What Is an Electronic Ignition?

An electronic ignition system is an important component of modern automotive engines. It replaces the traditional contact breaker points used in older ignition systems. The primary function of an electronic ignition system is to generate and deliver the high-voltage spark necessary to ignite the air-fuel mixture in the engine’s combustion chamber.

Unlike the older mechanical systems, an electronic ignition system does not rely on physical contact between moving parts to initiate spark. Instead, it utilizes solid-state components such as transistors, control modules, and sensors to accurately control the timing and intensity of the spark.

By using electronic technology, this system offers several advantages over conventional ignition systems, including improved engine performance, better fuel efficiency, and reduced maintenance requirements.

One of the key benefits of an electronic ignition system is the ability to provide a more accurate and reliable spark. The electronic components ensure precise timing of the spark, resulting in better combustion and increased power output. Additionally, the system can adjust the spark timing based on various engine operating conditions, such as engine speed and load, to optimize performance and fuel economy.

Another advantage of electronic ignition systems is their extended lifespan and decreased maintenance needs. Unlike the mechanical contact points that wear out over time, electronic ignition components are more durable and require less frequent replacement. This translates into lower maintenance costs for vehicle owners.

An electronic ignition system also enhances the overall reliability of the ignition process. The absence of physical contact means that there is less chance of wear and tear, reducing the risk of ignition failure. This can be particularly beneficial in harsh environments or extreme weather conditions where traditional ignition systems may struggle to function properly.

Furthermore, electronic ignition systems are compatible with a wide range of fuel types, including unleaded gasoline, ethanol blends, and even alternative fuels like compressed natural gas (CNG) or liquefied petroleum gas (LPG). This versatility allows vehicles equipped with electronic ignition systems to adapt to changing fuel availability and environmental regulations.

How Does an Electronic Ignition Work?

An electronic ignition system operates by controlling the timing and intensity of the spark that ignites the air-fuel mixture in the engine’s combustion chamber. It consists of several key components that work together to ensure optimal ignition performance.

The heart of the electronic ignition system is the ignition control module (ICM) or ignition control unit (ICU). This module acts as the brain, monitoring various engine parameters and determining the spark timing based on the inputs received from sensors. The ICM uses this information to trigger the ignition coil, which in turn generates the high-voltage spark necessary for combustion.

The ignition coil is responsible for transforming the low voltage supplied by the battery into the high voltage required to create a spark. It does this through a process called induction, where the primary coil winding generates a magnetic field that collapses suddenly, inducing a high voltage in the secondary coil winding. This high-voltage output is then sent to the spark plugs through the spark plug wires.

The spark plugs are integral to the ignition system as they create the actual sparks that ignite the air-fuel mixture. Each cylinder in the engine has its own spark plug, and the timing of the spark is crucial for optimal engine performance. The ICM determines the precise timing of the spark based on inputs from the engine’s sensors, such as the crankshaft position sensor and the camshaft position sensor.

The electronic ignition system relies on various sensors to gather information about the engine’s operating conditions and adjust the spark timing accordingly. For example, the crankshaft position sensor detects the position and speed of the crankshaft, providing data on the engine’s rotational speed. The camshaft position sensor monitors the position of the camshaft, helping to determine the position of the engine’s valves.

In addition to these components, the electronic ignition system also includes other essential elements such as the power transistor module, capacitor, and diodes, which ensure smooth operation and protect the system from voltage spikes and surges.

Overall, the electronic ignition system continuously monitors and adjusts the spark timing based on the input from sensors. This precision control allows for efficient combustion, improved fuel economy, and better overall engine performance.

Advantages of Electronic Ignition Systems

Electronic ignition systems offer several advantages over traditional mechanical ignition systems. These advancements in technology have revolutionized the way engines start and run, providing improved performance, efficiency, and reliability. Here are some of the key advantages of electronic ignition systems:

1. Enhanced Engine Performance: Electronic ignition systems provide more accurate and consistent spark timing, resulting in better combustion and increased power output. This leads to improved engine performance, smoother acceleration, and enhanced overall drivability.

2. Improved Fuel Efficiency: By precisely controlling the ignition timing, electronic ignition systems optimize the combustion process, ensuring that the air-fuel mixture ignites at the most efficient time. This leads to better fuel economy, helping drivers save money on fuel costs and reduce their environmental impact.

3. Increased Durability and Reliability: Unlike mechanical ignition systems that rely on moving parts that can wear out over time, electronic ignition systems are built with solid-state components that are more durable and reliable. This reduces the risk of ignition failures and extends the lifespan of the system.

