What is a grounded wrist strap?

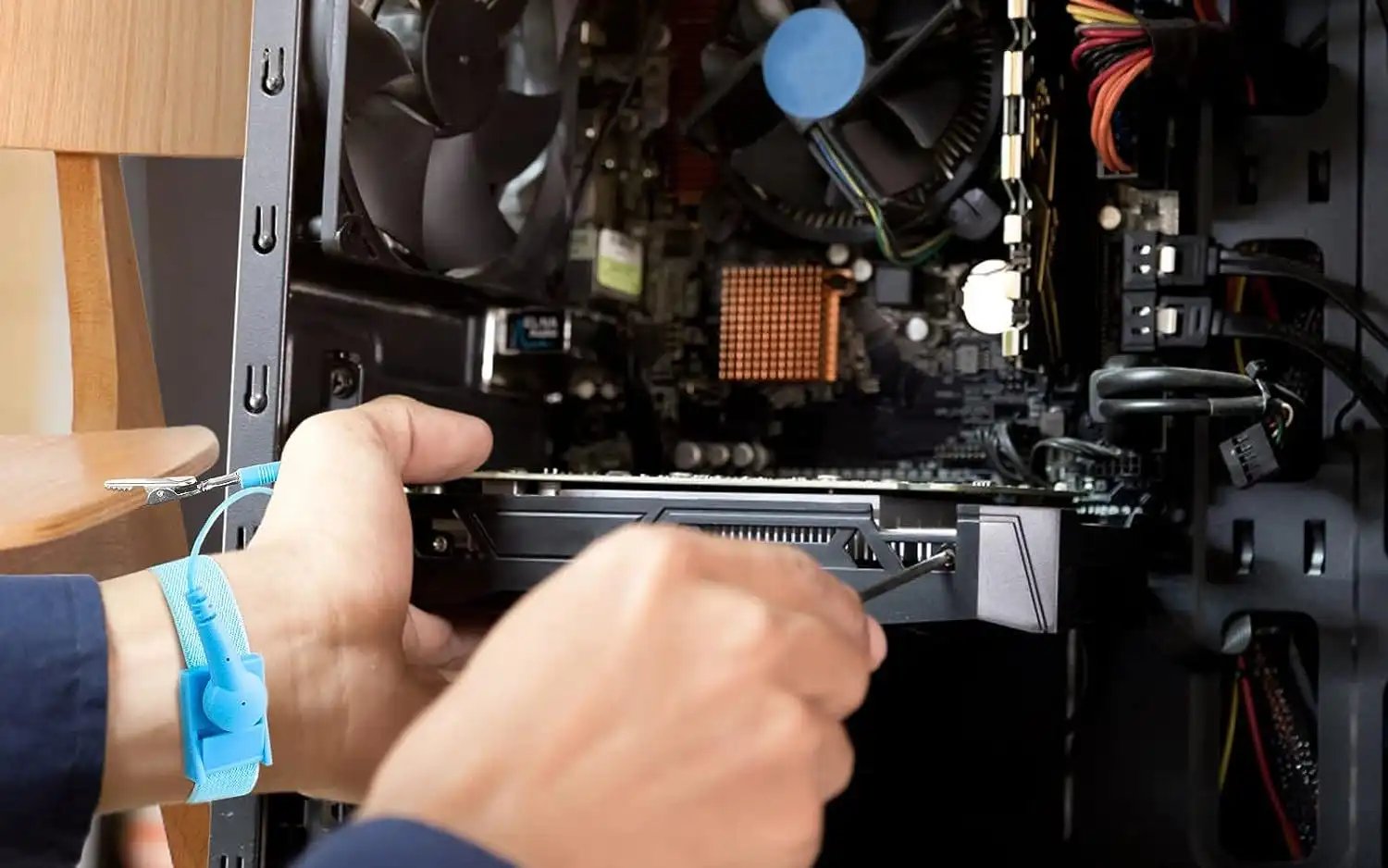

A grounded wrist strap, also known as an anti-static wrist strap or ESD wrist strap, is a device designed to dissipate static electricity from the human body to prevent damage to sensitive electronic components. It consists of a flexible band made of conductive material, usually constructed from a combination of elastic and woven metal fibers.

