Importance of Ground in Electronics

Grounding plays a critical role in ensuring the safe and efficient operation of electronic devices and systems. It serves as a reference point for electrical circuits and helps to regulate voltage levels, protect against electrical faults, and minimize the risk of electric shock.

One of the key reasons for the importance of grounding in electronics is to provide a path for excess electrical current to flow safely back to the ground. This is especially crucial in the event of a short circuit or power surge, as without a proper ground connection, the excess electricity could cause damage to the device or even lead to a fire.

Another important function of ground is to maintain a stable voltage reference throughout the electrical system. By connecting the ground pin of a device to the earth, any fluctuations or disturbances in voltage can be dissipated, ensuring that sensitive electronic components receive a consistent and reliable power supply.

Grounding also helps to minimize electromagnetic interference (EMI). Electronic devices emit electromagnetic fields during operation, which can interfere with nearby equipment or even cause disturbances in wireless communication. By grounding the devices, these unwanted electromagnetic emissions can be redirected to the ground, reducing their impact on other devices and improving overall system performance.

Furthermore, grounding is essential for personal safety. It helps to protect users from electric shock by providing a safe path for electric current to flow in the event of a malfunction or electrical fault. Without a proper ground connection, electrical charges could build up in devices and pose a risk to anyone coming into contact with them.

Definition of Ground

In the context of electronics, ground refers to a reference point that is used as a common return path for electrical current. It is typically connected to the Earth’s surface through a grounding electrode, such as a metal rod driven into the ground, to establish a direct physical connection.

Ground is commonly represented by the symbol “GND” or the symbol of horizontal lines intersecting at a perpendicular line. In electrical circuits, the ground serves as a zero-voltage reference point against which all other voltages are measured.

Ground can be thought of as the starting point or the baseline for voltage measurements. It is used as a point of comparison to determine the potential difference between different parts of an electrical system. When a voltage is measured between two points, one of the points is typically designated as the ground, and the other point’s voltage is measured relative to this ground reference.

The grounding system in electronics ensures that there is a stable and reliable reference point for voltage levels. This is crucial in maintaining the accuracy and integrity of signals in electronic circuits. Grounding also helps to protect against electrical interference and noise, as well as providing a path for the dissipation of excess electrical energy in case of faults or malfunctions.

It’s important to note that the term “ground” can have different interpretations in different contexts. In electronics, it refers to the reference point and the connection to the Earth’s surface. However, in other fields such as electrical power systems or telecommunications, the concept of ground may be used to describe different types of connections or reference points.

Overall, the definition of ground in electronics is the connection to the Earth’s surface that serves as a common reference point for electrical circuits, providing stability, safety, and a baseline for voltage measurements.

Functions of Ground in Electronics

Grounding in electronics serves several important functions that are critical for the proper functioning, safety, and performance of electronic devices and systems.

1. Voltage Reference: One of the main functions of ground is to establish a reference point for voltage levels. The ground serves as a zero-voltage baseline against which other voltages in the circuit are measured. This ensures accurate and consistent voltage measurements and helps maintain stable operation of electronic components.

2. Electrical Fault Protection: Grounding plays a crucial role in protecting electronic devices and systems from electrical faults. In the event of a short circuit or a fault that causes an excessive flow of current, grounding provides a path for the excess current to safely flow into the ground, preventing damage to the device and mitigating the risk of fire hazards.

3. Noise and Interference Reduction: Grounding helps minimize unwanted electrical noise and electromagnetic interference (EMI) in electronic circuits. By providing a low-resistance path to the ground, any unwanted electrical noise or interference can be redirected and dissipated, ensuring clean and reliable signals and enhancing the performance of sensitive electronic components.

4. Static Electricity Dissipation: Grounding is essential for dissipating static electricity to prevent damage to electronic components. Static electricity can build up on surfaces and can discharge through sensitive components, causing data corruption or component failure. Grounding ensures that any static charges get safely discharged into the ground, protecting the devices and maintaining their reliability.

5. Electrical Shock Protection: Grounding is crucial for human safety by providing a safe path for electrical current to flow in case of a fault or accidental contact with live parts. By establishing a direct connection to the ground, any excess current can be safely directed away from the user, reducing the risk of electric shock and potential injuries.

