The Basics of Shielding in Electronics

Shielding is a fundamental concept in electronics that involves the use of materials and techniques to protect electronic devices from electromagnetic interference (EMI). It plays a crucial role in ensuring the proper functioning and reliability of electronic equipment in various applications.

Electromagnetic interference refers to the disturbance caused by electromagnetic radiation that can interfere with the proper operation of electronic devices. This interference can lead to degraded performance, signal loss, or even complete failure of the electronic equipment. Shielding acts as a barrier, preventing external electromagnetic fields from affecting sensitive electronic components.

Shielding works based on the principle of confinement or blocking. It creates a physical barrier between the electronic device and the external electromagnetic fields. This barrier can be in the form of conductive materials, such as metal enclosures or shields, which can absorb or reflect electromagnetic radiation.

There are two types of shielding: electromagnetic shielding and radio frequency shielding. Electromagnetic shielding primarily focuses on attenuating low frequency magnetic fields, while radio frequency shielding is concerned with blocking high frequency electromagnetic radiation.

When shielding is implemented correctly, it can effectively reduce the impact of electromagnetic interference on electronic devices. It provides a shielded environment for the sensitive components, allowing them to function without interference from external sources.

Shielding is particularly important in applications where electronic devices are exposed to powerful electromagnetic fields. This includes sectors such as telecommunications, aerospace, automotive, healthcare, and industrial control systems. In these industries, shielding is crucial to ensure the reliable operation of equipment and to comply with electromagnetic compatibility (EMC) standards.

Overall, shielding in electronics is an essential aspect of design and engineering. It not only protects electronic devices from electromagnetic interference but also ensures their performance and longevity. By implementing appropriate shielding measures, electronic equipment can operate efficiently and reliably in various environments, even in the presence of external electromagnetic fields.

How Does Shielding Work?

Shielding works by creating a physical barrier or enclosure around electronic devices to block or redirect electromagnetic interference (EMI). This barrier can be constructed using conductive materials that have high electrical conductivity, such as metals like aluminum or copper.

When an electronic device is shielded, the conductive material forms a continuous path that provides a low impedance route for the unwanted electromagnetic waves. These waves, which could come from external sources or be generated internally, encounter the shielding material and are either reflected or absorbed.

Reflection occurs when the electromagnetic waves encounter the conductive surface of the shield and bounce off, similar to how light reflects off a mirror. This reflection helps to redirect the waves away from sensitive components, reducing their impact on the electronic device.

Absorption, on the other hand, happens when the conductive material of the shield absorbs the energy carried by the electromagnetic waves, converting it into heat. This absorption prevents the waves from reaching the internal components of the electronic device, effectively minimizing the interference.

In addition to reflection and absorption, shielding can also involve a technique called grounding. Grounding refers to connecting the shield to a low impedance path that leads the unwanted electromagnetic energy to the ground, effectively dissipating it.

To be effective, shielding must be continuous and properly sealed. Any gaps or openings in the shield can allow electromagnetic waves to leak in, compromising the shielding effectiveness. It is also essential to ensure that the shield is properly connected to ground to facilitate the dissipation of the unwanted energy.

The effectiveness of shielding can be measured using metrics such as shielding effectiveness (SE) or attenuation. Shielding effectiveness is the ratio of the electromagnetic field strength without shielding to the field strength with shielding. The higher the shielding effectiveness, the more effective the shield is at blocking or redirecting electromagnetic waves.

It is worth noting that the effectiveness of shielding can vary depending on the frequency range and strength of the electromagnetic waves. Different types of shielding materials may exhibit varying levels of effectiveness at different frequencies.

Overall, shielding in electronics is a complex and critical process that involves the careful selection of proper materials, design considerations, and meticulous implementation. By understanding how shielding works and employing effective shielding techniques, electronic devices can be protected from the detrimental effects of electromagnetic interference, ensuring their optimal performance and reliability.