The purpose of a grounded wrist strap is to create a path for the flow of excess static electricity from the body to a ground point, such as a grounding mat or a grounded surface. By connecting the wrist strap to a grounded source, the static charge is effectively neutralized, preventing it from accumulating and discharging onto electronic components.

Grounded wrist straps typically have a buckle or snap fastener for easy adjustment and secure attachment to the wrist. They are available in various sizes to accommodate different wrist sizes and can be worn comfortably for extended periods of time.

The use of a grounded wrist strap is essential in environments where electrostatic discharge (ESD) can occur, such as in manufacturing facilities, laboratories, and repair centers. It is particularly important for individuals who handle electronic components, as these components are highly sensitive to static electricity.

By wearing a grounded wrist strap, individuals can ensure that they are properly grounded and minimize the risk of causing ESD-related damage.

What are electronic components?

Electronic components are fundamental elements used in electronic circuits to control the flow of electrical current and perform specific functions. They are the building blocks of electronic devices and systems, ranging from small consumer electronics like smartphones and laptops to complex industrial machinery.

Electronic components can be divided into two main categories: active components and passive components. Active components are capable of controlling the flow of electrical current and include devices such as transistors, integrated circuits (ICs), and diodes. Passive components, on the other hand, do not have the ability to amplify or control current and include resistors, capacitors, and inductors.

Each electronic component has its unique properties and characteristics, and they are combined in a circuit to perform specific functions. For example, resistors are used to limit the flow of current, capacitors store and release electrical energy, and transistors act as switches or amplifiers.

Electronic components come in various shapes, sizes, and packages to accommodate different applications. They can be surface-mounted (SMD) or through-hole mounted (THM), depending on the circuit board’s design and manufacturing requirements.

The proper handling and protection of electronic components are essential as they are sensitive to various environmental factors. Static electricity, moisture, temperature fluctuations, and physical damage can all affect the performance and functionality of electronic components.

Understanding the different types of electronic components and their functions is crucial for professionals in fields such as electronics engineering, electrical maintenance, and circuit design. It allows them to select and integrate appropriate components to create reliable and efficient electronic systems.

The importance of protecting electronic components from static electricity

Protecting electronic components from static electricity is of utmost importance to ensure their proper functioning and longevity. Static electricity, also known as electrostatic discharge (ESD), can cause irreparable damage to sensitive electronic devices and components.

When a person comes into contact with an electronic component without proper precautions, such as wearing a grounded wrist strap, static electricity can build up on their body. This static charge can discharge in an instant, releasing a high voltage surge that can exceed the tolerance levels of the component, resulting in immediate or latent damage.

One of the main risks of static electricity is that it may not be immediately apparent when damage occurs. Components can be affected at a microscopic level, leading to decreased performance, intermittent malfunctions, or complete failure over time.

Electronic components such as integrated circuits (ICs), microprocessors, and memory chips are particularly vulnerable to static electricity. These delicate devices contain numerous transistors and tiny conductive pathways that can be easily disrupted or destroyed by even a small static discharge.

Furthermore, static electricity can have a cumulative effect on electronic components. Each illicit discharge exposes the component to stress, reducing its operational lifespan and increasing the likelihood of failure.

Protecting electronic components from static electricity requires implementing proper ESD control measures. The use of grounded wrist straps is a crucial step in these measures as they provide a safe and controlled path for static discharge away from vulnerable components.

By wearing a grounded wrist strap, static charges are directed through the strap and safely dissipated into the ground, preventing them from accumulating on the body or transferring to the electronic components.

Additionally, proper ESD protection involves creating an electrostatically controlled environment by using antistatic flooring, workstations, and packaging materials. These measures help to minimize the generation and accumulation of static charges and further protect electronic components from potential damage.

Overall, understanding the importance of protecting electronic components from static electricity is crucial for professionals working with sensitive electronic devices. By implementing appropriate ESD control measures and wearing grounded wrist straps, individuals can ensure the reliable performance and longevity of electronic components, saving time, money, and resources in the long run.

How does static electricity damage electronic components?

