The Definition of Automation Industry

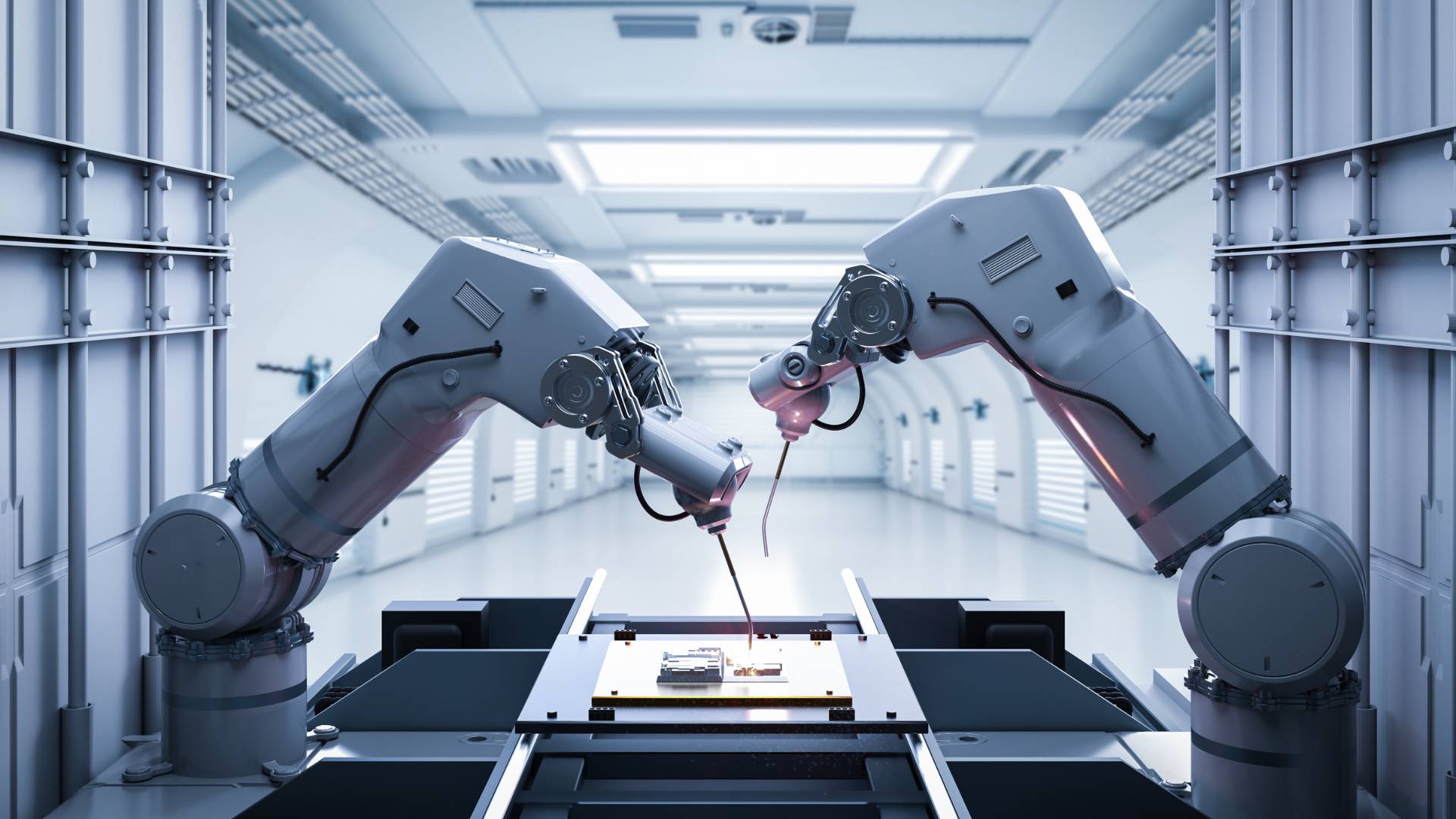

The automation industry refers to the sector that focuses on the development, implementation, and utilization of automated systems and technologies to streamline and optimize various industrial processes. Automation involves the use of machinery, software, and control systems to perform tasks traditionally carried out by human operators. These automated systems are designed to enhance efficiency, productivity, and safety in industries across different sectors.

