What is a Connector?

A connector, in the realm of technology, is a crucial component that facilitates the connection between various electronic devices, enabling them to exchange data, signals, or power. Essentially, it serves as the intermediary that establishes a seamless link between disparate systems, allowing for the transmission of information or energy. Connectors come in diverse forms and serve a wide array of functions, ranging from simple audio jacks to complex multi-pin connectors used in aerospace applications.

Connectors are designed to ensure a secure and reliable connection between devices, minimizing signal loss and interference while maintaining the integrity of the transmitted data or power. They are engineered to withstand mechanical stress, environmental factors, and electrical challenges, making them indispensable in numerous industries, including telecommunications, automotive, aerospace, and consumer electronics.

The design and construction of connectors vary based on their intended application, with factors such as size, shape, material, and electrical properties being carefully considered to meet the specific requirements of the connected devices. Whether it's a USB connector for data transfer, an HDMI connector for high-definition video and audio, or a power connector for charging electronic devices, each type of connector is tailored to fulfill a distinct purpose.

In essence, connectors play a pivotal role in enabling seamless communication and power distribution among electronic devices, serving as the linchpin that unites disparate technologies and empowers the functionality of modern systems. Their significance extends far beyond their physical attributes, as they are the conduits through which the digital and electrical worlds converge, fostering connectivity and driving technological advancement.

Types of Connectors

Connectors encompass a diverse range of designs, each tailored to specific applications and requirements. Understanding the various types of connectors is essential for selecting the most suitable option for a given purpose. Here are several common types of connectors:

- USB Connectors: These ubiquitous connectors are widely used for connecting peripherals to computers and charging mobile devices. With different iterations such as USB-A, USB-B, and USB-C, they offer versatile connectivity options for data transfer and power delivery.

- Audio Connectors: Including 3.5mm and 6.35mm audio jacks, these connectors are utilized for transmitting audio signals between devices such as headphones, microphones, and speakers.

- HDMI Connectors: High-Definition Multimedia Interface (HDMI) connectors are employed for transmitting high-quality audio and video signals, commonly used in home entertainment systems, gaming consoles, and computers.

- RJ45 Connectors: These connectors are the standard interface for Ethernet connections, facilitating the transmission of data in networking applications.

- Coaxial Connectors: Widely used in television and radio equipment, coaxial connectors enable the transfer of high-frequency electrical signals with minimal interference.

- Circular Connectors: Featuring a circular interface, these connectors are prevalent in aerospace, military, and industrial applications, offering robust and reliable connections in harsh environments.

- Power Connectors: Ranging from AC power plugs to DC power jacks, these connectors are designed specifically for transmitting electrical power, powering devices ranging from smartphones to industrial machinery.

These are just a few examples of the extensive array of connectors available, each serving distinct purposes and exhibiting unique characteristics tailored to their intended applications. Understanding the specific traits and functionalities of different connector types is essential for effectively integrating them into various technological systems and devices.

Importance of Connectors in Technology

Connectors are integral to the seamless functioning of modern technology, playing a pivotal role in enabling connectivity and data exchange across a myriad of devices and systems. Their significance extends across various domains, underscoring their indispensable nature in the technological landscape.

Interconnectivity: Connectors serve as the linchpin for establishing connections between devices, allowing for the seamless exchange of data, signals, and power. Without connectors, the interoperability of diverse technological components would be severely limited, impeding the fluid flow of information and functionality.

Reliability: In technological applications, the reliability of connections is paramount. Connectors are engineered to provide secure and stable links between devices, ensuring minimal signal loss and interference. This reliability is crucial in maintaining the integrity of data transmission and power delivery, ultimately contributing to the overall dependability of technological systems.

Versatility: The diverse range of connector types available caters to a wide spectrum of applications, from consumer electronics to industrial machinery. This versatility enables connectors to adapt to the specific needs of various industries and technological domains, making them indispensable across diverse sectors.

Facilitation of Innovation: Connectors play a vital role in driving technological innovation by enabling the seamless integration of new components and devices into existing systems. Their compatibility with emerging technologies fosters a dynamic environment for innovation and progress, allowing for the continuous evolution of technological capabilities.

