Gather the Necessary Materials

Before embarking on the journey of building your own USB charger, it’s essential to gather all the necessary materials. The following items are crucial for this DIY project:

- USB Cable: Choose a high-quality USB cable with a durable exterior and well-insulated wires. Ensure that the USB cable is compatible with the devices you intend to charge.

- Power Source: You will need a stable power source, such as a USB power adapter or a power bank, to provide the necessary electrical current to charge your devices.

- USB Port: If you opt for a power bank as your power source, ensure it features a USB port that can deliver the required power output.

- Soldering Iron and Solder: These tools are essential for connecting the wires and components securely. A good quality soldering iron and lead-free solder will ensure a reliable connection.

- Wire Cutters and Strippers: These tools are necessary for preparing the wires and ensuring a clean and precise connection.

- Electrical Tape or Heat Shrink Tubing: You will need these materials to insulate the connections and protect them from damage.

- Multimeter: A multimeter is crucial for testing the electrical connections and ensuring that the charger is functioning correctly.

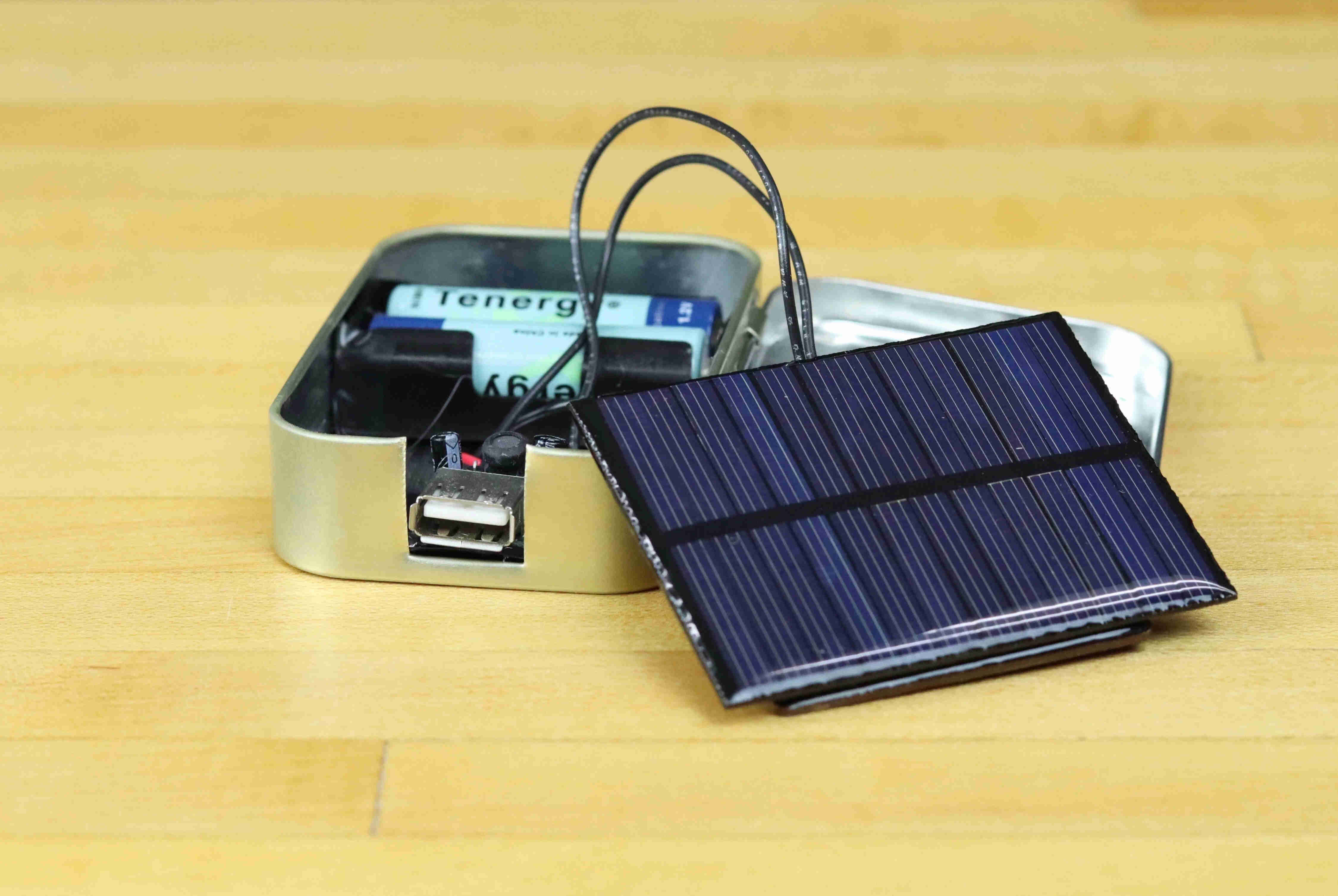

- Enclosure (Optional): If you wish to encase your USB charger in a protective housing, you will need an appropriate enclosure that fits the components securely.

By gathering these materials, you will be well-prepared to proceed with the construction of your DIY USB charger. With the right tools and components at your disposal, you can embark on this project with confidence and precision.

Prepare the USB Cable

Once you have gathered all the necessary materials, the next step is to prepare the USB cable for the construction of your DIY USB charger. Follow these steps to ensure the USB cable is ready for the assembly process:

- Inspect the USB Cable: Begin by carefully examining the USB cable to ensure there are no visible signs of damage or wear. Check the insulation and the integrity of the wires to ensure they are suitable for use in the charger.

