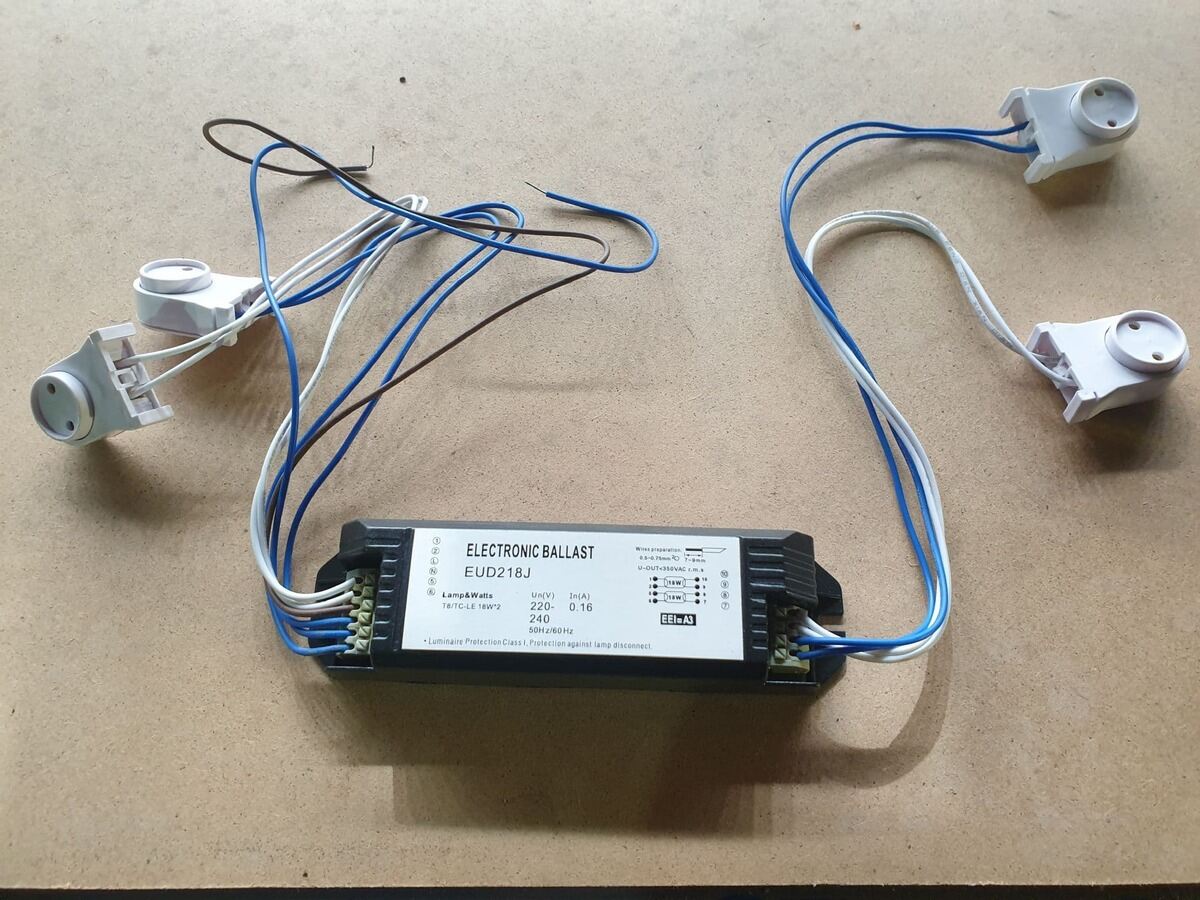

Components of an Electronic Ballast

An electronic ballast is a crucial component in modern lighting systems that provide efficient and reliable operation for fluorescent lamps. It consists of several key components that work in harmony to regulate the flow of current and voltage, ensuring optimal lamp performance. Here are the main components of an electronic ballast:

- Power Factor Correction circuit (PFC): The PFC circuit is responsible for improving the power factor of the ballast. It helps to minimize the reactive power and improves the overall efficiency of the electronic ballast.

- Rectifier: The rectifier converts the alternating current (AC) from the power source into direct current (DC) by using diodes. This DC current is then fed into the other components of the ballast.

- Inverter: The inverter circuit converts the DC current into high-frequency alternating current. It generates a square wave or a high-frequency pulse to power the fluorescent lamp.

