Understanding JST Connectors

JST connectors, also known as Japan Solderless Terminals, are miniature electrical connectors commonly used in a wide range of electronic applications. These connectors are known for their compact size, reliability, and versatility, making them an essential component in various industries. JST connectors are designed to provide secure and efficient electrical connections while minimizing space requirements, making them ideal for applications where space is limited.

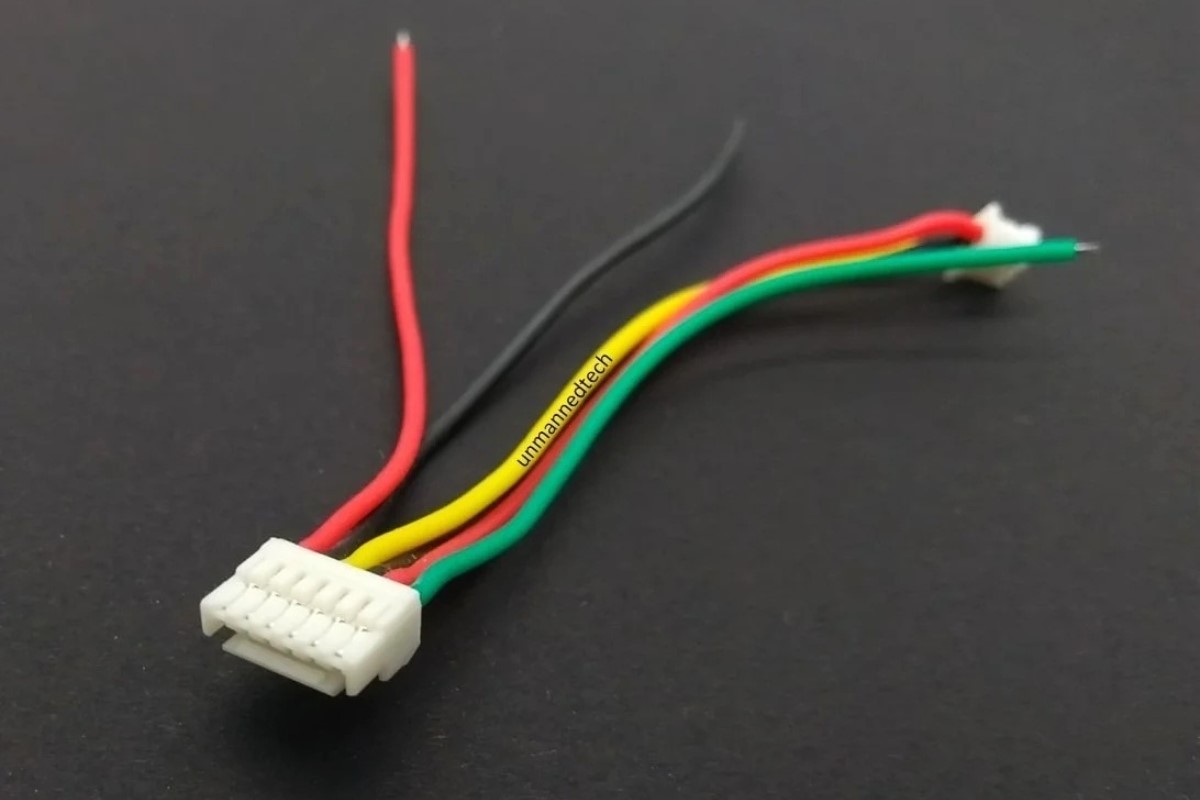

JST connectors consist of male and female components that can be easily mated and unmated, allowing for quick and convenient assembly and disassembly. The connectors are engineered to ensure proper alignment and secure locking, which helps prevent accidental disconnection due to vibration or movement. This feature makes JST connectors suitable for applications where reliability and stability are paramount.

These connectors come in a variety of pitch sizes, ranging from 1mm to 4.5mm, allowing for flexibility in design and integration. The pitch size refers to the distance between the center of one contact to the center of the adjacent contact. This variability in pitch size enables engineers and designers to select the most suitable connector based on the specific requirements of the application.

JST connectors are available in different configurations, including wire-to-board, wire-to-wire, and board-to-board, catering to a wide array of interconnection needs. Additionally, they support various wire gauges, accommodating different current and voltage requirements. This adaptability makes JST connectors highly versatile and applicable across diverse electronic devices and systems.

The connectors are engineered to withstand harsh environmental conditions, offering resistance to vibration, moisture, and temperature variations. This durability ensures reliable performance in challenging environments, making JST connectors a preferred choice in demanding applications such as automotive electronics, industrial equipment, consumer electronics, and medical devices.

Understanding the fundamental characteristics and capabilities of JST connectors is crucial for leveraging their potential in electronic designs and systems. With their compact design, reliability, and adaptability, JST connectors continue to be a cornerstone in modern electronic interconnection solutions, playing a pivotal role in advancing technological innovation across industries.

