influences and improve precision.

The capacity and sensitivity of the balance are also critical factors. An electronic balance with higher sensitivity can detect smaller weight differences, leading to increased precision. However, exceeding the maximum capacity of the balance can strain its components and compromise accuracy. It is important to choose a balance with an appropriate capacity for the intended measurements.

Regular calibration and maintenance are essential to maintain precision over time. Balances should be calibrated following the manufacturer’s guidelines or using certified weights. Routine maintenance, such as cleaning the weighing pan and checking for any damage or wear, can also contribute to sustained precision.

In summary, precision in electronic balances is influenced by factors such as the quality of the instrument, proper handling and technique, the type of sample, environmental conditions, capacity and sensitivity, as well as regular calibration and maintenance. By understanding and addressing these factors, users can ensure reliable and precise measurements, improving the overall accuracy of their experiments or processes.

Sensitivity of the Electronic Balance

The sensitivity of an electronic balance is a crucial factor that directly impacts its precision. It refers to the smallest weight difference that the balance can detect and display accurately. Understanding the sensitivity of the balance is essential for obtaining precise measurements in various scientific and industrial applications.

Electronic balances are designed with different levels of sensitivity, usually expressed in terms of readability. For example, a balance with a readability of 0.001g can measure weight differences as small as 0.001 grams. Balances with higher sensitivities can detect smaller weight variations and provide more precise measurements.

The sensitivity of an electronic balance is determined by several factors, including the design of the load cell or sensor used in the balance. Load cells are responsible for converting the mechanical force exerted by the weight on the balance into an electrical signal that is interpreted and displayed by the device. The design and quality of the load cell significantly impact sensitivity.

Another factor that affects sensitivity is the resolution of the balance. Resolution refers to the number of decimal places displayed by the balance. For example, a balance with a resolution of 0.001g can display weight measurements up to three decimal places. Higher resolution balances can provide more precise readings, allowing for better measurement accuracy.

The sensitivity of the balance can also be influenced by external factors such as temperature and vibration. Temperature changes can cause expansion or contraction of materials within the balance, affecting its performance. Inadequate vibration isolation can introduce fluctuations in the weight readings. It is crucial to consider these factors and ensure proper environmental conditions for optimal sensitivity.

It is important to note that the sensitivity of an electronic balance is different from its accuracy. While sensitivity refers to the ability to detect small weight differences, accuracy measures how close the balance readings are to the true value. A balance can be sensitive but still provide inaccurate measurements if not properly calibrated.

To maximize the sensitivity of an electronic balance, it is recommended to follow the manufacturer’s guidelines for operation and maintenance. Regular calibration using certified weights is essential to ensure accuracy and optimize sensitivity. Additionally, avoiding excessive load on the balance and maintaining a stable environment can help preserve its sensitivity over time.

In summary, the sensitivity of an electronic balance plays a crucial role in achieving precise measurements. Factors such as the design of the load cell, resolution, environmental conditions, and calibration influence the sensitivity of the balance. By understanding and optimizing these factors, users can ensure accurate and reliable measurements, improving the overall quality of their work.

Accuracy vs. Precision

Accuracy and precision are two important aspects of measurement that are often confused with each other. While they are related, they have distinct meanings and implications when it comes to the quality of measurements obtained from an electronic balance.

Accuracy refers to how close a measured value is to the true or accepted value. It is an indicator of the correctness of the measurement and is influenced by systematic errors or biases. An accurate balance will provide measurements that are consistently close to the expected value.

Precision, on the other hand, refers to the degree of consistency and reproducibility in the measurements obtained from the balance. It is a measure of the scatter or variability of the results. A precise balance will yield measurements that are tightly clustered around the mean value, regardless of whether the mean value is close to the true value or not.

To better understand the difference between accuracy and precision, consider the analogy of shooting at a target. Accuracy refers to hitting the bullseye or the intended target consistently, whereas precision refers to hitting the same spot repeatedly, even if it is far from the bullseye. A balanced balance would be accurate if the measured weights are close to the true values and precise if the measurements consistently fall within a narrow range.

