Materials Needed

To create a Dupont connector, you will need the following materials:

1. Dupont Connector Kit

A Dupont connector kit typically includes connector housings, male and female pins, and crimping tools. Ensure that the kit contains all the necessary components to complete the connector assembly.

2. Wire Strippers

Wire strippers are essential for removing the insulation from the tips of the wires. This tool allows for precise and clean stripping, ensuring a secure connection within the connector.

3. Wire Cutters

Wire cutters are used to trim the wires to the required length. They enable accurate and neat cuts, contributing to the overall quality and functionality of the connector.

4. Crimping Tool

A crimping tool is vital for attaching the pins to the stripped wires. It provides the necessary pressure to secure the pins in place, forming a reliable electrical connection.

5. Wires

Select wires of the appropriate gauge and length for your specific project. The wires should be compatible with the Dupont connector kit and capable of transmitting the required electrical signals effectively.

6. Safety Equipment

Safety should always be a priority. Ensure you have safety goggles and, if necessary, gloves to protect yourself from any potential hazards while working with the materials and tools.

7. Work Surface

Having a stable and well-lit work surface is crucial for performing the assembly with precision and accuracy. It is essential to work in a well-ventilated area with ample space to maneuver the tools and materials effectively.

Gathering these materials will set the stage for a successful DIY Dupont connector project. Now that you have all the necessary components, it's time to move on to the next step: gathering the tools.

Step 1: Gather the Tools

Before diving into the process of creating a Dupont connector, it’s crucial to ensure that you have all the necessary tools at your disposal. Each tool plays a vital role in achieving a successful and reliable connector assembly.

1. Organize the Work Area

Start by setting up a well-lit and organized work area. Clear any clutter and ensure that you have ample space to maneuver the tools and materials. A clutter-free environment minimizes the risk of misplacing components and promotes a focused and efficient workflow.

2. Prepare the Wire Strippers and Cutters

Have the wire strippers and cutters readily accessible. These tools are essential for preparing the wires before crimping the pins. Ensure that the wire strippers are adjusted to the appropriate gauge for the wires being used, and the wire cutters are sharp and precise for clean cuts.

3. Check the Crimping Tool

Inspect the crimping tool to ensure that it is in optimal working condition. The tool should provide a secure and uniform crimp to attach the pins to the wires effectively. Verify that the crimping tool is suitable for the specific type of Dupont connector being assembled.

4. Verify the Dupont Connector Kit Contents

Thoroughly review the contents of the Dupont connector kit. Ensure that it includes the necessary connector housings, male and female pins, and any additional components required for the specific connector type. Having a complete kit is essential for a seamless assembly process.

5. Safety Equipment

Prioritize safety by having safety goggles and, if necessary, gloves within reach. These items provide essential protection during the assembly process, especially when using wire strippers, cutters, and the crimping tool. Safety should always be a top priority in any DIY project.

By gathering the essential tools and ensuring that everything is in proper working order, you are setting the stage for a smooth and efficient process of creating a Dupont connector. With the tools organized and ready, you can proceed to the next step: preparing the wires.

Step 2: Prepare the Wires

Preparing the wires is a crucial step in creating a Dupont connector. Properly stripped and trimmed wires ensure a secure and reliable electrical connection within the connector. Follow these steps to prepare the wires for the assembly process:

1. Select the Wires

Choose wires of the appropriate gauge and length for your specific project. It’s essential to match the wire gauge with the connector’s specifications to ensure compatibility and optimal electrical conductivity. Selecting the correct wire length is also important to avoid excess wire that could lead to clutter within the connector.

2. Strip the Wires

Using the wire strippers, carefully strip off a small portion of the wire insulation from the tips of the wires. Exercise caution to avoid damaging the conductive wire strands during the stripping process. The exposed wire ends should be clean and free from any excess insulation to facilitate a secure connection.

3. Trim the Wires

Once the wires are stripped, use the wire cutters to trim them to the required length. Precision is key when trimming the wires, as it ensures a neat and organized arrangement within the connector housing. Properly trimmed wires contribute to a well-organized and efficient assembly process.

4. Verify the Wire Preparation

After stripping and trimming the wires, verify that each wire is prepared according to the project’s requirements. Check for any irregularities or damage to the wire strands that may affect the integrity of the electrical connection. Well-prepared wires are essential for the subsequent steps in the assembly process.

5. Organize the Prepared Wires

Once the wires are prepared, organize them in a systematic manner, ensuring that they are easily identifiable and accessible during the crimping and insertion process. Proper organization minimizes confusion and streamlines the assembly of the Dupont connector.

With the wires meticulously prepared, you are now ready to proceed to the next step: crimping the pins onto the wires.

Step 3: Crimping the Pins

Crimping the pins onto the prepared wires is a critical step in the assembly of a Dupont connector. This process ensures a secure and reliable connection, allowing for effective transmission of electrical signals. Follow these steps to properly crimp the pins onto the wires:

1. Position the Pin in the Crimping Tool

Place the pin securely in the crimping tool, ensuring that it is aligned properly for a uniform crimp. The pin should be positioned to receive the stripped end of the wire, allowing for a tight and secure connection. Proper positioning sets the stage for a successful crimping process.