Scalability: As technology advances and systems expand, connectors provide a scalable means of integrating new components and expanding the capabilities of existing devices. Their ability to accommodate evolving technological requirements contributes to the scalability and adaptability of modern systems.

Ultimately, the importance of connectors in technology cannot be overstated. Their role in fostering interconnectivity, reliability, versatility, innovation, and scalability underscores their status as fundamental components that underpin the seamless functionality and evolution of modern technology.

How Connectors Work

Connectors function as the essential interface that enables the seamless transfer of signals, data, and power between electronic devices. The working principle of connectors involves several key elements that ensure the efficacy of the connection:

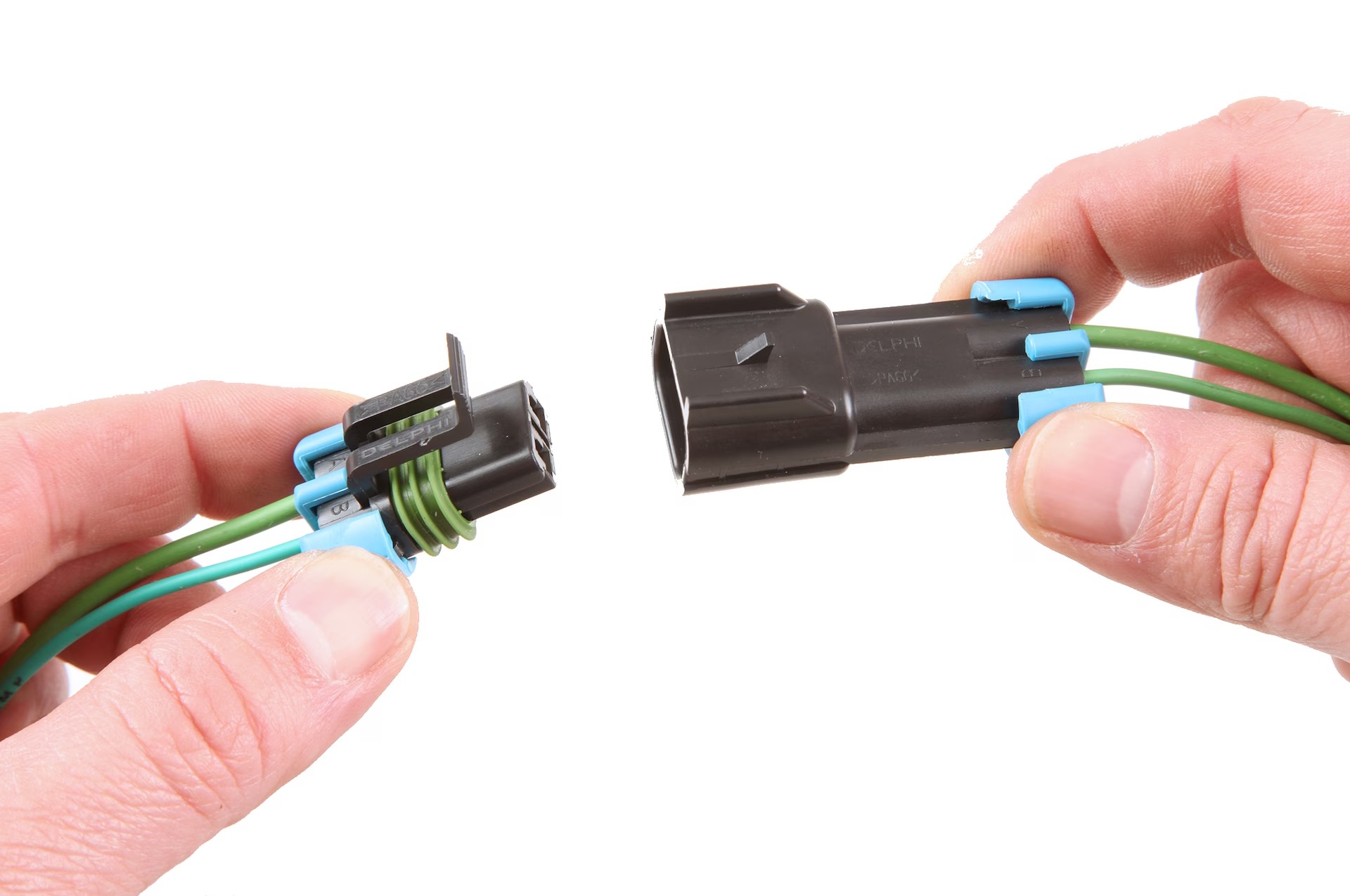

Physical Interface: Connectors feature a physical interface, comprising pins, sockets, or contacts, that establish the electrical and mechanical connection between devices. This interface is meticulously designed to ensure proper alignment and contact, facilitating the transmission of signals or power.

