What is Automation Control?

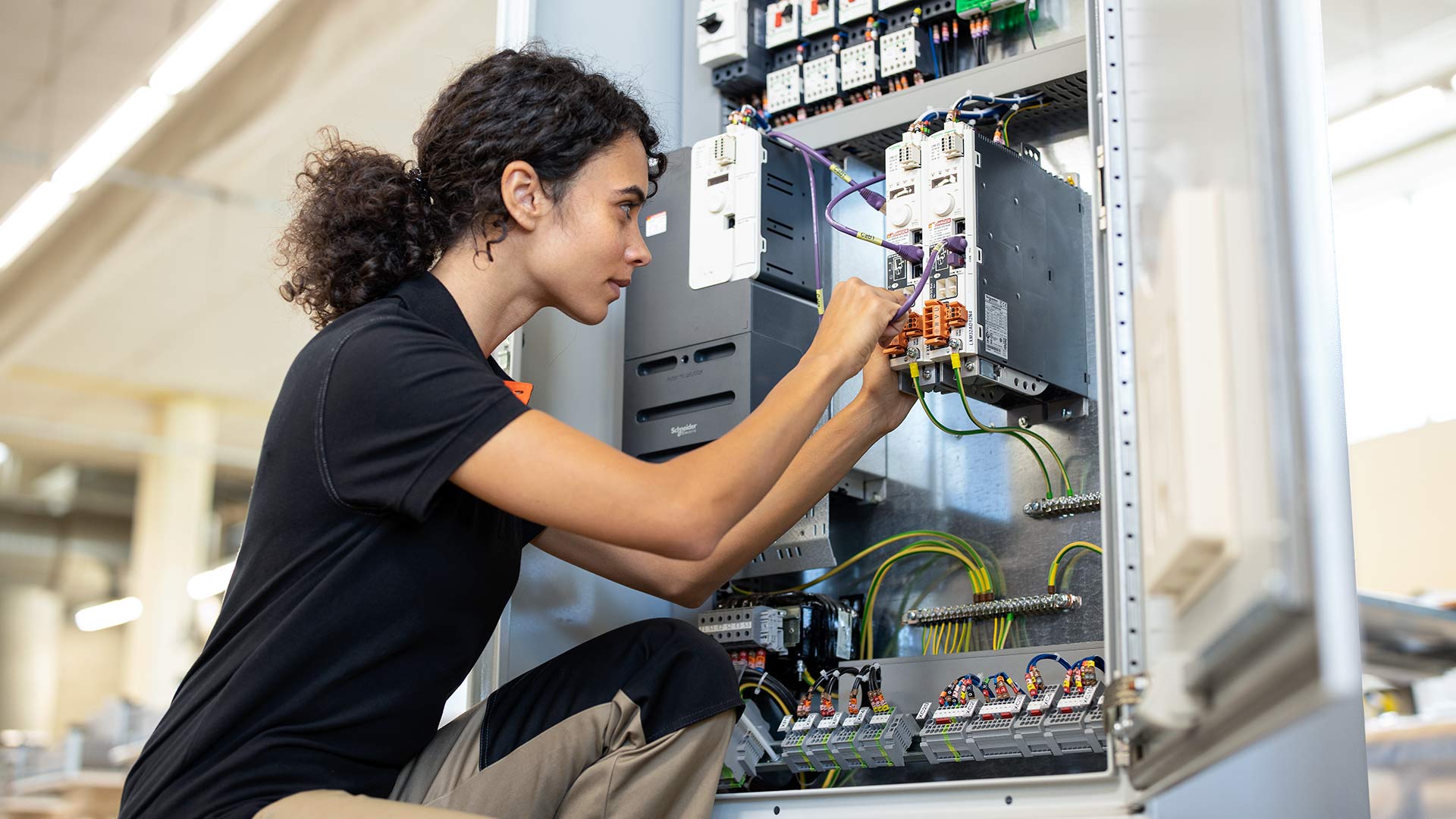

Automation control refers to the process of using technology to monitor and manage the operations of various systems and equipment in an automated manner. It involves the use of software, hardware, and sensors to regulate and control different processes, eliminating the need for manual intervention.

Automation control systems are designed to improve efficiency, precision, and reliability in a wide range of industries, from manufacturing and production to transportation and infrastructure. By automating tasks and workflows, businesses can streamline their operations, reduce costs, and increase productivity.