At its core, automation involves the integration of technology, such as robotics, artificial intelligence (AI), machine learning, and industrial control systems, to automate manual and repetitive tasks. This eliminates the need for human intervention and reduces the margin of error, resulting in higher accuracy and precision.

The automation industry has expanded significantly over the years, driven by advancements across various technological domains. It has revolutionized numerous industries, including manufacturing, logistics, healthcare, agriculture, transportation, and many others. From assembly line robots to self-driving vehicles, automation has become a cornerstone of modern industrial processes.

The automation industry focuses on improving efficiency, reducing costs, increasing output, and ensuring overall process optimization. It encompasses a wide range of technologies, including robotic process automation (RPA), industrial automation, process control systems, programmable logic controllers (PLCs), sensors, and data analytics solutions.

Automation systems can be adapted to different industries and production environments, ranging from large-scale manufacturing facilities to small businesses. These systems can automate tasks such as material handling, welding, packaging, quality control, inventory management, and even complex decision-making processes through AI algorithms.

The History of Automation Industry

The history of the automation industry dates back to the industrial revolution in the late 18th century when steam-powered machines replaced manual labor. However, the concept of automation gained significant traction in the early 20th century with the introduction of mass production techniques pioneered by Henry Ford.

Ford’s production line revolutionized the manufacturing industry by implementing conveyor belts and interchangeable parts, reducing the assembly time and cost. This marked the beginning of automation in industrial processes and laid the foundation for future advancements.

In the following decades, developments in electronics and computing technologies further accelerated the growth of the automation industry. In the 1950s, the first industrial robots were introduced, streamlining assembly line operations and increasing productivity. However, these early robots were limited in functionality and required extensive human programming.

With the advent of transistors and microprocessors in the 1960s, the automation industry witnessed a significant leap forward. The programmable logic controller (PLC) was introduced, providing a versatile solution for controlling and automating industrial processes. This breakthrough allowed for real-time control and monitoring, making automation more efficient and adaptable.

The 1980s and 1990s brought advancements in computer technology, leading to the development of computer-based control systems and more sophisticated automation solutions. The integration of graphical user interfaces (GUIs) and human-machine interfaces (HMIs) made it easier for operators to interact with automated systems and monitor their performance.

In the early 2000s, the rise of the internet and connectivity paved the way for the Industrial Internet of Things (IIoT). This marked a new era in automation, where machines and devices were interconnected, sharing data and enabling real-time analysis. The IIoT has enabled predictive maintenance, remote monitoring, and enhanced coordination between different components of the automated system.

Today, advancements in artificial intelligence and machine learning have brought automation to new heights. With the ability to process and analyze vast amounts of data, AI-powered automation systems can make intelligent decisions, optimize processes, and adapt to changing conditions.

The history of the automation industry demonstrates how it has evolved from basic mechanical systems to highly advanced and intelligent technologies. As we continue to push the boundaries of technology, the automation industry will undoubtedly shape the future of industries across the globe.

The Role of Automation in Various Industries

Automation plays a crucial role in revolutionizing industries across various sectors, delivering unprecedented efficiency, productivity, and quality. Let’s explore how automation is transforming key industries:

Manufacturing: In the manufacturing industry, automation has been a game-changer. Automated systems streamline production processes, reducing costs and minimizing errors. Robots and assembly line automation improve speed and precision, enabling mass production with consistent quality. Automation also facilitates predictive maintenance and optimized inventory management.

Logistics and Warehousing: Automation has significantly enhanced the efficiency of logistics and warehouse operations. Automated conveyor systems and robotic picking systems expedite order fulfillment, reducing manual labor and errors. Autonomous vehicles and drones optimize material handling and inventory management, ensuring faster and more accurate delivery.

Healthcare: Automation has transformed the healthcare industry, improving patient care and operational efficiency. Robotic-assisted surgeries enable higher precision and shorter recovery times. Automated medication dispensing systems enhance accuracy and reduce medication errors. AI-powered systems analyze patient data for diagnosis and treatment recommendations, augmenting the capabilities of healthcare professionals.

Agriculture: Automation has revolutionized the agricultural sector, boosting productivity and sustainability. Automated farm equipment, such as robotic harvesters and precision seeders, optimize crop production while minimizing resource wastage. Smart irrigation systems and sensors monitor soil conditions, saving water and enhancing crop yields. Automated drone surveillance aids in pest control and crop monitoring.