Contact Materials: The materials used in the construction of connector contacts are carefully selected to provide optimal conductivity, durability, and resistance to wear and corrosion. Common materials include copper alloys, gold plating, and various conductive coatings that ensure reliable electrical contact over the connector’s lifespan.

Mechanical Integrity: Connectors are engineered to withstand mechanical stress, ensuring that they can be mated and unmated repeatedly without compromising their structural integrity. This feature is critical for applications that require frequent connections and disconnections, such as in consumer electronics and industrial equipment.

Signal Transmission: Connectors facilitate the transmission of signals or power through the establishment of electrical pathways between devices. The design of the connector and the arrangement of its contacts are optimized to minimize signal loss, interference, and crosstalk, ensuring the fidelity of the transmitted data or power.

Locking Mechanisms: Many connectors incorporate locking mechanisms that secure the connection between devices, preventing accidental disconnection due to vibration or mechanical disturbances. These mechanisms vary from simple friction-based designs to more complex latching and screw-locking mechanisms, providing varying degrees of security based on the application’s requirements.

By embodying these fundamental principles, connectors facilitate the seamless exchange of information and power between electronic devices, serving as the essential conduit that underpins the functionality of modern technological systems. Their precise engineering and reliable performance ensure the integrity and efficiency of connections across a diverse array of applications.

Common Uses of Connectors

Connectors are ubiquitous in modern technology and find extensive applications across various industries and consumer products. Their versatility and adaptability make them indispensable for establishing connections and enabling the seamless exchange of data and power. Some common uses of connectors include:

- Consumer Electronics: In devices such as smartphones, laptops, and tablets, connectors are utilized for charging, data transfer, and audio-visual connectivity. USB, HDMI, and audio jacks are among the most prevalent connector types in consumer electronics.

- Networking and Telecommunications: Connectors play a crucial role in networking equipment, facilitating Ethernet connections, fiber optic links, and telecommunication infrastructure. RJ45, LC, and SC connectors are widely used in networking applications.

- Automotive Systems: Within vehicles, connectors enable the integration of electronic control units, sensors, and infotainment systems. They are instrumental in automotive diagnostics, power distribution, and signal transmission.

- Industrial Machinery: Connectors are integral to industrial automation, robotics, and machinery, providing reliable electrical connections for sensors, actuators, and control systems. They are designed to withstand harsh industrial environments and ensure consistent performance.

- Aerospace and Defense: In aerospace and defense applications, connectors are employed in avionics, radar systems, and communication equipment. They are engineered to meet stringent performance and reliability standards, withstanding extreme temperatures, vibrations, and electromagnetic interference.

- Medical Devices: Connectors are utilized in medical equipment and devices, facilitating the transmission of signals and power in diagnostic tools, patient monitoring systems, and imaging devices. Their design prioritizes safety, reliability, and compatibility with medical standards.

- Audio-Visual Systems: In home entertainment setups, professional audio, and video production, connectors enable the seamless interconnection of audio-visual equipment, including speakers, amplifiers, cameras, and displays.

These diverse applications underscore the pervasive nature of connectors in modern technology, highlighting their pivotal role in enabling connectivity and functionality across a broad spectrum of devices and systems. The adaptability and reliability of connectors make them indispensable components in the advancement of various industries and technological domains.

Factors to Consider When Choosing a Connector

When selecting a connector for a specific application, several critical factors must be taken into account to ensure optimal performance, reliability, and compatibility. The following considerations play a pivotal role in the connector selection process:

Application Requirements: Understanding the specific requirements of the application is paramount. Factors such as signal type, data transfer rates, power specifications, environmental conditions, and mating cycles must be carefully evaluated to determine the most suitable connector type and design.