At its core, automation control involves the integration of sensors, actuators, and controllers to collect data, make decisions, and execute actions. These systems often rely on programmable logic controllers (PLCs) or distributed control systems (DCS) to control and monitor the operation of machines, processes, or entire production lines.

Automation control can be found in various applications, such as industrial automation control, building automation control, and process automation control. In industrial settings, automation control systems are utilized to manage manufacturing processes, assembly lines, and quality control. Building automation control systems, on the other hand, control and regulate lighting, HVAC systems, and security features in commercial and residential buildings.

Process automation control is commonly used in industries like chemical, oil and gas, and pharmaceuticals to monitor and control complex processes, ensuring consistency, safety, and efficiency.

Overall, automation control plays a crucial role in modern industries by optimizing operations, improving safety, and enhancing overall productivity. It eliminates human error, reduces manual labor, and enables faster and more accurate decision-making. With the advancement of technology, automation control is becoming increasingly sophisticated, paving the way for even more efficient and intelligent systems in the future.

How Does Automation Control Work?

Automation control systems work by incorporating various technologies and components to monitor and regulate the operation of machines, processes, or entire systems. The process involves the collection of data, analysis of that data, and the execution of actions based on the analysis. Here’s a breakdown of how automation control works:

1. Data Collection: In an automation control system, sensors or other data collection devices are used to gather information from the target system. These sensors can measure parameters like temperature, pressure, flow rate, or position. The collected data is then sent to a central control system for analysis.

2. Data Analysis: The collected data is processed and analyzed by the control system using algorithms and predefined rules. The purpose of this analysis is to detect any anomalies, deviations, or patterns in the data that could indicate a need for action or intervention.

3. Decision Making: Based on the analysis, the control system makes decisions regarding the actions that need to be taken. These decisions are often made by comparing the collected data to established thresholds or set points. For example, if the temperature rises above a certain level, the system might trigger cooling mechanisms to bring it back to the desired range.

4. Action Execution: Once the decisions are made, the control system executes the necessary actions to regulate or adjust the target system. This can involve activating or deactivating certain equipment, adjusting parameters, or sending commands to actuators that control the physical operation of the system.

5. Feedback Loop: Automation control systems typically have a feedback loop to ensure continuous monitoring and adjustment. The feedback loop involves collecting data on the actions taken and the resulting effects. This feedback is then used to further improve the control system’s performance and accuracy.

Automation control systems can range from simple setups with basic control logic to complex systems utilizing artificial intelligence and machine learning algorithms. The level of sophistication depends on the complexity of the system being controlled and the desired level of automation.

Overall, automation control works by collecting data, analyzing it to make informed decisions, and executing actions to regulate and optimize the operation of various systems. It enables businesses to improve efficiency, reduce errors, and achieve consistent and reliable performance.

Types of Automation Control Systems

Automation control systems come in various types, each designed to cater to different industries and applications. Here are some of the most common types:

- Programmable Logic Controllers (PLCs): PLCs are widely used in industrial automation control systems. They are specialized computers that can be programmed to control and monitor various processes and machinery. PLCs are known for their reliability, ruggedness, and ability to handle complex tasks in real-time.

- Distributed Control Systems (DCS): DCS are used in large-scale industrial processes, such as chemical plants or power generation facilities. Unlike PLCs, DCS distribute control functions across multiple controllers, allowing for greater flexibility and scalability. DCS systems are known for their ability to handle extensive networks and manage complex process control requirements.

- Supervisory Control and Data Acquisition (SCADA) Systems: SCADA systems are commonly used in industries where real-time monitoring and control of geographically dispersed equipment and processes is required. SCADA systems provide a graphical interface that allows operators to monitor and control the processes remotely. They are often used in industries such as oil and gas, water treatment, and transportation.

- Building Automation Systems (BAS): BAS are used to control and regulate the various systems within a building, such as heating, ventilation, air conditioning, lighting, and security. These systems are designed to optimize energy efficiency, provide occupant comfort, and ensure the safety and security of the building.

- Robotics and Motion Control Systems: Robotics and motion control systems are used in manufacturing and industrial processes that involve robotic arms, conveyor systems, or other automated machinery. These systems provide precise control over the movement and operation of the equipment, ensuring accuracy and efficiency in production.

Additionally, there are specialized automation control systems for specific industries, such as healthcare, automotive, and aerospace, which have their unique requirements and challenges. For example, in the healthcare industry, there are automation control systems used in medical equipment, patient monitoring, and pharmaceutical production.

