What is an IR Blaster?

Before delving into the intricacies of creating your own IR blaster, it’s essential to grasp the fundamentals of this ingenious device. An infrared (IR) blaster, also known as an IR transmitter, is a tool that emits infrared signals to control various electronic devices remotely. This technology is commonly found in remote controls for televisions, air conditioners, and other home appliances. However, the versatility and convenience of an IR blaster extend far beyond traditional applications.

By harnessing the power of IR light, an IR blaster serves as a bridge between your electronic devices and a central control system, such as a smartphone or home automation hub. This enables you to command multiple devices simultaneously, creating a seamless and integrated user experience. Whether you want to adjust the temperature of your living room, dim the lights, or switch on your entertainment system, an IR blaster empowers you to do so effortlessly from a single point of control.

Beyond consumer electronics, IR blasters have also found their way into the realm of DIY projects and home automation. Enthusiasts and hobbyists are leveraging the capabilities of IR blasters to craft custom solutions for their unique needs, from creating smart home setups to developing innovative IoT applications.

Understanding the function and potential of an IR blaster lays the groundwork for embarking on the journey of crafting your own. With this knowledge, you’re poised to explore the components, circuitry, and programming required to bring your custom IR blaster to life.

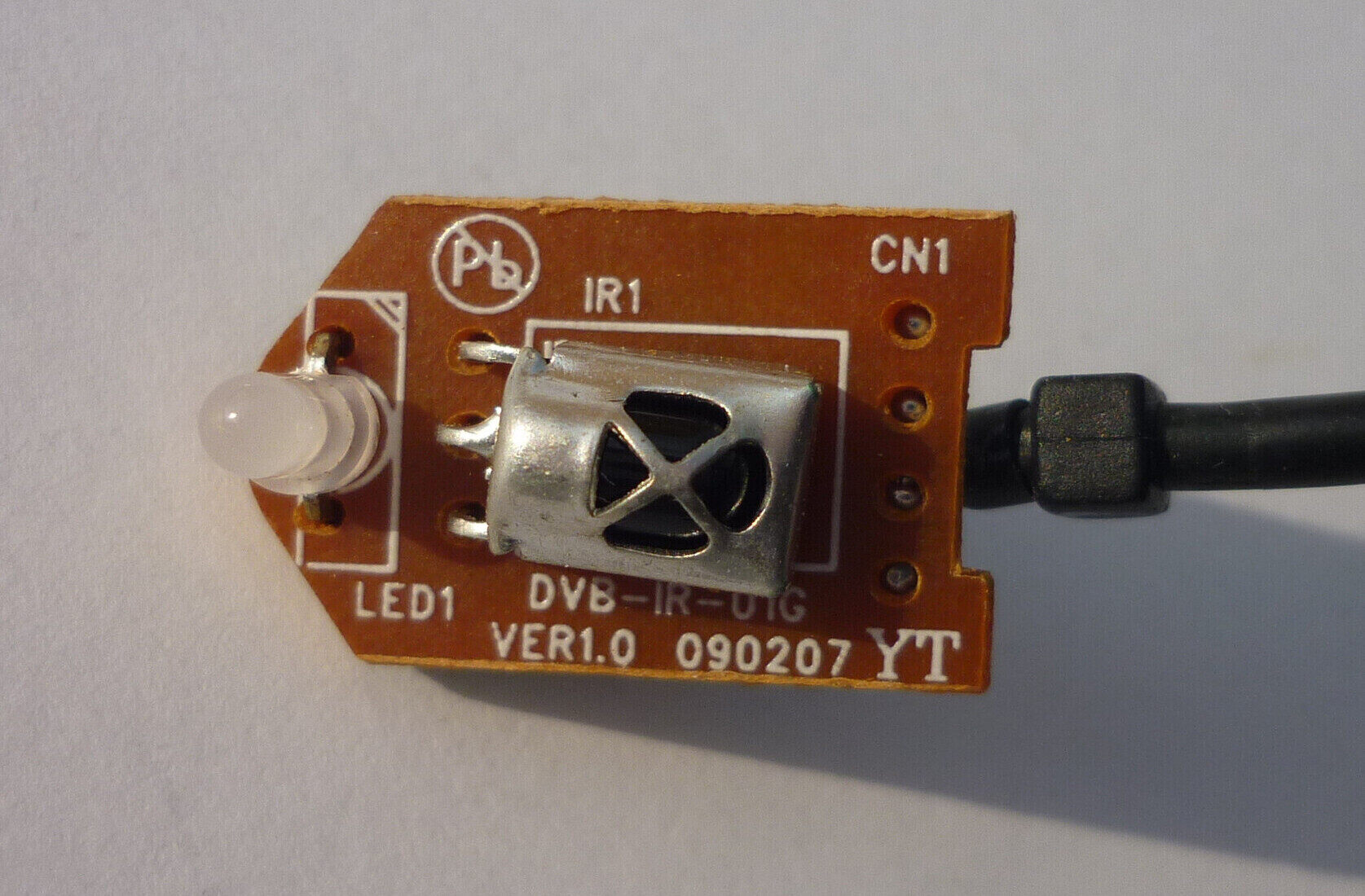

Understanding the Components

Embarking on the endeavor to create an IR blaster necessitates a comprehensive understanding of its core components. At the heart of this device lies the infrared light emitting diode (IR LED), the key element responsible for transmitting the control signals to target devices. The IR LED operates by emitting infrared radiation, which is invisible to the human eye but detectable by electronic receivers in appliances and gadgets.

