Definition of Potting Electronics

Potting electronics is a process commonly used in the field of electronics manufacturing to encase and protect electronic components, circuit boards, and assemblies. It involves encapsulating the sensitive electronic parts in a liquid or gel-like material, typically a thermosetting resin or polymeric compound.

The purpose of potting electronics is to provide a barrier against environmental factors such as moisture, dust, vibrations, and temperature fluctuations that can potentially damage or compromise the performance of the electronics. By completely enclosing the components, potting creates a protective layer that shields them from external elements and ensures their long-term functionality and reliability.

Potting materials are carefully selected based on the specific requirements of the application. They are typically non-conductive, insulating, and possess excellent thermal properties to dissipate heat generated by the electronics. The chosen material is poured or injected around the components, filling any voids or gaps to create a solid, homogenous enclosure.

This process not only offers mechanical protection but also enhances electrical insulation, reduces the risk of short circuits, and prevents the ingress of moisture, dust, or other contaminants that may cause corrosion or electrical failures. Additionally, potting can provide excellent resistance to chemicals, UV radiation, and mechanical stress, making it a reliable solution for demanding environments.

Potting materials can be customized to meet specific requirements, such as flame retardancy, thermal conductivity, or low shrinkage. This adaptability makes potting suitable for a wide range of applications in various industries, including automotive, aerospace, industrial automation, renewable energy, and consumer electronics.

Overall, potting electronics is a crucial process that ensures the longevity and reliability of electronic devices by providing a protective and durable encapsulation. It helps safeguard against external factors that can potentially compromise the performance and lifespan of the electronics, making it an integral part of modern electronics manufacturing.

Benefits of Potting Electronics

Potting electronics offers several key benefits, making it a preferred choice for protecting electronic components and assemblies in various industries. Let’s explore some of the advantages:

- Environmental Protection: Potting creates a robust barrier that shields electronic components from moisture, dust, and other environmental elements that can cause corrosion or damage. This protection ensures the longevity and reliability of the electronics, even in harsh conditions.

- Vibration and Shock Resistance: The encapsulating material used in potting electronics absorbs vibrations and shocks, thereby minimizing the risk of physical damage or disconnection of delicate components. This is particularly important in applications that experience high levels of vibration or constant movement.

- Electrical Insulation: Potting materials are non-conductive and offer excellent electrical insulation properties. This helps to prevent short circuits and protect the electronics from electrical interference, improving their overall performance and safety.

- Thermal Management: Potting compounds with high thermal conductivity can efficiently dissipate heat generated by the electronic components, ensuring optimal operating temperatures. This helps prolong the lifespan of the electronics and avoid potential performance issues caused by excessive heat.

- Chemical and UV Resistance: Many potting materials are resistant to a wide range of chemicals, including solvents, oils, and corrosive substances. They also offer excellent UV resistance, protecting the electronics from the potentially harmful effects of prolonged exposure to sunlight. This makes potting suitable for outdoor and industrial applications.

- Improved Durability: The protective enclosure created by potting electronics enhances the overall durability of the components. It increases their resistance to mechanical stress, reducing the risk of physical damage due to handling or environmental factors.

Potting electronics plays a crucial role in maintaining the integrity and performance of electronic devices in a wide range of applications. Its ability to provide a reliable and durable protective barrier against environmental hazards, vibrations, heat, and chemical exposure makes it an essential process in the electronics manufacturing industry.

Materials Used for Potting Electronics

The selection of materials for potting electronics is a critical aspect of the process, as it determines the level of protection and performance of the encapsulated components. Here are some common materials used for potting:

- Epoxy Resins: Epoxy resins are widely used for potting electronics due to their excellent electrical insulation properties and high chemical resistance. They offer good adhesion to various substrates and can be formulated to provide specific characteristics such as high temperature resistance or low shrinkage.

- Polyurethane Resins: Polyurethane resins are known for their flexibility, impact resistance, and resistance to environmental factors such as moisture and UV radiation. They provide good mechanical protection to the electronics and are often used in applications that require a balance between protection and flexibility.

- Silicone Rubbers: Silicone rubbers are highly flexible and have excellent thermal stability. They provide effective protection against moisture and are also known for their high dielectric strength and resistance to extreme temperatures. Silicone rubbers are commonly used in applications where the electronics may undergo significant temperature fluctuations.

- Polyester Resins: Polyester resins offer good mechanical protection and are resistant to moisture and chemicals. They are cost-effective and provide reliable encapsulation for a variety of electronic components. However, they are not suitable for high-temperature applications.

