Gold Conductivity in Electronics

When it comes to conducting electricity, gold has proven to be an exceptional material in the field of electronics. The high conductivity of gold makes it an ideal choice for many electronic applications. Let’s explore why gold is widely used for its conductivity in the electronics industry.

First and foremost, gold possesses excellent electrical conductivity. It ranks among the best conductors, surpassed only by silver and copper. With a low resistivity, gold allows electricity to flow efficiently, minimizing power loss and improving overall device performance.

Gold’s conductivity also remains stable over time, making it highly reliable. Unlike other metals, gold does not corrode or tarnish easily, ensuring continuous and consistent electrical performance. This characteristic is particularly crucial in electronic devices that require long-term reliability, such as smartphones, computers, and aerospace equipment.

Another reason for gold’s popularity in electronics is its compatibility with soldering processes. Gold has a relatively low melting point, which facilitates easy connection to circuit boards and other components. Gold’s ability to form reliable and durable connections is critical in electronic devices that experience vibrations, temperature fluctuations, or other environmental stresses.

Furthermore, gold’s malleability and ductility allow it to be shaped into thin wires or delicate components, enabling intricate circuit designs and miniaturization. This flexibility is vital in today’s electronics, where devices are becoming smaller and more compact while maintaining high-performance capabilities.

In addition to its conductivity, gold is also highly reflective to infrared and visible light, making it an ideal choice in optoelectronic applications. Gold coatings can enhance the performance of optoelectronic devices such as photodetectors, solar cells, and sensors by increasing light absorption and improving signal detection.

Gold as a Corrosion Resistant Material

One of the remarkable properties of gold is its exceptional resistance to corrosion, making it an invaluable material in the field of electronics. Let’s delve into why gold is widely utilized for its corrosion resistance in electronic applications.

First and foremost, gold is known for its inertness. Unlike many other metals, gold does not readily react with moisture, oxygen, or other atmospheric elements that typically cause corrosion. This characteristic is especially significant in electronic devices that are constantly exposed to various environmental conditions, such as smartphones, wearables, and industrial equipment.

Furthermore, gold’s resistance to tarnishing and oxidization ensures the longevity and reliability of electronic components. The absence of corrosion and the formation of oxides on the surface of gold contacts or connectors prevents degradation in electrical performance. This is critical in applications where even a minor decrease in conductivity can have a significant impact on device functionality.

Gold’s corrosion resistance is also advantageous in environments with high humidity, temperature fluctuations, or exposure to chemicals, as it remains unaffected by these factors. This resilience allows electronic devices utilizing gold contacts or connectors to perform reliably in challenging operating conditions.

Moreover, gold’s stability is not limited to its resistance to corrosion; it also extends to its compatibility with other materials and alloys. Gold can form robust bonds with various metals, ensuring excellent contact reliability in electronic connectors. This compatibility enhances the overall integrity of electronic connections, reducing the risk of signal loss or intermittent failures.

Another significant advantage of gold’s corrosion resistance is its impact on the recyclability and sustainability of electronic devices. Gold-plated components can be easily recovered and reused, reducing the demand for newly mined gold and minimizing environmental impact. This aspect aligns with the growing focus on sustainability in the electronics industry.

Gold’s Low Contact Resistance

When it comes to ensuring reliable and efficient electrical connections, gold excels in its ability to provide low contact resistance. This characteristic has made gold a preferred choice for electronic applications where uninterrupted power transmission is crucial. Let’s explore why gold is renowned for its low contact resistance in the field of electronics.

First and foremost, gold is an excellent conductor of electricity, exhibiting low resistivity. When gold contacts come into contact with each other or with other conductive materials, the electrical current flows smoothly due to the minimal opposition encountered. This results in a minimal voltage drop at the interface, ensuring efficient power transmission and minimizing energy loss.

Additionally, gold’s exceptional surface conductivity plays a significant role in achieving low contact resistance. The surface of gold is highly conductive, allowing for direct and efficient transfer of electrons between two contacting surfaces. This characteristic is particularly important in electronic devices that require precise and reliable signal transmission, such as high-speed data communication systems and sensitive measurement instruments.

