Understanding the Basics of Battery Testing

Batteries are ubiquitous in modern life, powering everything from small electronic devices to vehicles and backup power systems. Understanding the basics of battery testing is crucial for ensuring the reliability and longevity of these essential power sources. Whether you are a professional technician or a casual user, mastering the fundamentals of battery testing can save you time, money, and frustration in the long run.

Importance of Battery Testing

Proper battery testing is essential for diagnosing the health and performance of a battery. By conducting regular tests, you can identify potential issues before they escalate, thereby preventing unexpected failures and minimizing downtime. Additionally, testing allows for the optimization of battery usage, ensuring that you get the most out of your power sources.

Factors Affecting Battery Performance

Several factors can impact the performance and lifespan of a battery, including temperature, usage patterns, charging habits, and environmental conditions. Through effective testing, you can gain insights into how these factors influence the overall health of the battery, enabling you to make informed decisions regarding maintenance and replacement.

Types of Battery Testing

Battery testing encompasses various methods, including capacity testing, conductance testing, voltage testing, and impedance testing. Each method serves a specific purpose and provides unique information about the battery's condition. Understanding the differences between these testing techniques is crucial for obtaining accurate and comprehensive insights into the battery's health.

Safety Considerations

Before delving into battery testing, it's important to emphasize the significance of safety. Batteries, especially those in larger applications, can pose safety hazards if mishandled. Understanding proper safety protocols and using the appropriate personal protective equipment is paramount when dealing with battery testing to mitigate potential risks.

Environmental Impact

Proper disposal and recycling of batteries are essential for minimizing environmental impact. Understanding battery testing also involves being aware of the environmental implications of battery usage and disposal. By ensuring that batteries are tested, maintained, and disposed of responsibly, individuals and organizations can contribute to environmental sustainability.

Continuous Learning

The field of battery technology is dynamic, with new developments and innovations constantly emerging. Understanding the basics of battery testing is an ongoing process, and staying informed about the latest testing methods and technologies is crucial for maintaining optimal battery performance.

In essence, understanding the basics of battery testing is not only about performing routine diagnostics; it's also about embracing a proactive approach to battery management. By familiarizing yourself with the essentials of battery testing, you can safeguard your investments, enhance safety, and contribute to a more sustainable future.