Transportation: Automation has the potential to transform the transportation industry with self-driving vehicles. Autonomous cars, trucks, and public transportation systems promise enhanced safety, reduced traffic congestion, and optimized fuel consumption. Automated supply chain management and logistics systems streamline the movement of goods, improving delivery times and reducing costs.

Energy: Automation plays a vital role in the energy sector, optimizing power generation, distribution, and monitoring. Automated control systems regulate electricity generation, ensuring efficient output and load balancing. Smart grid technologies and automated metering enable real-time monitoring and consumption management. Renewable energy systems, such as solar and wind farms, utilize automation for optimal operation and maintenance.

Banking and Finance: Automation has transformed the banking and finance industry, enabling faster and more accurate transactions. Automated teller machines (ATMs) and online banking systems provide convenient access to banking services. Robotic process automation streamlines back-office operations, reducing manual errors and improving efficiency. AI-powered algorithms analyze vast amounts of financial data for risk management and investment decisions.

These examples illustrate how automation is reshaping various industries, resulting in increased productivity, improved safety, reduced costs, and enhanced customer experiences. As technology continues to advance, the role of automation will undoubtedly expand, driving innovation and transforming industries in ways we cannot yet imagine.

Benefits of Automation in Industries

Automation brings a wide range of benefits to industries across different sectors, revolutionizing the way businesses operate. Let’s explore some of the key advantages of automation:

Increased Efficiency: Automation eliminates the limitations of human labor, enabling faster and more accurate completion of tasks. Automated systems can work continuously without breaks, resulting in higher productivity and reduced downtime. This translates into increased efficiency and optimized resource utilization.

Improved Quality and Consistency: Automating processes reduces the likelihood of human errors and inconsistencies often associated with manual work. Machines and robots can perform tasks with precise measurements and minimal deviations, ensuring consistent output and product quality.

Enhanced Safety: Automation removes workers from hazardous and physically demanding environments, reducing the risks of accidents and injuries. Robots and machines can handle dangerous materials or operate in extreme conditions, protecting human workers from exposure to harm.

Cost Savings: While initial investment in automation may be significant, long-term cost savings are substantial. Automation eliminates the need for repetitive manual labor, reducing labor costs and increasing overall operational efficiency. Automation also minimizes material waste and optimizes resource usage, further contributing to cost reductions.

Increased Accuracy and Precision: Automated systems perform tasks with high accuracy and precision, minimizing errors and ensuring consistent results. This is particularly beneficial in industries that require strict adherence to quality standards and precision, such as manufacturing and healthcare.

Improved Data Collection and Analysis: Automation systems generate vast amounts of data that can be collected and analyzed in real-time. This data provides valuable insights on performance, efficiency, and potential areas for improvement. By leveraging data analytics, businesses can make data-driven decisions, optimize processes, and identify opportunities for innovation.

Increased Flexibility and Adaptability: Automation systems can be easily programmed and reconfigured to adapt to changing business needs. This flexibility allows for faster response times, product customization, and quick adjustments to production volumes. Businesses can quickly scale operations and introduce new products in response to market demands.

Streamlined Workflow: Automation simplifies and optimizes workflow by eliminating manual handoffs and dependencies. Seamless integration between different automated processes reduces bottlenecks, improves coordination, and enhances overall operational flow.

Workforce Augmentation: Automation does not replace human workers, but rather augments their abilities. By automating repetitive and mundane tasks, human workers can focus on more complex and value-added activities that require creativity, problem-solving, and critical thinking skills.

These benefits highlight the transformative impact of automation in industries. By harnessing the power of automation, businesses can achieve higher productivity, improved quality, cost savings, and a competitive edge in the rapidly evolving global marketplace.

Common Applications of Automation in Industries

Automation is widely utilized across various industries to streamline processes, increase efficiency, and improve productivity. Let’s explore some of the common applications of automation in different sectors:

Manufacturing: Automation is extensively used in manufacturing industries for tasks such as assembly, packaging, and material handling. Robotic arms and machines can perform repetitive and precise tasks with speed and accuracy, enhancing production efficiency and reducing labor costs.

Logistics and Warehousing: Automation plays a critical role in streamlining logistics and warehouse operations. Automated conveyor systems and sorting machines facilitate the movement of goods, reducing manual labor and errors. Autonomous guided vehicles (AGVs) and drones optimize material transport, inventory management, and order fulfillment.