- Resonant Circuit: The resonant circuit works in conjunction with the inverter circuit to create a controlled oscillation and regulate the power output. It helps to maintain a stable frequency and voltage across the lamp.

- Capacitors: Capacitors are used to store and release electrical energy. They help in maintaining a steady voltage supply to the lamp and improve the stability of the system.

- Inductors: Inductors are used to control the current flow in the ballast circuit. They help to limit the current and protect the lamp from overloading.

- Integrated Circuit (IC): The IC acts as the brain of the electronic ballast. It controls the overall operation of the ballast, including the frequency, current, and protection mechanisms.

These components work together seamlessly to provide consistent and efficient power to the fluorescent lamp. The design and quality of these components greatly impact the performance and lifespan of the electronic ballast.

Role of the Starting Circuit

The starting circuit is a crucial part of an electronic ballast that is responsible for initiating the lamp ignition process. It plays a vital role in ensuring reliable and efficient starting of fluorescent lamps. Here are the key functions and components of the starting circuit:

- Preheating: Before the lamp can be lit, the starting circuit preheats the lamp electrodes. It provides a low-level current to warm up the electrodes, promoting easier and faster ignition.

- Ignition: Once the electrodes are preheated, the starting circuit generates a high voltage pulse to initiate the discharge process in the lamp. This high voltage creates a spark across the lamp’s electrodes, ionizing the gas inside and enabling the fluorescent light to be emitted.

- Starting Components: The starting circuit consists of several components that work together to facilitate the ignition process. These typically include a starting capacitor, a starting inductor or transformer, and a starting resistor. These components help in generating the necessary high voltage pulse and regulate the current flow during lamp ignition.

- Resetting: After successful ignition, the starting circuit resets itself to ensure proper lamp operation. It disconnects the high-voltage pulse and transitions into a steady-state mode of operation.

The starting circuit is crucial because it ensures that the lamp starts quickly and reliably. Without a well-designed starting circuit, the lamp may fail to ignite or experience flickering, leading to reduced performance and shorter lamp lifespan.

Furthermore, the starting circuit also contributes to the overall power and energy efficiency of the electronic ballast. It helps to minimize power losses during the ignition process and ensures that the lamp reaches its full brightness efficiently.

Working Principle of an Electronic Ballast

An electronic ballast operates on the principle of converting the incoming AC voltage to a high-frequency AC voltage to regulate the current and voltage supplied to the fluorescent lamp. This efficient and precise control allows for improved lamp performance and energy efficiency. Here’s an overview of the working principle of an electronic ballast:

1. AC to DC Conversion: The electronic ballast starts by converting the incoming AC voltage from the power source into DC voltage using a rectifier circuit. The rectifier consists of diodes that convert the alternating current to direct current, which is essential for the subsequent stages of the ballast operation.

2. Inverter Stage: The converted DC voltage is then fed into an inverter circuit. The inverter stage uses high-frequency switching devices, such as MOSFETs or IGBTs, to convert the DC voltage into high-frequency AC voltage. This high-frequency AC voltage is typically in the range of 20,000 to 100,000 Hz.

3. Resonant Circuit: The high-frequency AC voltage from the inverter stage is then fed into a resonant circuit, which typically consists of capacitors and inductors. The resonant circuit helps regulate and stabilize the voltage and current supplied to the fluorescent lamp. It ensures that the lamp operates at its optimal performance by maintaining a consistent voltage and frequency.

4. Power Factor Correction: Many modern electronic ballasts incorporate a Power Factor Correction (PFC) circuit to improve the overall power factor of the ballast. The PFC circuit helps the ballast operate more efficiently by minimizing the reactive power and bringing the power factor closer to unity.

5. Lamp Operation and Regulation: The regulated AC voltage and current from the resonant circuit are then supplied to the fluorescent lamp for operation. The ballast ensures that the lamp receives the necessary voltage and current to produce light efficiently and consistently.

By utilizing high-frequency AC voltage, electronic ballasts eliminate the flickering commonly associated with magnetic ballasts. The high-frequency operation also reduces the overall size and weight of the ballast, making it more compact and easier to handle.

Furthermore, the precise control of voltage and current by electronic ballasts results in improved energy efficiency and longer lamp life compared to traditional magnetic ballasts.