4. Consistent Spark Output: Electronic ignition systems deliver a consistent and reliable spark to the spark plugs, regardless of engine operating conditions. This ensures consistent combustion throughout the engine’s RPM range, resulting in smooth engine performance and reduced emissions.

5. Compatibility with Modern Fuels: Electronic ignition systems are designed to be compatible with a wide range of fuels, including unleaded gasoline, ethanol blends, and alternative fuels like CNG and LPG. This makes them adaptable to changing fuel availability and environmental regulations.

6. Reduced Maintenance Requirements: Electronic ignition systems require less maintenance compared to mechanical systems. There are no contact breaker points to replace or adjust, minimizing the need for regular maintenance and reducing overall maintenance costs.

7. Improved Cold Starting: Electronic ignition systems provide a stronger and more consistent spark, making cold starting easier even in harsh weather conditions. This ensures reliable engine starting, particularly during winter months.

Overall, electronic ignition systems offer numerous benefits for vehicle owners, including improved engine performance, increased fuel efficiency, enhanced reliability, and reduced maintenance requirements. These advantages have contributed to the widespread adoption of electronic ignition systems in modern automotive engines.

Components of an Electronic Ignition System

An electronic ignition system is comprised of several key components that work together to provide precise control over the ignition process. Understanding these components is essential in troubleshooting and maintaining the system. Here are the main components of an electronic ignition system:

1. Ignition Control Module (ICM): The ICM is the brain of the electronic ignition system. It receives inputs from various sensors and determines the optimal timing and intensity of the spark. The ICM controls the ignition coil and ensures accurate spark delivery.

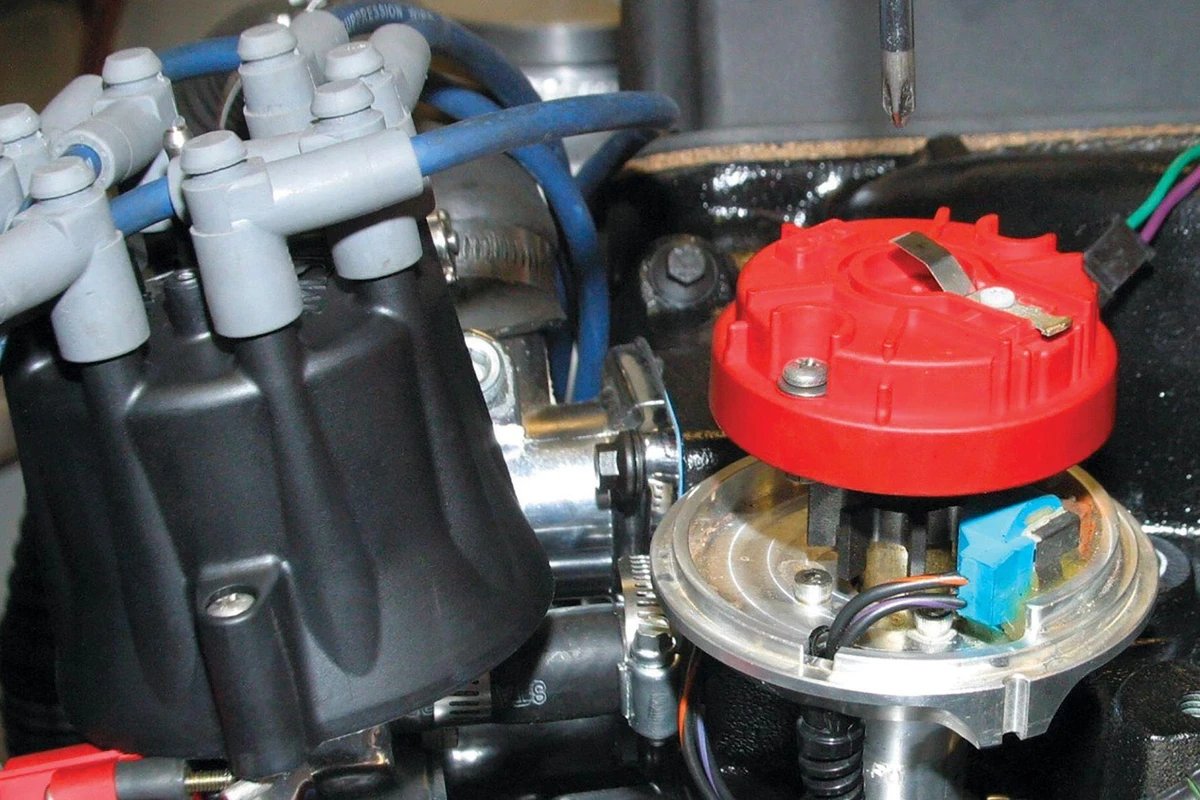

2. Ignition Coil: The ignition coil is responsible for transforming the low voltage from the battery into a high-voltage spark. It consists of primary and secondary windings that work together to produce the necessary energy for ignition. The ignition coil is connected to the ICM and the spark plugs through high-tension wires.