Static electricity can cause significant damage to electronic components and devices if proper precautions are not taken. Understanding how static electricity damages electronic components is crucial to emphasize the importance of ESD protection and the use of grounded wrist straps.

When a person with a static charge comes into contact with an electronic component, the excess charge can discharge through the component. This discharge can happen in a fraction of a second, resulting in a sudden surge of electrical current. The high voltage and current levels can exceed the component’s voltage tolerance, leading to immediate or latent damage.

One of the primary ways static electricity damages electronic components is through electrostatic discharge (ESD). ESD occurs when a charged object, such as a person’s hand, comes into direct contact with a sensitive component. The discharge can cause localized heating, melting or vaporization of interconnections, and the breakdown of insulation layers.

ESD-related damage can manifest in different ways, including catastrophic failure, reduced performance, or subtle changes that affect the long-term reliability of the component. The damage can be immediate, where the component stops working altogether, or latent, where the component appears to function but gradually degrades over time.

Microscopic electronic features, such as transistors and conductive pathways, are especially susceptible to static electricity damage. The discharge can cause physical changes in these delicate structures, altering their electrical properties or creating short circuits, resulting in malfunction or failure.

In addition to the direct physical damage caused by ESD, static electricity can also induce voltage spikes in nearby components. These voltage spikes, known as electromagnetic interference (EMI) or radiofrequency interference (RFI), can disrupt the performance of sensitive components and lead to data corruption or signal degradation.

It is worth noting that static electricity can damage not only active components like ICs and transistors but also passive components such as capacitors and resistors. Even though passive components do not amplify or control current like active components, they can still be affected by ESD and experience changes in capacitance, resistance, or insulation characteristics.

To mitigate the risks of static electricity damage, it is crucial to follow proper ESD control measures, including wearing grounded wrist straps, using antistatic workstations, and employing static-safe packaging materials. These measures divert and dissipate static charges away from electronic components, ensuring their reliable operation and longevity.

Understanding how static electricity can damage electronic components reinforces the need for effective ESD protection strategies and emphasizes the vital role of grounded wrist straps in preventing costly and avoidable damage.

How does a grounded wrist strap work?

A grounded wrist strap is an essential tool in preventing damage to electronic components caused by static electricity. It works by providing a controlled path for the dissipation of static charges from the human body.

The wrist strap consists of a conductive band that is usually made of a combination of elastic material and woven metal fibers. It is designed to be worn around the wrist and connected to a grounding point, such as a grounding mat or a grounded surface.

When properly worn, the conductive band of the wrist strap forms a direct electrical connection between the wearer’s body and the ground. This connection allows any static charges on the body to flow safely and efficiently from the body to the ground, preventing them from accumulating and damaging electronic components.

The mechanism by which a grounded wrist strap works is known as the principle of equipotential bonding. By creating a continuous path with low resistance, static charges are equalized, ensuring that there are no significant potential differences that can cause ESD.

It is important to note that a grounded wrist strap should always be connected to a reliable ground source. A grounding point may be a designated ground connection on a workstation, an ESD grounding mat, or a metal surface that is properly grounded.

One key consideration when using a grounded wrist strap is the need to maintain consistent and continuous contact between the strap and the skin. To ensure a reliable connection, the strap must be snug but comfortable around the wrist, with the metal fibers making direct contact with the skin.

It is also important to periodically check the integrity of the wrist strap to ensure that it is in good condition. Over time, the conductive properties of the strap may degrade due to wear or buildup of contaminants. Regular inspections and replacements, if necessary, help to maintain the effectiveness of the grounded wrist strap.

By wearing a grounded wrist strap, individuals who handle electronic components effectively eliminate the risk of static electricity buildup on their bodies. The strap ensures a safe path for static charge dissipation, protecting both the wearer and the sensitive electronic components from potential damage.

In conjunction with other ESD control measures, such as proper grounding of workstations and the use of static-safe packaging, a grounded wrist strap forms a crucial part of a comprehensive electrostatic protection program, safeguarding electronic components and maintaining their reliability and performance.

Benefits of wearing a grounded wrist strap when handling electronic components

Wearing a grounded wrist strap is a crucial practice for individuals who handle electronic components. It offers several key benefits that help protect sensitive electronic devices and ensure the reliable operation of electronic systems.