Types of Electromagnetic Interference (EMI)

Electromagnetic Interference (EMI) refers to the phenomenon where electromagnetic radiation disrupts the normal operation of electronic devices. It can occur in various forms, each with its own characteristics and impact on electronic equipment. Understanding the different types of EMI can help in implementing effective shielding strategies to mitigate their effects.

1. Conducted EMI: Conducted EMI refers to the interference that occurs through physical connections such as power lines or cables. It can be caused by electrical noise generated by other devices or conducted through inadequate grounding. Conducted EMI can result in signal degradation, increased noise levels, or even equipment malfunction.

2. Radiated EMI: Radiated EMI occurs when electromagnetic waves propagate through space and interfere with nearby electronic devices. It can be caused by external sources such as radio transmitters, cell phones, or other electronic equipment. Radiated EMI can be particularly challenging to mitigate as it requires effective shielding to prevent the waves from reaching sensitive components.

3. Common Mode EMI: Common Mode EMI refers to the interference that affects both signal and ground lines simultaneously. It occurs when unwanted electrical noise is present in both the signal and the reference path. Common mode EMI can disrupt sensitive circuits in electronic devices, leading to errors or malfunctions.

4. Differential Mode EMI: Differential Mode EMI refers to the interference that affects only the signal lines in a circuit. It occurs when unwanted electrical noise is present between the signal lines. Differential mode EMI can result in signal distortion, data corruption, or complete loss of communication.

5. Crosstalk: Crosstalk is a type of EMI that occurs when signals from different circuits interfere with each other, affecting the quality and integrity of the signals. It can happen when adjacent conductive traces or components are too close together, causing electromagnetic coupling between them.

6. Harmonic Distortion: Harmonic distortion is a type of EMI that occurs when harmonics, or multiples, of the fundamental frequency disrupt the normal operation of electronic devices. It can be generated by non-linear electronic components or external sources. Harmonic distortion can lead to voltage and current fluctuations, heating of components, and overall degradation of the electrical system.

By identifying the type of EMI affecting electronic devices, appropriate shielding measures can be implemented to mitigate its effects. Proper shielding materials and techniques can provide the necessary protection against the specific type of EMI, ensuring the reliable operation and longevity of electronic equipment.

Common Sources of EMI

Electromagnetic Interference (EMI) can originate from various sources, both internal and external to electronic devices. Understanding the common sources of EMI is crucial in identifying potential interference sources and implementing effective shielding strategies. Here are some of the most common sources of EMI:

1. Power Lines: Power lines can be a significant source of EMI, especially if there is improper power conditioning or grounding. Electrical noise, voltage fluctuations, or harmonics in the power grid can interfere with electronic devices connected to the same power source.

2. Electronic Devices: Other electronic devices within close proximity can generate electromagnetic waves that may interfere with neighboring equipment. This can include devices such as computers, televisions, smartphones, or any other electronic equipment that emits electromagnetic radiation during operation.

3. Switching Power Supplies: Switching power supplies are commonly used in many electronic devices to convert electrical energy from one voltage level to another. However, they can generate high-frequency noise that can propagate through the power lines and cause EMI in nearby electronics.

4. Radio Frequency Interference (RFI): RFI refers to electromagnetic radiation from sources such as radio transmitters, wireless communication devices, or broadcast antennas. The signals emitted by these sources can interfere with electronic devices, especially those operating at similar frequency bands.

5. Electromagnetic Fields (EMF): Electric motors, transformers, or other electrical equipment that generate strong magnetic fields can cause EMI. These electromagnetic fields can induce currents in nearby conductive materials, leading to unwanted interference in sensitive electronic devices.

6. Lightning: Lightning strikes or electrical discharges can produce extremely high-frequency electromagnetic waves that can cause severe interference with nearby electronic systems. These transient electromagnetic disturbances can damage or disrupt electronic devices if not adequately protected.

7. Ground Loops: Ground loops occur when there are multiple ground connections with different electrical potentials, causing unwanted current flows and introducing noise into the system. Ground loops can lead to EMI and signal distortions in electronic devices.