Mechanical and Electrical Characteristics: The mechanical and electrical properties of a connector, including its size, shape, contact material, current rating, voltage rating, and insertion force, should align with the demands of the application. Compatibility with industry standards and regulations is also crucial, especially in specialized fields such as aerospace, automotive, and medical technology.

Environmental Considerations: The operating environment, including factors such as temperature, humidity, vibration, and exposure to chemicals or contaminants, significantly influences connector selection. Connectors designed for harsh environments, such as industrial or outdoor settings, must exhibit robust construction and resistance to environmental stressors.

Reliability and Durability: The reliability of a connector under varying conditions and its longevity over repeated mating cycles are essential considerations. Connectors intended for mission-critical applications or those subjected to frequent connections and disconnections must demonstrate high durability and consistent performance.

Signal Integrity: Maintaining signal integrity is crucial in high-speed data transmission and sensitive electronic applications. Connectors should minimize signal loss, electromagnetic interference, and crosstalk to preserve the fidelity of transmitted signals and ensure data integrity.

Ease of Use and Maintenance: User-friendly features, such as ergonomic design, secure locking mechanisms, and ease of installation and maintenance, contribute to the overall usability of connectors. These factors are particularly relevant in consumer electronics and industrial settings where accessibility and convenience are paramount.

Cost and Availability: Balancing the cost of the connector with its performance and availability is essential. Factors such as initial procurement cost, total cost of ownership, and the availability of compatible mating connectors and accessories should be evaluated to make informed decisions.

By meticulously evaluating these factors and aligning them with the specific requirements of the application, engineers and designers can effectively choose connectors that optimize performance, reliability, and compatibility, ultimately contributing to the seamless integration and functionality of technological systems.

Future Trends in Connector Technology

The field of connector technology is poised for significant advancements, driven by evolving industry requirements and technological innovation. Several key trends are expected to shape the future of connector technology:

Miniaturization and High-Density Connectors: As electronic devices continue to shrink in size and complexity, there is a growing demand for smaller, high-density connectors that can accommodate the miniaturization trend without compromising performance. These connectors are crucial for applications such as wearable devices, mobile electronics, and compact industrial equipment.

High-Speed Data Transmission: With the proliferation of high-speed data applications, including 5G networks, cloud computing, and high-performance computing, connectors capable of supporting ultra-high data rates and minimizing signal degradation will be essential. Future connector designs will focus on mitigating signal loss and electromagnetic interference to enable reliable high-speed data transmission.

Enhanced Power Delivery: The demand for higher power transfer capabilities, particularly in electric vehicles, renewable energy systems, and industrial machinery, will drive the development of connectors capable of efficiently transmitting and managing high-power levels. This trend will encompass advancements in power connector designs, materials, and thermal management solutions.

Smart and Integrated Connectors: The integration of intelligence and functionality within connectors, including features such as self-diagnosis, self-locking mechanisms, and data communication capabilities, will enable enhanced system monitoring, diagnostics, and overall reliability. Smart connectors will contribute to improved maintenance, safety, and performance optimization in various applications.

Modularity and Customization: Modular connector designs that allow for flexible configurations and customization to meet specific application requirements will gain prominence. This trend will cater to diverse industry needs, enabling rapid deployment and adaptability in rapidly evolving technological landscapes.

Environmental Sustainability: The development of eco-friendly connector materials, recyclable designs, and sustainable manufacturing processes will align with the growing emphasis on environmental sustainability. Connectors engineered for reduced energy consumption, extended lifespan, and minimal environmental impact will be pivotal in sustainable technology development.

Advanced Materials and Manufacturing Techniques: Innovations in materials science and manufacturing processes will lead to the introduction of novel connector materials with enhanced electrical, mechanical, and thermal properties. Additive manufacturing techniques, such as 3D printing, will enable the production of complex, customized connector designs with improved performance characteristics.

These emerging trends signify the dynamic evolution of connector technology, reflecting the industry’s response to the demands of modern applications and the pursuit of enhanced performance, reliability, and sustainability. By embracing these trends, connector manufacturers and designers are poised to drive innovation and shape the future of interconnected technology.