The choice of automation control system depends on factors such as the industry, the complexity of the process, the level of automation required, and budget considerations. Regardless of the type of system, the ultimate goal of automation control is to improve efficiency, productivity, and safety in various industrial and commercial applications.

Components of Automation Control Systems

Automation control systems consist of various components that work together to monitor and regulate the operation of machines, processes, or systems. These components provide the necessary functionality for automation and ensure smooth and efficient control. Here are some essential components found in automation control systems:

- Sensors and Actuators: Sensors are devices that measure physical quantities, such as temperature, pressure, or position, and convert them into electrical signals. Actuators, on the other hand, are devices that convert electrical signals into physical action, such as the movement of a motor or the opening of a valve. Sensors and actuators are the backbone of automation control systems as they enable the collection of data and the execution of actions based on that data.

- Controllers: Controllers are responsible for processing the data and making decisions based on predefined algorithms and rules. They receive input from sensors, interpret the data, and calculate the appropriate actions to be taken. Controllers can be hardware-based, such as programmable logic controllers (PLCs) or distributed control systems (DCS), or software-based, such as computer-based control systems or embedded systems.

- HMI (Human-Machine Interface): The HMI is the user interface component of the automation control system that allows operators to interact with the system. It provides a graphical representation of the control system, displaying data, status information, alarms, and control options. The HMI allows operators to monitor the system in real-time, make manual adjustments if necessary, and review historical data.

- Communication Networks: Communication networks facilitate the exchange of data between different components of the automation control system. These networks can be wired or wireless and use protocols such as Ethernet, Modbus, Profibus, or DeviceNet. The communication network ensures that data is transferred reliably and efficiently, enabling real-time monitoring and control.

- Software: Software plays a significant role in automation control systems, providing the logic and algorithms needed for data analysis, decision making, and action execution. It allows for the configuration, programming, and customization of the control system. In addition, software can also include advanced features like data logging, trend analysis, and alarm management.

Other components that can be found in automation control systems include power supplies, relays, motors, drives, and safety devices. These components work together to ensure the efficient and safe operation of the automated processes.

It’s important to note that the specific components used in an automation control system can vary depending on the industry, application, and complexity of the system. Choosing the right components and integrating them effectively is crucial for the success of an automation control system.

Advantages of Automation Control

Automation control offers numerous benefits to businesses across a wide range of industries. By incorporating technology and streamlining processes, automation control systems provide advantages in terms of efficiency, accuracy, productivity, and safety. Here are some of the key advantages:

- Increased Efficiency: Automation control eliminates the need for manual intervention in repetitive or time-consuming tasks. By automating these processes, businesses can achieve higher efficiency levels, reducing the time and resources required to complete tasks. This leads to increased productivity and cost savings.

- Improved Accuracy and Precision: Automation control systems operate with a high degree of accuracy and precision, minimizing errors and inconsistencies. These systems rely on sensors and algorithms to collect data and make decisions, eliminating human errors that can occur in manual operations. With improved accuracy, businesses can ensure consistent and high-quality outputs.

- Enhanced Productivity: Automation control systems can handle repetitive tasks, complex calculations, and data analysis much faster than humans. This allows businesses to increase their productivity by automating time-consuming or difficult processes. Employees can then focus on more critical tasks that require human creativity and decision-making skills.

- Increased Safety: Automation control minimizes the exposure of workers to hazardous environments or risky tasks. By automating processes that involve dangerous or physically demanding tasks, businesses can improve workplace safety and reduce the risk of accidents or injuries. Automation control systems can also incorporate safety features such as emergency shutdowns or alarms to ensure a safe working environment.

- Cost Savings: While there may be an upfront investment in automation control systems, the long-term cost savings are significant. Automation reduces the need for human labor, decreases human error-related expenses, and optimizes resource utilization. It can lead to lower production costs, improved energy efficiency, and reduced waste, resulting in overall cost savings for businesses.

- Flexibility and Scalability: Automation control systems are highly flexible and scalable, allowing businesses to adapt to changing production demands and requirements. These systems can be easily reprogrammed, reconfigured, or expanded to accommodate new processes, product lines, or increased production volumes. This provides businesses with the agility to respond to market changes and scale their operations as needed.

The advantages of automation control extend across various industries, including manufacturing, healthcare, transportation, and energy. As technology advances and automation control systems become more sophisticated, the benefits will continue to grow, enabling businesses to stay competitive in a rapidly evolving marketplace.