2. Insert the Wire into the Pin

Gently insert the stripped end of the prepared wire into the pin, ensuring that it is fully seated and making contact with the metal conductor inside the pin. The wire should be positioned to receive the crimping action, creating a robust and stable connection within the pin.

3. Apply Even Pressure

With the wire inserted, apply even pressure using the crimping tool to secure the pin onto the wire. The crimping action should be uniform and firm, creating a tight bond between the wire and the pin. Consistent pressure ensures a reliable electrical connection that withstands movement and environmental factors.

4. Verify the Crimped Connection

After crimping the pin onto the wire, carefully inspect the connection to ensure that the wire is securely held within the pin. Verify that the crimping process has created a solid and stable connection without damaging the wire strands. A thorough inspection guarantees the integrity of the crimped connection.

5. Repeat for Each Wire

Repeat the crimping process for each wire that will be inserted into the Dupont connector. Exercise precision and care with each crimp to maintain consistency and reliability across all connections. Properly crimped pins are essential for the next phase of the assembly process.

With the pins successfully crimped onto the wires, you are now ready to proceed to the next step: inserting the pins into the connector housing.

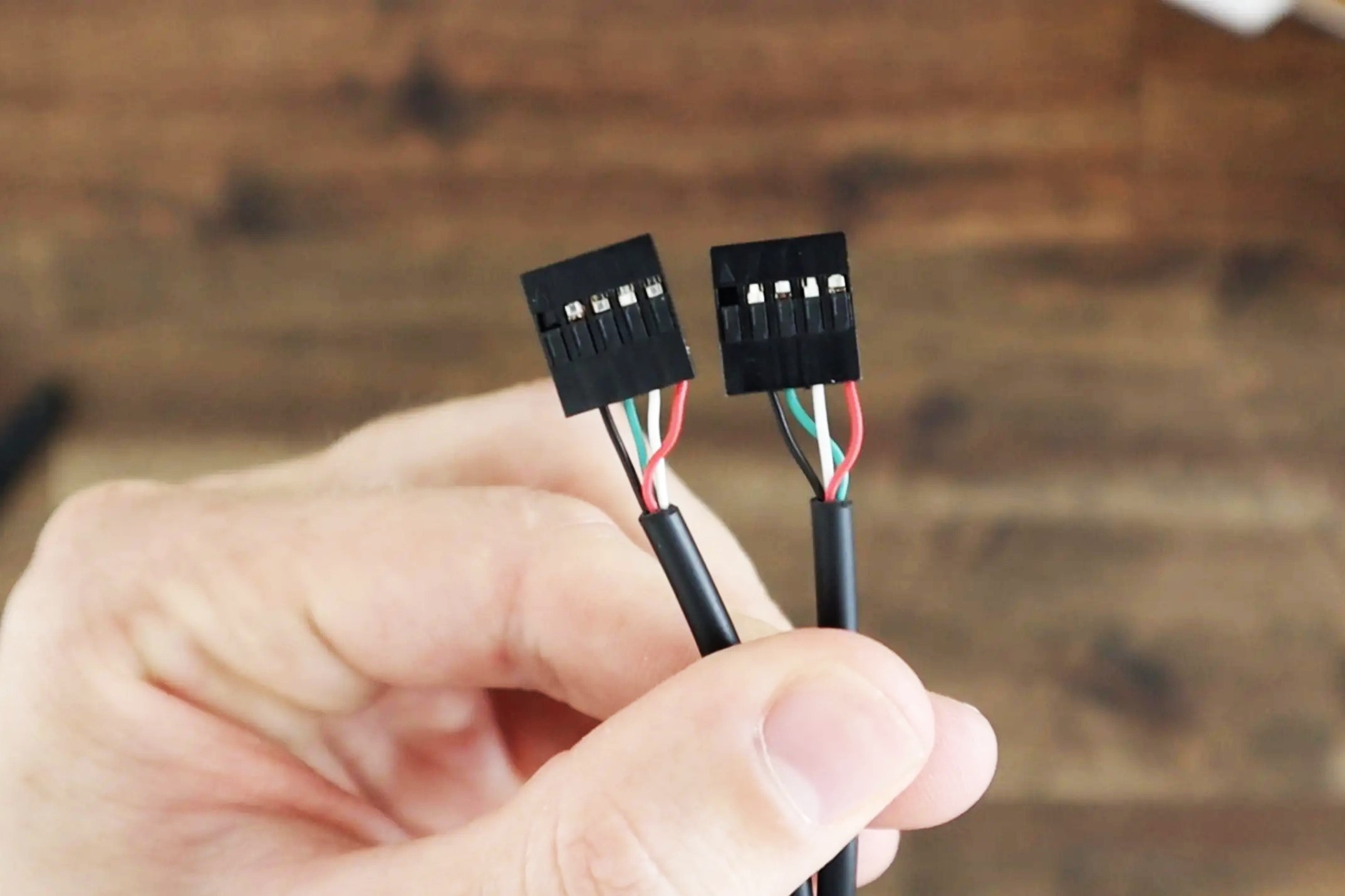

Step 4: Inserting the Pins into the Connector Housing

Inserting the crimped pins into the connector housing is a pivotal phase in the assembly of a Dupont connector. This step ensures that the pins are securely housed, providing a stable and organized platform for creating electrical connections. Follow these steps to effectively insert the pins into the connector housing:

1. Orient the Connector Housing

Take the connector housing and orient it to align with the arrangement of the pins. The housing should accommodate the pins comfortably, allowing for smooth insertion without any obstructions. Proper orientation sets the stage for a seamless insertion process.