1. Prevents static discharge: The primary benefit of wearing a grounded wrist strap is the prevention of static discharge. Static electricity can build up on the body and cause damage to electronic components if not properly grounded. The wrist strap provides a controlled path for the dissipation of static charges, preventing them from accumulating and discharging onto the components.

2. Protects against potential damage: Electronic components are highly sensitive to electrostatic discharge. Wearing a grounded wrist strap minimizes the risk of causing immediate damage or latent damage to the components. It helps prevent malfunctions, degradation in performance, and premature failure due to ESD-related issues.

3. Ensures accurate testing and measurements: When working with electronic components, precision is crucial. Static charges can interfere with accurate measurements and testing procedures, leading to inaccurate readings and unreliable results. By wearing a grounded wrist strap, static electricity is effectively eliminated, allowing for accurate testing and measurements.

4. Reduces downtime and maintenance costs: ESD-related damage to electronic components can result in costly downtime and increased maintenance expenses. By consistently wearing a grounded wrist strap, the risk of component failure due to static discharge is significantly reduced. This translates to fewer repairs, replacements, and disruptions in production or operation.

5. Promotes a safer working environment: In addition to protecting electronic components, a grounded wrist strap also contributes to a safer working environment. Electrostatic discharge can cause sparks that may ignite flammable substances, posing a fire hazard in certain industries. By effectively grounding static charges, the risk of accidents and potential injuries are minimized.

6. Supports compliance with industry standards: Many industries, such as electronics manufacturing, have strict guidelines and standards regarding ESD protection. Wearing a grounded wrist strap is often a requirement to ensure compliance with these standards. By adhering to industry regulations, professionals can demonstrate their commitment to maintaining the integrity and quality of electronic components.

7. Builds customer trust and satisfaction: When customers purchase electronic devices or equipment, they expect them to be reliable and long-lasting. Companies that prioritize ESD protection and require employees to wear grounded wrist straps convey a sense of professionalism, attention to detail, and commitment to delivering high-quality products. This helps build trust among customers and enhances overall satisfaction with the products and services offered.

Overall, the benefits of wearing a grounded wrist strap when handling electronic components are clear. It minimizes the risk of static discharge, protects against potential damage, ensures accurate testing and measurements, reduces maintenance costs, promotes a safer working environment, supports compliance with industry standards, and enhances customer trust and satisfaction. Incorporating this simple yet effective practice into electronic component handling procedures is essential for professionals in various industries.

How to properly wear and use a grounded wrist strap

To effectively protect electronic components from static electricity, it is important to know how to properly wear and use a grounded wrist strap. Following these guidelines ensures a reliable connection and reduces the risk of ESD-related damage.

1. Choose the right wrist strap: Select a wrist strap that is comfortable and fits securely around your wrist. It should have a conductive inner layer that makes direct contact with the skin. The strap should also have a buckle, snap fastener, or hook-and-loop closure for secure attachment.

2. Connect to a reliable ground source: Find a reliable ground source, such as a designated grounding point on your workstation or an ESD grounding mat. It is important to ensure that the ground connection is properly established and that the ground is functioning effectively.

3. Prepare the skin: Before wearing the wrist strap, ensure that the skin on your wrist is clean and free of any oils, lotions, or other substances that may interfere with the conductive connection. Wipe the area with a clean, lint-free cloth if necessary.

4. Securely attach the wrist strap: Place the conductive inner layer of the wrist strap directly against your skin, ensuring full contact. Fasten the buckle, snap, or closure securely to ensure a snug fit but not too tight to restrict circulation.

5. Check for a proper connection: After securing the wrist strap, verify that it is properly connected to the ground source. Ensure that all connections are secure and that there is minimal resistance between the wrist strap and the ground.

6. Avoid common pitfalls: Be cautious of potential pitfalls that can compromise the effectiveness of the wrist strap. Avoid touching the metal fibers or the conductive part of the strap as much as possible, as it may interrupt the grounding connection. Also, be mindful of movements that might dislodge or disconnect the strap during handling activities.