8. Environmental Factors: Environmental factors such as electromagnetic interference from natural sources like solar flares or geomagnetic storms can affect electronic devices. Additionally, electromagnetic radiation from sources like high-voltage power lines or radio towers can also contribute to EMI.

It is essential to identify the specific sources of EMI affecting electronic devices to implement appropriate shielding measures. By understanding the common sources of EMI and applying effective shielding strategies, the interference can be minimized, ensuring optimal performance and reliability of electronic equipment.

Ways to Shield Electronics

Shielding electronics is a vital aspect of protecting them from electromagnetic interference (EMI). There are various techniques that can be employed to effectively shield electronic devices and ensure their optimal performance. Here are some common ways to shield electronics:

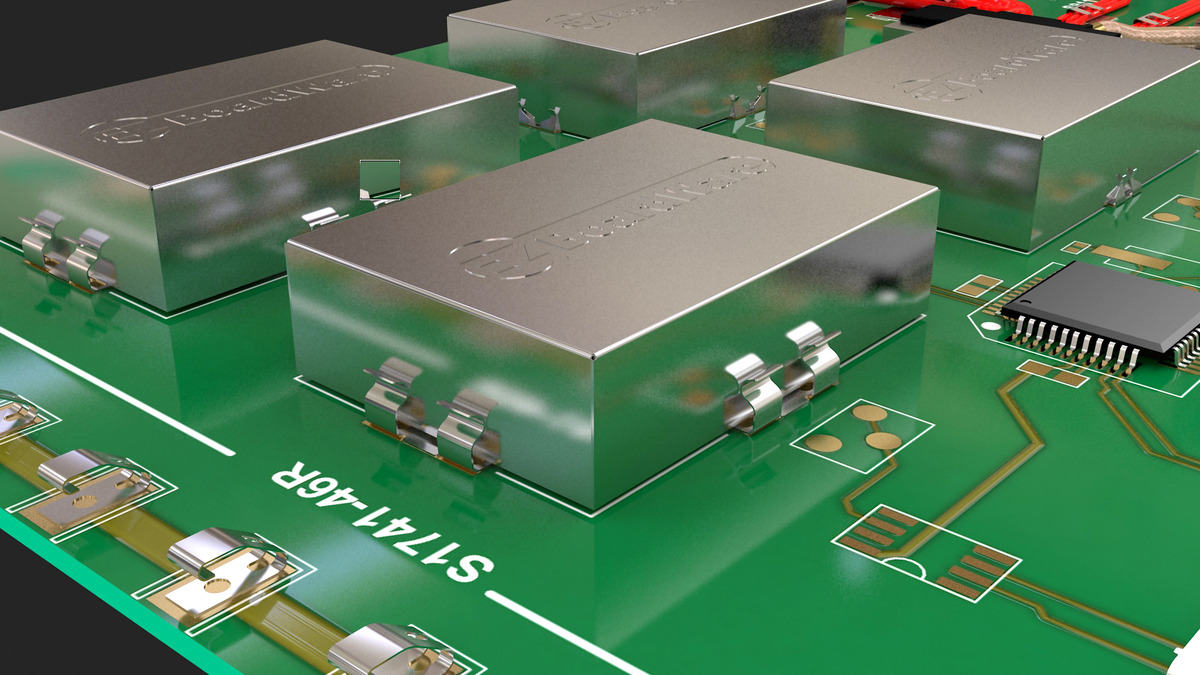

1. Enclosures: One of the most straightforward and effective ways to shield electronics is by using enclosures made of conductive materials. Metal enclosures, such as aluminum or steel, provide a physical barrier that can reflect or absorb electromagnetic waves. The enclosure should be continuous and properly sealed to prevent any gaps or openings that may compromise the shielding effectiveness.

2. Conductive Coatings: Applying conductive coatings on the surfaces of electronic devices or parts can enhance their shielding capabilities. Conductive paints or sprays containing metals like copper or nickel can be used to create a conductive layer that helps to reflect or absorb electromagnetic waves.

