The Definition of Digital Twins

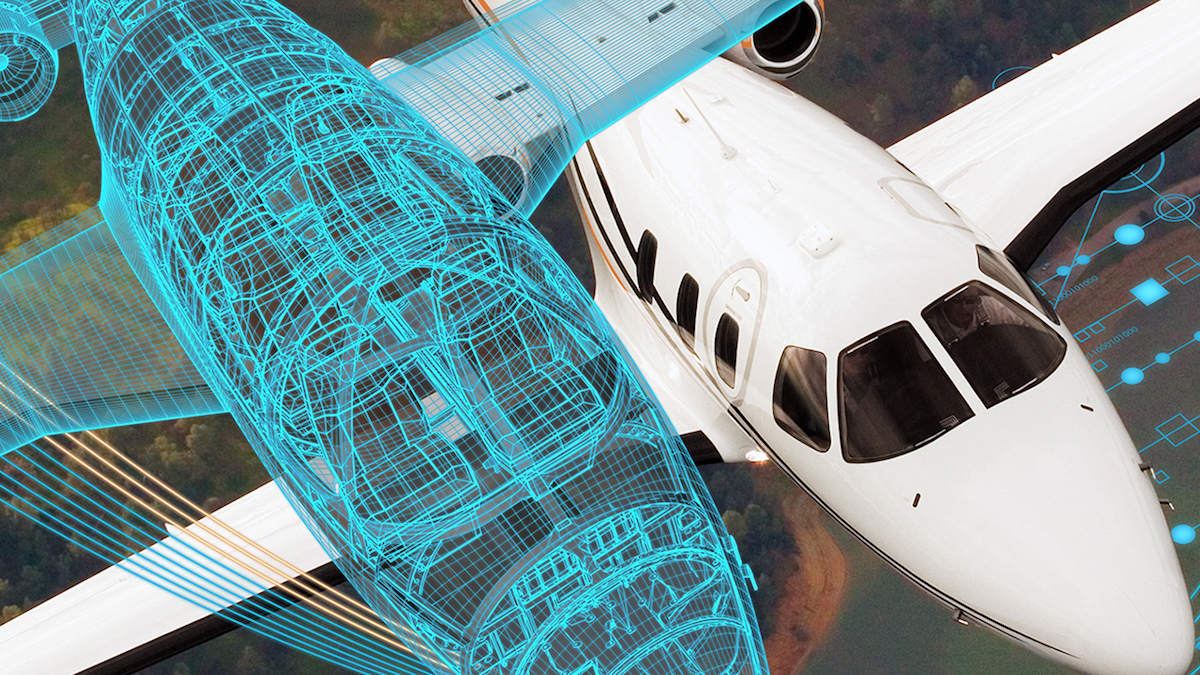

A digital twin is a virtual representation of a physical object, process, or system. It is a digital counterpart that mirrors the physical entity in real-time, providing a bridge between the physical and digital worlds. By creating a digital twin, organizations can monitor, analyze, and optimize the performance of their physical assets or operations.

The concept of digital twins has gained traction with the advent of Internet of Things (IoT) technology, which allows physical objects to be connected and communicate data in real-time. The digital twin serves as an intelligent replica, continuously updated with data and information from its physical counterpart.

Furthermore, a digital twin goes beyond a simple 3D modeling or visualization tool. It includes sensors, data analytics, and machine learning algorithms to capture, analyze, and simulate real-world behaviors and scenarios. It provides a holistic view of the physical entity, enabling organizations to identify patterns, predict outcomes, and make informed decisions.

One of the key characteristics of a digital twin is its ability to represent the state and behavior of the physical entity throughout its lifecycle. From design and manufacturing to operation and maintenance, the digital twin captures data at every stage, enabling organizations to optimize performance, improve efficiency, and reduce costs.