- Polyurethane Gels: Polyurethane gels are soft, gel-like materials that provide excellent shock absorption and vibration dampening properties. They are commonly used in applications where impact resistance and flexibility are crucial, such as in automotive electronics or handheld devices.

It is important to choose the right potting material based on the specific requirements of the application. Factors to consider include the level of environmental protection needed, thermal management requirements, flexibility requirements, and any specific chemical resistance properties needed for the electronics to operate in particular environments.

Manufacturers often work closely with potting material suppliers to select or develop the ideal material formulation that meets the desired specifications and performance criteria. This ensures that the encapsulated electronics are effectively protected and maintain their functionality and reliability over time.

Process of Potting Electronics

The process of potting electronics involves several steps to ensure effective encapsulation and protection of the electronic components. Here is an overview of the typical potting process:

- Component Preparation: Before potting, it is important to prepare the electronic components. This may involve cleaning, removing any existing coatings or residues, and ensuring that the components are dry and free from dirt or debris. Proper preparation is crucial to ensure a strong bond between the components and the potting material.

- Mold or Enclosure Selection: Depending on the complexity and size of the electronic assembly, a suitable mold or enclosure is selected. This mold or enclosure will hold the potting material and the components during the potting process. It should have the desired shape, size, and any necessary features such as channels for wire routing or mounting points for connectors.

- Mixing and Degassing: The potting material, such as epoxy resin or polyurethane, is mixed according to the manufacturer’s instructions. This ensures proper curing and desired properties. The mixture is then degassed to remove any air bubbles or pockets that could affect the integrity of the encapsulation.