Healthcare: Automation is transforming healthcare in various ways. Robotic-assisted surgeries provide surgeons with enhanced precision, control, and visibility during procedures. Automated medication dispensing systems ensure accurate and timely administration of medications. AI-powered medical imaging analysis helps in diagnosis and treatment planning.

Agriculture: Automation is revolutionizing the agriculture industry, improving crop yield, and optimizing resource usage. Automated systems for planting, watering, and harvesting enhance productivity and minimize waste. Sensors and AI algorithms facilitate precision agriculture, enabling farmers to monitor soil conditions, irrigation needs, and crop health.

Transportation: Automation is making significant strides in the transportation sector. Self-driving vehicles are being developed for both private and public transportation, promising improved safety, reduced congestion, and enhanced fuel efficiency. Automated systems are also used in logistics management for route optimization, tracking, and delivery coordination.

Energy: Automation plays a crucial role in optimizing energy generation, distribution, and management. Automated control systems regulate power generation and grid stability, ensuring efficient utilization of resources. Smart meters and energy management systems enable real-time monitoring and analysis for efficient energy consumption.

Banking and Finance: Automation has transformed banking and finance operations, enhancing speed and accuracy. Automated teller machines (ATMs) provide 24/7 access to banking services. Robotic process automation (RPA) is used for tasks such as document processing, loan approval, and fraud detection. AI-powered algorithms analyze data for risk assessment and investment recommendations.

Customer Service: Automation is increasingly being used in customer service and support. Chatbots and virtual assistants provide quick and efficient customer support, handling basic queries and transactions. Automated ticketing and booking systems simplify the reservation process and improve customer satisfaction.

Data Analysis and Insights: The automation of data collection and analysis is vital across industries. Automated systems gather and analyze large volumes of data in real-time, providing valuable insights for decision-making. This enhances operational efficiency, enables predictive analytics, and facilitates proactive maintenance.

These applications highlight how automation is driving innovation and transforming industries. By leveraging automation technologies, businesses can achieve greater efficiency, accuracy, and competitive advantage in an increasingly automated world.

Types of Automation Systems

Automation systems come in various forms, tailored to specific industry needs and processes. Let’s explore some of the common types of automation systems:

Robotic Automation: Robotic automation involves the use of robots or robotic systems to perform tasks traditionally carried out by humans. Industrial robots are programmable machines that can handle repetitive and complex tasks with high precision. They can be used for assembly, welding, material handling, and other manufacturing operations. Collaborative robots, also known as cobots, work alongside humans in a cooperative manner, enhancing productivity and safety.

Process Automation: Process automation focuses on automating and optimizing workflow processes and tasks. This is often achieved through the use of software applications and systems that automate routine and repetitive tasks, reducing errors and increasing efficiency. Business Process Management (BPM) tools automate and streamline business processes, such as document management, approval workflows, and data entry.

Industrial Control Systems: Industrial control systems include technologies that monitor and control industrial equipment and processes. Programmable Logic Controllers (PLCs) are commonly used control systems that automate machinery and equipment in manufacturing plants. SCADA (Supervisory Control and Data Acquisition) systems monitor and control industrial processes in real-time, providing operators with critical data for decision-making.

Machine Vision Systems: Machine vision systems use advanced imaging technologies and algorithms to inspect and analyze products and processes. These systems capture images or video of products on assembly lines and analyze them for defects, quality checks, and measurements. Machine vision systems are widely used in industries such as manufacturing, packaging, and quality control.

Artificial Intelligence (AI) Automation: AI automation involves the use of advanced algorithms and machine learning models to automate tasks that require cognitive capabilities. AI systems can analyze vast amounts of data, make complex decisions, and learn from patterns and trends. Chatbots and virtual assistants are examples of AI automation in customer service, while predictive maintenance systems use AI to anticipate equipment failures and optimize maintenance schedules.

Internet of Things (IoT) Automation: IoT automation utilizes interconnected devices and sensors to enable automation and data exchange. IoT devices can communicate with each other and with central systems, allowing for remote monitoring and control. Industrial IoT (IIoT) enables automation and optimization of processes by collecting real-time data, enabling predictive maintenance, and optimizing energy usage in smart buildings and factories.

RPA (Robotic Process Automation): RPA utilizes software robots or “bots” to automate repetitive, rule-based tasks typically performed by humans. These bots can interact with applications, perform data entry, extract information from documents, and carry out other mundane tasks. RPA improves accuracy and reduces human error, freeing up employees’ time for more strategic and value-added work.