Furthermore, the digital twin is not limited to a single object or system. It can be applied to complex systems that involve multiple interconnected components, such as smart cities, factories, or supply chains. By creating digital twins of the entire system, organizations can gain insights into the interdependencies and interactions between various elements, enabling better planning, coordination, and decision-making.

Overall, a digital twin is a powerful tool that brings together the physical and digital realms, enabling organizations to gain a deeper understanding of their assets and operations. It provides a virtual environment where organizations can simulate, test, and optimize various scenarios, leading to improved performance, enhanced productivity, and better outcomes.

The Concept of Digital Twins

The concept of digital twins revolves around creating a virtual replica that mirrors a physical entity, be it an object, process, or system. This virtual counterpart is connected to its physical counterpart through data streaming, enabling real-time monitoring, analysis, and optimization.

At the core of the concept is the idea that a digital twin serves as a bridge between the physical and digital worlds. It allows organizations to gather valuable insights about the performance, behavior, and condition of their physical assets or operations without directly interacting with them. By leveraging sensors, data analytics, and IoT technology, digital twins provide a comprehensive understanding of their physical counterparts.

One important aspect of digital twins is their ability to mimic the behavior and characteristics of their physical counterparts. This is achieved by continuously collecting and processing data from the physical entity, incorporating factors such as environmental conditions, usage patterns, and operational parameters. Through machine learning algorithms, the digital twin can predict future behavior, identify potential issues, and recommend optimal actions.

To ensure the accuracy and reliability of the digital twin, it is crucial to establish a bi-directional flow of data between the physical and digital realms. This allows the digital twin to receive real-time updates, such as sensor readings, and provide feedback, such as control commands, to the physical entity. This interaction enables organizations to remotely monitor, control, and optimize their assets or operations, leading to increased efficiency and cost savings.

Another critical aspect of digital twins is their ability to support simulation and analysis. By creating a virtual replica, organizations can run simulations and test different scenarios to gain insights and make informed decisions. For example, in manufacturing, digital twins can help optimize production processes, identify bottlenecks, and improve overall efficiency. In healthcare, digital twins can assist in personalized medicine by simulating patient-specific conditions and predicting treatment outcomes.

Overall, the concept of digital twins goes beyond simple visualization or modeling. It leverages advanced technologies to create dynamic, interconnected replicas that enable organizations to enhance their understanding, control, and optimization of physical assets or operations. By harnessing the power of digital twins, organizations can achieve improved performance, better decision-making, and a competitive edge in today’s digital age.

How Do Digital Twins Work?

Digital twins function through a combination of technologies and processes that enable the creation, synchronization, and interaction between the virtual and physical realms. The key components that make digital twins work include data collection, connectivity, analytics, and visualization.

The first step in creating a digital twin is gathering data from the physical entity. This data can come from various sources, including sensors, IoT devices, and existing data systems. The collected data is then processed and transformed into a digital format that can be used to create a virtual replica.

Connectivity plays a crucial role in digital twins. It allows the virtual replica to stay synchronized with its physical counterpart by continuously updating and exchanging data. This bi-directional flow of data ensures that the digital twin accurately represents the current state of the physical entity in real-time.

Analytics is another key aspect of digital twins. By leveraging advanced algorithms and machine learning techniques, the digital twin can analyze and interpret the collected data to gain valuable insights. This includes identifying patterns, predicting behavior, and detecting anomalies. These insights can help organizations optimize their operations, prevent failures, and improve overall performance.

Visualization is an important element in digital twins, as it allows users to interact with the virtual replica in a meaningful way. It provides a user-friendly interface that presents the data and insights in a visual format. This enables users to easily understand and interpret complex information, facilitating decision-making and problem-solving.

Furthermore, digital twins can incorporate simulation capabilities. By using the collected data and applying various scenarios, organizations can simulate different conditions and test potential solutions. This helps in predicting outcomes, optimizing processes, and mitigating risks.