Comparison with Magnetic Ballasts

Electronic ballasts have gained popularity over traditional magnetic ballasts due to their numerous advantages in terms of performance, efficiency, and lifespan. Let’s compare electronic ballasts with magnetic ballasts to understand their key differences:

1. Efficiency: Electronic ballasts are significantly more energy-efficient compared to magnetic ballasts. They utilize high-frequency AC voltage, which reduces energy losses and improves overall power factor. This results in lower energy consumption and reduced electricity costs.

2. Size and Weight: Electronic ballasts are smaller and lighter compared to magnetic ballasts. This makes them easier to handle, install, and integrate into lighting fixtures. The compact size of electronic ballasts also allows for more flexibility in design and placement of lighting systems.

3. Flickering and Noise: Electronic ballasts operate at high frequencies, typically between 20,000 to 100,000 Hz. This high-frequency operation eliminates flickering and reduces audible noise, providing a more comfortable and pleasant lighting experience compared to magnetic ballasts.

4. Lamp Life: Electronic ballasts contribute to longer lamp life. The precise control of voltage and current reduces stress on the lamp electrodes, resulting in less wear and tear. This leads to extended lamp life and lower maintenance costs compared to magnetic ballasts.

5. Dimming Capability: Electronic ballasts offer better dimming capabilities compared to magnetic ballasts. They can smoothly dim the lamp brightness without flickering or color shifting. This level of control allows for versatile lighting options in various environments.

6. Instant Start: Electronic ballasts provide instant lamp start-up without any noticeable delay. On the other hand, magnetic ballasts may require a brief delay before the lamp reaches full brightness.

7. Environmental Impact: Electronic ballasts are more environmentally friendly compared to magnetic ballasts. They consume less energy, resulting in reduced greenhouse gas emissions. Additionally, electronic ballasts do not contain harmful substances such as mercury, which is commonly found in magnetic ballasts.

Overall, electronic ballasts offer superior performance, energy efficiency, and lamp lifespan compared to magnetic ballasts. While magnetic ballasts may still be suitable for specific applications, such as in older lighting fixtures, electronic ballasts have become the preferred choice for modern lighting systems.

Benefits of Electronic Ballasts

Electronic ballasts offer a range of benefits compared to traditional magnetic ballasts. These advantages make electronic ballasts the preferred choice for modern lighting systems. Let’s explore the key benefits of electronic ballasts:

1. Energy Efficiency: Electronic ballasts are highly energy-efficient. They convert AC voltage to high-frequency AC voltage, minimizing energy losses and improving power factor. This results in reduced energy consumption and lower electricity costs.

2. Improved Lamp Performance: Electronic ballasts provide stable and precise control of voltage and current supplied to the lamp. This results in better light output, reduced flickering, and improved color rendering. Electronic ballasts can optimize the performance of fluorescent lamps, leading to enhanced visual comfort and productivity.

3. Longer Lamp Life: By regulating voltage and current, electronic ballasts reduce stress on the lamp electrodes, which extends the lamp’s lifespan. This translates to lower maintenance costs and fewer lamp replacements over time.

4. Compact Size and Lightweight: Electronic ballasts have a compact design, making them smaller and lighter compared to magnetic ballasts. This allows for easier installation and integration into lighting fixtures. The reduced size also provides flexibility in design and placement of lighting systems.

5. Dimming Capability: Electronic ballasts offer excellent dimming capabilities, allowing for flexible lighting control. They can smoothly dim the light output without flickering or color shifting. This feature is particularly advantageous in environments where variable lighting levels are desired, such as offices, restaurants, and residential spaces.

6. Instant Start and Restrike: Electronic ballasts enable instant lamp start-up without any noticeable delay. Additionally, in case of power interruptions, electronic ballasts can quickly restrike the lamp once power is restored. This ensures continuous lighting operation without disruption.

7. Reduced Noise and Flickering: The high-frequency operation of electronic ballasts eliminates audible noise and flickering commonly associated with magnetic ballasts. This provides a more comfortable and visually pleasing lighting experience for users.

8. Environmental Friendliness: Electronic ballasts have a reduced environmental impact compared to magnetic ballasts. They consume less energy, leading to lower greenhouse gas emissions. Additionally, electronic ballasts do not contain hazardous substances like mercury, which is present in some magnetic ballasts.