6. EMI Shielding: Grounding also plays a role in shielding electronic devices from external electromagnetic interference. By connecting the metal chassis or shielding of a device to the ground, any incoming electromagnetic waves or EMI can be directed to the ground, preventing them from affecting the internal components and ensuring the proper functioning of the device.

Overall, the functions of ground in electronics encompass voltage reference, electrical fault protection, noise reduction, static electricity dissipation, electrical shock protection, and EMI shielding. These functions are crucial for the safe and reliable operation of electronic devices and systems.

Types of Ground in Electronics

In electronics, there are several types of ground connections that serve different purposes and are used in various applications. Understanding these types of ground is essential for proper design and implementation of electronic systems.

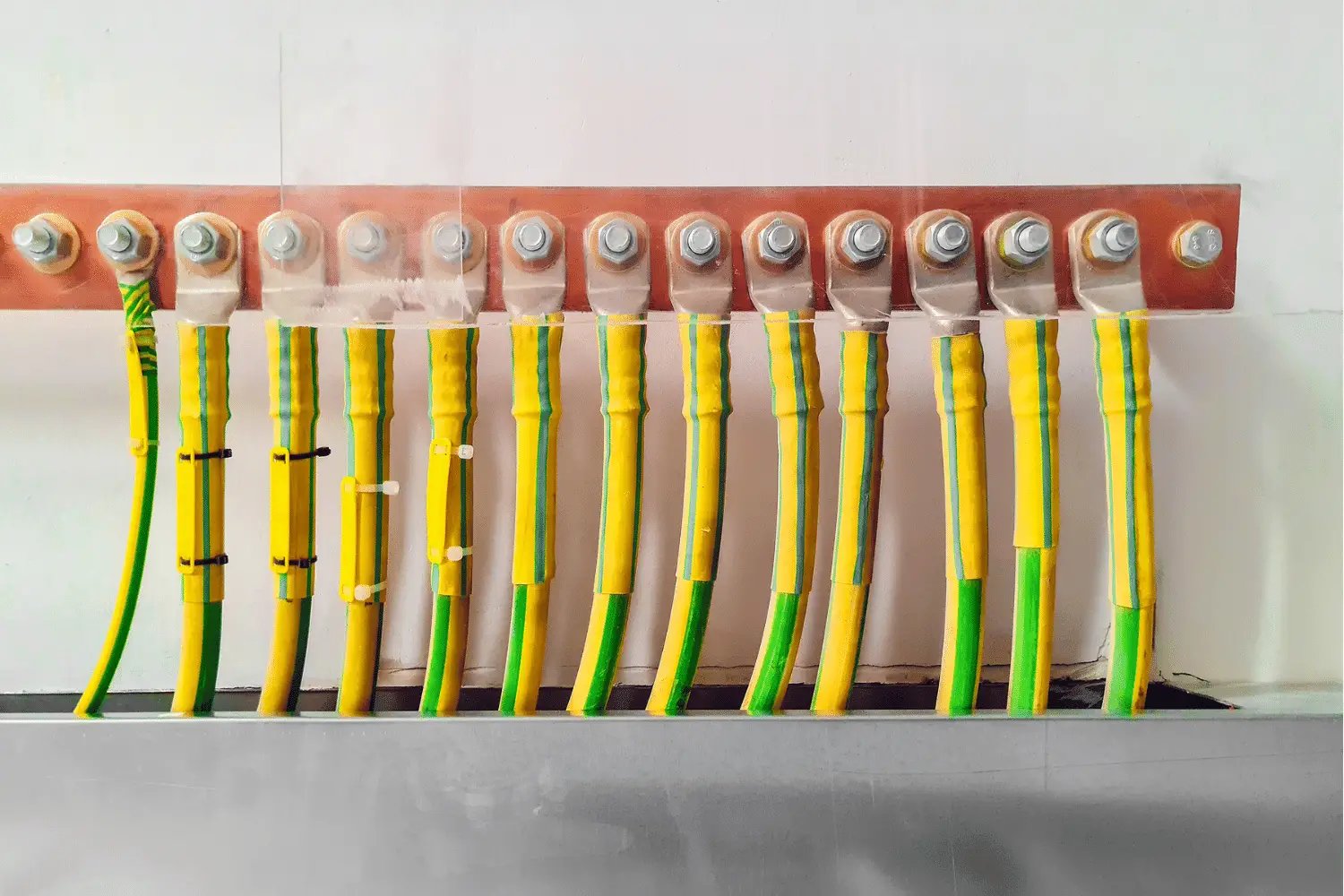

1. Earth Ground: Also known as safety ground or protective ground, this is the most common type of ground connection. It provides a direct physical connection between electronic devices and the Earth’s surface. The purpose of earth ground is to ensure electrical safety by providing a path for excess current to flow safely into the ground in the event of a fault or short circuit.

2. Chassis Ground: Chassis ground refers to the connection of the metal chassis or enclosure of a device to the ground. It helps protect against electrical shock by ensuring that any excess or stray current is safely directed into the ground, preventing it from reaching the user or other sensitive components. Chassis ground also helps in EMI shielding by providing a ground reference for shielding materials.

3. Digital Ground: Digital ground, also known as signal ground, is the reference point for digital signals in electronic circuits. It is important to have a separate ground for digital signals to prevent noise interference from affecting the digital circuitry. Digital ground is usually connected to the earth ground but kept separate to avoid interference between analog and digital components.

4. Analog Ground: Analog ground serves as the reference point for analog signals and sensitive analog components. Analog ground must be carefully isolated and separated from digital and high-frequency grounds to prevent noise and interference that could degrade the accuracy and performance of analog circuits.

5. Power Ground: Power ground is the ground connection for the power supply in electronic systems. It provides a low-impedance path for the return current from the power supply, ensuring stable voltage levels throughout the system. Power ground should be separate and isolated from other grounds, such as signal, analog, or chassis ground, to prevent interference and noise coupling.