It is possible to have a balance that is accurate but not precise, or vice versa. For example, if a balance consistently produces weight measurements that are slightly higher than the true values but are tightly clustered around the mean, it is precise but not accurate. Conversely, if a balance consistently produces weight measurements that are far apart but are close to the true value, it is accurate but not precise.

Ideally, users of electronic balances aim for both accuracy and precision. However, achieving both at the same time can be challenging. Systematic errors, such as calibration errors or equipment limitations, can affect accuracy. Random errors, such as environmental fluctuations or operator variability, can impact precision. Therefore, it is important to consider and manage both factors when using an electronic balance for measurement.

Calibration plays a vital role in addressing both accuracy and precision. Regular calibration using standard weights helps align the balance readings with the true values, improving accuracy. Additionally, calibration provides an opportunity to evaluate the precision and identify any drift or variability in the balance’s performance, allowing for adjustments or corrective measures to be taken.

In summary, accuracy refers to the correctness of a measured value, while precision refers to the consistency and reproducibility of measurements. Both factors are important in obtaining reliable and trustworthy results from an electronic balance. Regular calibration and consideration of both systematic and random errors can help achieve optimal accuracy and precision in measurements.

Calibration Process

The calibration of an electronic balance is a crucial step in ensuring accurate and reliable measurements. Calibration is the process of comparing the readings of a balance to known reference weights and adjusting the balance if necessary. It allows for the correction of any systematic errors or inaccuracies in the balance’s performance.

The calibration process typically involves the following steps:

- Preparation: Before starting the calibration process, it is important to ensure that the balance is clean and free from any residue or debris that may interfere with measurements. The balance should also be properly warmed up to stabilize its internal components.

- Selecting Reference Weights: Reference weights, also known as calibration weights, are used as the standard for comparison during calibration. These weights should be traceable to national or international standards to ensure accuracy. The weights selected should cover the full weight capacity of the balance and match the resolution of the balance as closely as possible.

- Performing the Calibration: The calibration process involves placing the reference weights on the balance and comparing the balance’s readings to the known values of the weights. The readings should ideally match the known values. If there are significant differences, adjustments may be required to correct any systematic errors. Some balances have built-in calibration functions, while others may require manual adjustments using calibration software or adjustment knobs.

- Verification and Documentation: Once the calibration process is complete, it is important to verify the accuracy and precision of the balance. This can be done by repeating the calibration process with different reference weights and comparing the results to ensure consistency. It is also crucial to document the calibration details, including the date, reference weights used, and any adjustments made. This documentation serves as a record of the balance’s performance and helps track its calibration history.

- Regular Calibration Schedule: Calibration is not a one-time process but should be performed at regular intervals. The frequency of calibration depends on various factors, including the balance’s usage, environmental conditions, and manufacturer recommendations. High-precision balances used in critical applications may require more frequent calibration than those used for general purposes.

It is worth noting that during the calibration process, it is important to minimize any external influences that can affect the accuracy of the measurements. This includes avoiding air drafts, vibrations, and temperature fluctuations in the calibration area. Additionally, proper handling and placement of the reference weights are necessary to ensure accurate readings.

Calibration should be performed by trained personnel who are familiar with the specific balance and calibration procedures. In cases where the balance shows consistent errors that cannot be corrected through calibration, professional servicing or repair may be needed.

In summary, the calibration process is an essential step in maintaining the accuracy and reliability of an electronic balance. It involves preparing the balance, selecting appropriate reference weights, performing the calibration, verifying the results, and documenting the details. Regular calibration at recommended intervals ensures that the balance continues to provide accurate and precise measurements, reducing the risk of errors in scientific experiments and industrial processes.

Uncertainty in Measurement

Uncertainty is an inherent component of any measurement, including those obtained from an electronic balance. It refers to the range of values within which the true value of a measured quantity is estimated to lie. Understanding and quantifying uncertainty is crucial for assessing the reliability and accuracy of the measurements obtained from the balance.

There are several factors that contribute to the uncertainty in measurements obtained from an electronic balance. One significant factor is the resolution or smallest unit of measurement of the balance. The readings provided by the balance are limited by its resolution, and any uncertainty associated with this resolution must be taken into consideration.