Accompanying the IR LED is a microcontroller, such as an Arduino or Raspberry Pi, which serves as the brain of the IR blaster. This programmable unit coordinates the transmission of IR signals, processes commands, and interfaces with other hardware components. Additionally, the circuitry includes supporting components such as resistors, capacitors, and transistors, which play pivotal roles in regulating the power supply, signal modulation, and amplification within the IR blaster.

Furthermore, to facilitate seamless integration with modern smart home systems, Wi-Fi or Bluetooth modules can be incorporated into the design. These wireless communication modules empower the IR blaster to connect to local networks, enabling remote control via smartphones, voice assistants, or other smart devices.

Understanding the intricate interplay of these components is crucial for designing a robust and versatile IR blaster. By comprehending the roles and interactions of the IR LED, microcontroller, supporting circuitry, and optional communication modules, you lay the groundwork for crafting a sophisticated and adaptable device that aligns with your specific needs and aspirations.

Choosing the Right IR LED

When embarking on the creation of an IR blaster, selecting the appropriate infrared light emitting diode (IR LED) is a critical decision that directly influences the device’s performance and range. IR LEDs are available in various wavelengths, typically ranging from 850 to 940 nanometers, each catering to specific transmission requirements.

The selection process begins with assessing the target devices you intend to control. Different appliances and electronics may be designed to receive IR signals at distinct wavelengths. Therefore, identifying the optimal wavelength compatibility is essential to ensure seamless communication between the IR blaster and the target devices.

Moreover, considering the power output and beam angle of the IR LED is paramount. Higher power output IR LEDs can extend the range and effectiveness of the blaster, enabling control over devices positioned at greater distances or within obstructed areas. Additionally, the beam angle dictates the dispersion of the IR signals, influencing the coverage area and the precision of signal transmission.

Furthermore, the physical dimensions of the IR LED should align with the design constraints and aesthetic considerations of your project. Compact and low-profile IR LEDs are suitable for sleek and discreet installations, while larger variants may offer enhanced performance at the cost of increased bulk.

Lastly, the efficiency and reliability of the IR LED are pivotal factors to consider. Opt for reputable and high-quality components to ensure consistent performance and longevity, mitigating the risk of signal degradation or premature failure.

By meticulously evaluating the wavelength compatibility, power output, beam angle, dimensions, and quality of the IR LED, you can make an informed decision that harmonizes with the specific requirements and objectives of your custom IR blaster project.

Building the Circuit

Constructing the circuit for your custom IR blaster demands a systematic approach and a keen understanding of electronic components and their interconnections. The foundation of the circuit revolves around the integration of the infrared light emitting diode (IR LED) with the microcontroller and supporting elements.

Commence the circuit assembly by identifying the appropriate pins on the chosen microcontroller for interfacing with the IR LED. Typically, the microcontroller’s digital output pins are utilized to modulate the IR signals and drive the IR LED. Ensuring the correct connection and polarity of the IR LED is essential to prevent damage and optimize signal transmission efficiency.

Resistors play a crucial role in the circuit, serving to limit the current flowing through the IR LED and safeguarding the microcontroller from potential damage. Understanding the required resistance value and wattage rating of the resistors is imperative to maintain the stability and longevity of the circuit.

Furthermore, capacitors are employed to stabilize the power supply and filter out unwanted noise or interference, contributing to the overall reliability and performance of the IR blaster. Transistors may also be integrated to amplify the signal output, extending the range and effectiveness of the IR transmission.

As you progress with the circuit assembly, meticulous attention to detail is paramount. Ensuring proper insulation, secure connections, and adherence to the circuit diagram or schematic is crucial to prevent short circuits and erratic behavior. Additionally, employing a breadboard or custom PCB (printed circuit board) can streamline the circuit prototyping and facilitate future modifications or enhancements.

Ultimately, the construction of the circuit demands a blend of precision, creativity, and technical acumen. By orchestrating the seamless integration of the IR LED, microcontroller, resistors, capacitors, and potentially transistors, you pave the way for a robust and versatile IR blaster that embodies your ingenuity and technical prowess.

Programming the Microcontroller

Programming the microcontroller is a pivotal phase in the creation of an IR blaster, as it dictates the behavior, functionality, and compatibility of the device with various appliances and control systems. Whether utilizing an Arduino, Raspberry Pi, or other programmable microcontroller, the code written for the device orchestrates the modulation and transmission of IR signals, as well as the integration with external communication interfaces.