3. Sensors: Electronic ignition systems utilize various sensors to gather information about engine operating conditions. These sensors include the crankshaft position sensor, camshaft position sensor, throttle position sensor, coolant temperature sensor, and oxygen sensor. The data collected by these sensors allows the ICM to adjust the spark timing for optimal performance and fuel efficiency.

4. Power Transistor Module (PTM): The PTM is responsible for controlling the flow of current to the ignition coil. It acts as an electronic switch, ensuring that the coil receives the necessary voltage at the right time to produce a spark. The PTM is controlled by the ICM based on the inputs received from the sensors.

5. Spark Plugs: Spark plugs are crucial components in the ignition system, as they create the spark that ignites the air-fuel mixture. Each cylinder in the engine has its own spark plug, and their condition and proper gap setting are essential for optimum ignition performance.

6. Wiring Harness: The wiring harness connects all the components of the electronic ignition system, allowing for the flow of electrical signals and power. It is essential to ensure that the wiring harness is properly connected and free from any damage or corrosion.

7. Capacitor and Diodes: These components help to protect the system from voltage spikes and surges by acting as voltage regulators. They help maintain a consistent and stable power supply to the ignition system, preventing damage to the sensitive electronic components.

By understanding the function and operation of each of these components, it becomes easier to diagnose and resolve any issues that may arise with the electronic ignition system. Regular inspection and maintenance of these components can ensure the system’s optimal performance and reliability.

Types of Electronic Ignition Systems

There are several different types of electronic ignition systems that have been developed over the years. Each type has its own unique design and method of generating and controlling the ignition spark. Here are some of the most common types of electronic ignition systems:

1. Capacitive Discharge Ignition (CDI) System: CDI systems store energy capacitively and release it in a rapid discharge, thereby generating a high-intensity spark. They typically use a separate ignition coil and discharge module to generate the spark. CDI systems are known for their high energy output and reliable performance.

2. Inductive Discharge Ignition (IDI) System: IDI systems are widely used in modern vehicles. They use an ignition coil and an electronic control module to generate the spark. These systems rely on the inductive discharge of the ignition coil to produce the high voltage needed for ignition. IDI systems are known for their simplicity and efficiency.

3. Distributorless Ignition System (DIS): DIS systems eliminate the need for a distributor by using multiple ignition coils, each mounted directly on the spark plug. These systems are controlled by an electronic control module that coordinates the timing and firing of each coil. DIS systems offer better ignition performance, improved fuel efficiency, and reduced maintenance requirements.

4. Direct Ignition System (DIS): Similar to DIS systems, DIS systems also eliminate the distributor. However, in DIS systems, each spark plug has its own dedicated ignition coil. This allows for more precise control over the ignition timing and eliminates the need for spark plug wires. DIS systems are commonly found in newer vehicles and offer improved engine performance and reliability.

5. Optical Triggering Ignition System: Optical triggering systems use optical sensors and a rotating shutter to determine the position of the engine’s crankshaft. Based on this information, the system controls the timing of the spark. These systems provide accurate and reliable ignition timing and are commonly used in high-performance applications.

6. Magnetic Triggering Ignition System: Magnetic triggering systems use a magnetic sensor, such as a reluctor or Hall effect sensor, to detect the position of the engine’s crankshaft. This information is then used to control the timing of the spark. Magnetic triggering systems are known for their accuracy and durability and are widely used in a variety of engines.

Each type of electronic ignition system has its own advantages and considerations. Factors such as engine type, application, and desired performance can determine the most suitable system for a particular vehicle. Understanding the different types of electronic ignition systems can help in selecting the right system for an engine or diagnosing issues related to the ignition system.

Common Problems with Electronic Ignition Systems

While electronic ignition systems offer improved performance and reliability, they are not immune to issues that can arise over time. Here are some common problems that can occur with electronic ignition systems:

1. Ignition Coil Failure: The ignition coil can fail due to prolonged use, heat, or electrical issues. This can result in a weak or no spark, leading to engine misfires, rough idle, and difficulty starting the vehicle.