3. Faraday Cages: A Faraday cage is a fully enclosed structure made of conductive materials that can effectively shield electronic devices. It works by creating an electrically conductive enclosure that redistributes electromagnetic waves around the exterior of the cage, keeping the internal components protected. A Faraday cage can be constructed using metal meshes, foils, or plates.

4. Cable Shielding: Cables can act as conduits for electromagnetic interference. To shield cables, they can be wrapped with metal foil or braided with metal wires, such as copper or aluminum. This shielding prevents the cables from emitting or picking up unwanted electromagnetic waves.

5. Filtering and Grounding: Implementing filters and proper grounding techniques can help reduce the impact of electromagnetic interference. Filters can block or attenuate specific frequencies, while grounding provides a low impedance path for unwanted electrical noise to dissipate. Properly designed filters and effective grounding can significantly improve the shielding performance of electronic devices.

6. Shielded Connectors: Using shielded connectors is another effective way to prevent EMI. Shielded connectors have an additional metal sleeve or coating that helps to reduce electromagnetic interference from entering or escaping through the connector interface.

7. Printed Circuit Board (PCB) Layout: Proper PCB layout techniques can help minimize the susceptibility of electronic devices to EMI. This includes optimizing the placement of components and traces, minimizing the loop area of signal paths, and separating sensitive components from noise sources.

8. Absorbing Materials: Absorbing materials, also known as absorbers or absorptive shielding, can be used to absorb and dissipate electromagnetic waves. These materials are designed to convert the energy carried by the waves into heat, reducing their impact on electronic devices. Absorbing materials can be applied as coatings or inserted between electronic components or within enclosures.

When shielding electronics, it is crucial to consider the specific requirements of the application and the frequency range of the electromagnetic waves involved. Choosing the appropriate shielding techniques and materials is essential to achieve maximum effectiveness and ensure the reliable operation of electronic devices in various environments.

Different Types of Shielding Materials

Shielding materials play a crucial role in protecting electronic devices from electromagnetic interference (EMI). There are various types of materials available that exhibit different shielding characteristics. Understanding the different types of shielding materials can help in selecting the most suitable option for specific shielding requirements. Here are some common types of shielding materials:

1. Metals: Metals such as aluminum, copper, and steel are commonly used for shielding electronic devices. These metals possess high electrical conductivity, making them effective in reflecting or absorbing electromagnetic waves. Aluminum is lightweight and offers good shielding performance, making it suitable for many applications. Copper is highly conductive and provides excellent shielding effectiveness, especially in high-frequency ranges. Steel offers high magnetic permeability, making it useful for blocking low-frequency magnetic fields.

2. Metal Foils: Metal foils, such as copper or aluminum foils, are flexible shielding materials commonly used in applications where conformability is required. They can be easily wrapped around cables, joints, or small areas to provide localized shielding. Metal foils can also be applied to the surface of enclosures or circuit boards to enhance overall shielding effectiveness.

3. Conductive Fabrics: Conductive fabrics, made from materials like silver-plated nylon or polyester, offer both shielding and flexibility. They can be used to make garments, pouches, or covers that provide personal shielding or enclosure shielding for electronic devices. Conductive fabrics typically have good electrical conductivity and can be effective at blocking electromagnetic waves.

4. Conductive Paints and Coatings: Conductive paints or coatings contain conductive particles, such as carbon or metal fillers, dispersed in a liquid or polymer base. They can be applied to various surfaces, including plastic enclosures or circuit boards. Conductive paints and coatings create a conductive layer that helps to reflect or absorb electromagnetic waves, enhancing overall shielding effectiveness.

5. Absorbers: Absorber materials are designed to convert the energy carried by electromagnetic waves into heat. They dissipate the waves rather than reflecting or transmitting them. Absorbers are typically made from materials like carbon-loaded foam, ferrite sheets, or microwave absorber composites. They are often used in conjunction with other shielding materials to optimize shielding performance.