Commence the programming endeavor by selecting a suitable development environment and programming language that aligns with the capabilities of the chosen microcontroller. Platforms such as Arduino IDE, PlatformIO, or Python for Raspberry Pi offer comprehensive toolsets and libraries tailored to IR communication and signal modulation.

Understanding the intricacies of IR protocols and communication standards is paramount when crafting the code for the microcontroller. Depending on the target devices and their respective IR reception protocols, the code must be tailored to emit signals compatible with the appliances being controlled. This may involve utilizing established IR protocols such as NEC, Sony SIRC, or customizing the code to emulate specific remote control commands.

Moreover, integrating the microcontroller with wireless communication modules, such as Wi-Fi or Bluetooth, necessitates additional programming to enable remote control and integration with smart home systems. Implementing secure and efficient communication protocols, interfacing with APIs, and handling user input are essential aspects of this phase.

Thorough testing and validation of the programmed microcontroller are imperative to ensure seamless IR signal transmission and compatibility with a diverse array of devices. Iterative refinement of the code, incorporating error handling, and optimizing the efficiency of signal transmission are integral to the programming process.

By meticulously crafting and refining the code for the microcontroller, you empower your custom IR blaster with the intelligence and adaptability to seamlessly interact with a myriad of electronic devices, enabling centralized control and integration within modern smart home ecosystems.

Assembling the IR Blaster

Assembling the IR blaster marks the culmination of meticulous planning, component selection, circuit construction, and programming efforts. This phase involves integrating the individual elements into a cohesive and functional device that embodies the power and versatility of infrared control.

Commence the assembly process by carefully mounting the components onto a suitable platform, such as a custom PCB or a prototyping board. Ensuring secure and organized placement of the microcontroller, IR LED, resistors, capacitors, and any additional components is essential to facilitate efficient signal transmission and minimize the risk of electrical interference.

Interconnecting the components with precision and attention to detail is paramount. Employing soldering techniques or reliable connectors, such as jumper wires or headers, fosters robust electrical connections and enhances the overall durability and longevity of the IR blaster.

Furthermore, integrating the optional wireless communication modules, such as Wi-Fi or Bluetooth, demands meticulous attention to wiring and interfacing with the microcontroller. Ensuring seamless integration and compatibility with the chosen communication protocols and smart home systems enriches the functionality and versatility of the IR blaster.

Upon completing the physical assembly, validating the integrity of the connections, insulating exposed conductors, and conducting a comprehensive visual inspection are critical steps to mitigate potential malfunctions or safety hazards.

Additionally, embedding the assembled components within a suitable enclosure or housing enhances the aesthetics, protection, and user-friendliness of the IR blaster. Selecting a housing that aligns with the envisioned application, whether discreet integration within a home entertainment system or prominent placement within a smart home hub, contributes to the overall appeal and functionality of the device.

By orchestrating the meticulous assembly of the IR blaster, you transform a collection of electronic components and code into a tangible and potent tool for controlling and automating a myriad of electronic devices, heralding the dawn of a truly connected and intelligent living space.

Testing and Troubleshooting

Upon assembling the IR blaster, thorough testing is essential to validate its functionality, range, and compatibility with various electronic devices. The testing phase serves as a critical checkpoint to identify potential issues, refine the device’s performance, and ensure seamless integration into your intended application.

Initiate the testing process by verifying the IR blaster’s ability to transmit signals to target devices. Utilize a diverse array of appliances, such as TVs, audio systems, and air conditioners, to assess the blaster’s compatibility and effectiveness across different makes and models. This comprehensive evaluation is pivotal in ensuring broad compatibility and reliable operation.

Assessing the range and coverage of the IR blaster is imperative to ascertain its effectiveness in controlling devices positioned at varying distances and angles. This involves testing the blaster’s performance in different environments and configurations to identify potential signal obstructions or limitations.

Furthermore, validating the integration of optional wireless communication modules, such as Wi-Fi or Bluetooth, is crucial. Verifying the seamless interaction with smart home systems, mobile applications, and voice assistants ensures the blaster’s adaptability and convenience in modern connected environments.

In the event of any discrepancies or malfunctions during testing, troubleshooting the IR blaster is essential to pinpoint and rectify the underlying issues. This involves a systematic approach of reviewing the circuitry, inspecting the soldering and connections, and validating the code and programming of the microcontroller.

Utilizing diagnostic tools such as multimeters, oscilloscopes, and IR receivers can aid in identifying irregularities and anomalies within the IR blaster’s operation. Additionally, leveraging online communities, forums, and resources dedicated to DIY electronics and IR communication can provide valuable insights and solutions for troubleshooting common issues.

Iterative testing, refinement, and troubleshooting are integral to the development of a robust and reliable IR blaster. By meticulously validating its performance, addressing potential challenges, and fine-tuning its operation, you fortify the blaster’s capabilities and readiness for seamless integration into your smart home ecosystem or electronic control setup.