What are Electronic Components?

Electronic components are crucial building blocks of electronic devices and systems. They are the fundamental units that enable the functioning of various electrical circuits. These components perform specific functions, such as amplifying signals, storing data, regulating current, or converting energy. The electronic components can be passive, such as resistors and capacitors, which do not require a power source for their operation. They can also be active, such as transistors and integrated circuits, which require a power source to function.

Passive electronic components, like resistors and capacitors, are used to control the flow of electricity within a circuit. Resistors limit the flow of current, while capacitors store and release electrical energy. On the other hand, active electronic components, like transistors and integrated circuits, are responsible for amplifying and controlling the electrical signals within a circuit. They can perform complex functions and are essential for the operation of advanced electronic devices.

Electronic components come in various shapes, sizes, and types, allowing for versatility in designing electronic systems. Some common electronic components include diodes, transistors, integrated circuits (ICs), resistors, capacitors, inductors, and connectors. Each component has specific electrical characteristics and is designed for a particular purpose. For example, diodes allow current flow in one direction, while transistors act as switches or amplifiers.

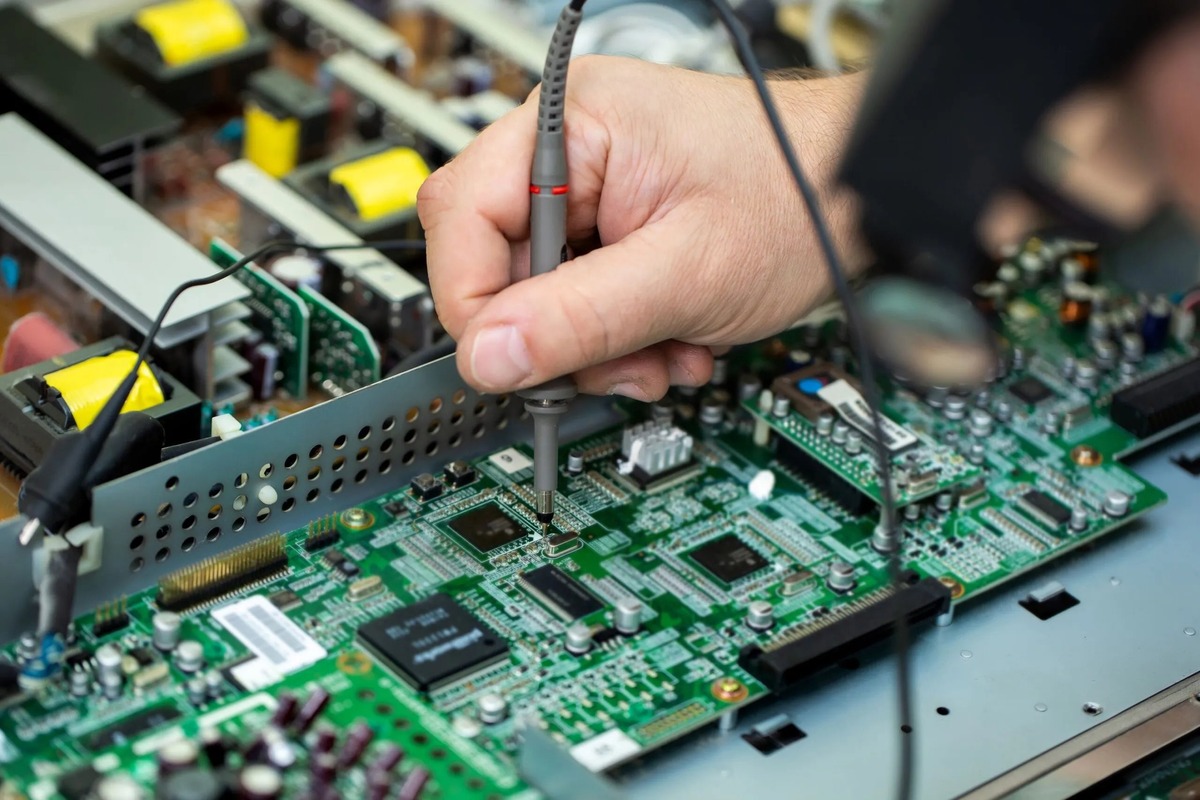

Electronic components can be found in everyday electronics, such as smartphones, computers, televisions, and home appliances. These components work together to create functional circuits that enable the device to perform its intended tasks. Understanding electronic components and how they interact is crucial for troubleshooting and repairing electronic devices.