6. Magnetic Materials: Magnetic shielding materials, such as mu-metal or permalloy, are specifically designed to attenuate low-frequency magnetic fields. These materials have high magnetic permeability, allowing them to redirect and absorb magnetic flux. Magnetic shielding materials are commonly used in applications where blocking magnetic fields is critical, such as in magnetic resonance imaging (MRI) rooms or sensitive scientific instruments.

7. Dielectric Materials: Dielectric materials, also known as insulators, are used as shields to prevent electromagnetic waves from entering or escaping electronic devices. These materials have low electrical conductivity but high dielectric strength. Common dielectric materials used for shielding include ceramics, polymers, or glass. Dielectrics can be used as enclosures, barriers, or as coatings to prevent electromagnetic interference.

When selecting shielding materials, it is essential to consider factors such as the frequency range of the electromagnetic waves, the environment in which the electronic devices will operate, and the specific shielding requirements. Proper material selection is critical in achieving effective electromagnetic shielding for electronic devices.

Factors to Consider When Choosing Shielding Materials

Choosing the right shielding materials for electronic devices is crucial to ensure effective protection against electromagnetic interference (EMI). Several factors need to be considered when selecting shielding materials for specific applications. Here are some key factors to keep in mind:

1. Frequency Range: The frequency range of the electromagnetic waves that need to be shielded is an important consideration. Different materials exhibit varying effectiveness at different frequencies. For example, metals like copper and aluminum are effective at blocking high-frequency electromagnetic waves, while magnetic materials like mu-metal are better at attenuating low-frequency magnetic fields.

2. Shielding Effectiveness: The shielding effectiveness of a material determines how well it can reflect, absorb, or attenuate electromagnetic waves. It is essential to consider the required level of shielding effectiveness for the specific application. Shielding effectiveness is usually measured in decibels (dB) and can vary depending on the material, thickness, and design of the shield.

3. Conductivity: The electrical conductivity of the shielding material impacts its ability to reflect or absorb electromagnetic waves. Materials with high conductivity, such as copper or aluminum, are often preferred for their efficient shielding capabilities. However, it is important to balance conductivity with other factors such as cost, weight, and flexibility.

4. Mechanical Properties: The mechanical properties of the shielding materials should align with the application requirements. For example, if flexibility is crucial, conductive fabrics or metal foils may be more suitable. On the other hand, if structural integrity is important, rigid materials like metal enclosures or panels may be preferred.

5. Corrosion Resistance: Consider the environment in which the electronic devices will be operating. If there is a possibility of exposure to moisture, chemicals, or other corrosive elements, it is important to choose shielding materials that are resistant to corrosion. Stainless steel, for example, offers excellent corrosion resistance compared to other metals.

6. Weight and Size: The weight and size of the shielding materials can impact the overall weight and dimensions of the electronic devices. Lightweight materials are desirable, especially in applications where portability or weight restrictions are a concern. Conductive fabrics or thin metal foils can be advantageous in such situations.

7. Cost: The cost of shielding materials should be taken into account, especially for large-scale or cost-sensitive projects. Conductive fabrics or conductive paints may be more budget-friendly options compared to elaborate metal enclosures or high-performance shielding materials.

8. Environmental Friendliness: Consider the environmental impact of the selected shielding materials. Opt for materials that are recyclable or made from environmentally friendly sources. Additionally, ensure that the chosen materials comply with relevant regulations or standards for environmental sustainability.

By considering these factors, engineers and designers can make informed decisions when choosing shielding materials for electronic devices. The selection should be based on the specific requirements of the application, balancing performance, cost, environmental considerations, and other relevant factors.

Benefits and Limitations of Shielding

Shielding is a crucial technique used to protect electronic devices from electromagnetic interference (EMI). It offers several benefits in ensuring the reliable performance and longevity of electronic equipment. However, it also has certain limitations that need to be considered. Here are the key benefits and limitations of shielding:

Benefits of Shielding:

– Electromagnetic Interference (EMI) Reduction: The primary benefit of shielding is its ability to reduce or eliminate the impact of EMI on electronic devices. By creating a physical barrier or enclosure, shielding prevents external electromagnetic waves from interfering with delicate electronic components, ensuring proper functioning and improved performance.