7. Maintain the wrist strap: Regularly inspect the wrist strap for any signs of wear, damage, or contamination. Replace it if you notice any issues that may affect its conductive properties. Clean the strap as recommended by the manufacturer to remove any buildup or residue that could interfere with its effectiveness.

By following these guidelines, individuals can ensure proper usage of a grounded wrist strap and maintain a reliable connection throughout their work with electronic components. Taking the time to establish and maintain a secure and effective connection greatly reduces the risk of ESD-related damage and helps protect the integrity of electronic devices and systems.

What are the alternatives to using a grounded wrist strap?

While wearing a grounded wrist strap is the most effective method of preventing static electricity damage when handling electronic components, there are alternative measures that can be implemented in situations where a wrist strap may not be practical or feasible.

1. ESD smocks and clothing: In some cases, individuals may opt to wear ESD smocks or clothing that are specially designed to dissipate electrostatic charges. These garments are made of conductive fabrics or have conductive elements integrated into the fabric to provide a path for static discharge. However, it is important to note that ESD clothing alone may not offer the same level of protection as a grounded wrist strap.

2. ESD mats and workstations: Using ESD mats and workstations is another effective alternative to a grounded wrist strap. These mats are made of conductive materials that are connected to a ground source, providing a static-safe surface for handling electronic components. By working on these mats, static charges are effectively dissipated, reducing the risk of ESD damage. However, it is important to avoid contact with non-grounded surfaces while using ESD mats to maintain the integrity of the protection.

3. Grounded handling tools: Another option is to use grounded handling tools and equipment, such as ESD-safe tweezers, pliers, or vacuum tools. These tools are designed with conductive materials or coatings that help dissipate static charges and minimize the risk of ESD transfer to the components being handled. However, it is important to ensure that the grounding connection of these tools is maintained and periodically verified.

4. ESD packaging: Proper packaging of electronic components in ESD-safe bags or containers is essential, especially during transportation and storage. ESD packaging provides a protective barrier that prevents static charges from accumulating on the components. The packaging materials are designed to dissipate static charges and minimize the risk of ESD damage. However, careful handling and grounding are still necessary when removing components from the packaging.

5. Workstation grounding: Ensuring that workstations, tables, and surfaces are properly grounded is another alternative to using a wrist strap. By connecting work surfaces to a ground source, any static charges that may accumulate on the surface are effectively dissipated. However, it is important to note that this method alone may not provide adequate protection if the individual is not grounded themselves.

While these alternatives can help minimize the risk of static electricity damage, it is important to recognize that they may not offer the same level of protection as a grounded wrist strap. Wearing a wrist strap provides a direct connection to dissipate static charges from the body, offering the most reliable ESD protection in environments where ESD is a concern.

When considering alternatives to using a grounded wrist strap, it is essential to evaluate the specific requirements of the situation and the level of protection needed to ensure the safety and integrity of the electronic components being handled.

The role of other anti-static measures in addition to a grounded wrist strap

While a grounded wrist strap is a critical component of protecting electronic components from static electricity, it is important to recognize that it is not the only measure that can be taken. Other anti-static measures play a complementary role in minimizing the risk of ESD-related damage and ensuring the integrity of electronic devices.

1. ESD-safe work surfaces: Utilizing ESD-safe work surfaces, such as mats or tabletops, is crucial in creating a static-safe environment. These surfaces are designed to dissipate static charges and prevent the buildup of static electricity on the work area. By providing a conductive path to ground, ESD-safe surfaces minimize the risk of static discharge and ensure that electronic components are handled in an electrostatically controlled environment.

2. Grounded flooring: Implementing grounded flooring systems, such as conductive or static-dissipative floor tiles or carpets, further enhances ESD protection in the workplace. These flooring materials help to disperse static charges and prevent the accumulation of static electricity. By maintaining a consistent ground potential throughout the environment, grounded flooring systems reduce the risk of electrostatic discharge and improve overall ESD control measures.

3. ESD-safe clothing and footwear: Wearing ESD-safe clothing and footwear is another essential measure in minimizing the risk of static electricity buildup. ESD-safe garments, such as smocks or lab coats, are made from conductive materials that help dissipate static charges. ESD-safe footwear typically incorporates conductive soles or heel straps to maintain a grounded connection. These measures prevent static charges from accumulating on the body and reduce the likelihood of ESD transfer to electronic components.