It’s important to note that in some cases, different types of grounds can be interconnected to ensure proper functionality and safety. However, it is crucial to maintain proper grounding practices and ensure that each ground connection serves its intended purpose without causing interference or compromising safety.

By understanding the different types of ground in electronics, engineers and designers can make informed decisions about grounding strategies and effectively manage electrical safety, signal integrity, and system performance.

Grounding Techniques in Electronics

Proper grounding techniques are crucial in electronics to ensure reliable operation, signal integrity, and safety. Here are some commonly used grounding techniques in electronic systems:

1. Single-Point Grounding: This technique involves connecting all ground points of the system to a single point, typically referred to as the central ground. By consolidating all ground connections at a single location, it helps minimize ground loops and ensures a common voltage reference for the entire system. Single-point grounding is commonly used in low-noise analog circuits to prevent noise and interference.

2. Star Grounding: Star grounding involves connecting all ground points of the system directly to a central grounding point, often represented by a star-shaped ground bus or a ground plane. This technique helps reduce ground loop effects and provides a low-impedance ground path, minimizing noise and interference in the system. Star grounding is commonly used in audio and high-frequency circuits to maintain signal clarity.

3. Isolated Grounding: Isolated grounding is used to minimize or eliminate ground loops and interference caused by shared ground paths. It involves isolating the ground connection of sensitive equipment from the main ground system using isolation transformers or dedicated grounding conductors. Isolated grounding is commonly used in sensitive electronic devices that require a clean and noise-free ground reference.

4. Ground Plane Implementation: A ground plane is a conductive layer or plane in printed circuit boards (PCBs) that acts as a reference ground for electronic components and traces. Implementing a dedicated ground plane helps provide a low-impedance ground path, reduces EMI, and improves circuit performance by minimizing ground signal interference. Ground planes are commonly used in high-frequency circuits, such as RF and digital circuits.

5. Separation of Grounds: In certain applications, it is necessary to separate different ground connections to prevent interference and noise coupling. This involves creating separate ground paths for sensitive analog, digital, and power circuits. By keeping the ground paths isolated, the risk of cross-talk and signal degradation between different types of circuits is reduced, improving overall system performance.