Understanding Voltage and Current

When discussing electronic components, it is essential to have a basic understanding of voltage and current. Voltage is the electrical potential difference between two points in a circuit, measured in volts (V). It determines the force that drives the electric current through a circuit. Current, on the other hand, refers to the flow of electrical charge, measured in amperes (A). It represents the rate at which charges move through a conductor, such as a wire.

In a circuit, voltage is the driving force that pushes the current through the components. It can be compared to the pressure in a water pipe, where the voltage is the water pressure and the current is the flow of water. The relationship between voltage and current is governed by Ohm’s Law. According to Ohm’s Law, the current flowing through a conductor is directly proportional to the voltage across it and inversely proportional to the resistance of the conductor.

Resistors are electronic components that impede the flow of electrical current. They are measured in ohms (Ω) and are used to limit the amount of current in a circuit. The resistance of a resistor determines how much voltage is required to produce a certain current through it. Understanding the relationship between voltage, current, and resistance is crucial for designing and troubleshooting electronic circuits.

It is important to note that electronic components have voltage and current ratings that specify their operating limits. Exceeding these ratings can lead to component failure or damage. Different components have different voltage and current tolerance levels based on their construction and intended use. Therefore, it is crucial to select components that can handle the voltage and current levels expected in a circuit.

When working with electronic components, it is also important to consider the power dissipation. Power is the product of voltage and current, measured in watts (W). Components have power ratings that indicate the maximum amount of power they can handle without exceeding their operating limits. Exceeding the power rating can cause components to overheat and fail.

The Relationship Between Voltage and Damage

Voltage plays a critical role in determining the level of damage that can occur to electronic components. When the voltage exceeds the rated voltage of a component, it can lead to irreversible damage. Components are designed to operate within a certain voltage range, known as the voltage rating. Exceeding this voltage rating can result in a phenomenon known as voltage breakdown.

Voltage breakdown occurs when the voltage applied to a component exceeds its insulation capabilities. This can cause the insulating materials within the component to break down, leading to a short circuit or catastrophic failure. In some cases, the excess voltage can even cause the component to emit sparks or release smoke.

The damage caused by excessive voltage can vary depending on the type of component and its construction. Some components, like diodes and transistors, have built-in protection mechanisms that can handle limited voltage spikes. However, sustained overvoltage can still cause damage to these components. Other components, like capacitors and integrated circuits, are typically more sensitive to overvoltage and can be easily damaged.

In addition to voltage levels, the duration of the excess voltage also plays a role in component damage. Short voltage spikes or transients can sometimes be tolerated by components without causing long-term damage. However, sustained overvoltage can generate excess heat, which can lead to component failure due to thermal stress.

It is important to note that different components have different voltage tolerances. For example, a resistor may have a higher voltage rating compared to a small surface-mounted capacitor. Understanding the voltage ratings and limitations of each component is crucial for designing electronic circuits that can withstand the expected voltage fluctuations.

In some cases, voltage surges can occur due to power disruptions in the electrical grid, lightning strikes, or faulty wiring. To protect electronic components from these voltage surges, it is common to use circuit protection devices such as surge protectors, voltage regulators, and fuses. These devices help to limit the voltage applied to the components and prevent damage from occurring.

How Different Electronic Components Handle Voltage

Electronic components have different construction and design characteristics that influence how they handle voltage. Understanding these differences is crucial for selecting the appropriate components for a circuit and ensuring their reliable operation.

1. Resistors: Resistors are passive components that are commonly used to control the flow of electrical current. They can handle voltage up to their maximum rating, which is typically specified by the manufacturer. Exceeding the rated voltage for a resistor can cause it to overheat and potentially burn out.

2. Capacitors: Capacitors store and release electrical charge and are commonly used in timing circuits, filtering, and energy storage applications. Capacitors have voltage ratings that indicate the maximum voltage they can withstand before the dielectric material breaks down. Exceeding the rated voltage can lead to capacitance loss, leakage current, or even capacitor failure.