- Strip the Cable: Use wire strippers to carefully remove the outer insulation from the USB cable, exposing the inner wires. Take caution to strip the cable gently to avoid damaging the inner wires.

- Identify the Wires: Once the inner wires are exposed, identify the positive (usually red) and negative (usually black) wires. It’s crucial to correctly identify these wires to ensure proper connection to the power source.

- Trim and Tin the Wires: Trim the exposed wires to remove any frayed ends, and then carefully tin the wires by applying a small amount of solder to the exposed ends. Tinning the wires will make it easier to connect them to the power source later on.

- Insulate the Wires: After tinning the wires, insulate each wire individually using electrical tape or heat shrink tubing. This will prevent any accidental short circuits and ensure the connections remain secure.

By meticulously preparing the USB cable and ensuring the wires are properly insulated and identified, you will set the stage for the successful construction of your DIY USB charger. Taking the time to prepare the USB cable with precision and care will contribute to the overall reliability and longevity of the finished charger.

Connect the USB Cable to the Power Source

With the USB cable prepared, the next crucial step in building your own USB charger is to connect the USB cable to the power source. This process requires careful attention to detail and precision to ensure the charger functions safely and effectively. Follow these steps to connect the USB cable to the power source:

- Prepare the Power Source: If you are using a USB power adapter, ensure it is unplugged and powered off before proceeding. If you are using a power bank, make sure it is not connected to any devices and is powered off as well.

- Identify the Power Source Terminals: Examine the power source to identify the positive and negative terminals or connectors. This is crucial for ensuring the correct connection of the USB cable.

- Solder the Wires: Carefully solder the positive (red) wire from the USB cable to the positive terminal of the power source. Similarly, solder the negative (black) wire from the USB cable to the negative terminal of the power source. Ensure the connections are secure and free from any stray solder or loose wires.

- Insulate the Connections: Once the wires are securely soldered to the power source, insulate the connections using electrical tape or heat shrink tubing. This step is essential for preventing any short circuits and ensuring the connections remain stable.

- Perform a Continuity Test: Use a multimeter to perform a continuity test on the connections. This test will verify that the positive and negative wires are correctly connected to the respective terminals of the power source.

By meticulously connecting the USB cable to the power source and ensuring secure and insulated connections, you will lay the foundation for a reliable and safe USB charger. Taking the time to execute this step with precision is crucial for the overall functionality and safety of the completed DIY USB charger.

Test the USB Charger

After connecting the USB cable to the power source, it’s essential to thoroughly test the DIY USB charger to ensure it functions as intended and meets safety standards. Testing the charger will help identify any potential issues and ensure that it can reliably charge your devices. Follow these steps to test the USB charger:

- Power On the Source: If using a USB power adapter, plug it into a power outlet and turn it on. For a power bank, ensure it is adequately charged and powered on.

- Connect a Device: Use a compatible device, such as a smartphone or tablet, and connect it to the USB charger using a suitable charging cable. Ensure the device is capable of charging via USB.

- Monitor the Charging Process: Once the device is connected, monitor the charging process to ensure it initiates correctly and the device’s battery level increases as expected. Keep an eye on the charging indicator or screen of the connected device.

- Check for Overheating: While the device is charging, monitor the USB charger and the connected device for any signs of overheating. Ensure that the charger and the device remain at a safe operating temperature throughout the charging process.

- Test Multiple Devices: If possible, test the USB charger with multiple compatible devices to verify its compatibility and charging performance across different devices.

Thoroughly testing the DIY USB charger is crucial for ensuring its functionality and safety. By following these testing steps, you can identify any potential issues and make necessary adjustments to guarantee that the charger operates reliably and safely when charging your devices.

Encase the USB Charger in a Casing

Once the DIY USB charger has been tested and proven to function reliably, the final step involves encasing the charger in a protective casing. This not only adds a professional and polished look to the charger but also provides essential protection for the internal components. Follow these steps to encase the USB charger in a casing:

- Select a Suitable Enclosure: Choose an enclosure that comfortably accommodates the internal components of the USB charger. Ensure that the enclosure provides ample space for the USB cable, power source, and any additional components.

- Prepare the Enclosure: If the enclosure has any sharp edges or rough surfaces, use sandpaper to smooth them out. This will prevent any damage to the internal components or the USB cable.

- Secure the Internal Components: Carefully position the USB cable, power source, and any other internal components within the enclosure. Ensure that the components fit securely and that the USB cable’s connection to the power source is not strained or compromised.

- Drill Holes for Ports and Indicators: If the enclosure does not have pre-existing holes for ports and indicators, carefully drill holes for the USB port, charging indicator, and any other necessary openings. Take precise measurements to ensure the holes align perfectly with the internal components.

- Seal the Enclosure: Once the internal components are securely positioned, seal the enclosure using appropriate fasteners or adhesives. Ensure that the enclosure is tightly sealed to protect the internal components from dust, moisture, and physical damage.

- Add Finishing Touches: If desired, add labels, decals, or markings to the exterior of the enclosure to indicate the type of charger and any relevant specifications. This step adds a professional and personalized touch to the finished USB charger.

Encasing the USB charger in a protective casing not only enhances its aesthetic appeal but also safeguards the internal components from external elements. By following these steps, you can ensure that the DIY USB charger is securely housed within a durable and professional-looking enclosure.