6. Proper Grounding of Enclosures: The metal enclosures of electronic devices should be properly grounded to prevent electrostatic discharge (ESD) and to provide EMI shielding. By connecting the enclosure to the ground, any static charges or unwanted electromagnetic fields can be safely dissipated, protecting the internal components and improving the overall electromagnetic compatibility (EMC) of the device.

Each grounding technique should be chosen based on the specific requirements and characteristics of the electronic system. It is important to consider factors such as noise reduction, signal integrity, safety, and compliance with industry standards when implementing grounding techniques in electronic circuits and systems.

Common Grounding Problems and Solutions

Proper grounding is essential for the reliable and safe operation of electronic systems. However, there are common grounding problems that can occur and cause issues in electronic circuits. Here are some of these problems along with their solutions:

1. Ground Loops: Ground loops occur when there are multiple paths for ground current flow in a system, resulting in noise, hum, or interference. To mitigate ground loop problems, one solution is to use a single-point grounding technique, where all ground connections are brought to a single common ground point. Isolation transformers or ground loop isolators can also be used to break the unwanted ground paths.

2. Insufficient Grounding: Insufficient grounding can lead to unstable voltage levels, noise, and interference in electronic circuits. Ensuring proper grounding connections, such as using dedicated grounding conductors and following manufacturer’s guidelines, can help address this issue. Adding additional grounding electrodes or using grounding rods can also improve grounding effectiveness.

3. Inadequate Grounding in PCBs: Poor grounding in printed circuit boards (PCBs) can result in signal integrity issues and noise coupling between different traces and components. Implementing a ground plane on the PCB can provide a low-impedance ground path and minimize unwanted signal interference. Careful routing of ground traces and keeping the ground plane as complete as possible can also help maintain a solid ground reference.

4. Improper ESD Grounding: Electrostatic discharge (ESD) can cause damage to sensitive electronic components. Proper grounding techniques should be employed to ensure the discharge of any static charges to the ground. This includes the use of antistatic wrist straps, ESD mats, and proper grounding of workstations and handling equipment.

5. Inadequate Grounding of Enclosures: Metal enclosures of electronic devices should be effectively grounded to prevent EMI issues and protect against electrostatic discharge. Ensuring a solid connection between the enclosure and the ground can provide EMI shielding and prevent the buildup of static charges on the enclosure surface.

6. Grounding in High-Frequency Circuits: High-frequency circuits require careful grounding due to the potential for unwanted signal reflections and noise. Separating the ground planes for analog, digital, and RF sections of the circuit can help minimize interference. The use of proper grounding techniques, such as low impedance connections and ground vias, is essential to maintain signal integrity.

Addressing these common grounding problems requires a systematic approach that includes proper system design, adherence to grounding guidelines, and regular testing and maintenance of grounding connections. Consulting with experienced engineers and following industry standards can help identify and resolve grounding issues in electronic systems.

Grounding Safety Tips

Proper grounding is crucial for the safe operation of electronic systems. Here are some important grounding safety tips to keep in mind:

1. Familiarize Yourself with Grounding Standards: Understand and follow the grounding standards and guidelines provided by regulatory bodies and industry organizations. Familiarize yourself with local electrical codes and ensure compliance in all grounding practices.

2. Use Ground Fault Circuit Interrupters (GFCIs): Install GFCIs in areas where electrical equipment is used, such as kitchens, bathrooms, and outdoor areas. GFCIs detect ground faults and quickly interrupt the circuit to prevent electric shock. Test GFCIs regularly to ensure they are functioning properly.

3. Inspect Grounding Connections: Regularly check the grounding connections of electronic devices and systems. Ensure all grounding wires and connections are secure, free from damage, and properly connected to the ground terminals or grounding electrodes.

4. Avoid Overloading Ground Circuits: Do not overload ground circuits with excessive current or connect multiple devices to a single ground point beyond its capacity. Distribute the load evenly across multiple ground connections or use a suitable grounding busbar when necessary.

5. Properly Ground Outdoor Electronic Equipment: Ensure outdoor electronic equipment, such as antennas or satellite dishes, is properly grounded to protect against lightning strikes and static buildup. Use lightning arrestors and grounding rods to provide a safe path for electrical discharge.