Overall, electronic ballasts offer a range of benefits, including energy efficiency, improved lamp performance, extended lamp life, compact size, dimming capability, instant start and restrike, reduced noise and flickering, and environmental friendliness. These advantages make electronic ballasts an excellent choice for efficient and sustainable lighting solutions.

Common Problems with Electronic Ballasts

While electronic ballasts offer numerous advantages, they are not immune to certain issues and challenges. Here are some common problems that can arise with electronic ballasts:

1. Lamp Flickering: One common issue experienced with electronic ballasts is lamp flickering. This can occur due to various reasons, such as incompatible lamps, poor connections, or faulty components. Flickering can not only be visually distracting but can also lead to reduced lamp lifespan.

2. Incompatibility with Dimmer Switches: Some electronic ballasts may not be compatible with certain dimmer switches. This can result in inconsistent dimming performance, flickering, or even damage to the ballast. It is essential to ensure compatibility between the electronic ballast and the dimmer switch before installation.

3. Ballast Failure: Like any electronic device, electronic ballasts can experience failures. This can be due to factors such as power surges, overheating, or component deterioration over time. Ballast failure will result in the lamp not turning on or sporadic lamp operation, requiring replacement of the ballast.

4. EMI Interference: Electronic ballasts can emit electromagnetic interference (EMI), which may interfere with nearby electronic devices. This can lead to operational issues or affect the performance of sensitive equipment. Proper shielding and grounding techniques can help reduce EMI interference.

5. Ignition Issues: Problems with lamp ignition can occur with electronic ballasts. This can result from insufficient preheating of the lamp electrodes or faulty starting components. Ignition issues may lead to delay in lamp start-up, intermittent lamp operation, or complete failure to ignite the lamp.

6. Overheating: Electronic ballasts can generate heat during operation, and if not properly managed, this can cause overheating. Excessive heat can damage the ballast components and reduce its lifespan. Adequate ventilation and ensuring the ballast operates within its specified temperature range are crucial to prevent overheating issues.

7. Power Quality Sensitivity: Some electronic ballasts may be sensitive to fluctuations in power quality. Variations in voltage or frequency beyond the ballast’s tolerance range can affect its performance and lamp operation. Using voltage stabilizers or surge protectors can help mitigate power quality issues.

8. Compatibility with Lamps: Certain electronic ballasts may have limited compatibility with specific lamp types, wattages, or brands. It is important to ensure that the ballast is compatible with the intended lamps to ensure optimal performance and prevent issues such as premature lamp failure or erratic lamp operation.

Addressing these common problems requires proper installation, regular maintenance, and quality components. It is always recommended to consult the manufacturer’s instructions and guidelines when troubleshooting issues with electronic ballasts.

Troubleshooting Tips for Electronic Ballasts

When encountering issues with electronic ballasts, there are several troubleshooting steps you can take to identify and resolve the problem. Here are some useful tips to help troubleshoot electronic ballast issues:

1. Ensure Proper Wiring: Check that all connections are secure and properly wired. Loose or faulty connections can result in flickering, intermittent operation, or complete failure of the ballast. Verify that the wiring follows the manufacturer’s instructions to ensure accurate installation.

2. Inspect for Physical Damage: Visually inspect the ballast for any signs of physical damage, such as burns, melted components, or bulging capacitors. Physical damage may indicate a faulty ballast that requires replacement.

3. Check for Lamp Compatibility: Verify that the lamps being used are compatible with the electronic ballast. Incorrect lamp types or wattages can cause flickering, reduced performance, or premature lamp failure. Consult the ballast manufacturer’s specifications for the recommended lamp compatibility.

4. Test the Power Supply: Ensure that the power supply to the electronic ballast is stable and within the specified voltage and frequency ranges. Fluctuations in power supply can result in issues such as flickering, dimming, or erratic operation of the ballast. Consider using a voltage stabilizer or surge protector to regulate the power supply.

5. Inspect Starting Components: Check the starting components, such as the starting capacitor and inductor, for any damage or signs of wear. Faulty starting components can lead to ignition issues, lamp flickering, or failure to start. Replace any faulty components as necessary.

6. Allow for Warm-Up Time: Fluorescent lamps may require a short warm-up time before reaching full brightness. If the lamp takes longer than usual to start, allow it a few minutes to warm up before assuming there is a problem with the ballast.

