How Does an Electronic Fuse Work?

An electronic fuse, also known as an e-fuse, is a device designed to protect electronic circuits from overcurrent or short circuit conditions. Unlike traditional fuses that use a physical element like a wire or a strip which melts under excessive current, electronic fuses utilize semiconductor devices to monitor and control the flow of current.

An electronic fuse consists of three main components: a current sensing element, a control circuit, and a power switching element. The current sensing element constantly monitors the current flowing through the circuit. When the current exceeds a predefined threshold, the control circuit triggers the power switching element to open and interrupt the current flow, protecting the rest of the circuit from damage.

One of the key advantages of electronic fuses is their speed of operation. Unlike traditional fuses that require physical elements to melt, electronic fuses utilize electronic components that can respond almost instantaneously to overcurrent conditions. This rapid response helps to minimize the damage to the circuit and the components connected to it, reducing downtime and repair costs.

Another important feature of electronic fuses is their resetability. Unlike traditional fuses that need to be replaced once they are blown, electronic fuses can be reset either automatically or manually after the fault condition has been resolved. This eliminates the need for frequent fuse replacements, making electronic fuses more cost-effective in the long run.

Electronic fuses also offer better precision and accuracy in current protection. They can be designed to provide precise current limiting, ensuring that only the excessive current is interrupted while allowing normal operating currents to pass through. This level of control not only protects the circuit but also safeguards the sensitive electronic components from damage.

In addition to overcurrent protection, electronic fuses can also provide additional features such as overvoltage protection and thermal protection. By incorporating these functionalities into a single device, electronic fuses offer comprehensive protection for electronic circuits, further enhancing their reliability and safety.

Advantages of Using an Electronic Fuse

Electronic fuses have gained popularity in various industries due to their numerous advantages over traditional fuses. Let’s explore some of the key benefits of using an electronic fuse:

Rapid Response: One of the significant advantages of electronic fuses is their quick response time. Unlike traditional fuses, which can take some time to melt and interrupt the circuit, electronic fuses can detect and react to overcurrent conditions almost instantaneously. This rapid response helps in preventing damage to the components and reducing downtime.

Resetability: Electronic fuses can be easily reset after the fault condition is resolved. This eliminates the need for frequent replacements and reduces maintenance costs. With a traditional fuse, once it blows, it needs to be replaced. In contrast, electronic fuses can be reset either automatically or manually, making them more convenient and cost-effective in the long run.

Precision and Accuracy: Electronic fuses offer precise current limiting, ensuring that only the excessive current is interrupted while allowing normal operating currents to pass through. This level of control helps to protect the circuit and sensitive electronic components from damage. Furthermore, electronic fuses can be designed to provide accurate and consistent current protection, ensuring consistent performance over time.

Compact Size: Electronic fuses are typically smaller and lighter than their traditional counterparts. This compact size makes them ideal for applications where space is limited, such as in portable electronic devices or densely packed circuit boards. The smaller size also allows for more flexibility in product design and layout.

Improved Reliability: With their advanced technology and comprehensive protection features, electronic fuses offer enhanced reliability for electronic circuits. They can provide not only overcurrent protection but also additional functions like overvoltage and thermal protection. This helps to safeguard the circuit and its components from various faults and potential damage.

Integration Possibilities: Electronic fuses can easily be integrated into larger electronic systems or circuit designs. They can be connected directly to microcontrollers or other control devices to provide real-time monitoring and protection. This integration capability makes them compatible with modern electronic applications and facilitates the development of smart and connected systems.

Types of Electronic Fuses

Electronic fuses come in various types to suit different applications and requirements. Let’s explore some of the common types of electronic fuses:

Resettable Fuses: Also known as polymeric positive temperature coefficient (PPTC) fuses, resettable fuses are designed to automatically reset once the fault condition is removed. They use a polymer-based material that acts as a temperature-sensitive resistor. When the current exceeds the threshold, the polymer heats up and increases its resistance, effectively limiting the current. Once the current returns to normal, the polymer cools down and restores its original low resistance, allowing the circuit to operate again.