Challenges in Automation Control

While automation control offers numerous advantages, implementing and maintaining an effective automation control system also comes with its fair share of challenges. It’s important for businesses to be aware of these challenges to ensure a successful automation integration. Here are some common challenges in automation control:

- Initial Investment: One of the primary challenges of implementing automation control is the upfront cost. Purchasing and installing the necessary hardware, software, and systems can be a significant initial investment. Businesses need to carefully assess and justify the costs, considering the long-term benefits and return on investment.

- Complexity of Integration: Integrating automation control systems into existing workflows and processes can be complex. It requires expertise in areas such as system design, software programming, and process optimization. Businesses may need to invest in training or seek assistance from outside experts to ensure a smooth integration and minimize disruptions to operations.

- Interoperability and Compatibility: Automation control systems often consist of multiple components from various manufacturers. Ensuring interoperability and compatibility between these components can be a challenge. Businesses need to carefully select components that work well together and rely on established industry standards to ensure seamless integration.

- Maintenance and Upkeep: Automation control systems require regular maintenance and updates to ensure their continuous and reliable operation. This includes monitoring system performance, conducting preventive maintenance, and keeping up with evolving technology and software updates. Businesses need to allocate resources and establish maintenance protocols to keep the automation control system running optimally.

- Employee Training and Adaptation: Introducing automation control systems often requires employees to acquire new skills or adapt to new ways of working. Training employees on how to operate and interact with the automation control system is crucial for success. Businesses need to ensure proper training programs and ongoing support to help employees navigate the changes effectively.

- Data Security and Cybersecurity: Automation control systems rely on data collection, storage, and communication. Protecting the integrity and security of this data is paramount. Businesses need to implement robust cybersecurity measures, including firewalls, encryption, user authentication, and regular vulnerability assessments, to safeguard sensitive information from unauthorized access or malicious activities.

Overcoming these challenges requires careful planning, collaboration, and a proactive approach to address any issues that may arise. With proper strategy and management, businesses can successfully navigate these challenges and unlock the full potential of automation control systems.

Industries that Use Automation Control

Automation control has broad applications across numerous industries, playing a vital role in improving efficiency, productivity, and safety. Here are some industries that extensively utilize automation control systems:

- Manufacturing: The manufacturing industry has been a pioneer in adopting automation control systems. Automation control is used in various manufacturing processes, including assembly lines, quality control, and inventory management. By automating repetitive tasks and optimizing production workflows, manufacturers can achieve higher production rates, reduce errors, and enhance overall productivity.

- Energy and Utilities: The energy and utilities sector relies heavily on automation control systems for monitoring and managing power generation, distribution, and consumption. Automation control is employed in power plants, smart grids, and water treatment facilities to optimize energy efficiency, ensure uninterrupted supply, and improve the overall reliability of energy infrastructure.

- Pharmaceuticals and Healthcare: The pharmaceutical and healthcare industries utilize automation control systems in various capacities. Automation control is employed in pharmaceutical manufacturing processes to maintain precise dosages, ensure product quality, and enhance safety. In healthcare, automation control is utilized in medical equipment, patient monitoring systems, and drug dispensing systems, improving accuracy and patient care.

- Transportation and Logistics: Automation control is integral to transportation and logistics operations. It is used in automated warehouses, sorting and tracking systems, and autonomous vehicles. Automation control helps streamline operations, improve supply chain efficiency, and enable real-time tracking and management of goods and vehicles.

- Chemical and Process Industries: The chemical and process industries heavily rely on automation control to regulate complex and potentially hazardous processes. Automation control systems ensure precise control of temperature, pressure, flow rates, and chemical reactions, minimizing human error and ensuring safety. These systems are crucial for maintaining consistent quality, improving efficiency, and reducing risks associated with hazardous materials.

- Automotive: Automation control plays a significant role in the automotive industry, enabling efficient manufacturing processes, quality control, and automated assembly lines. Automation control systems are used for precision-based tasks like welding, painting, and robotic assembly, resulting in improved production speed, product quality, and overall cost-effectiveness.

These are just a few examples of the industries that heavily rely on automation control systems. However, automation control has applications in various other sectors as well, including aerospace, agriculture, telecommunications, and retail. As technology continues to advance, we can expect to see further integration of automation control systems across an even wider range of industries.

Career Opportunities in Automation Control

The growing adoption of automation control systems has led to an increased demand for skilled professionals in this field. The field of automation control offers a wide range of career opportunities across various industries. Here are some of the key roles and positions in automation control:

- Automation Engineer: Automation engineers are responsible for designing, developing, and implementing automation control systems. They work on system integration, programming, and troubleshooting to ensure the smooth operation of automated processes. Automation engineers need a strong understanding of control systems, programming languages, and industrial protocols.