4. ESD-safe packaging: Properly packaging electronic components in ESD-safe materials is crucial for protecting them during transportation and storage. ESD-safe packaging, such as anti-static bags or containers, provides a protective barrier that prevents static charges from accumulating on components. These materials are designed to dissipate static charges and minimize the risk of ESD damage when handling or moving components.

5. Ionizers: Ionizers are devices used to neutralize static charges in the surrounding air. They release ions that counteract the charges, reducing the potential for electrostatic discharge. Ionizers are particularly useful in environments where static charges cannot be adequately controlled by other means, such as cleanrooms or areas with frequent air movement. By neutralizing the air, ionizers help maintain a static-free environment and reduce the risk of ESD-related damage.

When used in conjunction with a grounded wrist strap, these additional anti-static measures work together to create a comprehensive ESD protection program. They provide a multi-layered approach to minimize the risk of ESD-related damage and ensure the safe handling of electronic components throughout the entire work process.

It is important to note that the specific combination of anti-static measures implemented will depend on the requirements and sensitivity of the electronic components being handled. By considering the nature of the work environment, the handling procedures, and the level of ESD protection needed, professionals can implement a robust ESD control program to safeguard electronic devices and maintain their optimal performance and reliability.

When is it necessary to wear a grounded wrist strap?

Wearing a grounded wrist strap is necessary in situations where there is a risk of static electricity causing damage to electronic components. It is essential to understand when wearing a wrist strap is critical to maintaining the integrity and reliability of sensitive electronic devices.

1. During manufacturing and assembly: Anytime electronic components are being manufactured or assembled, wearing a grounded wrist strap is necessary. This includes processes like PCB assembly, soldering, or component installation. The presence of static electricity during these processes poses a significant risk to the functionality and lifespan of the components. Wearing a wrist strap helps prevent static discharge and ensures that components are handled safely and protected from potential damage.

2. When handling sensitive electronic devices: Electronic devices such as smartphones, tablets, and computer components are highly susceptible to static electricity. Whether it is repairing, upgrading, or performing maintenance on these devices, it is crucial to wear a grounded wrist strap. Even a small discharge of static electricity can adversely affect the delicate internal circuitry, leading to malfunctions or complete failure.

3. In cleanroom environments: Cleanrooms, particularly those found in semiconductor manufacturing or pharmaceutical industries, have stringent requirements for ESD protection. Even a minimal static discharge in these environments can have catastrophic consequences. Wearing a grounded wrist strap is imperative to maintain the controlled environment and prevent damage to sensitive electronic components.

4. When working with integrated circuits (ICs) and microprocessors: ICs and microprocessors are highly sensitive to static electricity and can be easily damaged during handling. These components contain numerous transistors and intricate circuitry that can be disrupted by even the smallest static discharge. Wearing a grounded wrist strap is essential when dealing with ICs and microprocessors to prevent ESD-related damage and ensure their proper functionality.

5. In environments with low humidity: Static electricity is more likely to occur in environments with low humidity. Dry air promotes the buildup and retention of static charges on surfaces and bodies. If working in low-humidity conditions, such as during winter or in climate-controlled environments, wearing a grounded wrist strap becomes even more necessary to prevent the accumulation of static electricity and protect electronic components from ESD damage.

6. When working with sensitive electronic test equipment: Sensitive electronic test equipment, such as oscilloscopes, signal generators, or spectrum analyzers, are prone to ESD damage. It is crucial to wear a grounded wrist strap when using or manipulating these devices to prevent static discharge from compromising their accuracy and performance.

7. In ESD-controlled areas: In environments where ESD protection measures are mandated, such as electronics manufacturing facilities or laboratories, wearing a grounded wrist strap is a requirement. These areas are specifically designed and equipped to prevent and control static electricity. Compliance with ESD safety guidelines includes using wrist straps to minimize the risk of ESD damage.

Overall, wearing a grounded wrist strap is necessary whenever there is a possibility of static electricity causing damage to sensitive electronic components. By incorporating this simple yet effective practice, professionals can protect electronic devices, ensure their optimal performance, and uphold the reliability of electronic systems.