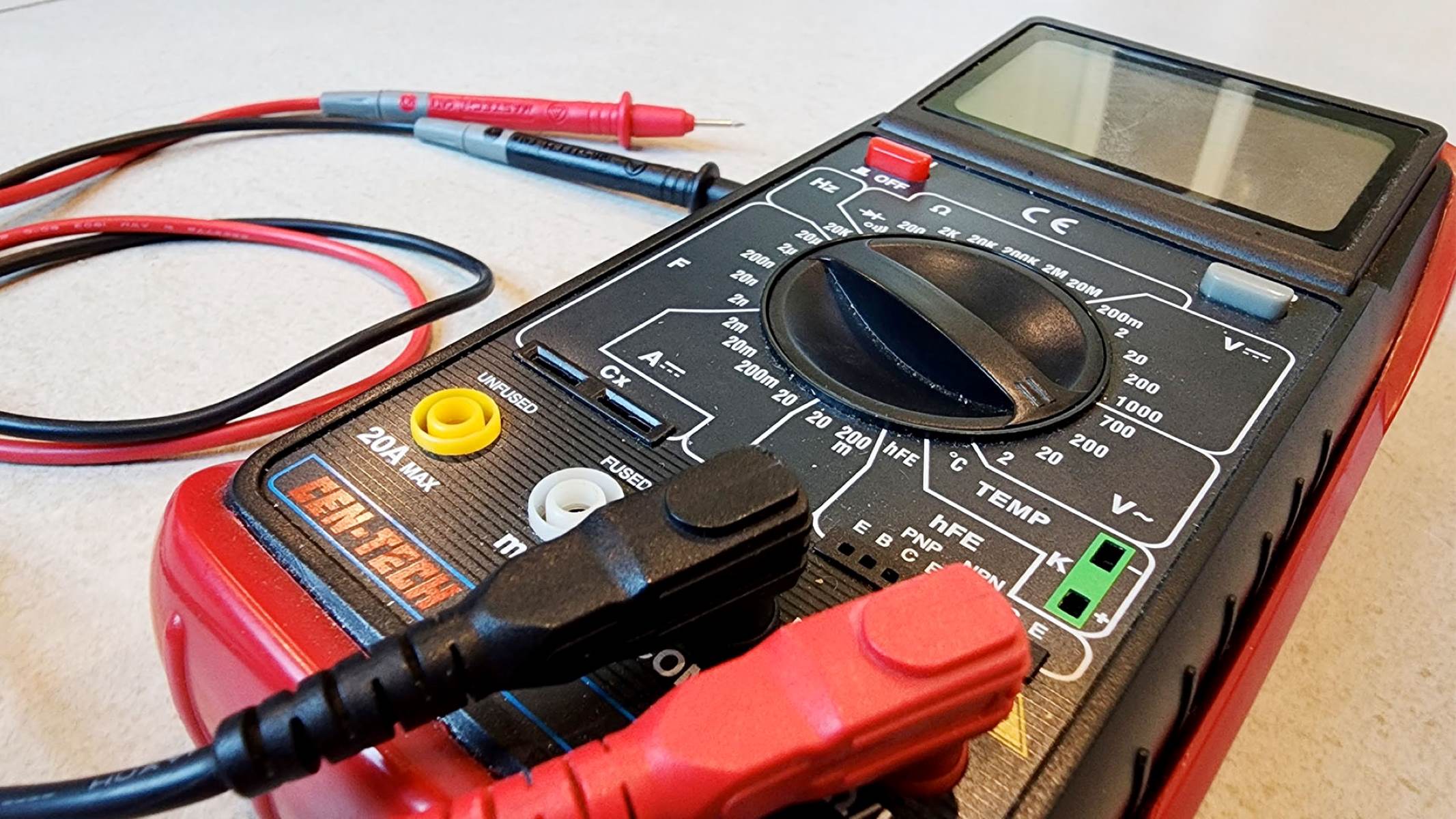

Choosing the Right Battery Tester for Your Needs

When it comes to selecting a battery tester, the options can be overwhelming. Understanding the key factors to consider can help you make an informed decision that aligns with your specific testing requirements. Whether you are dealing with automotive batteries, household batteries, or industrial power sources, choosing the right battery tester is essential for accurate diagnostics and maintenance.

Considered Battery Types

The first step in choosing a battery tester is to identify the types of batteries you will be testing. Different battery chemistries, such as lead-acid, lithium-ion, nickel-metal hydride, and others, require specific testing methods and equipment. Ensuring that the battery tester is compatible with the batteries in question is crucial for obtaining reliable results.

Testing Capabilities

Assessing the testing capabilities of a battery tester is paramount. Some testers may only provide basic voltage readings, while others offer comprehensive diagnostics, including conductance testing, capacity testing, and internal resistance measurements. Understanding the depth of information you need from the tests will guide you in selecting a tester with the appropriate features.

User-Friendliness

For both professionals and casual users, the ease of use of a battery tester is a significant consideration. Intuitive interfaces, clear display screens, and simple operation can enhance the testing experience and minimize the likelihood of errors. Additionally, portability and ergonomic design can contribute to the overall usability of the tester.

Accuracy and Precision

Reliable and consistent results are imperative in battery testing. Evaluating the accuracy and precision of a battery tester, as well as its calibration requirements, ensures that the testing process yields dependable data. Look for testers with proven track records of accuracy to maintain confidence in the diagnostic outcomes.

Compatibility with Accessories

Some battery testers offer compatibility with additional accessories, such as thermal printers, data management software, and test probes. Considering the potential need for these accessories in your testing operations can influence your choice of a battery tester, especially if you require comprehensive documentation and data analysis capabilities.

Long-Term Value

Investing in a quality battery tester that aligns with your current and future testing needs can yield long-term value. While upfront costs are a consideration, evaluating the durability, warranty, and potential for software updates or expansions can contribute to the overall cost-effectiveness of the chosen battery tester.

Ultimately, choosing the right battery tester involves a balance of technical specifications, usability, and long-term suitability. By carefully assessing your testing requirements and considering the diverse options available, you can select a battery tester that empowers you to effectively manage and maintain your batteries.