Types of JST Connectors

JST connectors encompass a diverse range of types, each tailored to specific applications and requirements. Understanding the various types of JST connectors is essential for selecting the most suitable option based on the intended use. Here are some common types of JST connectors:

- Wire-to-Board Connectors: These connectors are designed to establish a connection between a wire and a printed circuit board (PCB). They are widely used in applications where secure and reliable electrical connections are essential, such as in consumer electronics, industrial machinery, and automotive systems.

- Wire-to-Wire Connectors: Wire-to-wire JST connectors facilitate direct connections between individual wires, enabling the creation of custom cable assemblies. They are commonly employed in applications requiring flexible and customizable wiring solutions, such as in lighting fixtures, home appliances, and audio-visual equipment.

- Board-to-Board Connectors: These connectors enable the interconnection of PCBs within electronic devices or systems. Board-to-board JST connectors support the seamless integration of multiple circuit boards, fostering efficient signal transmission and power distribution in compact electronic designs.

- SMT (Surface Mount Technology) Connectors: SMT JST connectors are designed for surface mount applications, allowing for direct installation onto the surface of PCBs. They are well-suited for high-density circuit designs and automated assembly processes, contributing to enhanced manufacturing efficiency and reliability.

- Shrouded Headers: Shrouded headers provide additional protection and alignment features, ensuring precise mating and secure connections. These connectors are commonly utilized in applications where signal integrity and mechanical stability are critical, such as in data communication systems and industrial control devices.

Each type of JST connector offers unique advantages and is engineered to meet specific interconnection needs, providing engineers and designers with a diverse array of options to accommodate various electronic designs and systems. By understanding the distinct characteristics and applications of each type, professionals can make informed decisions when selecting JST connectors for their projects, ultimately contributing to the optimal performance and reliability of electronic devices and equipment.

Applications of JST Connectors

JST connectors find widespread application across diverse industries, playing a pivotal role in facilitating secure and efficient electrical connections in various electronic devices and systems. Their versatility, reliability, and compact design make them well-suited for an array of applications, contributing to the seamless operation of electronic equipment. Some common applications of JST connectors include:

- Consumer Electronics: JST connectors are extensively utilized in consumer electronic devices such as smartphones, tablets, digital cameras, and portable audio players. Their compact size and dependable connectivity make them ideal for integrating various components within compact electronic gadgets, contributing to the sleek and functional design of consumer electronics.

- Automotive Electronics: In the automotive industry, JST connectors play a critical role in establishing connections within vehicle electronic systems, including control units, sensors, lighting assemblies, and infotainment systems. Their robust construction and resistance to environmental factors make them well-suited for withstanding the demanding conditions encountered in automotive applications.

- Industrial Equipment: JST connectors are integral to the operation of industrial machinery and equipment, where reliable electrical connections are essential for maintaining productivity and safety. These connectors are employed in control panels, motor drives, sensors, and automation systems, contributing to the efficient and dependable performance of industrial machinery.

- Medical Devices: The medical industry relies on JST connectors to ensure secure and precise electrical connections in various medical devices and equipment, including patient monitoring systems, diagnostic devices, and medical imaging equipment. The connectors’ compact form factor and reliability support the seamless integration of electronic components in medical applications, contributing to the delivery of accurate and reliable healthcare solutions.

- Telecommunications: JST connectors play a crucial role in telecommunications infrastructure, facilitating the interconnection of networking equipment, data transmission devices, and communication systems. Their ability to provide secure and stable connections is instrumental in maintaining the integrity and efficiency of telecommunications networks and data centers.

These applications underscore the adaptability and reliability of JST connectors across a spectrum of industries, demonstrating their significance in enabling the functionality and performance of electronic devices and systems. By catering to diverse application requirements, JST connectors continue to be an indispensable component in advancing technological innovation and enhancing the functionality of electronic products in various domains.

Advantages of Using JST Connectors

JST connectors offer a multitude of advantages that contribute to their widespread adoption and utility across various industries. Understanding these advantages is crucial for appreciating the value that these connectors bring to electronic designs and systems. Some key advantages of using JST connectors include:

- Compact Design: JST connectors are renowned for their compact and space-saving design, making them ideal for applications where size constraints are a consideration. Their small form factor enables efficient use of space and facilitates the integration of electronic components in compact devices and equipment.

- Reliable Connectivity: These connectors are engineered to provide secure and dependable electrical connections, minimizing the risk of signal loss or intermittent contact. The robust design of JST connectors ensures stable connectivity, contributing to the overall reliability and performance of electronic systems.

- Versatility: JST connectors are available in a diverse range of types, pitch sizes, and configurations, catering to a wide spectrum of interconnection needs. This versatility allows for flexibility in design and application, empowering engineers to select the most suitable connector for specific requirements.