In addition to the technical aspects, successful implementation of digital twins requires collaboration between various stakeholders. This includes domain experts, data scientists, engineers, and IT professionals. By working together, they ensure that the digital twin is accurately representing the physical entity and providing meaningful insights to support decision-making and optimization.

Overall, digital twins work by leveraging data, connectivity, analytics, visualization, and simulation to create a virtual replica that mirrors a physical entity. Through continuous synchronization, analysis, and visualization, organizations can gain valuable insights to optimize their operations, enhance performance, and drive innovation.

Real-World Examples of Digital Twins

Digital twins have become increasingly prevalent across various industries, transforming the way organizations operate, optimize, and innovate. Here are some real-world examples of digital twins in action:

- Smart Manufacturing: In the manufacturing industry, digital twins are revolutionizing production processes. For example, General Electric has implemented digital twins for jet engines. These digital twins enable real-time monitoring, analysis, and prediction of engine performance, allowing for proactive maintenance, reduced downtime, and improved efficiency.

- Smart Cities: Digital twins have a significant impact on urban design and planning. For instance, Singapore is utilizing digital twins to create a virtual replica of the entire city. This enables urban planners to simulate and test various scenarios, such as traffic flow optimization, energy consumption analysis, and urban infrastructure development, leading to more sustainable and efficient city planning.

- Healthcare: Digital twins are revolutionizing personalized medicine and patient care. For instance, in medical imaging, digital twins can be created to simulate and analyze patient-specific conditions, aiding in diagnosis and treatment planning. Additionally, researchers are exploring the use of digital twins to monitor and predict the progression of diseases, such as Alzheimer’s and cancer, for more effective interventions.

- Energy Sector: Digital twins are transforming the energy sector, particularly in renewable energy. For example, wind farms are utilizing digital twins to optimize turbine performance, predict maintenance needs, and ensure efficient energy generation. These digital twins enable operators to monitor key parameters, such as wind speed, temperature, and turbine health, to maximize energy output and minimize downtime.

- Automotive Industry: Digital twins play a crucial role in the design, manufacturing, and maintenance of vehicles. For instance, automotive manufacturers can create digital twins of vehicles to simulate crash tests, optimize fuel efficiency, and identify potential design flaws. Additionally, digital twins are used in predictive maintenance to monitor the health of components and detect anomalies, leading to cost savings and improved reliability.

These examples illustrate the wide-ranging applications of digital twins in various industries. They showcase how digital twins enable organizations to gain insights, optimize processes, and deliver enhanced products and services. As technology continues to advance, we can expect to see even more innovative uses of digital twins across multiple sectors.

Benefits of Using Digital Twins

The adoption of digital twins offers several significant benefits for organizations across different industries. Here are some key advantages of using digital twins:

- Improved Understanding and Insights: Digital twins provide organizations with a holistic view of their assets or operations. By capturing real-time data and simulating various scenarios, digital twins offer valuable insights into performance, behavior, and potential issues. This deeper understanding enables organizations to make data-driven decisions, optimize processes, and improve overall efficiency.

- Real-Time Monitoring and Predictive Analytics: Digital twins enable organizations to monitor and analyze their assets or operations in real-time. By continuously collecting and analyzing data, organizations can identify patterns, detect anomalies, and predict future behavior. This allows for proactive maintenance, reduced downtime, and improved operational efficiency.

- Optimization and Simulation: Digital twins enable organizations to simulate and test various scenarios in a virtual environment. This helps in optimizing processes, testing new ideas, and predicting outcomes. For instance, in manufacturing, digital twins can streamline production, reduce waste, and improve product quality by identifying bottlenecks and optimizing workflows.

- Cost and Time Savings: Digital twins can lead to significant cost and time savings. By identifying inefficiencies, predicting maintenance needs, and optimizing processes, organizations can reduce operational costs and improve resource allocation. Additionally, digital twins can accelerate product development cycles by enabling faster prototyping, testing, and optimization.