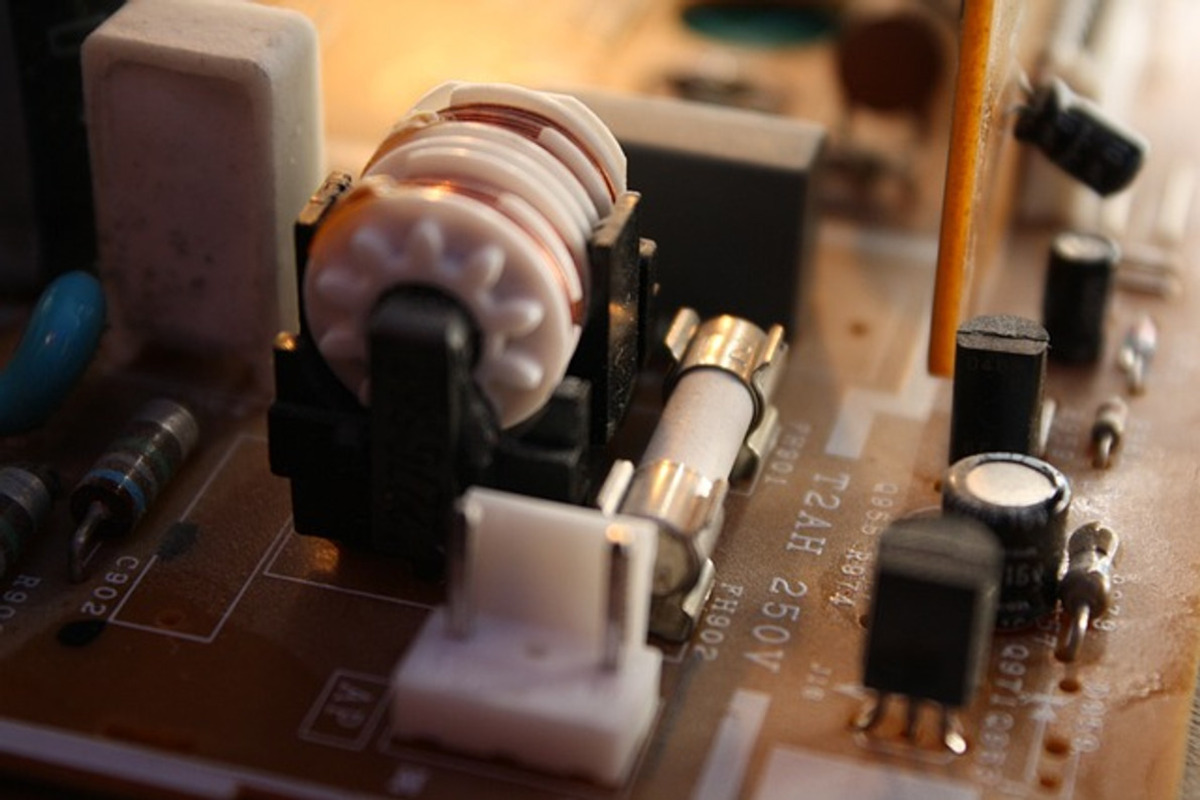

Fast-Acting Fuses: Fast-acting fuses are designed to respond quickly to overcurrent conditions. These fuses have a low melting point and a small thermal mass, enabling them to melt and interrupt the circuit rapidly when excessive current is detected. Fast-acting fuses are commonly used in applications where high-speed protection is required, such as in sensitive electronic devices or circuits.

Slow-Blow Fuses: Slow-blow fuses, also known as time-delay fuses, are designed to tolerate temporary overcurrent conditions. These fuses have a higher melting point and a larger thermal mass compared to fast-acting fuses. They are designed to withstand moderate overcurrent for a short duration before melting and interrupting the circuit. Slow-blow fuses are commonly used in applications where brief current surges or inrush currents are expected, such as in power supplies or motor control circuits.

Surface Mount Fuses: Surface mount fuses, as the name suggests, are designed to be directly mounted onto the surface of a printed circuit board (PCB). These fuses are compact in size and have low profile packages, making them ideal for applications with limited PCB space. Surface mount fuses are widely used in consumer electronics, automotive electronics, and other compact electronic devices.

High Voltage Fuses: High voltage fuses are specifically designed to handle higher voltage levels. These fuses are used in power distribution systems, electrical substations, and other high voltage applications. They are designed to interrupt the flow of current in the event of a fault, protecting the system and preventing potential hazards.