3. Diodes: Diodes are used to allow current flow in one direction while blocking it in the reverse direction. Diodes have a maximum reverse voltage rating, also known as the breakdown voltage. Exceeding this rating can lead to diode breakdown, resulting in a short circuit or component failure.

4. Transistors: Transistors are active components that amplify or switch electronic signals. They have voltage ratings that specify the maximum voltages the different terminals can handle. Exceeding these voltage ratings can cause transistor failure or degradation of performance.

5. Integrated Circuits (ICs): Integrated circuits contain multiple electronic components and circuits on a single chip. They have voltage ratings that specify the maximum voltage that can be applied to the inputs, outputs, and power supply pins. Exceeding these voltage ratings can damage the internal transistors and other components within the IC.

6. Inductors: Inductors store energy in a magnetic field and are commonly used in power supplies, filters, and oscillators. They have a maximum current rating that indicates the maximum current flow they can handle without overheating. Exceeding the rated current can lead to excessive heating and component failure.

It is essential to consult the datasheets and specifications provided by component manufacturers to understand the voltage ratings and limitations of each component. Using components within their specified voltage ranges ensures their reliable operation and prolongs their lifespan.

The Role of Circuit Protection Devices

Circuit protection devices play a crucial role in safeguarding electronic components and circuits from excessive voltage, current, and other potential hazards. These devices are designed to detect and respond to abnormal conditions in the circuit, protecting the components from damage and preventing potential safety hazards.

1. Surge Protectors: Surge protectors are designed to handle voltage spikes or surges caused by power grid fluctuations, lightning strikes, or other external factors. They divert excess voltage to the ground, preventing it from reaching the connected devices. Surge protectors typically utilize metal oxide varistors (MOVs) or gas discharge tubes (GDTs) to absorb and dissipate the excess voltage.

2. Fuses: Fuses are protective devices that interrupt the flow of current when it exceeds a certain threshold. Fuses contain a metal strip or wire that melts when the current exceeds its rated value, thereby breaking the circuit. This helps to prevent excessive current from damaging the electronic components. Fuses need to be replaced after they are blown.

3. Circuit Breakers: Circuit breakers are automatic switches that can be reset after they trip due to overcurrent conditions. They provide protection against short circuits, overloads, and excessive currents. When the current exceeds the breaker’s rated value, it will automatically disconnect the circuit, preventing damage to the components. Circuit breakers can be manually reset after the cause of the excess current is resolved.

4. Voltage Regulators: Voltage regulators are devices used to maintain a stable and regulated voltage level. They provide a constant voltage output, regardless of voltage fluctuations at the input. Voltage regulators protect electronic components from voltage variations, ensuring that they receive a consistent voltage level within their operating range.

5. ESD Protection Devices: Electrostatic discharge (ESD) protection devices are used to prevent damage caused by static electricity. They divert static charges safely to the ground, protecting sensitive electronic components. ESD protection devices are particularly critical when handling or assembling electronic components to prevent ESD-related failures.

By incorporating these circuit protection devices into electronic systems, the risk of damage to components and circuits can be significantly reduced. They provide a vital layer of defense against voltage spikes, overcurrent conditions, static electricity, and other potential risks that can compromise the functionality and lifespan of electronic devices.

Factors Affecting the Tolerance of Electronic Components

The tolerance of electronic components refers to their ability to withstand and operate within specified limits of voltage, current, temperature, and other environmental conditions. Various factors can influence the tolerance and performance of electronic components, and understanding these factors is essential for selecting and designing reliable electronic systems.

1. Component Quality: The quality of electronic components plays a significant role in their tolerance. Components from reputable manufacturers tend to have tighter tolerances and undergo rigorous testing to ensure their reliability. Low-quality or counterfeit components may have looser tolerances and may not perform consistently under varying conditions.

2. Temperature: Temperature has a substantial impact on the performance and durability of electronic components. Extreme temperatures, both hot and cold, can cause component degradation or failure. Components rated for industrial or automotive applications typically have a wider temperature range compared to those designed for consumer electronics.

3. Environmental Conditions: Electronic components can be exposed to various environmental factors such as moisture, dust, vibration, and electromagnetic interference. Components with higher levels of environmental protection, such as conformal coatings or sealed enclosures, are more tolerant to these adverse conditions.