Another factor contributing to gold’s low contact resistance is its ability to form robust and stable oxide-free connections. Unlike some other metals, gold does not easily form oxides or other electrically resistive compounds on its surface. This prevents the buildup of insulating layers that can hinder the flow of electricity, ensuring continuous and uninterrupted contact conductivity.

Furthermore, gold’s low contact resistance is maintained over time due to its exceptional resistance to corrosion and tarnishing. The absence of surface degradation maintains the smoothness and integrity of gold contacts, enabling consistent performance even after prolonged use. This attribute is particularly crucial in electronic devices that require long-term reliability and stability, such as medical equipment, automotive electronics, and aerospace applications.

Lastly, gold’s low contact resistance is beneficial in reducing signal loss and minimizing the generation of heat, making it an ideal material for high-frequency and high-power applications. The low resistance offered by gold contacts enables efficient energy transfer and helps maintain the integrity of the transmitted signals, ensuring optimal device performance.

Gold’s Malleability and Ductility

Gold is not only valued for its conductivity and corrosion resistance in electronics but also for its remarkable malleability and ductility. These properties make gold a versatile material, allowing it to be easily shaped and formed into various electronic components. Let’s explore why gold’s malleability and ductility are highly advantageous in the field of electronics.

Firstly, gold is one of the most malleable metals known to humankind. It can be hammered or rolled into extremely thin sheets, that is, gold leaf, without cracking or breaking. This exceptional malleability facilitates the fabrication of delicate electronic components, such as wires, connectors, and bonding wires, with intricate designs and precise dimensions. Gold’s malleability supports the miniaturization trend in the electronics industry, where devices are becoming increasingly compact without compromising functionality.

In addition to its malleability, gold exhibits excellent ductility, meaning it can be drawn into long, thin wires without fracturing. This property is crucial in the production of electrical cables, interconnects, and other conductive elements in the electronics field. The ability of gold to withstand high levels of deformation without compromising its structural integrity ensures reliable electrical connectivity and signal transmission.

The malleability and ductility of gold also enable it to form reliable bonds with other materials. Gold wire bonding, for example, is a widely used technique in semiconductor packaging. Thin gold wires are carefully bonded to connect the electronic components to the chip and the package, providing excellent electrical and mechanical performance. Gold’s ability to withstand the stresses and strains associated with bonding processes contributes to the reliability of electronic devices.

Furthermore, gold’s malleability and ductility allow for ease of assembly and repair in the electronics industry. Components with gold leads or connectors can be soldered and desoldered without damage, facilitating the repair of electronic devices. Gold’s ability to undergo repeated assembly and disassembly processes without degradation makes it advantageous in applications where maintenance or component replacement is necessary.

Lastly, the malleability and ductility of gold contribute to its aesthetic appeal in electronics. Gold-plated surfaces and connectors not only provide excellent functionality but also enhance the visual appeal of electronic devices. The use of gold in high-end consumer electronics and luxury gadgets is a testament to its versatility and elegance.

Gold’s Reflectivity in Optoelectronics

When it comes to optoelectronics, the reflective properties of gold make it an invaluable material in various applications. Gold exhibits exceptional reflectivity to both infrared and visible light, making it highly desirable for enhancing optical performance. Let’s explore why gold’s reflectivity is crucial in the field of optoelectronics.

One of the key advantages of gold is its high reflectivity to infrared light. Infrared reflectivity is particularly important in applications such as thermal imaging, remote sensing, and communication systems that utilize infrared wavelengths. Gold-coated surfaces can effectively reflect and redirect infrared radiation, optimizing system functionality and improving signal detection.

Gold’s reflectivity is not limited to infrared light – it also possesses excellent reflectivity in the visible spectrum. The yellowish hue of gold is a result of its ability to reflect a significant portion of visible light. This property is exploited in various optoelectronics applications such as mirrors, optical coatings, and display technologies, where high reflectivity and minimal light absorption are key considerations.