Preparing the Battery for Testing

Before initiating the testing process, proper preparation of the battery is essential to ensure accurate and reliable results. Whether you are testing a small household battery or a large industrial power source, following specific preparatory steps can optimize the testing procedure and contribute to the overall effectiveness of the diagnostics.

Visual Inspection

Begin by conducting a visual inspection of the battery. Look for any signs of physical damage, corrosion, leaks, or other irregularities. Cleaning the battery terminals and ensuring that the external surfaces are free from debris can enhance the accuracy of the testing process and reduce the risk of erroneous readings.

Resting Period

Allow the battery to rest before testing, especially if it has been recently charged or discharged. This resting period enables the internal components of the battery to stabilize, providing a more accurate representation of its actual state. For lead-acid batteries, a resting period of at least four hours is recommended before testing.

Temperature Stabilization

Temperature can significantly impact battery performance and test results. It is crucial to ensure that the battery is at a stable temperature before testing, as extreme temperatures can skew the readings. If the battery has been exposed to high or low temperatures, allowing it to equilibrate to the testing environment is essential for accurate diagnostics.

Disconnecting Loads

If the battery is connected to any loads or equipment, disconnect them before testing. External loads can interfere with the testing process and lead to misleading results. By isolating the battery from any connected devices or systems, you can focus solely on evaluating the battery’s intrinsic performance.

Record Keeping

Prior to testing, document relevant information about the battery, including its type, model, age, and any previous test results. Maintaining a comprehensive record of the battery’s history enables you to track its performance over time and identify any trends or anomalies. This historical data serves as a valuable reference for future comparisons.

Safety Precautions

Adhering to safety precautions during battery preparation is paramount. Wear appropriate personal protective equipment, such as gloves and eye protection, especially when dealing with larger or industrial batteries. Additionally, ensure that the testing environment is well-ventilated to mitigate potential risks associated with battery testing.

By meticulously preparing the battery for testing, you can lay the groundwork for accurate and insightful diagnostics. These preparatory measures not only contribute to the reliability of the test results but also promote a safe and systematic approach to battery testing.

Performing the Test with Accuracy

Once the battery is adequately prepared, conducting the test with precision is crucial for obtaining reliable data that can inform maintenance decisions and ensure optimal performance. Whether you are performing a voltage test, conductance test, or comprehensive battery analysis, adhering to best practices during the testing phase is essential.

Follow Manufacturer Guidelines

Consult the manufacturer’s guidelines and the user manual of the battery tester to understand the specific testing procedures recommended for the type of battery being tested. Different battery chemistries and models may require unique testing protocols to ensure accurate readings and prevent potential damage to the battery.

Consistent Testing Conditions

Maintaining consistent testing conditions is imperative for accurate results. Factors such as ambient temperature, humidity, and testing equipment calibration can influence the outcome of the test. By standardizing the testing environment and procedures, you can minimize variables that may compromise the accuracy of the results.

Proper Connection and Contact Points

Ensure that the battery tester’s probes or clamps are securely connected to the battery terminals, establishing good contact for the duration of the test. Loose connections or corroded contact points can introduce resistance and lead to inaccurate readings. Verify that the testing equipment is properly calibrated and functioning optimally prior to initiating the test.

Stable Power Supply

If the battery tester operates on its own power source, such as batteries or an internal rechargeable battery pack, verify that the power supply is stable and adequate for the duration of the test. Inconsistent power supply to the tester can affect its performance and compromise the accuracy of the readings.

Appropriate Test Duration

Adhere to the recommended test duration specified by the battery tester’s manufacturer. Testing for the appropriate duration allows the equipment to gather sufficient data and stabilize readings, especially for tests that involve dynamic parameters such as conductance and internal resistance.

Data Interpretation

Once the test is complete, carefully review and interpret the data provided by the battery tester. Understand the significance of the readings, including voltage levels, conductance values, and any diagnostic codes or indicators. Compare the results with the battery’s specifications and previous test data to assess its current condition accurately.

By performing the test with meticulous attention to detail and adherence to standardized procedures, you can generate accurate and actionable insights into the health and performance of the battery. These insights form the basis for informed maintenance decisions and proactive measures to optimize the longevity and reliability of the battery.