7. Consult the Manufacturer: If troubleshooting steps do not resolve the issue, it is recommended to reach out to the ballast manufacturer’s technical support or customer service. They can provide specific guidance or arrange for further troubleshooting or ballast replacement if necessary.

8. Seek Professional Assistance: If you are not familiar with electrical systems or troubleshooting techniques, it is advisable to seek assistance from a qualified electrician. They have the necessary skills and knowledge to diagnose and repair issues with electronic ballasts safely and effectively.

Remember to exercise caution when working with electrical components and ensure that the power supply is disconnected before inspecting or replacing any parts. Adhering to manufacturer guidelines and seeking professional help when needed will help resolve electronic ballast problems efficiently.

Maintenance Tips for Electronic Ballasts

Maintaining electronic ballasts is essential to ensure optimal performance and longevity of the lighting system. Regular maintenance can help prevent issues and prolong the lifespan of the ballasts. Here are some helpful maintenance tips for electronic ballasts:

1. Clean the Ballast: Over time, dust and debris can accumulate on the surface of the ballast. Cleaning the ballast regularly using a soft brush or compressed air can prevent heat buildup and improve ventilation. Ensure the power supply is turned off before cleaning to prevent any accidents.

2. Inspect for Physical Damage: Periodically inspect the electronic ballasts for any physical damage, such as cracks, leaks, or bent pins. Physical damage can impact the ballast’s performance and may require immediate repair or replacement.

3. Check for Loose Connections: Ensure that all connections, including wiring and terminals, are secure and properly tightened. Loose connections can lead to flickering or intermittent operation. Regularly inspect and tighten any loose connections to maintain a stable electrical connection.

4. Avoid Overloading: Ensure that the electronic ballast is not overloaded with too many lamps or fixtures. Excessive load can put strain on the ballast, leading to reduced performance and potential failure. Follow the manufacturer’s guidelines regarding the maximum load capacity for the ballast.

5. Maintain Proper Ventilation: Ensure that the electronic ballasts have adequate ventilation in their installation location. Proper airflow helps dissipate heat and prevents overheating. Avoid placing the ballast in enclosed spaces or covering it with objects that obstruct airflow.

6. Monitor Operating Conditions: Regularly monitor the operating conditions of the electronic ballasts, including temperature and voltage fluctuations. Ensure that the ballasts are operating within the specified temperature range and in a stable voltage environment. Fluctuations beyond the ballast’s tolerance range can lead to performance issues and reduced lifespan.

7. Follow Manufacturer’s Guidelines: Adhere to the manufacturer’s guidelines and recommendations for maintenance and care. These guidelines provide specific instructions for cleaning, installation, and troubleshooting. Following these instructions ensures that the electronic ballasts are properly maintained and operated.

8. Replace Faulty Components Promptly: If any components within the electronic ballast are damaged or malfunctioning, replace them promptly. Faulty components can adversely affect the performance of the ballast and may lead to further issues if left unaddressed.

9. Stay Updated with Technology: Keep abreast of advancements in electronic ballast technology and industry standards. Regularly check for firmware updates or software enhancements provided by the manufacturer to ensure optimal performance and compatibility.

Regular maintenance of electronic ballasts helps maximize their lifespan, minimize performance issues, and ensure efficient and reliable operation. By following these maintenance tips, you can extend the longevity of your electronic ballasts and maintain a well-functioning lighting system.

Applications of Electronic Ballasts

The wide range of benefits offered by electronic ballasts has led to their widespread adoption in various lighting applications. From residential to commercial and industrial settings, electronic ballasts provide efficient and reliable lighting solutions. Here are some key applications of electronic ballasts:

1. Residential Lighting: Electronic ballasts are commonly used in residential lighting applications, including homes, apartments, and condominiums. They are compatible with a variety of fluorescent lamps, providing energy-efficient and flicker-free lighting for everyday use.

2. Office and Commercial Spaces: Electronic ballasts are extensively used in office buildings, retail stores, and commercial spaces. They offer high-quality illumination, improved color rendering, and efficient operation, resulting in a comfortable and productive working environment.

3. Educational Institutions: Schools, colleges, and universities often rely on electronic ballasts to provide consistent and energy-efficient lighting in classrooms, libraries, laboratories, and other educational spaces. The technology’s ability to reduce flickering enhances the learning experience for students.

