The Definition of Automation System

An automation system refers to the use of technology and machines to perform tasks or processes with minimal human intervention. It involves the application of various tools, software, and hardware components to streamline operations and increase efficiency in different industries and sectors.

At its core, automation aims to eliminate or reduce the need for human involvement in repetitive or mundane tasks. By automating these tasks, businesses can not only save time and resources but also minimize errors and improve overall productivity.

Automation systems can encompass a wide range of processes, from simple repetitive actions to complex workflows that involve multiple steps and decision-making capabilities. These systems can be found in various industries, including manufacturing, transportation, healthcare, finance, and many others.

One of the key components of an automation system is the use of sensors and control mechanisms that monitor and regulate the operation of machines and equipment. These sensors provide real-time data, allowing the system to make decisions and perform actions based on predefined rules or parameters.

Furthermore, automation systems often rely on software programs and algorithms to execute tasks, analyze data, and generate reports. These programs can be customized to meet specific requirements and can be continuously improved and updated to optimize performance.

Automation systems can be classified into different levels based on the extent of human involvement. At the lowest level, there is basic automation, where machines are used to perform simple tasks without human intervention. As we move up the ladder, we encounter more advanced levels of automation, such as intelligent automation or autonomous systems, where machines can learn, adapt, and make decisions on their own.

The concept of automation is closely related to concepts such as robotics, artificial intelligence, and machine learning. These technologies enable machines to perform complex tasks, learn from experience, and improve their performance over time.

While the primary goal of automation is to increase efficiency and productivity, it also brings about numerous other benefits. With automation, businesses can reduce costs, enhance safety, improve accuracy, and provide a better working environment for employees.

Why Do We Need Automation Systems

In today’s fast-paced and highly competitive world, businesses and industries are constantly seeking ways to improve efficiency, reduce costs, and stay ahead of the curve. Automation systems have emerged as a crucial tool in achieving these goals. Here are several reasons why we need automation systems:

Increased Efficiency: Automation systems can enhance operational efficiency by eliminating manual errors and streamlining processes. By automating repetitive tasks, businesses can significantly reduce the time and effort required to complete them, allowing employees to focus on more critical and value-added activities.

Cost Savings: Automation systems can lead to substantial cost savings in the long run. By reducing the need for human labor, businesses can cut down on labor costs, training expenses, and employee turnover. Additionally, automation systems can optimize resource utilization, minimize waste, and lower maintenance and operating expenses.

Improved Accuracy: Humans are prone to errors, no matter how skilled or diligent they are. Automation systems, on the other hand, can perform tasks with precision and consistency, eliminating the risk of human-made mistakes. This improved accuracy can be particularly beneficial in industries such as manufacturing, healthcare, and finance, where even minor errors can have significant consequences.

Enhanced Safety: Automation systems can improve safety in hazardous work environments or industries where human involvement may pose risks. By replacing humans with machines in tasks that expose individuals to dangerous conditions, businesses can mitigate the risk of accidents, injuries, and even fatalities.

Increased Productivity: Automation systems allow businesses to achieve higher levels of productivity by maximizing output and minimizing downtime. Machines can operate continuously without breaks, fatigue, or distractions, enabling businesses to operate 24/7 and meet increasing customer demands efficiently.

Consistency and Standardization: Automation systems ensure consistent and standardized results by following predefined rules and parameters. This is particularly important in industries that require strict adherence to quality, regulatory compliance, and operational standards.

Competitive Advantage: Implementing automation systems can provide a competitive edge by enabling businesses to deliver products and services faster, at a lower cost, and with higher quality. Automation allows for faster response times, shorter production cycles, and improved customer satisfaction, ultimately positioning companies as leaders in their respective industries.

Employee Satisfaction: Automation systems can relieve employees from repetitive and monotonous tasks, allowing them to focus on more stimulating and creative work. This can lead to increased job satisfaction, engagement, and professional growth opportunities.