2. Faulty Sensors: Sensors play a critical role in the operation of electronic ignition systems. If a sensor becomes faulty or malfunctions, it can affect the timing and intensity of the spark. This can result in poor engine performance, decreased fuel efficiency, and an illuminated check engine light.

3. Wiring Issues: Wiring problems can occur in the electronic ignition system, leading to intermittent or no spark. Damaged or corroded wiring connections can cause disruptions in the electrical flow, affecting the performance of the ignition system. It is crucial to check the wiring harness regularly and address any signs of damage or deterioration.

4. Module Failure: The ignition control module (ICM) or other control modules within the system can fail due to age, heat, or electrical issues. When a module malfunctions, it can cause erratic timing, inconsistent spark output, or a complete loss of spark. This can result in engine performance issues and difficulty starting the vehicle.

5. Spark Plug Problems: Worn or fouled spark plugs can hinder the ignition process, leading to misfires, decreased power, and rough idling. It is important to regularly inspect and replace spark plugs as recommended by the vehicle manufacturer to ensure optimal ignition performance.

6. Power Supply Issues: A weak or fluctuating power supply to the ignition system can cause problems with spark generation and delivery. Issues such as a weak battery, a faulty alternator, or corroded battery terminals can disrupt the proper functioning of the ignition system.

7. High Voltage Leakage: In some cases, high voltage leakage can occur within the ignition system. This can be caused by damaged insulation, loose connections, or faulty components. High voltage leakage can result in weak sparks, misfires, and engine performance issues.

When encountering problems with the electronic ignition system, it is crucial to diagnose the specific issue and address it promptly. Seeking assistance from a qualified technician or conducting in-depth troubleshooting can help resolve the problem and restore the optimal performance of the ignition system.

Troubleshooting Electronic Ignition Systems

Troubleshooting electronic ignition systems can help identify and fix issues that may arise with the system. Here are some steps to follow when troubleshooting electronic ignition systems:

1. Check for Spark: Start by checking for a spark in order to determine if the ignition system is functioning properly. Remove a spark plug wire, insert a spark tester into the wire, and crank the engine. If there is no spark or a weak spark, there may be an issue with the ignition system.

2. Inspect Wiring and Connections: Examine the wiring harness and connections for any signs of damage, corrosion, or loose connections. Ensure that all connections are secure and in good condition. Repair or replace any damaged wiring or connections as necessary.

3. Test Sensors: Use a diagnostic tool to test the sensors in the ignition system. Check for proper voltage outputs and signals from the sensors. If any sensor readings are outside of the normal range, they may need to be replaced.

4. Check Ignition Coil: Test the ignition coil to ensure that it is generating the required voltage. Use a multimeter to measure the primary and secondary resistance of the coil. If the readings are outside of the manufacturer’s specifications, the ignition coil may need to be replaced.

5. Evaluate Control Module: Test the ignition control module (ICM) or other control modules in the system to verify their proper functionality. Follow the manufacturer’s instructions for testing and diagnosing the module. If the module is faulty, it may need to be replaced.

6. Inspect Spark Plugs: Remove and inspect the spark plugs for signs of fouling, wear, or damage. Replace any worn or damaged spark plugs. Ensure that the spark plug gap is set to the manufacturer’s specifications.

7. Check Battery and Charging System: Verify that the battery is fully charged and in good condition. Test the alternator output to ensure that it is providing sufficient voltage to the ignition system. A weak or faulty battery or alternator can cause ignition issues.

8. Verify Grounds: Ensure that all ignition system grounds are clean and properly connected. A poor or faulty ground connection can affect the performance of the ignition system.

9. Consult Service Manual: Refer to the vehicle’s service manual or technical specifications for specific troubleshooting steps and diagnostic procedures for the particular electronic ignition system in question. Follow the recommended guidelines for proper troubleshooting and repair.

By following these troubleshooting steps, it is possible to pinpoint and resolve issues with electronic ignition systems. However, if the problem persists or if you are not comfortable performing the troubleshooting yourself, it is recommended to seek assistance from a qualified technician or automotive professional.

Maintenance Tips for Electronic Ignition Systems

Maintaining an electronic ignition system is crucial for optimal performance and longevity. Here are some maintenance tips to keep your electronic ignition system in top shape:

1. Regular Inspection: Periodically inspect the wiring harness, connectors, and components of the ignition system for any signs of damage, wear, or corrosion. Repair or replace any damaged or deteriorated parts in a timely manner.