– Signal Integrity Preservation: Shielding effectively blocks or redirects electromagnetic waves, ensuring that signals within electronic devices remain intact and undistorted. This preservation of signal integrity is crucial, particularly in applications that rely on accurate transmission and reception of data, such as telecommunications, aerospace, and healthcare.

– Compliance with Standards: Shielding plays a vital role in meeting electromagnetic compatibility (EMC) standards and regulations. Many industries have strict requirements for EMI levels to ensure the proper operation of electronic equipment and to prevent interference with other devices or systems. Implementing effective shielding measures helps achieve compliance with these standards.

– Protection from External Sources: Shielding not only guards against external electromagnetic waves but also protects electronic devices from external sources of EMI. This includes sources like radio transmitters, power lines, or nearby electronic equipment. Shielding prevents interference from these sources, promoting the longevity and reliability of electronic devices.

– Enhanced Safety: Shielding helps minimize the risk of interference-related safety hazards. By preventing EMI from affecting critical electronic components, shielding reduces the likelihood of malfunctions, data corruption, or even equipment failure that could pose safety risks in various applications, including medical devices or automotive systems.

Limitations of Shielding:

– Frequency Limitations: Different shielding materials have varying effectiveness at different frequencies. Some materials may provide excellent shielding at high frequencies, but their performance may diminish at lower frequencies. Careful consideration of the frequency range is necessary to select the appropriate shielding materials for a specific application.

– Cost and Complexity: Implementing effective shielding measures can involve additional costs and complexity in the design and manufacturing processes. Shielding materials, enclosures, and installation techniques may add to the overall cost of the electronic device. Moreover, shielding may require careful attention to maintain proper grounding and the integrity of signal paths.

– Size and Weight Considerations: Shielding materials, such as metal enclosures or shields, can add to the size and weight of electronic devices. In portable or space-constrained applications, the added bulk and weight of shielding may pose challenges. Lightweight shielding options, such as conductive fabrics or thin metal foils, can help alleviate this limitation.

– Incomplete Shielding: Achieving complete and perfect shielding can be challenging, especially in environments with high levels of EMI. Imperfections in the shield or gaps in enclosures can allow some level of EMI penetration. Meticulous design, installation, and testing processes are necessary to minimize any potential leakage of electromagnetic waves.

Despite these limitations, shielding remains an essential technique in maintaining the integrity and reliability of electronic devices in the presence of EMI. By understanding the benefits and limitations, engineers and designers can make informed decisions and implement effective shielding strategies to protect electronic equipment.

Testing and Certifications for Shielded Electronics

Testing and certifications for shielded electronics are crucial steps in verifying the performance and effectiveness of the shielding measures implemented. These processes ensure that electronic devices meet specified standards for electromagnetic compatibility (EMC) and provide reliable operation in the presence of electromagnetic interference (EMI). Here are the key aspects of testing and certifications for shielded electronics:

1. Shielding Effectiveness Testing: Shielding effectiveness measures the ability of a shielding material or enclosure to attenuate or block electromagnetic waves. It is evaluated through testing procedures in specialized laboratories. Shielding effectiveness testing involves exposing the shielded device or enclosure to specific electromagnetic fields and measuring the reduction in field strength achieved by the shielding. The test results are presented in decibels (dB) and demonstrate the ability of the shielding to block or reflect electromagnetic waves.

2. Electromagnetic Compatibility (EMC) Testing: EMC testing evaluates the overall electromagnetic compatibility of electronic devices. It involves assessing the device’s ability to function properly in its intended operating environment without causing interference to other devices or systems. EMC testing typically includes radiated emissions testing to measure the amount of electromagnetic radiation emitted by the device, as well as conducted emissions testing to assess the noise conducted through power and signal lines. These tests ensure that the shielded electronics comply with industry standards and regulations.