Types of Automation Systems

Automation systems come in various forms, each designed to address specific needs and requirements. Here are some common types of automation systems:

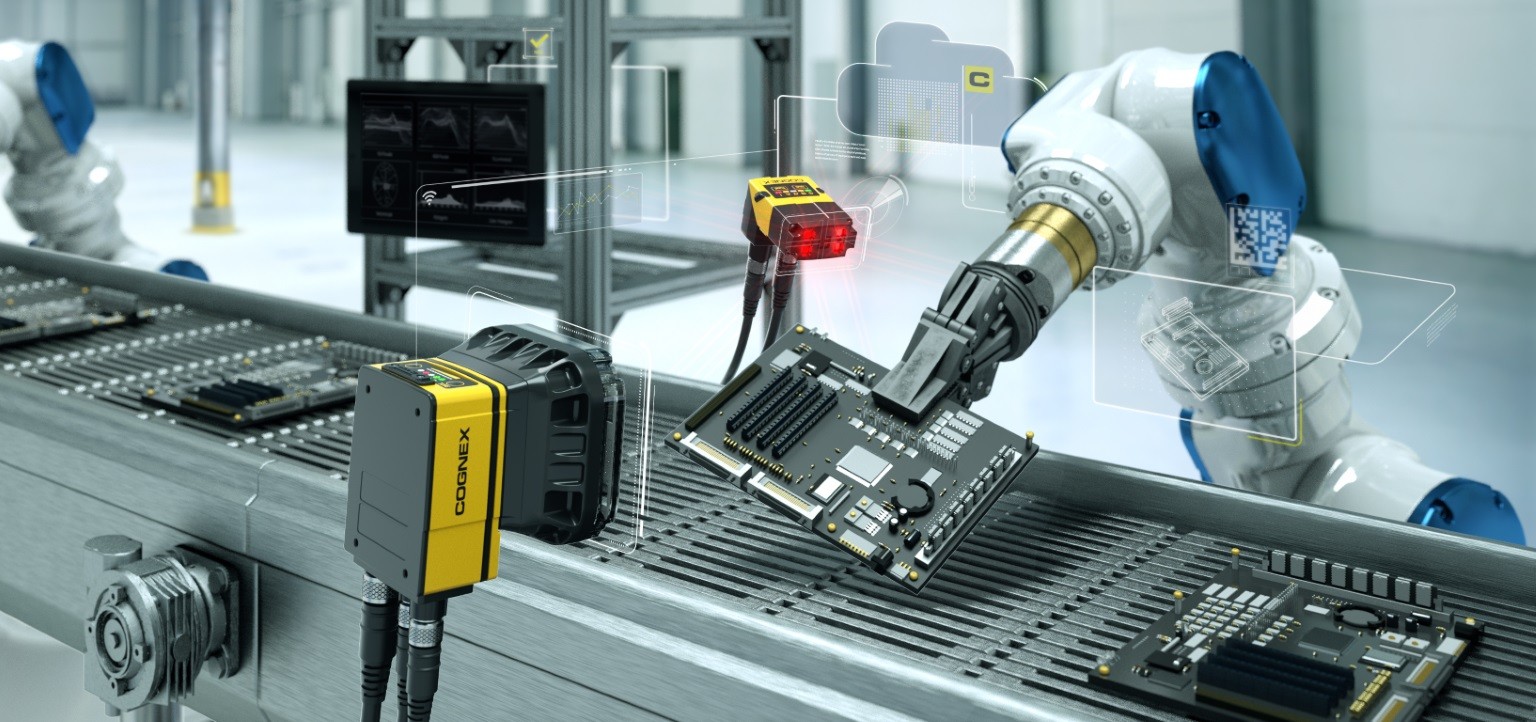

1. Manufacturing Automation: This type of automation system is widely used in the manufacturing industry to optimize production processes. It involves the use of machines, robotics, and computer-controlled systems to automate tasks such as assembly, packaging, material handling, and quality control. Manufacturing automation systems can significantly improve efficiency, accuracy, and productivity in manufacturing operations.