2. Clean Connections: Keep the connectors and terminals clean and free from corrosion or build-up. Use a wire brush or electrical contact cleaner to remove any dirt or corrosion that may hinder proper electrical connections.

3. Check Spark Plugs: Inspect the spark plugs regularly for fouling, wear, or damage. Clean or replace the spark plugs according to the manufacturer’s recommendations. Ensure that the spark plug gaps are correctly set for optimal performance.

4. Test Sensors: Use a diagnostic tool to test the sensors in the ignition system periodically. Check for proper voltage outputs and signal consistency. Replace any faulty or worn sensors as necessary to maintain accurate ignition control.

5. Maintain Battery Health: A weak or damaged battery can affect the performance of the electronic ignition system. Keep the battery terminals clean and tight. Test the battery voltage regularly and replace it if it fails to hold a charge or falls below the recommended voltage range.

6. Ensure Proper Grounding: Verify that all ground connections in the ignition system are secure and free from corrosion. Good grounding is essential for optimal electrical flow and system performance.

7. Use Quality Ignition Components: When replacing any ignition components, use high-quality parts that are recommended by the vehicle manufacturer. This helps ensure proper fit, function, and reliability of the ignition system.

8. Follow Service Intervals: Adhere to the recommended service intervals outlined in your vehicle’s owner’s manual or service schedule. This includes regular maintenance tasks such as oil changes, air filter replacement, and overall engine tune-ups, which can indirectly impact the performance of the ignition system.

9. Keep the Ignition System Clean: Clean the external surfaces of the ignition system components regularly to remove dirt, oil, or debris that may accumulate. This helps maintain proper heat dissipation and prevents potential contact issues.

10. Consult Professional Help: If you are unsure or uncomfortable performing maintenance tasks on the electronic ignition system, consult a qualified technician or automotive professional. They can provide expert guidance and perform necessary maintenance tasks correctly.

By following these maintenance tips, you can help ensure the longevity and reliable performance of your electronic ignition system. Regular inspection, cleaning, and upkeep will contribute to a properly functioning system, improving engine performance and minimizing the risk of ignition-related issues.

Upgrading to an Electronic Ignition System

Upgrading to an electronic ignition system can provide several benefits, including improved engine performance, enhanced fuel efficiency, and reduced maintenance requirements. Here are some important considerations for upgrading to an electronic ignition system:

1. Compatibility: Ensure that the electronic ignition system you are considering is compatible with your specific vehicle make and model. Some electronic ignition systems are designed for specific engine configurations or ignition types, so it is important to choose one that is suitable for your vehicle.

2. Research and Selection: Research different electronic ignition systems available in the market and choose one that suits your needs and budget. Look for reputable brands that have a track record of performance and reliability.

3. Professional Installation: Unless you have experience and expertise in automotive electrical systems, it is recommended to have the electronic ignition system professionally installed. This ensures that the system is correctly integrated with your vehicle’s existing wiring and components.

4. Engine Timing Adjustments: When upgrading to an electronic ignition system, it may be necessary to make adjustments to the engine’s timing. Consult the installation manual or seek professional assistance to ensure that the timing is set correctly for optimal performance and fuel efficiency.

5. Proper Calibration: Follow the manufacturer’s instructions for calibrating the electronic ignition system to your specific engine parameters. This may include adjusting the system’s settings, such as spark advance, idle speed, or fuel-to-air ratio, to achieve the best performance and efficiency.

6. Verify Sensor Compatibility: Electronic ignition systems often rely on various sensors to gather information about engine conditions. Ensure that the sensors in your vehicle are compatible with the new electronic ignition system. In some cases, you may need to replace or upgrade sensors to ensure proper functionality.

7. Retain Original Components: When upgrading to an electronic ignition system, it is advisable to keep the original components, such as the distributor and ignition coil, in case you decide to revert to the original ignition system in the future. This can be helpful if you encounter any compatibility issues or if you plan to sell the vehicle.

8. Follow Manufacturer’s Recommendations: Strictly adhere to the manufacturer’s recommendations for maintenance and servicing of the electronic ignition system. Regularly inspect and clean the system’s components, and replace any worn or damaged parts as needed.

Upgrading to an electronic ignition system can be a worthwhile investment, offering improved engine performance, better fuel efficiency, and reduced maintenance needs. By considering compatibility, seeking professional installation, and following proper calibration procedures, you can enjoy the benefits of this upgrade and enhance the overall driving experience of your vehicle.