Another factor that contributes to uncertainty is the repeatability of measurements. Repeatability refers to the variation of measurements obtained under identical conditions. Even with a precise balance, there will always be slight differences between repeated measurements due to factors such as electronic noise, instrument drift, or ambient conditions. The standard deviation or range of these repeated measurements reflects the uncertainty associated with repeatability.

The uncertainty in the calibration of the balance also plays a role. Depending on the calibration method used and the accuracy of the reference weights, there may be associated uncertainties that need to be considered. The calibration certificate or documentation provided by the calibration service should specify these uncertainties.

Environmental conditions can impact the uncertainty of measurements. Temperature variations, air drafts, and vibrations can introduce additional sources of uncertainty. It is important to control and minimize these environmental factors to reduce their impact on the measurements obtained from the balance.

It is crucial to note that uncertainty is not an indication of measurement error. While uncertainty accounts for the range of possible values within which the true value is estimated to lie, it does not imply that the measured value is incorrect. Uncertainty provides a statistical estimate of the confidence in the measured value, considering all the sources of uncertainty.

To quantify and express uncertainty, various statistical methods and calculations can be employed, such as the calculation of standard deviation, confidence intervals, or expanded uncertainty. These methods help provide a numerical estimate of uncertainty, allowing for comparison and evaluation of the reliability of measurements obtained from different balances or laboratories.

Understanding and addressing uncertainty in measurement is crucial for making informed decisions based on the obtained data. It allows for the appropriate interpretation of results, consideration of potential variations, and propagation of uncertainties in subsequent calculations or analyses. By quantifying and accounting for uncertainty, users can enhance the accuracy, reliability, and traceability of their measurements.

Error Sources

When using an electronic balance, it is important to be aware of the various sources of error that can affect the accuracy and reliability of measurements. By understanding and addressing these error sources, users can minimize their impact and obtain more accurate results.

One common source of error is instrumental or systematic error. This type of error arises from the inherent limitations or biases of the electronic balance itself. It can be caused by factors such as misalignment of the balance, non-linearity of the sensor, or drift in the calibration. Regular calibration, maintenance, and adherence to proper usage techniques help minimize instrumental errors.

Another source of error is environmental factors. Temperature fluctuations, air drafts, and vibrations can all influence the measurement accuracy of the balance. These factors can introduce variations in the readings and compromise the precision and validity of the measurements. Minimizing these environmental influences by working in a controlled environment or using additional devices such as draft shields can reduce the impact of this error source.

Operator error is another important source of error that can affect the measurements. Improper sample handling, inaccurate taring of the balance, and inconsistent technique in placing samples on the balance can all contribute to measurement inaccuracies. Training operators in proper weighing techniques, ensuring adherence to standard operating procedures, and practicing good laboratory habits can help mitigate this type of error.

Sample characteristics can also introduce errors in measurement. For example, certain samples may have static charges that can affect the balance readings. Handling samples carefully, using appropriate sample holders, and taking precautions to minimize static charges can help mitigate this source of error.

Error can also arise from improper sample preparation or presentation. Using an incorrect sample size, uneven distribution of the sample on the balance pan, or improper sample containment can all lead to measurement errors. Following established sample preparation procedures and ensuring consistency in sample handling can help minimize these errors.

Another potential source of error is the use of inappropriate calibration weights. Using weights that are not properly calibrated or traceable to reliable standards can introduce measurement inaccuracies. It is important to use certified calibration weights and ensure they are properly maintained and calibrated.

Lastly, data entry and recording errors can introduce inaccuracies in measurements. Mistakes in recording or transcribing values can compromise the reliability of the data. Ensuring attention to detail and using electronic data management systems can help minimize data entry errors.

While it is not possible to completely eliminate errors, understanding the potential sources of error and taking appropriate precautions can help minimize their impact on measurements obtained from an electronic balance. Regular calibration, proper training, adherence to standard procedures, and attention to environmental conditions are all critical in obtaining accurate and reliable results.

Environmental Conditions

The environmental conditions in which an electronic balance is used can significantly impact its performance and the accuracy of the measurements obtained. Understanding and controlling these environmental factors are crucial for obtaining reliable and precise results.