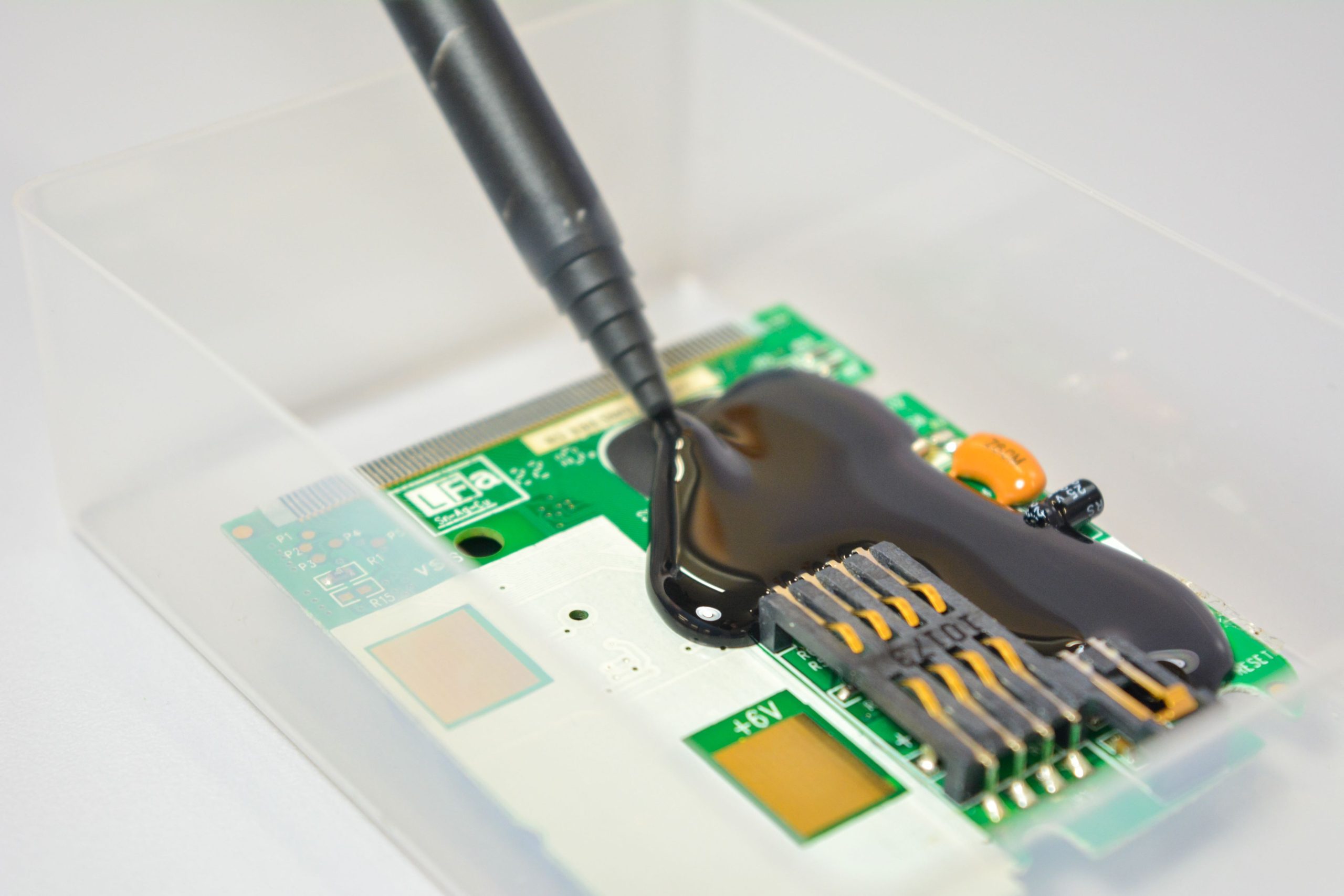

- Potting Application: The prepared components are placed in the selected mold or enclosure, and the mixed potting material is poured or injected into the space around the components. Care must be taken to fill all gaps and voids thoroughly to achieve complete encapsulation and avoid any potential weak points.

- Curing and Hardening: Once the potting material is applied, it undergoes a curing and hardening process. This may involve exposure to heat, UV light, or a catalyst, depending on the type of material used. Curing time can vary depending on the material and desired properties.

- Post-Curing and Finishing: After the potting material has cured, any excess material is removed, and the encapsulated electronics are inspected for any defects or imperfections. Depending on the application, additional finishing processes such as sanding or coating may be applied to enhance the aesthetics or provide additional protection.

It is important to note that the potting process should be conducted in a controlled environment, ensuring proper ventilation and safety measures. This helps to minimize the potential for exposure to hazardous fumes or substances and ensures the quality and integrity of the encapsulated electronics.

By following these steps, the potting process effectively encapsulates and protects the electronic components, providing them with the necessary barrier against environmental factors and enhancing their longevity and reliability.

Importance of Potting Electronics for Protection

Potting electronics plays a crucial role in ensuring the protection and longevity of electronic components and assemblies. Here are some key reasons why potting is important:

- Environmental Protection: Electronic components are often exposed to harsh environmental conditions, including moisture, dust, vibrations, and temperature fluctuations. Potting electronics provides a protective barrier that shields the components from these external factors, preventing damage caused by corrosion, short circuits, or electrical failures.

- Enhanced Reliability: By encapsulating electronic components in a protective enclosure, potting significantly improves their reliability. The encapsulation helps to eliminate possible points of failure and decreases the risk of physical damage due to mishandling or exposure to environmental elements.

- Electrical Isolation: Potting materials are non-conductive and offer excellent electrical insulation properties. This isolation prevents short circuits, minimizes electromagnetic interference, and protects the electronics from electrical shocks. It ensures the safe and proper functioning of the components and reduces the risk of electrical failures.

- Thermal Management: Electronic components generate heat during operation, and excessive heat can lead to performance degradation or even component failure. Potting compounds with high thermal conductivity can effectively dissipate heat, maintaining optimal operating temperatures and extending the lifespan of the electronics.

- Chemical and Mechanical Protection: Many industries, such as automotive and aerospace, involve exposure to chemicals, solvents, and mechanical stress. Potting electronics with chemically resistant materials provides a protective shield against corrosive substances and prevents mechanical damage caused by vibration, shock, or impact, ensuring the long-term durability of the devices.

- Longevity and Cost Savings: Potting electronics enhances the lifespan of electronic components, reducing the need for frequent repairs or replacements. This leads to cost savings by avoiding potential downtime, warranty claims, and production delays. Additionally, the extended lifespan of the electronics improves product reliability and customer satisfaction.

Overall, potting electronics is of paramount importance for the protection and reliable performance of electronic components. It safeguards against environmental hazards, electrical failures, thermal issues, and chemical exposure, ensuring the longevity and durability of the devices. By incorporating potting into the manufacturing process, companies can enhance product quality, reduce maintenance costs, and provide customers with electronics that can withstand demanding operating conditions.

Potting vs. Conformal Coating: Understanding the Difference

When it comes to protecting electronic components, two common methods are potting and conformal coating. While both techniques serve the purpose of safeguarding electronics, there are distinct differences between the two. Understanding these differences is crucial in choosing the most suitable method for specific applications. Let’s explore the disparities between potting and conformal coating:

Potting:

- Potting involves completely encapsulating electronic components within a solid or gel-like material, such as epoxy or polyurethane resins.