- Control Systems Engineer: Control systems engineers specialize in designing, testing, and implementing control strategies for automation systems. They are involved in selecting and configuring components, developing control algorithms, and optimizing system performance. Control systems engineers also work on system modeling and simulation to determine optimal control parameters.

- PLC Programmer: PLC programmers focus on programming and configuring programmable logic controllers (PLCs) used in automation control systems. They develop ladder logic or structured text code to control and monitor various processes or machinery. PLC programmers should have a sound understanding of PLC programming languages, hardware configurations, and industrial automation standards.

- SCADA Engineer: SCADA (Supervisory Control and Data Acquisition) engineers specialize in the design and implementation of SCADA systems used for real-time monitoring and control. They configure SCADA software, develop HMI (Human-Machine Interface) screens, and establish communication protocols between field devices and the SCADA system.

- Robotics Engineer: Robotics engineers work on automation control systems that involve robotic arms, automated guided vehicles (AGVs), or other robotic systems. They design, program, and implement robotic control systems, ensuring smooth movement and precise operation. Robotics engineers need a strong knowledge of robotic kinematics, programming languages, and sensor integration.

- Industrial Maintenance Technician: Industrial maintenance technicians are responsible for the installation, troubleshooting, and maintenance of automation control systems. They perform regular inspections, repair faulty components, and ensure the proper functioning of the automation equipment. Industrial maintenance technicians should have a strong background in electrical systems, troubleshooting, and equipment calibration.

These are just a few examples of the career opportunities in automation control. Additional roles include automation project managers, system integrators, instrumentation technicians, and quality control engineers. As automation continues to evolve, new career opportunities are likely to emerge.

A strong foundation in engineering, computer science, or a related field is typically required for a career in automation control. Ongoing professional development, staying updated with the latest technologies, and obtaining industry certifications can also enhance job prospects in this field.

With the increasing demand for automation control systems, pursuing a career in this field presents excellent opportunities for professional growth and advancement.

Recent Developments in Automation Control

The field of automation control continues to evolve rapidly, driven by advancements in technology and the demand for increased efficiency and productivity. Here are some of the recent developments in automation control:

- Artificial Intelligence (AI) and Machine Learning: Automation control systems are increasingly incorporating AI and machine learning algorithms. These technologies enable systems to learn from data, adapt to changing conditions, and make intelligent decisions. AI-powered automation control systems can optimize processes, predict failures, and automatically adjust parameters for maximum efficiency.

- Internet of Things (IoT) Integration: The integration of automation control systems with the Internet of Things (IoT) has expanded possibilities in remote monitoring, control, and data analysis. IoT sensors and devices enable the collection of real-time data from various sources, allowing for more comprehensive monitoring and analysis. This integration enhances the ability of automation control systems to improve efficiency and optimize performance.

- Cloud Computing: Cloud computing has revolutionized automation control by providing a flexible and scalable infrastructure for data storage, processing, and analysis. Automation control systems can leverage cloud-based platforms to store and access vast amounts of data. Cloud computing also enables remote access to automation control systems, allowing for real-time monitoring and control from anywhere in the world.

- Edge Computing: Edge computing has emerged as a solution to process data closer to the source, reducing latency and enabling faster decision-making in automation control systems. By processing data at the edge of the network, in close proximity to where it is generated, edge computing improves the speed and efficiency of automation control systems, especially in real-time applications and critical processes.

- Cybersecurity and Industrial Control Systems (ICS) Protection: As automation control systems become more interconnected and reliant on digital technologies, the need for robust cybersecurity measures has become paramount. Recent developments in cybersecurity address the unique challenges of protecting industrial control systems (ICS). Enhanced security frameworks, secure communication protocols, and increased focus on training and awareness have been key developments to protect automation control systems from cybersecurity threats.

- Collaborative Robotics: Collaborative robots, or cobots, are designed to work alongside humans, assisting and collaborating with them in tasks that require both manual dexterity and automation control. These robots are equipped with advanced sensors, safety features, and programming capabilities that allow them to work harmoniously with humans, improving productivity and safety in industrial settings.

These recent developments are shaping the future of automation control, enabling more intelligent, interconnected, and efficient systems. As technologies continue to advance, automation control is expected to become more sophisticated, adaptive, and integral to various industries.