4. Healthcare Facilities: Electronic ballasts are suitable for healthcare environments, such as hospitals, clinics, and medical offices. The flicker-free operation and precise control of lighting ensure comfortable and accurate illumination in patient rooms, operating theaters, and diagnostic areas.

5. Hospitality Industry: Hotels, restaurants, and resorts utilize electronic ballasts to create a pleasant ambiance for guests. The dimming capabilities of electronic ballasts allow for adjustable lighting levels in dining areas, lobbies, and guestrooms, enhancing the overall guest experience.

6. Industrial and Manufacturing Facilities: Electronic ballasts find applications in industrial and manufacturing facilities, providing energy-efficient lighting for warehouses, factories, and assembly lines. The flicker-free illumination reduces eye strain and enables better visibility, contributing to increased productivity and worker safety.

7. Outdoor Lighting: Electronic ballasts are utilized in outdoor lighting systems, including street lighting, parking lots, and sports fields. The energy efficiency and durability of electronic ballasts ensure reliable operation and reduced maintenance requirements in these applications.

8. Sustainable and Green Building Projects: Electronic ballasts align with sustainability goals in green building projects. Their energy-efficient operation decreases power consumption, leading to reduced carbon emissions. Incorporating electronic ballasts in energy-efficient lighting systems contributes to achieving green building certifications, such as LEED.

9. Retrofit Applications: Electronic ballasts are also suitable for retrofitting existing lighting systems. They can replace obsolete magnetic ballasts, providing upgraded performance, improved energy efficiency, and enhanced lighting quality without major modifications to the fixture design.

With their versatility, efficiency, and improved lighting performance, electronic ballasts are widely used in various applications. Their adoption continues to grow as lighting technology evolves and energy conservation becomes increasingly important for sustainable and cost-effective lighting solutions.

Future Trends in Electronic Ballast Technology

As technology continues to advance, the field of electronic ballast technology is not exempt from innovation and evolution. Several trends are shaping the future of electronic ballasts, enabling even more efficient and sustainable lighting solutions. Here are some key trends to watch for:

1. Improved Energy Efficiency: The pursuit of enhanced energy efficiency remains a primary focus in electronic ballast technology. Advances in power electronics and circuit design aim to further reduce energy losses and optimize power factor correction. This will lead to even more efficient electronic ballasts that consume less energy while maintaining high performance.

2. Integration with Smart Lighting Systems: Electronic ballasts are becoming increasingly integrated with smart lighting systems and Internet of Things (IoT) technologies. This integration allows for better control and automation of lighting, enabling features such as occupancy sensing, daylight harvesting, and remote monitoring and control. Smart lighting systems, when combined with electronic ballasts, provide flexible and energy-efficient lighting solutions.

3. Wireless Communication and Connectivity: The future of electronic ballasts lies in wireless communication and connectivity capabilities. This allows for seamless integration with lighting control systems, facilitating simplified installation and operation. Wireless communication also enables dynamic lighting control, enabling changes in lighting intensity or color temperature according to specific requirements or preferences.

4. Miniaturization and Integration: The trend towards miniaturization and integration is set to continue in electronic ballast technology. Smaller form factors and increased integration of components will enable easier installation and integration into various lighting fixtures. This will provide greater flexibility in lighting design and help create sleek and aesthetically pleasing luminaires.

5. Enhanced Compatibility and Retrofit Solutions: Future electronic ballasts will offer improved compatibility with a wide range of lamps, ensuring seamless integration and retrofitting options. This will make it easier to upgrade existing lighting systems from older magnetic ballasts to more efficient electronic ballasts, reducing energy consumption and enhancing lighting performance without the need for extensive modifications.

6. Integration of Power Quality Monitoring: Electronic ballasts of the future may incorporate power quality monitoring capabilities. This will enable real-time monitoring of voltage, current, and power quality parameters, allowing for optimized operation and early detection of power issues. Power quality monitoring will contribute to enhanced performance, longer lifespan, and improved reliability of the electronic ballasts.

7. Focus on Environmental Sustainability: With a growing emphasis on sustainability, future electronic ballast technologies will continue to prioritize environmental-friendly features. This includes reduced material waste, increased use of recyclable components, and the elimination of hazardous substances. Electronic ballasts will continue to contribute to achieving energy efficiency goals and reducing carbon footprints.