4. Voltage and Current Variation: Electronic components have voltage and current ratings that specify the limits they can safely handle. Exceeding these ratings can cause components to malfunction or permanently fail. Designing circuits and selecting components within their specified voltage and current limits is crucial for ensuring their tolerance.

5. Aging and Wear: Over time, electronic components can experience degradation and wear. Components such as capacitors and batteries may suffer from decreased performance or increased internal resistance. Components with longer lifespans or those designed for high-reliability applications typically have better tolerance to aging effects.

6. Operating Conditions: The specific operating conditions of a circuit can also impact the tolerance of electronic components. Factors such as duty cycle, load fluctuations, and power supply stability can affect the performance and lifespan of components. Components selected for critical applications should be chosen to withstand the anticipated operating conditions.

7. Circuit Design and Layout: The design and layout of the circuit board can influence the tolerance of components. Proper circuit layout techniques, such as minimizing trace lengths and reducing electromagnetic interference, can enhance the tolerance and reliability of components. Design considerations should also be given to thermal management and component spacing.

By taking into account these factors, engineers can ensure the selection and implementation of electronic components that can withstand the required operating conditions, resulting in reliable and long-lasting electronic systems.

Common Mistakes in Handling Electronic Components

Handling electronic components requires care, attention to detail, and adherence to best practices. When not handled properly, mistakes can lead to component damage, malfunctioning circuits, and decreased reliability. Avoiding these common mistakes is crucial for ensuring the proper functioning and longevity of electronic systems.

1. ESD (Electrostatic Discharge): One of the most common mistakes is not taking sufficient precautions against electrostatic discharge. Static electricity can build up in our bodies and transfer to sensitive electronic components, causing immediate or latent damage. To prevent ESD, it is important to use antistatic wrist straps, grounding mats, or conductive containers when handling components.

2. Improper Component Storage: Electronic components should be stored in appropriate conditions to prevent damage. Exposure to moisture, dust, extreme temperatures, or excessive humidity can compromise the integrity of the components. Components should be stored in antistatic bags or containers, in a clean and dry environment, away from direct sunlight or corrosive substances.

3. Insufficient Heat Management: Overheating is a common issue in electronic systems, particularly with power-hungry components or inadequate heat dissipation mechanisms. Insufficient cooling can lead to component failure, reduced performance, and premature aging. Proper heat sinking, fans, or thermal management solutions should be implemented to maintain safe operating temperatures.

4. Poor Soldering Technique: Inaccurate or improper soldering practices can lead to weak solder joints, cold solder joints, or solder bridges. These issues can result in intermittent or failed connections, affecting the overall functionality of the circuit. It is important to follow proper soldering techniques, including using the right temperature, flux, and soldering iron, and to ensure the cleanliness of the component leads and PCB pads.

5. Overloading Components: Exceeding the voltage or current ratings of electronic components is a common mistake. Overloading components beyond their specified limits can cause irreparable damage or even pose safety risks. It is important to understand the voltage and current requirements of the components and design circuits that operate within their specified limits.

6. Incorrect Component Handling: Mishandling components can damage delicate structures or sensitive leads. Bending, flexing, or improperly seating components can cause internal damage or result in poor electrical contact. It is crucial to handle components with care, avoiding excessive force or mishandling that could lead to physical damage.

7. Lack of Testing and Verification: Not testing or verifying electronic systems before deployment can result in undetected issues that may lead to failures in real-world operating conditions. Proper testing and verification procedures should be implemented to identify problems early on, ensuring the reliability and functionality of the electronic system.

To avoid these common mistakes, it is important to follow best practices, adhere to manufacturer guidelines, and continuously educate oneself on proper handling and usage techniques for electronic components.

Testing the Limits: Examples of Component Damage from Voltage

Exceeding the voltage limits of electronic components can have disastrous consequences, causing irreparable damage or complete failure. Understanding the potential damage that can occur from voltage overload is crucial for designing electronic circuits and ensuring the longevity of the components. Here are a few examples of the damage that can result from voltage exceeding the rated limits:

1. Diode Failure: Diodes have a maximum reverse voltage rating, also known as the breakdown voltage. If this rating is exceeded, the diode can experience reverse breakdown, leading to a short circuit or component failure. The diode may stop functioning as a one-way valve for current flow, allowing current to flow in both directions and compromising the overall circuit operation.