2. Process Automation: Process automation systems aim to streamline and monitor complex, repetitive processes in industries such as chemical, pharmaceutical, and oil and gas. These systems can control and monitor variables such as temperature, pressure, flow, and quality in real-time, ensuring consistent and efficient process performance. Process automation systems often involve the use of programmable logic controllers (PLCs) and distributed control systems (DCS).

3. Home Automation: Home automation systems are designed to control and integrate various functions and appliances within a household, providing convenience, energy efficiency, and improved security. These systems enable homeowners to automate tasks such as lighting, heating and cooling, security systems, and entertainment devices. Home automation systems can be controlled remotely through mobile devices or voice commands.

4. Robotic Automation: Robotic automation systems involve the use of robots to perform tasks traditionally done by humans. These systems can be found in industries such as automotive manufacturing, healthcare, logistics, and agriculture. Robotic automation can enhance efficiency, precision, and safety, as robots can handle complex tasks with speed and accuracy.

5. Office Automation: Office automation systems are designed to improve productivity and streamline administrative tasks in office settings. These systems often include software applications for document management, email automation, scheduling, and collaboration. Office automation systems can reduce manual effort and improve communication and workflow efficiency.

6. Warehouse Automation: Warehouse automation systems automate various operations in warehouses and distribution centers, including inventory management, order fulfillment, and material handling. These systems often involve the use of automated storage and retrieval systems (AS/RS), conveyor systems, robotics, and software solutions for inventory tracking and optimization. Warehouse automation can increase efficiency, accuracy, and throughput while reducing labor and operational costs.

7. Financial Automation: Financial automation systems automate financial processes and tasks, such as accounting, invoicing, payroll, and expense management. These systems integrate software applications and tools to streamline financial workflows, ensure compliance, and provide real-time financial insights. Financial automation can reduce manual errors, improve accuracy, and save time in financial operations.

These are just a few examples of automation systems, and the applications extend to various other industries and sectors. The choice of automation system depends on the specific needs, goals, and operations of the business or organization implementing it.

Benefits of Implementing Automation Systems

Implementing automation systems can bring a wide range of benefits to businesses and organizations across various industries. Here are some key advantages of implementing automation systems:

1. Increased Efficiency and Productivity: By automating repetitive and time-consuming tasks, automation systems can drastically improve efficiency and productivity. This allows employees to focus on more strategic and value-added activities, ultimately leading to higher output and better use of resources.

2. Cost Savings: Automation systems can lead to significant cost savings in the long run. By reducing labor costs, minimizing errors, optimizing resource utilization, and streamlining processes, businesses can lower operational expenses and allocate resources more efficiently.

3. Improved Accuracy and Quality: Automation systems can eliminate the risk of human errors, resulting in improved accuracy, consistency, and quality of work. This is particularly beneficial in industries where precision and strict adherence to standards are crucial, such as manufacturing, healthcare, and finance.

4. Enhanced Safety: Automation systems can help create safer work environments by replacing humans in hazardous tasks or by implementing safety protocols and controls. This reduces the risk of accidents, injuries, and occupational hazards, promoting a safer workplace for employees.

5. Faster and More Consistent Operations: Automation systems enable faster and more consistent operations by reducing manual intervention and eliminating process delays and bottlenecks. With automation, businesses can achieve higher throughput rates, shorter cycle times, and a more predictable workflow.

6. Improved Customer Experience: Automation systems allow businesses to enhance the overall customer experience. By enabling faster response times, accurate order processing, personalized services, and timely updates, businesses can meet customer expectations and build stronger, long-lasting relationships.

7. Better Business Insights: Automation systems often generate valuable data and insights that can be used for decision-making and strategic planning. By capturing and analyzing data in real-time, businesses can identify trends, spot opportunities, and make data-driven decisions to optimize operations and drive growth.

8. Scalability and Flexibility: Automation systems can easily adapt to changing business needs and growing demands. With the ability to scale operations and adjust processes, businesses can quickly accommodate fluctuations in customer requirements, market trends, and operational demands.