Temperature fluctuations can have a significant effect on the balance’s performance. When the temperature changes, the materials within the balance, such as the load cell and electronic components, can expand or contract. This can lead to variations in the readings and compromise the accuracy of the measurements. Maintaining a stable temperature in the weighing area, using temperature-controlled chambers or dedicated rooms, can help minimize this source of error.

Air drafts are another environmental factor that can introduce uncertainties in measurement. Air movements, such as from open doors, windows, or air conditioning vents, can cause vibrations or disturbances that affect the balance’s stability. These vibrations can lead to fluctuating readings and reduced precision. Working in a draft-free area or using draft shields can help minimize the impact of air drafts on the balance.

Humidity is another factor that can affect the performance of an electronic balance. High levels of humidity can cause materials to absorb or release moisture, leading to changes in weight readings. It is important to work in a controlled humidity environment or use desiccant packs to minimize the effects of humidity on the balance.

Electrostatic charges can also impact the balance’s accuracy. Certain samples or environmental conditions can generate static charges, which can cause particles to cling to the weighing pan or influence the balance’s sensors. Using antistatic measures, such as grounding the balance and using antistatic containers or sample holders, can help mitigate the influence of electrostatic charges.

The location of the balance within the laboratory or workspace can also affect its performance. Placing the balance on a stable and level surface free from vibrations is crucial for obtaining accurate measurements. Avoiding placement near heavy machinery, foot traffic, or sources of electromagnetic interference can help maintain the stability and precision of the balance.

Lastly, it is worth noting that the balance itself may have specific environmental requirements specified by the manufacturer. It is important to follow these guidelines to ensure optimal performance and accurate measurements.

In summary, environmental conditions play a significant role in the performance of an electronic balance. Temperature fluctuations, air drafts, humidity, electrostatic charges, and the placement of the balance can all introduce errors and uncertainties in measurements. By controlling and minimizing these environmental factors, users can enhance the accuracy, repeatability, and reliability of the measurements obtained from the balance.

Maintenance and Care

Proper maintenance and care of an electronic balance are essential for its longevity, accuracy, and continued reliable performance. Regular maintenance routines and adherence to best practices help ensure optimal functionality and minimize errors in measurements.

Cleaning the balance is an important maintenance task. Accumulated dust, debris, or spills on the weighing pan or internal components can impact the balance’s performance. Regularly wiping down the balance with a soft, lint-free cloth and using a mild cleaning solution, if necessary, helps keep it clean and free from contaminants.

It is important to handle the balance with care to avoid damage or misalignment. Rough handling, dropping, or exposing the balance to excessive vibrations can affect its internal components, leading to measurement errors or even permanent damage. Proper handling techniques, such as lifting and moving the balance with caution, help maintain its integrity and performance.

Regular calibration is a crucial maintenance task that ensures the accuracy of the balance’s measurements. Calibration should be performed at regular intervals or as recommended by the manufacturer or calibration standards. Using certified weights or a calibration service, calibration ensures that the balance’s readings align with known values, enhancing the trustworthiness of the measurements obtained.

Periodic performance checks can also be conducted to evaluate the balance’s overall functionality and detect any deviations or drift from its calibrated state. These checks involve weighing objects of known weights and comparing the readings to the expected values. If significant discrepancies are observed, adjustments or professional servicing may be required.

Regular software updates, if applicable, are important to ensure that the balance’s firmware and software are up to date. These updates may include bug fixes, performance improvements, or enhancements to the balance’s features. Manufacturers often provide updates or firmware downloads on their websites, and following their recommendations helps ensure optimal function and compatibility.

In addition to regular maintenance, it is important to create an appropriate operating environment for the balance. This involves considering factors such as temperature, humidity, air drafts, and vibrations. Ideally, the balance should be placed in a clean, stable, and controlled environment with minimal external disturbances. Taking precautions to minimize environmental influences enhances the accuracy and reliability of the measurements obtained.

Proactive maintenance also includes having a reliable service and support system in place. Keeping in touch with the manufacturer or authorized service centers ensures access to technical assistance, repair services, or replacement parts when needed. Reporting any observed issues or anomalies promptly allows for timely resolution and prevents prolonged disruptions.