2. Capacitor Damage: Capacitors store and release electrical energy. Exceeding the voltage rating of a capacitor can cause the dielectric material to break down, leading to decreased capacitance, increased leakage current, or even catastrophic failure. Capacitors may physically rupture or emit smoke when subjected to excessive voltage.

3. Transistor Degradation: Transistors, particularly those used for amplification or switching, have maximum voltage ratings for their various terminals. Overloading a transistor beyond its voltage rating can cause permanent damage or degrade its performance. The transistor may exhibit increased leakage current, reduced gain or switching speed, or even complete failure.

4. Integrated Circuit Failure: Integrated circuits (ICs) contain multiple components on a single chip. If the voltage exceeds the maximum rating specified by the IC manufacturer, it can damage the internal transistors, interfere with logical operations, or cause the IC to malfunction. Overvoltage can lead to irreversible damage and render the IC unusable.

5. Inductor Saturation: Inductors store energy in a magnetic field and have a current rating that indicates the maximum current they can handle. If the current exceeds the rated value, the magnetic field within the inductor can saturate, causing a loss of inductance and affecting the circuit’s performance. Excessive voltage can cause increased current flow, pushing the inductor beyond its limits and resulting in improper circuit operation or component failure.

These examples highlight the importance of operating components within their specified voltage limits. Exceeding these limits can lead to immediate or long-term damage, compromising the functionality, reliability, and lifespan of electronic circuits and systems. It is crucial to design circuits and select components that can handle the expected voltage levels to ensure optimal performance and longevity.

Protecting Your Electronic Components

Protecting electronic components is essential for maintaining their functionality, preventing damage, and ensuring the longevity of your electronic systems. By implementing proper protection measures, you can safeguard your components from voltage spikes, electrostatic discharge (ESD), and other potential hazards. Here are some ways to protect your electronic components:

1. Use Circuit Protection Devices: Incorporate circuit protection devices such as surge protectors, fuses, circuit breakers, and voltage regulators. Surge protectors divert excess voltage spikes to protect sensitive components. Fuses and circuit breakers provide overcurrent protection, interrupting the flow of current when it exceeds safe limits. Voltage regulators maintain a stable and regulated voltage output, protecting components from voltage fluctuations.

2. Handle Components Properly: Take precautions to prevent ESD. Wear an antistatic wrist strap and use antistatic mats or conductive containers when handling components. Avoid touching sensitive leads or pins directly. Properly discharge static electricity before touching or installing components. Keep components in antistatic bags until ready for use.

3. Implement Proper Cooling: Overheating can lead to component damage and decreased lifespan. Ensure proper heat sinking and ventilation to dissipate heat effectively. Use fans, heat sinks, or thermal management solutions to maintain safe operating temperatures. Consider the thermal tolerance of the components when designing the system and provide adequate cooling measures accordingly.

4. Follow Soldering Best Practices: Practice proper soldering techniques to ensure reliable connections and prevent damage to components. Use the correct temperature, flux, and soldering iron for the specific components being soldered. Ensure clean and properly heated connections, avoiding cold solder joints or bridges. Properly clean excess flux residue after soldering to prevent corrosion.

5. Perform Component Testing: Test components before integration into the circuit to identify any potential issues or defects. Use multimeters, oscilloscopes, or dedicated testing equipment to measure resistance, voltage, and other relevant parameters. Verify the functionality of the components, ensuring they are within their specified limits.

6. Design for Component Protection: Consider component protection during the circuit design phase. Select components with suitable voltage and current ratings for the intended application. Pay attention to the environmental conditions in which the circuit will operate and design accordingly. Provide proper shielding or encapsulation for components exposed to moisture, dust, or other environmental factors.

7. Plan for Proper Maintenance: Regularly inspect and maintain your electronic systems to keep them in optimal condition. Replace components that show signs of degradation or damage. Keep track of component lifespans and plan for timely replacements. Implement proper cleaning procedures and periodic inspections to prevent problems caused by dust, corrosion, or mechanical wear.

By taking these protective measures, you can safeguard your electronic components from potential risks and enhance their performance and longevity. Remember to consult component datasheets and manufacturer guidelines for specific recommendations on handling, storage, and operation to ensure proper protection of your components.