6. Practice ESD Safety Measures: When working with sensitive electronic components, follow proper electrostatic discharge (ESD) precautions. Use ESD wrist straps, grounded mats, and ESD-safe tools to prevent damage caused by static electricity. Ground yourself by touching a grounded object before handling sensitive components.

7. Ensure Proper Grounding in Temporary Installations: For temporary installations or events, such as outdoor concerts or construction sites, ensure proper grounding of electrical equipment. Use grounding mats or grounding rods to establish a safe ground connection.

8. Educate and Train Personnel: Provide training and education to personnel working with electronic systems regarding proper grounding practices and safety protocols. Emphasize the importance of following safety guidelines and reporting any grounding issues or anomalies.

9. Regularly Test Grounding Systems: Perform regular testing and maintenance of grounding systems to ensure their effectiveness. Use ground testers and multimeters to measure ground resistance and continuity. Regular inspections and testing help identify and address any grounding problems before they can cause safety hazards or affect system performance.

Always prioritize safety when working with electronic systems. By following these grounding safety tips and implementing proper grounding practices, you can protect both yourself and the equipment from potential electrical hazards.

Grounding in AC and DC Circuits

In both AC (alternating current) and DC (direct current) circuits, grounding serves important functions related to safety, voltage reference, and noise reduction. However, there are some key differences in how grounding is implemented in AC and DC circuits.

Grounding in AC Circuits: In AC circuits, the neutral wire is typically grounded to provide a reference point for voltage measurements and to ensure electrical safety. The neutral wire carries the return current from electrical loads back to the source, while the hot wire carries the current to the loads. By grounding the neutral wire, the potential difference between the neutral and ground is minimized, reducing the risk of electrical shock.

AC systems often use a three-pronged power plug, with two prongs for the hot and neutral wires and an additional prong for the ground wire. The ground wire is connected to the earth, either directly or through a grounding electrode, providing an alternative path for current in the event of a fault or short circuit. This helps protect against electric shock and ensures the safe dissipation of excess current.

In AC systems, proper grounding is essential for maintaining consistent voltage levels, reducing noise and interference, and protecting against electrical faults. It also plays a role in grounding surge protectors and electrical panels to divert excess voltage spikes safely to the ground.

Grounding in DC Circuits: Grounding techniques in DC circuits differ from AC circuits since there is typically no neutral wire. In DC systems, the negative terminal or common reference point of the power supply is often connected to the ground. This serves as a voltage reference for the circuit and helps minimize ground potential differences that can affect the accuracy and reliability of measurements.

Grounding in DC circuits is also important for safety, especially in devices and systems where exposed conductive parts might become live in the event of a fault. By properly grounding these parts, any fault current can safely flow into the ground, reducing the risk of electric shock.

It’s important to note that in certain DC applications, such as sensitive measurement systems or analog circuits, isolated grounding techniques may be employed to minimize noise, interference, and voltage fluctuations. These techniques involve isolating the ground connection of specific components or subsystems to prevent circulating ground currents and noise coupling.

Overall, whether in AC or DC circuits, grounding plays a critical role in maintaining safety, providing voltage reference, and reducing noise and interference. Understanding the specific grounding requirements of each type of circuit is crucial for proper system design, operation, and protection against potential electrical hazards.

Grounding in Printed Circuit Boards (PCBs)

Grounding in printed circuit boards (PCBs) is a crucial aspect of circuit design that influences the performance, reliability, and noise immunity of electronic systems. Proper grounding techniques ensure a solid reference plane for electrical signals, minimize noise and interference, and provide a low-impedance path for return currents.

Ground Plane: The ground plane is a dedicated layer or region on the PCB that serves as a common ground reference for components, traces, and signal return paths. It is typically located on one of the inner layers of the PCB but may also be on the outer layer for two-sided boards. The ground plane provides a large conductive area that helps distribute current evenly and minimize impedance, resulting in better signal integrity and noise reduction.

Ground Traces: Ground traces or copper pours are used to provide additional grounding connections and establish low-impedance paths between components and the ground plane. These traces are placed strategically to ensure that all components have a reliable ground connection and minimize the potential for ground loops or noise coupling. Ground traces should be wide and short to minimize resistance and inductance, reducing the chances of voltage drops and signal degradation.