The high reflectivity of gold plays a crucial role in enhancing the efficiency of solar cells. Gold coatings can be used as back contacts in photovoltaic cells, reflecting a considerable amount of sunlight back into the active layer of the cell. This reflection helps to optimize light absorption and electron generation, resulting in improved energy conversion efficiency.

Gold’s reflective properties also contribute to the performance of optoelectronic devices such as photodetectors and image sensors. Gold surfaces can be utilized as reflective elements in these devices, assisting in the collection and detection of light. The ability of gold to efficiently reflect light onto the active areas of the sensor enhances sensitivity and signal-to-noise ratio.

Furthermore, gold’s reflectivity is advantageous in enhancing the output of optical devices such as lasers and LEDs. Gold coatings or reflectors can be employed to minimize the loss of emitted light and improve overall efficiency. This property is particularly significant in high-power applications where every photon counts.

It is worth noting that gold’s high reflectivity is also utilized in decorative elements and aesthetic features of electronic devices. Gold-plated surfaces and accents not only provide functionality but also add a touch of elegance and luxury to consumer electronics and high-end gadgets.

Gold’s Durability in Connectors and Printed Circuit Boards

When it comes to electronic connectors and printed circuit boards (PCBs), gold’s durability is highly valued in the electronics industry. The exceptional durability of gold ensures reliable and long-lasting performance in these critical components. Let’s delve into why gold is renowned for its durability in connectors and printed circuit boards.

First and foremost, gold is highly resistant to wear and corrosion. This durability makes it an ideal choice for connector pins and contacts that experience frequent insertion and removal cycles. The smooth and inert nature of gold surfaces prevents the accumulation of debris, oxidation, and other forms of surface degradation that can hinder electrical conductivity. As a result, gold-plated connectors maintain their integrity over time, ensuring consistent and reliable electrical connections.

Furthermore, gold’s durability is crucial in ensuring the longevity of connectors and PCBs in harsh operating conditions. Electronic devices often encounter vibrations, temperature fluctuations, and exposure to moisture or chemicals, which can impact the performance of connectors and PCBs. Gold’s resistance to corrosion and tarnishing allows these components to withstand such environmental stresses, ensuring continued functionality and minimizing the risk of failure.

Gold’s durability is not limited to its resistance to wear and corrosion – it also exhibits excellent resistance to electrical erosion. In high-current or high-frequency applications, connectors and PCB traces can experience electrical arcing and erosion due to the flow of electricity. Gold’s ability to withstand these conditions arises from its low contact resistance, superb conductivity, and stable surface properties. This durability ensures the consistent performance of connectors and PCBs, even in demanding electrical environments.

Moreover, gold’s durability contributes to the reliability of printed circuit boards. Gold is commonly used in PCB surface finishes, such as gold plating or gold immersion, to protect copper traces from oxidation and ensure reliable solder joints. The durability of gold coatings eliminates the risk of solder joint failure due to degradation, ensuring the long-term stability and reliability of the assembled electronics.

Gold’s durability in connectors and printed circuit boards also has practical benefits in terms of servicing and repair. Connectors with gold contacts can be repeatedly plugged and unplugged without significant wear or loss of electrical performance. Similarly, PCBs with gold finishes can be reworked or repaired more easily due to the durability of the gold coatings, reducing the costs and efforts associated with maintenance.

Overall, gold’s durability in connectors and printed circuit boards ensures robust and reliable electrical connections, extended operational lifetimes, and simplified maintenance procedures in electronic devices.

Gold’s Stability in High-Temperature Environments

When it comes to high-temperature applications in the electronics industry, gold’s stability is highly valued. Gold exhibits exceptional resistance to high temperatures, making it an ideal material for electronic components and devices that operate in demanding thermal conditions. Let’s explore why gold’s stability in high-temperature environments is crucial in the field of electronics.

First and foremost, gold has a high melting point, exceeding 1,064 degrees Celsius (1,947 degrees Fahrenheit). This characteristic allows gold to retain its structural integrity and electrical conductivity at elevated temperatures. Electronic components, such as connectors and solder joints, that have gold plating or gold alloys can withstand high-temperature environments without deforming or compromising their functionality. Gold’s ability to maintain its stability in extreme heat is particularly important in applications such as automotive electronics, aerospace systems, and energy exploration equipment.