Automotive Fuses: Automotive fuses are designed for use in vehicles to protect electrical circuits from short circuits or overloads. These fuses are available in various types, such as blade fuses, mini fuses, and micro fuses, to accommodate different automotive systems and current ratings.

It’s important to select the appropriate type of electronic fuse based on the specific application requirements, current ratings, voltage levels, and response times needed to ensure effective and reliable protection for electronic circuits.

Overcurrent Protection with Electronic Fuses

Overcurrent protection is one of the primary functions of electronic fuses. It involves detecting and interrupting excessive currents flowing through the circuit to prevent damage to the components and ensure the safe operation of the system. Let’s explore how electronic fuses provide overcurrent protection:

Current Sensing: Electronic fuses use a current sensing mechanism to continuously monitor the current passing through the circuit. This can be done using a variety of methods, such as shunt resistors, current transformers, or Hall effect sensors. The current sensing element measures the current and sends the information to the control circuit for analysis.

Threshold Detection: The control circuit of the electronic fuse compares the sensed current with a predetermined threshold value. If the current exceeds the threshold, it indicates an overcurrent condition, and the control circuit initiates the protection mechanism to interrupt the current flow and protect the circuit from damage.

Power Switching: Once an overcurrent condition is detected, the electronic fuse triggers the power switching element to open and interrupt the current flow. The power switching element can be a MOSFET, a relay, or other solid-state devices capable of handling the current and voltage levels of the circuit. By opening the switch, the excessive current is prevented from flowing through the circuit, protecting the components and preventing potential damage.

Response Time: Electronic fuses offer fast response times, allowing them to quickly detect and interrupt overcurrent conditions. The response time of electronic fuses is typically in microseconds to milliseconds, ensuring swift protection and minimizing damage to the circuit and its components.

Current Limiting: In addition to interrupting excessive currents, electronic fuses can also provide current limiting functionality. They can be designed to limit the current to a safe level instead of immediately interrupting it completely. This helps in protecting the circuit and components from the damaging effects of high currents while still allowing the operation of the system under a reduced load.

Accuracy and Consistency: Electronic fuses offer precise and consistent overcurrent protection. They can be designed with tight tolerances to ensure accurate current sensing and reliable operation. This high level of accuracy helps in preventing false triggers or failure to detect actual overcurrent conditions, enhancing the overall performance and reliability of the system.

By employing these mechanisms, electronic fuses effectively protect electronic circuits from overcurrent conditions, providing a crucial safeguard against potential damage and ensuring the smooth and safe operation of the system.

Characteristics of Electronic Fuses

Electronic fuses possess several characteristic features that make them unique and advantageous in various applications. Let’s explore the key characteristics of electronic fuses:

Rapid Response: Electronic fuses exhibit fast response times, allowing them to quickly detect and respond to overcurrent conditions. This rapid response helps in minimizing damage to the circuit and its components, reducing downtime and preventing potential hazards.

Resetability: Unlike traditional fuses that need to be replaced after they have blown, electronic fuses are resettable. Once the fault condition is resolved, electronic fuses can be reset, either automatically or manually, allowing the circuit to resume normal operation without the need for fuse replacement.

Precision Protection: Electronic fuses offer precise and accurate current protection. They can be designed with specific threshold levels, ensuring that only currents above the threshold are interrupted while allowing normal operating currents to pass through. This level of precision protection helps in safeguarding the circuit and its components from damage.

Customizable Current Ratings: Electronic fuses come in a range of current ratings, allowing users to select the most appropriate fuse for their specific application. From low current applications to high-power systems, electronic fuses can be customized to match the required current rating, ensuring optimal protection and efficient operation.

Compact Size: Electronic fuses are compact in size, making them suitable for applications where space is limited. Their small footprint makes them ideal for integration into electronic devices, circuit boards, and systems with tight spatial constraints.

Reliability: Electronic fuses provide enhanced reliability for electronic circuits. With their advanced technology and comprehensive protection features, they can effectively prevent damage caused by overcurrent or short circuit conditions, ensuring the reliable operation of the system.