Component Placement: Strategic placement of components on the PCB can also aid in grounding. Grouping components that share common ground connections enables shorter ground paths and reduces the risks of cross-talk and interference. Care should be taken to keep high-speed or noise-sensitive components away from noisy or high-current areas to prevent signal corruption and maintain signal integrity.

Grounding Techniques: Some common grounding techniques employed in PCB design include star grounding, where all ground connections converge at a single point on the ground plane, and split-plane grounding, which involves separating the ground plane into different regions for analog and digital components to prevent noise coupling. Grounding vias can also be used to connect the ground plane to other layers and ensure a continuous ground connection throughout the PCB.

PCB Layout Considerations: In PCB layout, it is essential to pay attention to the placement of ground connections and their relationship with signal traces. Properly separating analog and digital ground regions, avoiding loops in ground traces, and reducing the length of ground traces can help mitigate noise and interference. Adequate clearance between signal and ground traces should also be maintained to prevent coupling and unwanted capacitance.

Testing and Validation: After PCB fabrication, it is crucial to test and validate the grounding integrity. Tools such as multimeters and network analyzers can be utilized to measure ground resistance, impedance, and signal integrity to ensure that the grounding system is functioning correctly.

Proper grounding in PCBs is essential for achieving optimal circuit performance, minimizing noise, and ensuring the reliability and functionality of electronic systems. By following sound grounding techniques and considering the specific requirements of the application, designers can create well-grounded PCB layouts that contribute to overall system success.

Grounding in Electronic Devices and Appliances

Grounding is an important aspect of electronic devices and appliances, ensuring both user safety and optimal operation. Proper grounding helps protect against electric shock, dissipates excess electrical energy, and reduces the risk of electrical malfunctions. Here is a closer look at grounding in electronic devices and appliances:

Electrical Safety: The primary purpose of grounding in electronic devices and appliances is to ensure electrical safety. Grounding provides a path of least resistance for excess electrical current in case of a fault or malfunction, diverting it safely to the ground. This helps protect users from electric shock and can prevent damage to the device or surrounding environment.

Reduction of Electrical Noise: Grounding also helps reduce electrical noise in electronic devices and appliances. Electrical noise can interfere with the proper operation of sensitive components and circuits, leading to degraded performance or malfunction. Proper grounding provides a reliable reference point, minimizing noise and ensuring accurate signal transmission and reception.

Protection Against Static Electricity: Grounding is essential in electronic devices to dissipate static electricity. Static charges can build up on surfaces or accumulate within devices, posing a risk to sensitive electronic components. Grounding provides a means to safely discharge static electricity, protecting components and reducing the potential for damage due to electrostatic discharge (ESD).

Ground Fault Protection: Ground fault protection is a critical aspect of grounding in electronic devices and appliances. Ground fault circuit interrupters (GFCIs) are commonly used to detect ground faults and rapidly shut off the power supply in the event of a fault. This helps prevent electric shock hazards and protects against potential fire risks.

EMI Shielding: Grounding is important for shielding electronic devices and appliances from electromagnetic interference (EMI). By properly grounding metal enclosures or shielding, any unwanted electromagnetic radiation or interference can be directed to the ground, protecting internal components and reducing the impact of external EMI sources.

Equipment Grounding: In appliances and electronic devices, certain metal components or exposed conductive parts may become live in the event of a fault. Proper equipment grounding ensures the safe dissipation of fault currents, preventing the risk of electrocution from accidental contact with live parts.

Compliance with Electrical Codes: Grounding requirements for electronic devices and appliances are specified by electrical codes and regulations. Compliance with these codes is essential for ensuring the safe and legal operation of electronic devices. Manufacturers must adhere to specific grounding standards and certification requirements to meet safety regulations.

Overall, grounding in electronic devices and appliances is crucial for electrical safety, noise reduction, protection against static electricity, and compliance with regulatory standards. By incorporating effective grounding techniques, designers and manufacturers can ensure the reliable and safe operation of electronic devices and appliances.