Moreover, gold’s resistance to oxidation and tarnishing ensures its stability in high-temperature environments. Unlike many other metals, gold does not readily react with oxygen or atmospheric gases at elevated temperatures. This property is critical in electronic devices that operate in hot or corrosive environments, where maintaining the integrity and performance of components is paramount. Gold’s stability in high-temperature environments contributes to the reliability and longevity of such devices.

Additionally, gold’s stability extends to its compatibility with other materials commonly used in high-temperature applications. Gold exhibits excellent thermal compatibility with ceramics, glass, and other metals, which allows for reliable bonding and integration in electronic assemblies. This compatibility ensures that the overall device structure remains intact and functional even under extreme thermal conditions.

Another notable advantage of gold’s stability in high temperatures is its suitability for high-power electronic applications. Power electronic devices, such as transistors and power modules, often generate significant amounts of heat during operation. Gold’s stability allows it to maintain reliable electrical connections and performance, even when subjected to high-temperature cycling or continuous operation. This enables efficient power transmission and minimizes the risk of thermal-related failures.

Furthermore, gold’s stability in high-temperature environments makes it advantageous for applications that involve soldering or reflow processes. Gold-plated connectors, for example, can withstand the high temperatures required for soldering without degradation or loss of electrical performance. This facilitates the assembly and manufacturing of electronic devices, ensuring consistent and reliable connections in high-temperature processes.