Multiple Protection Features: Electronic fuses can incorporate additional protection features beyond overcurrent protection. These may include overvoltage protection, thermal protection, and even self-diagnostic capabilities. The inclusion of these features further enhances the safety and reliability of the electronic system.

Integration Possibilities: Electronic fuses can easily be integrated into larger electronic systems and circuit designs. They can interface with microcontrollers or other control devices, allowing for real-time monitoring and coordination with other protective elements in the system.

Overall, the characteristics of electronic fuses make them a versatile and reliable option for circuit protection in a wide range of applications across various industries.

Choosing the Right Electronic Fuse

When selecting an electronic fuse for a specific application, it is crucial to consider several factors to ensure optimal circuit protection and performance. Here are key considerations to keep in mind when choosing the right electronic fuse:

Current Rating: Determine the maximum current that the fuse will need to handle. It is important to choose an electronic fuse with a current rating that matches the specific requirements of the circuit to ensure effective protection without the risk of damage or failure.

Voltage Rating: Consider the voltage level at which the electronic fuse will operate. Ensure that the selected fuse has an appropriate voltage rating to handle the maximum voltage expected in the circuit. Using a fuse with a voltage rating lower than the circuit’s requirements can lead to premature failure or inadequate protection.

Response Time: Evaluate the response time required for the application. Different applications may have different tolerance for response times. Some circuits may demand quick response times to minimize damage, while others may tolerate slightly longer response times without significant consequences. Select an electronic fuse with a response time that aligns with the specific requirements of the circuit.

Resetability: Determine if resetability is essential for the application. If the ability to reset the fuse after a fault condition is critical for maintaining the operation of the circuit, consider choosing a resettable electronic fuse. However, if immediate replacement of the fuse is acceptable, non-resettable options can be considered.

Operating Environment: Take into account the environmental conditions in which the electronic fuse will operate. Consider factors such as temperature, humidity, vibration, or exposure to dust or chemicals. Choose an electronic fuse that is designed to withstand the specific environmental conditions of the application to ensure reliable and long-lasting performance.

Space Constraints: Consider the available space for the installation of the electronic fuse. Determine if compact size or specific package types, such as surface mount or through-hole, are required. This will help in selecting an electronic fuse that fits within the spatial constraints of the application without compromising protection or performance.

Application-Specific Features: Assess if the application requires additional features beyond overcurrent protection. Consider if features like overvoltage protection, thermal protection, or self-diagnostic capabilities are necessary. Choosing an electronic fuse with the specific additional features required by the application can add an extra layer of protection and functionality.

Manufacturer Reputation: Lastly, consider the reputation and reliability of the electronic fuse manufacturer. Opt for trusted brands that have a proven track record of producing high-quality and reliable components. This ensures that the electronic fuse will meet the required specifications and perform effectively in the intended application.

By carefully considering these factors, one can choose the right electronic fuse that meets the specific requirements of the application and provides robust and reliable circuit protection.

Installation and Maintenance of Electronic Fuses

Proper installation and maintenance of electronic fuses are essential to ensure their effective operation and maximize circuit protection. Here are important considerations for installing and maintaining electronic fuses:

Proper Placement: When installing electronic fuses, ensure they are placed as close as possible to the power source or the circuit board. This minimizes the length of the circuit that is unprotected and reduces the risk of voltage drops and unnecessary resistance.

Correct Current and Voltage Ratings: Always verify that the electronic fuse’s current and voltage ratings match the requirements of the circuit. Using a fuse with lower ratings may result in inadequate protection, while using one with higher ratings may lead to the fuse not blowing under fault conditions, compromising safety.

Fuse Holder or Socket: For easier replacement and maintenance, consider using a fuse holder or socket that is compatible with the electronic fuse. This allows for easy removal and replacement of the fuse without the need for additional tools or soldering.

Inspect for Damage: Regularly inspect the electronic fuse for any signs of physical damage, such as cracks or discoloration. Replace the fuse immediately if any damage is detected, as it may compromise the fuse’s ability to provide proper circuit protection.

Operational Testing: Periodically test the electronic fuse to ensure it is functioning correctly. This can be done through a variety of methods, such as using a multimeter to measure the continuity or resistance across the fuse. If the fuse fails the test, replace it with a new one to maintain optimal circuit protection.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s guidelines and recommendations for installation and maintenance procedures. They provide specific instructions and precautions that will help ensure the proper functioning and longevity of the electronic fuse.