- Ease of Assembly: The design of JST connectors facilitates quick and convenient assembly, allowing for efficient integration into electronic designs. The connectors’ mating and locking mechanisms enable swift and secure connections, streamlining the assembly process and reducing installation time.

- Durability: JST connectors are engineered to withstand harsh environmental conditions, offering resistance to vibration, moisture, and temperature variations. This durability ensures reliable performance in challenging environments, making these connectors well-suited for demanding applications across industries.

- Cost-Effectiveness: The reliability and longevity of JST connectors contribute to cost savings over the long term by reducing the need for frequent maintenance or replacement. Their robust construction and dependable performance minimize downtime and enhance the overall cost-effectiveness of electronic systems.

These advantages collectively position JST connectors as essential components in electronic interconnection solutions, empowering engineers and designers to create reliable and efficient electronic devices and systems. By leveraging the benefits offered by JST connectors, industries can achieve enhanced functionality, durability, and performance in their electronic applications, ultimately driving innovation and progress in the field of electronics.

Considerations for Choosing JST Connectors

When selecting JST connectors for a specific application, several key considerations come into play to ensure optimal performance and compatibility. Understanding these considerations is essential for making informed decisions regarding the choice of connectors. Some crucial factors to consider when choosing JST connectors include:

- Electrical Requirements: Assessing the electrical specifications of the application, including current and voltage ratings, is essential for selecting JST connectors that can accommodate the specific electrical demands of the system. Ensuring that the connectors can reliably handle the required power levels is critical for preventing performance issues and potential safety hazards.

- Environmental Conditions: Evaluating the environmental factors to which the connectors will be exposed is vital for choosing JST connectors with the appropriate level of protection. Factors such as temperature extremes, moisture, and exposure to chemicals or solvents should be taken into account to select connectors that offer the necessary resistance and durability for the intended environment.

- Physical Space and Layout: Considering the available space for connector installation and the layout of the electronic system is crucial for choosing connectors that can be seamlessly integrated without compromising the overall design. The compactness and configuration of the connectors should align with the spatial constraints and layout requirements of the application.

- Mating Cycles: Understanding the frequency of mating and unmating cycles that the connectors will undergo is essential for selecting connectors with the appropriate durability and longevity. Applications with frequent connection/disconnection requirements necessitate connectors designed to withstand repeated mating cycles without compromising performance.

- Application Specificity: Taking into account the unique requirements and constraints of the application, such as signal integrity, mechanical stability, and EMI/RFI considerations, is crucial for choosing JST connectors that align with the specific demands of the system. Customizing the selection based on the application’s distinct needs ensures optimal performance and reliability.

By carefully considering these factors in the selection process, engineers and designers can identify the most suitable JST connectors for their applications, ultimately contributing to the seamless integration and reliable operation of electronic systems. Addressing these considerations empowers professionals to make informed choices that align with the performance, environmental, and spatial requirements of their electronic designs, fostering efficiency and longevity in electronic interconnections.

How to Use JST Connectors

Utilizing JST connectors effectively involves a systematic approach to ensure secure and reliable electrical connections. The following steps outline the process of using JST connectors:

- Identify Connector Types: Begin by identifying the specific type of JST connectors required for the application, considering factors such as wire-to-board, wire-to-wire, or board-to-board configurations based on the interconnection needs.

- Prepare the Wires: Strip the insulation from the ends of the wires to expose the conductors. Ensure that the exposed conductors are clean and free from any debris or damage to facilitate proper electrical contact within the connectors.

- Insert Wires into Connectors: Insert the prepared wires into the corresponding male and female connectors, ensuring that the conductors are aligned with the connector terminals. The connectors are designed to securely hold the wires in place, providing stable electrical connections.

- Crimp or Solder Connections: Depending on the type of JST connectors being used, crimp the terminals onto the wires or solder the connections to establish a secure and reliable electrical joint. Follow the manufacturer’s guidelines for crimping or soldering to ensure proper attachment.

- Secure Locking Mechanism: Engage the locking mechanism of the connectors to ensure a secure and stable connection. This step is crucial for preventing accidental disconnection and maintaining the integrity of the electrical joint, especially in applications prone to vibration or movement.

- Perform Insulation and Strain Relief: Apply insulation materials or heat-shrink tubing to the crimped or soldered connections to provide electrical insulation and mechanical protection. Additionally, incorporate strain relief measures to minimize stress on the wires and connections, enhancing long-term reliability.

Following these steps ensures the proper utilization of JST connectors, resulting in secure, reliable, and durable electrical connections within electronic systems. Adhering to best practices for handling and using JST connectors contributes to the overall performance and longevity of electronic interconnections, fostering efficiency and reliability in electronic designs and applications.