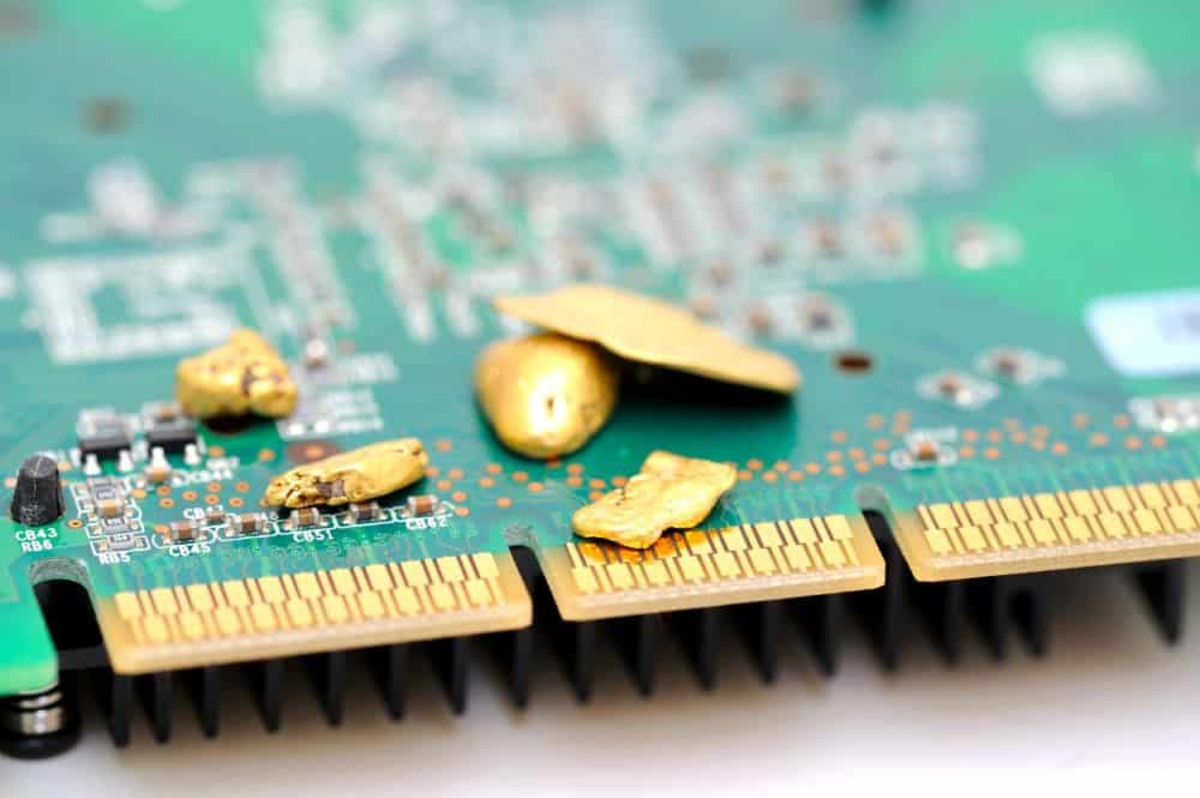

Gold’s Use in Memory Modules and Hard Drives

Gold plays a crucial role in the manufacturing of memory modules and hard drives, two fundamental components in modern electronic devices. The unique properties of gold make it an essential material for achieving high performance, reliability, and data storage capacity. Let’s delve into why gold is extensively used in memory modules and hard drives in the electronics industry.

Firstly, gold is commonly employed in the production of memory modules, such as RAM (Random Access Memory), due to its excellent conductivity and durability. Gold wire bonding is a prevalent technique used in connecting the memory chips to the module. The high conductivity of gold ensures efficient signal transmission and minimal signal loss, thereby enhancing the memory module’s performance. Additionally, gold’s durability enables the memory module to withstand frequent read and write operations without degradation or loss of functionality.

Moreover, gold is utilized in the fabrication of microelectromechanical systems (MEMS) components found in memory modules. MEMS devices, such as accelerometers and gyroscopes, rely on gold’s exceptional properties to achieve precise sensing and measurements. Gold’s high conductivity, stability, and resistance to corrosion make it an ideal material for these sensitive and high-performance applications, ensuring accurate data acquisition and reliable operation.

In the context of hard drives, gold is primarily utilized in the manufacture of hard disk drives (HDDs). HDDs employ gold as a critical component in the read-write heads and connectors. The use of gold in these components is driven by its excellent electrical conductivity and resistance to corrosion, ensuring reliable and consistent data read and write operations. Gold’s durability and stability are vital in hard drive applications, where high-speed data transfer and data retention are essential.

Additionally, gold is employed in hard drives for its superior contact performance and wear resistance. Gold’s low contact resistance ensures efficient and reliable electrical connections between various components within the hard drive. The wear-resistant nature of gold allows the connectors to withstand numerous insertion and removal cycles without experiencing significant degradation, mitigating the risk of data loss or interruption.

Furthermore, gold’s stable electrical characteristics and compatibility with different materials make it a suitable material for hard drive interfaces and connectors. Gold-plated contacts ensure optimal signal transmission, reducing the chances of data corruption or loss. The corrosion-resistant nature of gold plays a crucial role in maintaining reliable connections and preventing performance degradation in the harsh and demanding operating conditions of hard drives.

Overall, gold’s properties of high conductivity, durability, stability, and corrosion resistance make it an indispensable material for memory modules and hard drives, enabling high-performance data storage and reliable operation in electronic devices.

Gold Recycling and Sustainability in Electronics

As the demand for electronic devices continues to increase, the need for sustainable practices in the electronics industry becomes more crucial. Gold recycling plays a significant role in promoting sustainability by reducing the environmental impact of gold mining and preserving valuable resources. Let’s explore why gold recycling is essential for sustainability in the electronics sector.

First and foremost, gold recycling helps to reduce the need for new gold extraction through mining. Mining for gold comes with various environmental impacts, including habitat destruction, water pollution, and carbon emissions. By recycling gold from discarded electronic devices, valuable resources are conserved, and the negative environmental impacts associated with mining are minimized.

Furthermore, gold recycling helps to reduce electronic waste. Electronic waste, or e-waste, is a major environmental concern as it poses risks through improper disposal and contains hazardous substances. Recycling gold from e-waste enables the recovery of valuable gold resources and avoids the accumulation of electronic waste in landfills or incineration facilities.

Gold recycling offers economic benefits as well. Gold is a precious metal with a high market value, and recycling gold from electronic devices presents a viable economic opportunity. It reduces the dependence on newly mined gold and provides a sustainable source of gold supply, benefiting both the environment and the economy.