Labeling and Documentation: Properly label the installed electronic fuses, indicating their ratings and any relevant information. This helps in quickly identifying and replacing fuses when needed. Additionally, maintain documentation of the fuse’s location and its specifications for future reference.

Safety Measures: When working with electronic fuses, observe proper safety measures, such as shutting off the power supply before installation or maintenance. Follow industry-standard safety protocols to protect yourself and prevent accidents or damage to the circuit.

Regular Inspection: Incorporate regular inspection and maintenance schedules into the overall system maintenance plan. This ensures that electronic fuses are in good working condition and provides assurance that the circuit is adequately protected.

By following these installation and maintenance practices, electronic fuses can be effectively utilized for circuit protection, providing reliable and continuous operation of electronic systems.

Common Applications of Electronic Fuses

Electronic fuses find wide applications in various industries and electronic systems where circuit protection is crucial. Let’s explore some of the common applications of electronic fuses:

Consumer Electronics: Electronic fuses are commonly used in consumer electronic devices such as televisions, audio systems, computers, and mobile devices. They protect sensitive circuits from overcurrent conditions that could damage the components or disrupt the operation of the devices.

Automotive Electronics: Electronic fuses play a critical role in automotive electronics. They protect electrical systems and sensitive components in vehicles, including the engine control unit (ECU), power distribution units, infotainment systems, lighting systems, and various other systems, from overcurrent or short circuit conditions.

Industrial Control Systems: In industrial environments, electronic fuses are utilized to protect control panels, motor starters, programmable logic controllers (PLCs), and other critical equipment. They ensure the safe and reliable operation of industrial control systems, preventing damage caused by overloads or faults in the electrical circuits.

Power Distribution Systems: Electronic fuses are used extensively in power distribution systems, such as those found in electrical substations, power plants, and renewable energy installations. They protect transformers, generators, and other components from overcurrent conditions, ensuring the stability and reliability of the power distribution network.

Telecommunications: Electronic fuses are employed in telecommunications equipment and infrastructure to protect sensitive circuits from overloads or short circuits. They are utilized in communication networks, base stations, data centers, and other telecommunications-related systems to safeguard critical equipment and ensure uninterrupted communication services.

Medical Devices: Medical devices rely on electronic fuses to protect both the patients and the delicate electronic components. They are used in various medical equipment, including patient monitors, imaging systems, defibrillators, and infusion pumps. Electronic fuses provide essential safety measures, preventing potential harm caused by electrical faults.

Aerospace and Defense: In the aerospace and defense industries, electronic fuses are utilized in aircraft, satellites, missiles, and other critical systems. They provide overcurrent protection to ensure the safe and reliable operation of avionics, communications systems, navigation equipment, and various other electronic subsystems.

Renewable Energy Systems: Electronic fuses are essential for protecting renewable energy systems, including solar power and wind energy installations. They safeguard the power inverters, battery systems, and other components from overcurrent or short circuit conditions, maximizing the efficiency and reliability of these sustainable energy sources.

Home Appliances: Electronic fuses are found in various household appliances, such as refrigerators, air conditioners, washing machines, and microwave ovens. They provide protection against overloads and short circuits, ensuring the safety and reliable operation of these appliances.

These are just a few examples of the many applications where electronic fuses are utilized. From consumer electronics to industrial systems, electronic fuses play a critical role in protecting circuits, preventing damage, and ensuring the smooth operation of various electronic devices and systems.

Difference between Electronic Fuses and Traditional Fuses

Electronic fuses and traditional fuses serve the same fundamental purpose of protecting electrical circuits from overcurrent conditions. However, there are several key differences between the two. Let’s explore the distinctions between electronic fuses and traditional fuses:

Operating Principle: The primary difference lies in their operating principles. Traditional fuses use a physical element, typically a wire or a strip, which melts under excessive current, interrupting the circuit. In contrast, electronic fuses utilize semiconductor devices and control circuits to sense and control the current flow, providing quicker and more precise protection.