- The potting material forms a protective enclosure around the components, shielding them from moisture, dust, vibrations, and other environmental elements.

- Potting provides excellent mechanical protection and thermal management due to the solid nature of the encapsulation.

- It offers higher level of protection against chemical exposure and physical damage compared to conformal coating.

- However, potting can add weight to the overall assembly and may complicate repairs or modifications due to the permanent encapsulation.

- Potting is ideal for applications with high-risk environmental conditions, where total protection and superior performance are critical, such as automotive or military electronics.

Conformal Coating:

- Conformal coating involves applying a thin protective layer, typically a liquid polymer, onto the surface of electronic components.

- The coating conforms to the shape of the components, providing a protective barrier against moisture, dust, and some level of chemical exposure.

- Conformal coating offers flexibility and ease of application, enabling rework or repairs if needed, as it can be removed or re-applied.

- While it offers good protection, conformal coating may not provide the same level of mechanical or thermal protection as potting due to its thin and flexible nature.

- Conformal coating is commonly used in applications where moderate levels of protection are needed, such as consumer electronics, PCBs, or electronic assemblies not exposed to extreme environments.

Choosing between potting and conformal coating depends on the specific requirements of the application. Factors to consider include the level of protection needed, environmental conditions, repairability, and the potential impact on weight or size constraints. Working closely with experts in the field can help determine the most appropriate method for ensuring the desired level of protection and performance for electronic components.

Common Applications of Potting Electronics

Potting electronics is a versatile process that finds application in various industries and for a wide range of electronic devices and components. Here are some common applications where potting is employed:

- Automotive Electronics: Potting is widely used in automotive electronics to protect sensitive components such as control units, sensors, and connectors from moisture, vibrations, and heat. It ensures the reliable operation of automotive systems in demanding environments.

- Aerospace and Defense: The aerospace and defense industries require robust protection for electronic components in aircraft, satellites, and military equipment. Potting electronics provides insulation from extreme temperatures, mechanical stress, and harsh conditions while maintaining signal integrity.

- Industrial Automation: In industrial automation, electronic control systems and sensors need reliable protection to withstand harsh environments, such as high temperatures, dust, humidity, and vibration. Potting electronics ensures the functional integrity of these components in industrial machinery and automation systems.

- Renewable Energy: Potting is used extensively in renewable energy systems such as solar inverters and wind turbines. These systems are exposed to outdoor elements and require protection against moisture, temperature fluctuations, and UV radiation to ensure long-term performance and reliability.

- LED Lighting: LED lighting fixtures often incorporate electronic driver circuits that require protection from moisture and vibrations. Potting electronics provides a reliable barrier, extending the lifespan and maintaining the efficiency of LED lighting products.

- Consumer Electronics: Portable devices, home appliances, and other consumer electronics benefit from potting to protect internal components from external factors. Potting provides insulation, protection against moisture, and enhanced durability, ensuring the longevity of these devices.

These are just a few examples of the many applications where potting electronics serves a crucial role in protecting electronic components and ensuring their reliable and long-term performance. The versatility of potting materials and the ability to customize potting formulations make it a widely adopted method across various industries.

Considerations for Potting Electronics

When it comes to potting electronics, several important considerations should be taken into account to ensure a successful and effective encapsulation process. These considerations include:

- Material Selection: Choosing the right potting material is crucial, as it should have the necessary properties to meet the specific requirements of the application. Factors to consider include electrical insulation, thermal conductivity, chemical resistance, and compatibility with the electronics and the operating environment.

- Component Design: The design of the electronic components and assemblies should be considered, as it can affect the potting process. Components with complex shapes, delicate parts, or fine-pitched connectors may require additional precautions or modifications to ensure proper encapsulation and easy maintenance, if required.

- Potting Process: The potting process should be carefully planned and executed. This includes determining the appropriate amount of potting material, the method of application (pouring, injection, or vacuum potting), curing time, and any necessary post-curing steps. Following the manufacturer’s recommendations and industry best practices is key to achieving optimal results.

- Environmental Considerations: The operating environment of the electronics should be carefully evaluated. Factors such as temperature extremes, humidity, exposure to chemicals, or vibrations should be taken into account while selecting the potting material and designing the encapsulation system.

- Long-Term Maintenance: Considerations for long-term maintenance and potential repair or rework should be established during the potting process. The ability to access and replace components, as well as compatibility with future modifications, should be thoroughly evaluated to ensure practicality and cost-effectiveness.