2. Position the Crimped Pins

Gently position the crimped pins, ensuring that each pin is aligned with its respective slot or receptacle within the connector housing. The pins should slide into place smoothly, without resistance, to establish a secure and organized configuration within the housing.

3. Verify the Alignment

Verify that the pins are aligned correctly within the housing, with each pin securely seated in its designated position. Proper alignment ensures that the electrical connections will be established accurately when the connector is engaged, contributing to the functionality and reliability of the assembly.

4. Ensure a Snug Fit

Confirm that the crimped pins fit snugly within the connector housing, preventing any unnecessary movement or dislodgment. A secure fit minimizes the risk of intermittent connections and ensures the stability of the electrical contacts within the connector assembly.

5. Double-Check the Arrangement

Double-check the arrangement of the crimped pins within the connector housing to ensure that each pin is in its designated location and that the overall configuration is orderly and secure. Attention to detail at this stage contributes to a reliable and well-organized connector assembly.

With the crimped pins successfully inserted into the connector housing, you are now ready to proceed to the next step: securing the pins in the connector housing.

Step 5: Securing the Pins in the Connector Housing

Securing the pins within the connector housing is a critical phase in the assembly of a Dupont connector. This step ensures that the pins remain in position, maintaining stable electrical connections and preventing dislodgment during use. Follow these steps to effectively secure the pins in the connector housing:

1. Assess the Retention Mechanism

Examine the retention mechanism of the connector housing to identify the method for securing the pins in place. Different Dupont connectors may utilize locking tabs, clips, or other retention features to ensure the stability of the inserted pins. Understanding the retention mechanism is crucial for the next steps.

2. Engage the Retention Feature

Activate the retention feature, whether it involves locking tabs, clips, or other securing elements. Follow the specific instructions for the connector housing to engage the retention mechanism, ensuring that it firmly holds the inserted pins in place. A secure retention feature is vital for the stability of the connector assembly.

3. Verify the Secure Fit

After engaging the retention feature, carefully verify that each pin is held securely within the connector housing. Confirm that the retention mechanism effectively prevents the pins from shifting or dislodging, maintaining the integrity of the electrical connections. A thorough check ensures the stability of the secured pins.

4. Test the Stability

Gently test the stability of the secured pins by applying slight pressure to ensure that they remain in place. The pins should withstand minimal force without shifting or coming loose from the connector housing. Testing the stability guarantees the reliability of the secured pins in practical use.

5. Inspect the Completed Assembly

Inspect the completed assembly to ensure that all pins are securely housed and that the retention mechanism effectively maintains their position. A comprehensive inspection confirms the successful securing of the pins within the connector housing, setting the stage for the final step in the assembly process.

With the pins securely housed and the retention mechanism engaged, you are now ready to proceed to the next step: testing the connection.

Step 6: Testing the Connection

Testing the connection of the assembled Dupont connector is a crucial final step to ensure its functionality and reliability. By conducting thorough testing, you can verify the integrity of the electrical connections and identify any potential issues that require adjustment. Follow these steps to effectively test the connection of the Dupont connector:

1. Conduct a Visual Inspection

Begin by visually inspecting the connector assembly, focusing on the arrangement of the pins within the housing and the overall condition of the wires and crimped connections. Look for any signs of misalignment, damage, or irregularities that may affect the performance of the connector.

2. Use a Multimeter

Utilize a multimeter to conduct continuity tests on the connector assembly. Check for proper electrical continuity between the corresponding pins, ensuring that the connections are established without any breaks or inconsistencies. The multimeter provides valuable insights into the integrity of the electrical pathways within the connector.

3. Perform a Tug Test

Gently perform a tug test on the wires to assess the strength of the crimped connections and the stability of the pins within the housing. The wires should remain securely attached to the pins, demonstrating the resilience of the crimped connections and the effectiveness of the housing retention mechanism.

4. Verify Signal Transmission

If applicable to your project, verify the transmission of electrical signals through the connector assembly. Connect the assembled Dupont connector to the corresponding interface or device and test the transmission of signals, ensuring that the connector effectively facilitates the intended electrical connections.

5. Check for Intermittent Connections

Vigorously manipulate the connector assembly to simulate real-world usage and identify any potential intermittent connections. Flex the wires and gently move the connector to determine if the connections remain stable and reliable during movement and vibration, ensuring the robustness of the assembly.

By thoroughly testing the connection of the Dupont connector, you can confidently assess its functionality and reliability for integration into your project or application. Successful testing validates the quality of the assembly and prepares the connector for deployment in electrical systems or devices.