Response Time: Electronic fuses offer faster response times compared to traditional fuses. Traditional fuses may take a significant amount of time to melt under overcurrent conditions, causing potential damage to the circuit and its components. Electronic fuses, on the other hand, can detect and respond to overcurrent conditions almost instantaneously, minimizing damage and downtime.

Resetability: Traditional fuses are typically not resettable and need to be replaced when they melt. In contrast, electronic fuses are often resettable, either automatically or manually, once the fault condition is resolved. This eliminates the need for frequent replacements and reduces maintenance costs.

Precision and Accuracy: Electronic fuses provide precise and accurate current protection. They can be designed to have specific current thresholds, allowing only excessive currents to be interrupted while allowing normal operating currents to pass through. This precision helps protect the circuit and sensitive components. Traditional fuses, on the other hand, have less control over the current flow, which can lead to less precise protection.

Additional Features: Electronic fuses can incorporate additional functionalities beyond overcurrent protection, such as overvoltage protection and thermal protection. These features enhance the overall reliability and safety of the electronic systems. Traditional fuses, on the contrary, focus solely on interrupting the current flow in the event of excess current.

Size and Placement: Electronic fuses are typically smaller and lighter than traditional fuses, making them more suitable for applications with space constraints or compact electronic devices. Traditional fuses, especially high-current ones, tend to be larger and bulkier, requiring more space for installation.

Cost and Longevity: Electronic fuses are often more expensive upfront compared to traditional fuses. However, electronic fuses can be reset and reused, resulting in cost savings over time. Traditional fuses need replacements each time they are blown, which can lead to more frequent expenses. Overall, the longevity and potential cost savings of electronic fuses can outweigh the higher initial investment.

Overall, electronic fuses offer faster response times, precision protection, resetability, and additional features compared to traditional fuses. While traditional fuses are more simple and cost-effective upfront, electronic fuses provide enhanced performance, greater control, and improved reliability, making them a preferred choice in many modern electronic applications.

Why Should You Consider Using Electronic Fuses?

Electronic fuses offer numerous advantages over traditional fuses, making them an attractive choice for circuit protection in a wide range of applications. Here are some compelling reasons why you should consider using electronic fuses:

Faster Response Time: Electronic fuses have rapid response times, almost instantaneously detecting and responding to overcurrent conditions. This swift response helps minimize damage to the circuit and its components, reducing downtime and preventing potential hazards.

Resetability: Unlike traditional fuses that need to be replaced after they blow, electronic fuses are resettable. Once the fault condition is resolved, electronic fuses can be reset, either automatically or manually. This eliminates the need for frequent replacements and reduces maintenance costs over time.

Precision Protection: Electronic fuses offer precise and accurate current protection. They can be designed with specific threshold levels, ensuring that only currents above the threshold are interrupted while allowing normal operating currents to pass through. This level of precision protection helps safeguard the circuit and its components from damage.

Additional Features: Electronic fuses can incorporate additional functionalities beyond overcurrent protection. They can provide overvoltage protection, thermal protection, and other features that enhance the overall reliability and safety of electronic systems. This makes electronic fuses versatile and suitable for a wide range of applications.

Rapid Recovery: Electronic fuses have quick recovery times once the fault condition is resolved. They can promptly restore the circuit to normal operation, minimizing downtime and improving system efficiency. This is particularly advantageous in applications where uninterrupted operation is crucial.

Compact Size: Electronic fuses are typically smaller and lighter than traditional fuses, making them ideal for applications with limited space or compact electronic devices. Their smaller footprint provides more flexibility in product design and layout, enabling efficient use of available space.

Longevity and Cost Savings: Electronic fuses offer longevity and potential cost savings over time. They can be reset and reused, reducing the need for frequent replacements. Although electronic fuses may have a higher upfront cost compared to traditional fuses, their ability to withstand multiple fault conditions without requiring replacement can result in long-term cost savings.

Enhanced Reliability: With their advanced technology and comprehensive protection features, electronic fuses provide enhanced reliability for electronic circuits. They offer precise protection, faster response times, and added functionalities, ensuring the safe and uninterrupted operation of electronic systems.

Considering these benefits, electronic fuses are a reliable and efficient solution for circuit protection. Whether in consumer electronics, automotive applications, industrial systems, or any other electronic devices, electronic fuses provide the necessary protection, convenience, and reliability required for optimal performance.