Interpreting the Results and Taking Action

Interpreting the results of a battery test is a critical step in the maintenance and management of batteries. The data obtained from the test provides valuable insights into the current condition of the battery, guiding the decision-making process regarding maintenance, replacement, or further diagnostics. Understanding how to interpret the results and take appropriate action is essential for maximizing the performance and lifespan of the battery.

Comparison with Specifications

Begin by comparing the test results with the specifications provided by the battery manufacturer. Assess whether the voltage, conductance, and other parameters align with the expected values for the battery type and model. Deviations from the specifications can indicate potential issues that require attention.

Trend Analysis

Review historical test data and analyze trends in the battery’s performance over time. Identifying patterns of degradation or improvement can offer insights into the battery’s long-term health and aid in predicting future behavior. Trend analysis facilitates proactive maintenance and replacement strategies.

Diagnostic Codes and Indicators

If the battery tester provides diagnostic codes or indicators, carefully interpret these signals to understand any specific issues detected during the test. These codes can pinpoint abnormalities such as sulfation, internal shorts, or other conditions that may impact the battery’s performance and longevity.

Contextual Considerations

Take into account the operational context and criticality of the battery when interpreting the results. For example, a slight decrease in capacity for a backup power system may warrant a different response than a similar decrease in a non-essential application. Contextual considerations help prioritize actions based on the impact of the battery’s condition.

Maintenance and Remedial Actions

Based on the interpretation of the test results, determine the appropriate maintenance actions or remedial measures. This may include recharging the battery, equalizing cells in a multi-cell battery, desulfation treatments, or implementing conditioning cycles to improve performance. For severely degraded batteries, replacement may be the most viable solution.

Documentation and Reporting

Document the test results, interpretations, and subsequent actions taken. Maintaining a comprehensive record of battery tests and maintenance activities facilitates informed decision-making and enables future comparisons. Reporting on the battery’s condition and the actions taken is valuable for accountability and compliance purposes.

By effectively interpreting the results of battery tests and taking proactive action based on the findings, you can optimize the performance, reliability, and longevity of the batteries under your care. These actions contribute to efficient resource utilization and ensure that batteries continue to fulfill their intended functions effectively.

Maintaining and Calibrating Your Battery Tester

Regular maintenance and calibration of your battery tester are essential for ensuring accurate and consistent performance when conducting battery tests. By incorporating proper maintenance and calibration practices into your testing regimen, you can uphold the reliability of your testing equipment and enhance the precision of diagnostic results.

Regular Cleaning and Inspection

Periodically clean the probes, clamps, and contact points of the battery tester to remove dirt, debris, and oxidation that may affect the accuracy of the readings. Inspect the physical condition of the tester for any signs of wear, damage, or loose components, addressing any issues promptly to maintain its integrity.

Calibration Verification

Verify the calibration of the battery tester at regular intervals, adhering to the recommended calibration schedule provided by the manufacturer. Calibration ensures that the tester provides accurate and reliable measurements, minimizing potential errors in the test results. Follow the prescribed calibration procedures to maintain the integrity of the testing equipment.

Software Updates and Upgrades

If your battery tester is equipped with software or firmware, stay informed about available updates and upgrades provided by the manufacturer. Updating the testing equipment’s software ensures compatibility with new battery technologies and enhances the functionality and accuracy of the tester.

Battery Tester Storage

Proper storage of the battery tester when not in use is crucial for preserving its functionality. Store the tester in a clean, dry, and temperature-stable environment, protecting it from excessive heat, moisture, and physical damage. Follow the manufacturer’s recommendations for long-term storage to prolong the lifespan of the equipment.

Performance Verification

Conduct performance verification tests on the battery tester to confirm its functionality and accuracy. Utilize reference batteries or standard test loads to validate the tester’s readings and ensure that it continues to deliver reliable results. Address any discrepancies or anomalies identified during the verification process.

Professional Calibration Services

Engage professional calibration services if required by the manufacturer or if you encounter persistent issues with the tester’s accuracy. Certified calibration technicians can perform comprehensive assessments and adjustments to restore the tester to its optimal performance, providing peace of mind regarding the accuracy of your battery tests.

By prioritizing the maintenance and calibration of your battery tester, you uphold the integrity of your testing processes and uphold the reliability of your diagnostic outcomes. These proactive measures contribute to the overall effectiveness of battery management and enable informed decision-making based on accurate and dependable test results.