- Testing and Quality Control: It is important to implement rigorous testing and quality control measures throughout the potting process. This may include inspecting for voids, bubbles, or incomplete encapsulation, electrical resistance testing, thermal cycling, and performance verification. These measures help ensure the reliability and performance of the potting and the encapsulated electronics.

By considering these factors during the potting process, manufacturers can achieve optimal protection and performance for electronic components. Collaboration with material suppliers, design engineers, and potting specialists can provide valuable insights and solutions to address specific considerations for each application.

Challenges and Limitations of Potting Electronics

While potting electronics offers numerous benefits, it also presents certain challenges and limitations that should be considered. Understanding these limitations is crucial for effectively implementing potting processes. Here are some common challenges and limitations:

- Accessibility and Repairability: Once electronic components are encapsulated, accessing or repairing individual components can be challenging. Potting may require the complete removal of the encapsulation material, making repairs time-consuming and costly. Careful consideration is needed to design a potting system that allows for future repairs or component replacements, if necessary.

- Thermal Management: While potting materials can offer good thermal conductivity, the encapsulation process can create a thermal barrier between the components and the surrounding environment. This may lead to increased heat buildup, potentially affecting the performance and lifespan of the electronics. Additional thermal management strategies, such as incorporating heat sinks or designing ventilation channels, may need to be employed.

- Weight and Size Constraints: Potting can add additional weight and increase the physical size of the electronic assembly due to the volume of the potting material. In applications where weight or size constraints are critical, alternative protective measures, such as conformal coating or vented encapsulations, may need to be considered.

- Cost Considerations: The cost of potting materials, equipment, and the additional time required for the potting process should be taken into account. Potting can add to the overall manufacturing cost, especially for complex assemblies or large-scale production. Care should be taken to balance the cost of potting with the level of protection required for the specific application.

- Chemical Compatibility: Potting materials need to be carefully selected to ensure compatibility with the electronic components and their operating environment. Some potting materials may react with certain materials or chemicals, leading to potential performance issues or degradation of the encapsulated components. Thorough testing and evaluation of material compatibility are essential.

- Design Considerations: The design of the potting system, including mold or enclosure selection, component placement, and wire routing, can impact the effectiveness of the potting process. Careful consideration should be given to ensure adequate space for potting material flow, proper encapsulation of all components, and effective strain relief for wires and connectors.

Despite these challenges and limitations, potting electronics remains an effective method for providing protection and enhancing the performance and reliability of electronic components. Through careful planning, consideration of limitations, and collaboration with potting experts, manufacturers can overcome these challenges and optimize the potting process for their specific application.

Examples of Potting Electronics in Real-Life Applications

Potting electronics is utilized in a wide range of real-life applications across various industries. Let’s explore some examples of how potting is employed to protect electronic components:

- Automotive Electronics: In the automotive industry, potting is commonly used to protect electronic control units (ECUs), sensors, and connectors. By encapsulating these components, potting helps safeguard them from moisture, dust, vibrations, and temperature fluctuations, ensuring reliable operation in challenging automotive environments.

- Solar Power Systems: Potting plays a crucial role in safeguarding electronic components in solar power systems. Potting the inverters, charge controllers, and junction boxes protects these components from environmental factors such as moisture, dust, heat, and UV radiation, allowing them to efficiently convert and manage solar energy.

- Medical Devices: Medical devices often require protection from moisture, chemicals, and sterilization processes. Potting electronics ensures the reliability and longevity of electronic components used in devices such as pacemakers, defibrillators, and patient monitors, allowing them to withstand the demanding conditions of medical environments.

- Industrial Sensors and Control Systems: Potting is widely used in industrial automation to protect sensors, control systems, and data loggers. Encapsulating these components ensures their functionality and reliability in harsh industrial environments, including exposure to moisture, dust, chemicals, and vibrations.

- LED Lighting: The electronics used in LED lighting fixtures can be vulnerable to moisture and temperature fluctuations. Potting provides a protective barrier that shelters the LED drivers and control circuits, extending the lifespan and ensuring consistent performance in a variety of lighting applications.

- Marine Electronics: In marine applications, electronic components face constant exposure to moisture, saltwater, and extreme temperature variations. Potting protects navigational systems, communication devices, and other marine electronics from corrosion and water ingress, ensuring reliable operation in marine environments.

These examples highlight the diverse applications of potting electronics across industries that rely on the protection and reliability of electronic components. Potting not only enhances the performance and lifespan of these components but also ensures the overall functionality and safety of the systems in which they are employed.