In addition to the environmental and economic advantages, gold recycling in electronics supports the development of a circular economy. In a circular economy, resources are kept in use for as long as possible through recycling, reusing, and refurbishing. Gold recycling contributes to the closed-loop approach, where gold from end-of-life electronic devices is recovered and reused in the production of new electronic components. This reduces the reliance on virgin resources and promotes a more sustainable and resource-efficient electronics industry.

Gold recycling is facilitated through various methods, including mechanical processing and chemical extraction. Many electronic equipment manufacturers and recycling companies have established recycling programs to collect discarded devices and extract precious metals like gold in a responsible manner. These initiatives ensure that the valuable gold resources present in old electronic devices can be salvaged and reintroduced into the supply chain.

Efforts are also being made to improve the efficiency of gold recycling processes and increase the recovery rate of gold from electronic waste. Research and technological innovations in the recycling sector aim to develop more efficient and environmentally friendly methods for gold extraction, further enhancing the sustainability of gold recycling in electronics.

Overall, gold recycling plays a crucial role in promoting sustainability in the electronics industry. It reduces the environmental impact of gold mining, conserves valuable resources, reduces electronic waste, and supports the development of a circular economy. With continued focus and investment in gold recycling practices, the electronics industry can move towards a more sustainable and responsible future.

Future Trends and Innovations in Gold Usage in Electronics

The field of electronics is constantly evolving, and so is the usage of gold within it. As technology advances, new trends and innovations in gold usage are emerging, shaping the future of electronics. Let’s explore some of the exciting developments and potential applications of gold in the electronics industry.

One significant trend is the increasing use of gold nanoparticles in various electronic devices. Gold nanoparticles possess unique optical and electrical properties due to their small size and large surface area-to-volume ratio. These nanoparticles can be utilized in areas such as sensors, optoelectronics, and displays, offering improved performance and functionality. Potential applications include enhanced chemical and biological sensing, energy-efficient displays, and advanced data storage systems.

Another area of innovation is the exploration of gold as a catalyst in electronic devices. Gold nanoparticles have shown promise in catalytic applications, enabling more efficient and sustainable electronic processes. This includes the use of gold catalysts in fuel cells, hydrogen production, and chemical synthesis, where gold’s unique properties can contribute to improved performance and reduced environmental impact.

Furthermore, there is growing interest in utilizing gold for flexible and stretchable electronics. Advances in nanotechnology and material science are enabling the development of flexible circuits and electronic devices. Gold, with its excellent electrical conductivity and mechanical durability, can serve as a key component in these applications. The use of gold in flexible and stretchable electronics opens up new possibilities for wearable devices, bendable displays, and other innovative form factors.

In the realm of biotechnology and medical electronics, gold is being explored for its compatibility with biological systems. Gold nanostructures and surfaces can be modified to interact with biological molecules, making them valuable tools in diagnostics, therapeutics, and biosensing. The use of gold in biomedical applications is paving the way for advancements in personalized medicine, point-of-care diagnostics, and targeted drug delivery systems.

Additionally, advancements in nanotechnology are enabling the development of miniaturized electronic devices, where gold plays a vital role. Gold nanowires and nanoscale interconnects can be employed for ultra-fine wiring and high-density integration. These nanoscale applications of gold contribute to the continuous progress of miniaturization and integration in electronics, leading to devices with higher performance and reduced power consumption.

Moreover, the sustainable use of gold in electronics is an ongoing focus, driven by the environmental concerns associated with gold mining. Efforts to develop alternative materials and processes are underway, aiming to reduce the reliance on gold while maintaining the desired electrical and mechanical properties. Innovations in gold recycling technologies are also being pursued to maximize the recovery of gold from electronic waste, further promoting sustainability in the electronics industry.

As technology advances and new applications are discovered, the future of gold usage in electronics is filled with endless possibilities. From nanoelectronics to biomedical devices and beyond, gold continues to prove its value as a versatile and indispensable material in shaping the future of the electronics industry.