- Enhanced Collaboration and Communication: Digital twins facilitate collaboration and communication among teams and stakeholders. By providing a visual and interactive representation of the physical entity, digital twins make it easier for different departments and individuals to understand and discuss complex concepts. This improves coordination, decision-making, and problem-solving.

- Reduced Risks and Improved Safety: Digital twins can help identify potential risks and enhance safety measures. For example, in the oil and gas industry, digital twins can simulate and analyze safety scenarios to prevent accidents or respond effectively in case of emergencies. This proactive approach minimizes risks, improves safety measures, and protects both assets and human lives.

Overall, the benefits of using digital twins are far-reaching. They enable organizations to gain insights, optimize processes, reduce costs, improve collaboration, and enhance safety. As technology continues to advance, the transformative potential of digital twins is only expected to grow, making them a valuable tool for organizations in the digital age.

Challenges and Limitations of Digital Twins

While digital twins offer numerous benefits, their implementation also comes with certain challenges and limitations that organizations need to consider. Here are some key challenges and limitations of using digital twins:

- Data Integration and Quality: Digital twins rely heavily on accurate and high-quality data. Ensuring data integration from various sources and maintaining data quality can be a complex task. Issues such as data inconsistencies, incomplete data, or data silos can hinder the effectiveness of digital twins and lead to inaccurate insights and predictions.

- Complexity and Scalability: Creating and managing digital twins for complex systems with numerous components can be challenging. The more complex the system, the more data needs to be collected and analyzed. This requires sophisticated algorithms, robust computational power, and scalable infrastructure to handle the vast amount of data and ensure real-time performance.

- Data Privacy and Security: Collecting and sharing data in digital twins raise concerns about data privacy and security. Organizations need to ensure proper data encryption, access control, and compliance with data protection regulations. Additionally, as digital twins often involve interconnectivity, there is a need to safeguard against potential cyber threats and unauthorized access to sensitive information.

- Dependency on Accurate Models: Digital twins require accurate models to simulate and predict real-world behavior effectively. Developing accurate models can be challenging, especially for complex systems with multiple variables and dynamic conditions. The accuracy of predictions relies heavily on the quality of the underlying models and the completeness of the data used to develop them.

- Adoption and Organizational Change: Implementing digital twins often requires a shift in organizational culture and processes. It may involve acquiring new skills, restructuring workflows, and redefining responsibilities. Resistance to change and lack of organizational buy-in can impede successful implementation and utilization of digital twins.

- Costs and ROI: Developing and maintaining digital twins can be a significant investment. It requires resources for data infrastructure, software development, analytics capabilities, and ongoing updates. Organizations need to carefully assess the costs and potential return on investment (ROI) to ensure that the benefits of using digital twins outweigh the associated expenses.

Despite these challenges and limitations, with careful planning, effective implementation, and continuous improvement, organizations can overcome these hurdles and fully leverage the power of digital twins. It is essential to address these challenges proactively to maximize the value that digital twins can bring to operations, decision-making, and innovation.

Industries and Applications of Digital Twins

Digital twins have the potential to revolutionize various industries, enabling organizations to optimize operations, improve decision-making, and drive innovation. Here are some key industries and their applications of digital twins:

- Manufacturing: In manufacturing, digital twins are used to optimize production processes, enhance product quality, and reduce downtime. By creating digital twins of production lines, manufacturers can simulate different scenarios, identify bottlenecks, and optimize workflows for increased efficiency and productivity. Digital twins also enable predictive maintenance, allowing organizations to proactively address machinery issues and minimize unplanned downtime.

- Energy and Utilities: The energy sector leverages digital twins to optimize energy generation, distribution, and consumption. For example, digital twins of power grids enable real-time monitoring, predictive analytics, and optimization of energy flow, leading to enhanced grid stability and improved energy management. Digital twins also play a crucial role in renewable energy systems, optimizing output and reducing costs.