Overall, the implementation of automation systems can revolutionize how businesses operate, delivering improved efficiency, cost savings, accuracy, and customer satisfaction. It is crucial for organizations to carefully evaluate their specific needs and goals to choose the right automation solutions that align with their operations and provide the most significant benefits.

Common Applications of Automation Systems

Automation systems have become prevalent across a wide range of industries and sectors, revolutionizing how businesses operate. Here are some common applications of automation systems:

1. Manufacturing: Automation systems play a crucial role in the manufacturing industry, where they streamline production processes and enhance efficiency. These systems automate tasks such as assembly, packaging, material handling, quality control, and inventory management, leading to improved productivity, reduced costs, and higher product quality.

2. Healthcare: Automation systems have transformed healthcare delivery by automating various administrative and clinical processes. These systems can streamline patient registration, appointment scheduling, medical records management, and laboratory testing, allowing healthcare professionals to focus more on patient care and improving overall efficiency within healthcare facilities.

3. Logistics and Supply Chain: Automation systems have revolutionized the logistics and supply chain industry with automation technologies such as robotic pickers, automated sorting systems, and inventory management software. These systems optimize warehousing, order fulfillment, transportation, and inventory control, ensuring accurate and timely delivery of goods while reducing costs and enhancing customer satisfaction.

4. Finance and Banking: Automation systems have significantly transformed finance and banking operations. These systems automate tasks such as account management, transaction processing, risk assessment, and fraud detection, streamlining processes, enhancing accuracy, and improving compliance and security.

5. Agriculture: Automation systems have found applications in agriculture, increasing productivity and efficiency. These systems automate processes such as planting, harvesting, irrigation, and monitoring crop health. By using sensors, drones, and autonomous machinery, farmers can optimize resource usage, improve yields, and achieve precision farming.

6. Customer Service and Support: Automation systems have been integrated into customer service and support functions through the use of AI-powered chatbots and virtual assistants. These systems provide instant responses, handle routine inquiries, and offer personalized support, improving customer experience and reducing the workload of customer service teams.

7. Energy and Utilities: Automation systems are commonly used in the energy and utilities sector to monitor and control infrastructure and optimize energy consumption. These systems automate tasks such as load balancing, energy usage monitoring, and equipment maintenance, leading to improved energy efficiency, reduced costs, and enhanced sustainability.

8. Home and Building Automation: Automation systems are extensively used in homes and buildings to control and manage various functions. These systems include smart thermostats, lighting controls, security systems, and automated appliances. By integrating these technologies, homeowners and building operators can enhance comfort, energy efficiency, and security.

These are just a few examples of the widespread applications of automation systems. As technology continues to advance, automation systems will continue to play a significant role in optimizing operations, increasing efficiency, and improving overall business outcomes across various industries.

Challenges and Limitations of Automation Systems

While automation systems offer numerous benefits, there are also challenges and limitations that need to be considered. Here are some of the common challenges and limitations of automation systems:

1. Initial Investment: Implementing automation systems often requires a significant upfront investment in technology, equipment, and software. This financial barrier may pose challenges for small or financially constrained businesses, limiting their ability to adopt automation solutions.

2. Complexity and Integration: Automation systems can be complex and require integration with existing processes, systems, and infrastructure. The integration process may involve technical complexities, compatibility issues, and the need for specialized expertise, resulting in challenges during implementation.

3. Adaptability and Scalability: Automation systems need to be adaptable and scalable to accommodate changing business needs, technological advancements, and market dynamics. Implementing and maintaining flexible and scalable automation solutions can be a challenge as businesses grow and evolve.

4. Workforce Transition: The implementation of automation systems may require reskilling or restructuring of the workforce. This transition can create resistance, anxiety, and job displacement among employees. Managing this change effectively and ensuring employee buy-in can be a significant challenge for organizations.

5. Maintenance and Technical Support: Automation systems require ongoing maintenance, updates, and technical support to ensure smooth operations. This may require specialized expertise, and the reliance on external vendors for support can pose challenges in terms of response time, cost, and availability.