In summary, regular maintenance and care of an electronic balance are vital for its long-term performance and measurement accuracy. Cleaning, proper handling, regular calibration, periodic performance checks, software updates, and creating an appropriate operating environment all contribute to the balance’s optimal functionality. By maintaining the balance properly, users can maximize its lifespan, reliability, and accuracy, ensuring high-quality measurements for various applications.

Choosing the Right Electronic Balance

Selecting the appropriate electronic balance is crucial for obtaining accurate and reliable measurements in scientific, industrial, or laboratory settings. Several factors should be considered when choosing the right balance to ensure it meets the specific requirements of the application.

The first consideration is the weighing capacity of the balance. It is important to choose a balance with a capacity that is appropriate for the maximum weight range expected in the measurements. Selecting a balance with a capacity higher than the anticipated maximum weight allows for flexibility and prevents overloading, which can affect accuracy and balance performance.

The sensitivity or readability of the balance is another critical factor. Readability refers to the smallest weight difference that the balance can detect and display. Choosing a balance with higher sensitivity ensures the capability to measure smaller weight variations, leading to increased precision and accuracy.

Accuracy is also a key consideration. High-precision applications may require balances with better accuracy specifications. It is important to review the specifications provided by the manufacturer, such as the balance’s linearity, repeatability, and uncertainties, to ensure they align with the desired measurement requirements.

The type of samples to be weighed should also be considered. If the samples are corrosive or reactive, it is important to choose a balance constructed with suitable materials that can withstand such conditions. Additionally, specialized sample holders or containers may be necessary to ensure accurate and safe measurements.

The physical dimensions and form factor of the balance should be compatible with the available workspace. Consideration should be given to the size of the weighing pan, the overall footprint, and any additional features or accessories that may be required for specific applications.

Ease of use and user interface are important factors, especially for routine weighing tasks. A well-designed user interface with intuitive controls and an informative display can improve efficiency and user experience. Features such as touchscreen operation, customizable settings, and multiple weighing units can enhance usability.

Consideration should also be given to the connectivity options available with the balance. USB, Bluetooth, or Wi-Fi connectivity allows for easy data transfer to external devices or computer systems. Compatibility with data management software or integration with laboratory information management systems (LIMS) can further streamline workflows and data analysis.

Finally, budgetary constraints should be taken into account. Balances with higher specifications and features often come with a higher price tag. It is important to strike a balance between the required performance and the available budget to ensure a cost-effective solution.

In summary, when choosing the right electronic balance, factors such as weighing capacity, sensitivity, accuracy, sample compatibility, physical dimensions, user interface, connectivity options, and budget should be carefully considered. By evaluating these factors and aligning them with the specific needs of the application, users can select a balance that provides accurate, reliable, and efficient weighing for their intended purposes.

Summary

An electronic balance is a valuable tool for accurate and precise measurements in various scientific, industrial, and laboratory applications. Understanding the factors that affect its precision, such as instrument quality, handling techniques, sample characteristics, and environmental conditions, is vital for obtaining reliable results.

The sensitivity of an electronic balance determines its ability to detect small weight differences, while accuracy refers to how close the measured values are to the true values. Calibration is a crucial process to ensure the balance’s accuracy, and regular calibration using certified weights is essential.

Uncertainty is an inherent part of any measurement and should be considered to assess the reliability of the obtained results. Sources of error, such as instrumental limitations, environmental factors, operator errors, and improper sample handling, should be minimized through proper maintenance, care, and adherence to best practices.

Choosing the right electronic balance involves considering factors such as weighing capacity, sensitivity, accuracy, sample compatibility, user interface, connectivity options, and budget. By carefully evaluating these factors, users can select a balance that meets their specific requirements and provides accurate and efficient weighing.

In summary, understanding the precision, sensitivity, accuracy, uncertainty, error sources, maintenance requirements, and selection criteria is essential for maximizing the performance and reliability of an electronic balance. By implementing proper handling techniques, regular calibration, and maintenance routines, and creating an appropriate environment, users can ensure accurate and precise measurements, enhancing the integrity of their work.