- Healthcare: Digital twins offer significant potential in the healthcare industry. They can be applied to create personalized treatment plans, simulate surgical procedures, and predict disease progression. Digital twins of patient organs or biological systems help researchers and doctors gain insights into individual health conditions, leading to more accurate diagnoses, optimized treatments, and improved patient outcomes.

- Transportation and Logistics: In transportation, digital twins improve efficiency and safety. For example, in the aviation industry, digital twins of aircraft enable real-time monitoring and predictive maintenance of critical components, ensuring the safety and reliability of flights. In logistics, digital twins optimize supply chain operations by tracking inventory, simulating scenarios, and optimizing routes for efficient delivery.

- Construction and Infrastructure: Digital twins improve project design, construction, and maintenance in the construction industry. By creating digital twins of buildings or infrastructure projects, organizations can simulate construction processes, optimize resource allocation, and identify potential clashes or flaws before actual construction begins. During the maintenance phase, digital twins aid in monitoring systems, analyzing performance, and optimizing maintenance schedules.

- Agriculture: Digital twins in agriculture help optimize farming operations, increase crop yield, and reduce resource wastage. By creating digital twins of farmland, farmers can monitor soil conditions, predict crop growth, and optimize irrigation and fertilizer usage. This enables efficient resource management, maximizes crop production, and reduces environmental impact in the agricultural sector.

These are just a few examples of the industries and applications of digital twins. As technology continues to advance, the possibilities for digital twin implementation will expand further, offering organizations in various sectors the opportunity to revolutionize their operations, improve efficiencies, and achieve better outcomes.

The Future of Digital Twins

The future of digital twins holds immense potential, with advancements in technology and the increasing adoption across industries. Here are some key trends that will shape the future of digital twins:

- Advanced Analytics and AI: As artificial intelligence (AI) algorithms become more sophisticated, digital twins will benefit from enhanced predictive analytics capabilities. Advanced machine learning techniques will enable more accurate simulations, predictive maintenance, and optimization of complex systems. With AI-driven insights, organizations can make data-driven decisions, identify efficiencies, and drive innovation.

- Edge Computing and Real-time Processing: The emergence of edge computing technology will enable digital twins to process and analyze data in real-time at the source. This reduces latency, improves responsiveness, and allows for faster decision-making. Edge computing will empower organizations to harness the full potential of digital twins in dynamic and time-sensitive applications.

- Virtual and Augmented Reality Integration: The integration of virtual and augmented reality technologies with digital twins will enable immersive and interactive experiences. These technologies will allow users to visualize and manipulate the digital twin in a more intuitive and realistic manner. This, in turn, will enhance collaboration, training, and remote operations across industries.

- Blockchain for Data Security: The incorporation of blockchain technology in digital twins will enhance data security and trust. Blockchain’s distributed ledger system provides a transparent and immutable record of data transactions, ensuring data integrity and preventing unauthorized modifications. This will address concerns regarding data privacy, sharing, and authentication in digital twin ecosystems.

- Integration of Digital Twins Across Systems: Digital twins will increasingly be integrated across different systems and organizations. For instance, in smart cities, digital twins of individual buildings, transportation networks, and utility infrastructures will be interconnected, allowing for holistic city planning and optimization. Integration across systems will enable more comprehensive insights, better coordination, and enhanced efficiencies.

- Internet of Things (IoT) Proliferation: The widespread adoption of IoT devices will further fuel the growth of digital twins. The increasing number of connected devices will provide more data streams, enabling richer and more detailed digital twins. This will lead to more accurate modeling, improved predictions, and better optimization of physical assets and operations.

As these trends continue to evolve, the use of digital twins will become more prevalent and sophisticated. Organizations will leverage digital twins to drive innovation, improve efficiencies, and deliver enhanced products and services. The future of digital twins holds great promise for industries across the board, transforming the way we design, monitor, and interact with the physical world.