6. Data Security and Privacy: Automation systems involve the collection, storage, and analysis of vast amounts of data. Ensuring data security and privacy can be challenging, as systems need to meet strict regulatory requirements and protect sensitive information from potential breaches or unauthorized access.

7. Limited Decision-Making Capabilities: While automation systems can automate routine tasks and processes, they may lack the ability to handle complex decision-making situations that require human judgment, intuition, or creative problem-solving. This limitation may restrict the application of automation systems in certain industries or contexts.

8. Dependence on Technology: Automation systems heavily rely on technology infrastructure, such as hardware, software, and network connectivity. Any disruptions in technology infrastructure, such as power outages or system failures, can impact the performance and reliability of automation systems.

It is important for businesses to be aware of and address these challenges and limitations during the planning, implementation, and management stages of automation systems. With proper planning, consideration of these factors, and continuous evaluation, businesses can overcome these obstacles and maximize the benefits offered by automation systems.

How to Implement an Automation System

Implementing an automation system requires careful planning, consideration, and a systematic approach. Here are some steps to guide you through the implementation process:

1. Assess Your Needs and Goals: Begin by identifying your specific needs, pain points, and goals for automation. Determine which tasks or processes can benefit from automation and set clear objectives for what you aim to achieve through automation.

2. Research and Select the Right Automation Solution: Conduct thorough research on available automation solutions that align with your needs and goals. Consider factors such as functionalities, scalability, integration capabilities, vendor reputation, and cost. Select a solution that best fits your requirements and budget.

3. Plan and Allocate Resources: Create a detailed implementation plan that outlines timelines, milestones, and resource allocation. Determine the budget, personnel, and infrastructure required for successful implementation. Ensure that you have a dedicated project team or point person responsible for overseeing the implementation process.

4. Prepare Data and Infrastructure: Prepare the data and infrastructure necessary for the automation system. This may involve cleaning and organizing data, ensuring compatibility with the automation solution, and establishing the necessary network and hardware infrastructure.

5. Customization and Configuration: Customize and configure the automation solution to align with your specific business processes. This may involve setting up workflows, defining rules and parameters, and integrating the solution with existing systems or applications.

6. Testing and Training: Before fully deploying the automation system, conduct thorough testing to ensure functionality, accuracy, and compatibility. Train your employees on how to use the system effectively and provide ongoing support to address any questions or concerns they may have.

7. Pilot Implementation: Consider piloting the automation system in a controlled environment or specific department before implementing it across the entire organization. This allows for testing and fine-tuning, identifying any potential challenges, and gathering feedback from users.

8. Full-scale Implementation: Once the pilot phase is successful, proceed with the full-scale implementation of the automation system. Ensure a smooth transition by communicating the benefits, providing adequate support, and addressing any issues or concerns that may arise during the process.

9. Monitor, Evaluate, and Improve: Continuously monitor the performance and impact of the automation system. Evaluate key metrics and gather feedback from users to identify areas for improvement. Regularly update and optimize the automation system to ensure it remains aligned with evolving business needs and objectives.

Remember, successful implementation of an automation system is an ongoing process. It requires active involvement, collaboration, and a willingness to adapt to changes as you integrate automation deeply into your organization.

Tips for Successful Automation System Integration

Integrating an automation system into your organization can be a transformative process. To ensure a successful integration, consider the following tips:

1. Clearly Define Objectives: Before implementing an automation system, clearly define your objectives and expected outcomes. Make sure everyone involved understands the purpose and potential benefits of the system, aligning their efforts toward achieving those goals.

2. Involve Key Stakeholders: Engage key stakeholders, including employees, managers, and executives, throughout the integration process. Seek their input, address their concerns, and make them active participants in the decision-making and implementation processes.

3. Plan for Change Management: Implementing an automation system can bring about changes in workflows, roles, and responsibilities. Develop a comprehensive change management plan that includes communication, training, and support to help employees adapt to the new system and embrace the changes it brings.

4. Select the Right Implementation Team: Assemble a skilled and dedicated team to lead the implementation process. Include members with technical expertise, project management skills, and a deep understanding of the organization’s operations. Ensure clear roles and responsibilities are defined for each team member.