3. Regulatory Certifications: Various regulatory bodies and standards organizations establish guidelines and certifications for shielded electronics. Some common certifications include the Federal Communications Commission (FCC) certification in the United States, CE marking in Europe, and International Electrotechnical Commission (IEC) certifications. These certifications demonstrate compliance with specific EMC requirements and ensure that the shielded devices meet stringent standards for performance and safety.

4. Pre-Compliance Testing: Pre-compliance testing allows manufacturers to evaluate the performance of their shielded electronics before undergoing formal certification testing. It helps identify potential issues or areas of improvement, ensuring that the devices will likely pass the final compliance testing. Pre-compliance testing can save time and resources by addressing any problems early on and preventing the need for costly redesigns or retesting.

5. Continuous Monitoring and Assessment: Shielded electronics should undergo regular monitoring and assessment to ensure ongoing compliance and performance. This can include periodic retesting, evaluation of changes or upgrades to the device or its shielding components, and monitoring the shielding effectiveness in real-world operating conditions. Continuous assessment ensures that the shielding remains effective against evolving electromagnetic environments and potential sources of interference.

Testing and certifications for shielded electronics are critical in ensuring the reliable operation and performance of electronic devices in the presence of EMI. By complying with industry standards and regulations, manufacturers can provide customers with confidence in the shielding effectiveness and overall electromagnetic compatibility of their products.

Tips for Effective Shielding in Electronics

Implementing effective shielding in electronics is essential to protect devices from electromagnetic interference (EMI) and ensure their optimal performance. Here are some practical tips to achieve effective shielding:

1. Understand the EMI Source: Identify the sources of EMI that could potentially affect the electronic device. This knowledge will help determine the appropriate shielding methods and materials needed to counteract the specific interference sources.

2. Proper Grounding: Ensure that the shielding is properly grounded to provide a low-impedance path for unwanted electrical noise to dissipate. Good grounding connections and grounding techniques minimize the risk of ground loop-induced interference.

3. Shield Early in the Design Process: Incorporate shielding considerations early in the design phase of electronic devices. This includes proper layout and routing of signal paths, separating sensitive components from noise sources, and providing adequate space for shielding materials.

4. Verify Shielding Effectiveness: Test and measure the shielding effectiveness of different materials and enclosure configurations to ensure they meet the required specifications. Shielding effectiveness testing helps identify the best options for optimal EMI reduction.

5. Consider Shielding Material Selection: Choose appropriate shielding materials based on factors such as the frequency range of the EMI, conductivity, flexibility, weight, and cost. Consider a combination of materials, such as conductive paints, metal enclosures, or conductive fabrics, depending on the specific requirements.

6. Seal Any Gaps and Apertures: Ensure that enclosures, seams, and joints are properly sealed to prevent electromagnetic waves from leaking in or out. Any gaps or apertures can compromise the shielding effectiveness and allow unwanted interference to penetrate the device.

7. Avoid Signal Leakage: Properly route cables and trace paths to prevent signal leakage and minimize the risk of electromagnetic coupling. Keep signal lines away from potential noise sources, and use shielded cables where necessary to block or contain EMI.

8. Consider Environmental Factors: Take into account the environment in which the electronic device will be operating. If the device will be exposed to moisture, temperature variations, or other environmental factors, choose shielding materials that are resistant to corrosion, temperature extremes, or other potential hazards.

9. Continuous Improvement and Monitoring: Shielding effectiveness should be continuously monitored and assessed, particularly in evolving EMI environments or when modifications are made to the device. Regularly evaluate and upgrade shielding measures to maintain optimal performance.

10. Consult with Experts: When in doubt or faced with challenging shielding requirements, consult with experts or specialists experienced in shielding techniques. They can provide valuable insights and recommendations for effective shielding solutions.

By following these tips, engineers and designers can implement effective shielding strategies to mitigate the impact of electromagnetic interference and ensure the reliable operation of electronic devices in various applications.