5. Data Integration and Migration: Assess your existing data systems and plan for seamless integration, ensuring data compatibility and security. Develop a plan for data migration, ensuring that historical data is transferred accurately and that the new system aligns with your data management policies and requirements.

6. Establish Clear Processes and Workflows: Review and reconfigure your existing processes and workflows to optimize them for the automation system. Clearly define roles, responsibilities, and handoffs to ensure smooth operations and maximize the benefits of automation.

7. Test Thoroughly: Conduct extensive testing and quality assurance to identify and address any issues before full implementation. Test the system with sample data, scenarios, and real-world use cases to validate its functionality and ensure it aligns with your expectations and requirements.

8. Monitor Performance and Gather Feedback: Regularly monitor the performance and efficiency of the automation system. Collect feedback from users and stakeholders to identify areas of improvement, address any usability issues, and make necessary adjustments to optimize system performance.

9. Continuous Training and Support: Provide ongoing training and support to users throughout the integration process and beyond. Offer resources, documentation, and opportunities for learning to help users fully leverage the capabilities of the automation system.

10. Embrace Continuous Improvement: View automation system integration as an iterative process. Continuously evaluate and improve the system based on user feedback and changing business needs. Stay up to date with advancements in the technology to ensure your automation system remains effective and aligned with your goals.

By following these tips, you can enhance the likelihood of a successful integration of the automation system, maximizing its benefits and driving positive outcomes for your organization.

Future Trends in Automation Systems

The field of automation systems is continuously evolving, driven by advancements in technology and changing business needs. Here are some future trends that we can expect to see in automation systems:

1. Artificial Intelligence and Machine Learning: The integration of artificial intelligence (AI) and machine learning (ML) algorithms will play a significant role in the future of automation systems. These technologies will enable systems to learn and adapt based on data analysis, allowing for more sophisticated and intelligent automation decision-making capabilities.

2. Robotic Process Automation (RPA): Robotic process automation is expected to expand further, automating rule-based, repetitive tasks that were traditionally performed by humans. RPA allows businesses to automate processes across different applications and systems, freeing up human resources for more complex and strategic work.

3. Internet of Things (IoT) Integration: The integration of automation systems with the Internet of Things (IoT) will enable the automation and control of devices and systems remotely. This connectivity will enhance real-time monitoring, predictive maintenance, and the ability to collect data from interconnected devices, bringing greater efficiency and insights to automation processes.

4. Cloud-Based Automation: Cloud computing will continue to play a crucial role in automation systems, enabling access to computing resources, storage, and software applications on demand. Cloud-based automation offers scalability, flexibility, cost-effectiveness, and the ability to collaborate and integrate data across different platforms and locations.

5. Cognitive Automation: Cognitive automation combines AI, natural language processing, and machine learning to automate more complex tasks that involve understanding and interpreting unstructured data, such as emails, documents, and conversations. This trend will enable automation systems to handle and analyze vast amounts of data with minimal human intervention.

6. Human-Robot Collaboration: Rather than replacing humans, automation systems will increasingly focus on augmenting human capabilities and enabling collaboration between humans and robots. This collaboration will involve tasks that require human judgment, creativity, and empathy, while robots handle repetitive or physically demanding tasks.

7. Process Mining and Optimization: Process mining and optimization techniques will gain prominence in automation systems. These methods analyze real-time data to identify bottlenecks, inefficiencies, and areas for improvement in processes. The insights gained from process mining can be used to optimize workflows, reduce costs, and enhance productivity.

8. Ethical Automation: As automation systems become more pervasive, there will be a growing focus on ethical considerations. Organizations will need to ensure that automation systems are designed and implemented with ethical frameworks that address issues such as bias, privacy, accountability, and the impact on the workforce.

These future trends in automation systems demonstrate the potential for even greater efficiency, intelligence, and collaboration between humans and machines. By embracing these trends, businesses can stay ahead of the curve and leverage automation technologies to drive innovation and achieve their strategic goals.