These are just a few examples of automation systems, and the possibilities are continually expanding as technology advances. Organizations can leverage these automation systems to streamline processes, enhance productivity, and drive innovation in their respective industries.

Challenges and Limitations of Automation in Industries

While automation brings numerous benefits, it also presents several challenges and limitations that industries need to address. Let’s explore some of the key challenges:

High Initial Investment: Implementing automation systems often requires a significant initial investment in equipment, software, and infrastructure. The costs involved in purchasing, integrating, and training employees on new technologies can be a barrier, especially for small and medium-sized businesses.

Technological Complexity: Automation technologies can be complex and require specialized skills and knowledge to implement and maintain. Finding employees with the necessary expertise can be a challenge, and ongoing training and updates are necessary to keep up with evolving technologies.

Limited Flexibility and Adaptability: Some automation systems are designed for specific tasks or processes, which can limit their flexibility and adaptability to changing business needs. Upgrading or modifying automation systems may require significant time and resources.

Job Displacement: Automation often leads to concerns about job displacement and potential unemployment. While automation can eliminate repetitive and mundane tasks, it can also create new job opportunities that require different skill sets. Organizations need to invest in retraining and upskilling employees to ensure a smooth transition and harness the full potential of automation.

Data Security and Privacy: Automation systems rely on digital data and connectivity, which raises concerns about data security and privacy. Organizations need robust cybersecurity protocols and measures to safeguard sensitive information and protect against potential cyber threats.

Technical Limitations: Automation technologies may have certain limitations based on their design and functionality. For example, robots may not have the dexterity or problem-solving skills of human workers, limiting their adaptability in certain tasks. AI algorithms may also be limited by the quality and quantity of data available for analysis.

Resistance to Change: Introducing automation can face resistance from employees who fear job loss or are hesitant to adopt new technologies. Clear communication, training, and involving employees in the transformation process can help mitigate resistance and foster a positive organizational culture around automation.

Lack of Standardization: The automation landscape encompasses a wide range of technologies, systems, and vendors, leading to a lack of standardization. This can create compatibility issues between different automation components and systems, requiring additional effort and resources for integration.

Ethical Considerations: Automation raises ethical considerations, particularly when it involves AI and robotics. Questions around data privacy, decision-making algorithms, and the impact on society need to be carefully considered and addressed to ensure responsible and ethical use of automation technologies.

By being aware of these challenges and limitations, industries can develop strategies to overcome them and maximize the benefits of automation. Addressing these challenges requires a holistic approach that includes careful planning, investment in employee development, ensuring data security, and a focus on responsible adoption of automation technologies.

Future Trends in the Automation Industry

The automation industry continues to evolve at a rapid pace, driven by advancements in technology and changing industry demands. Here are some key trends that are shaping the future of automation:

Artificial Intelligence (AI) and Machine Learning: AI is poised to play a central role in the future of automation. Machine learning algorithms enable machines and systems to learn from data, make predictions, and continuously optimize performance. AI-powered automation will lead to more intelligent systems, capable of analyzing complex data, recognizing patterns, and making autonomous decisions.

Collaborative Robotics: Collaborative robots, or cobots, are designed to work alongside humans, augmenting their capabilities rather than replacing them. These robots are equipped with advanced sensors and safety features that allow them to operate in close proximity to humans safely. The future will see increased collaboration between robots and humans in industries such as manufacturing, healthcare, and logistics.

Internet of Things (IoT) Integration: The integration of automation systems with the Internet of Things (IoT) is a growing trend. Connecting devices, sensors, and machines allows for seamless data exchange, remote monitoring, and control of automated systems. This integration enables predictive maintenance, real-time analytics, and enhanced operational efficiency.

Edge Computing: Edge computing involves processing data closer to the source, reducing latency and dependence on cloud-based systems. In the automation industry, edge computing enables faster decision-making and optimized control in real-time. This trend supports the growth of automation in industries that require near-instantaneous responses, such as autonomous vehicles and robotic manufacturing.

Robotic Process Automation (RPA) Expansion: Robotic Process Automation (RPA) will continue to expand its reach across industries. RPA software robots will handle more complex tasks, combining AI and machine learning capabilities. The increased adoption of RPA will lead to significant efficiency gains, improved accuracy, and reduced costs in areas such as finance, customer service, and supply chain management.

Intelligent Automation: The convergence of AI, machine learning, and automation technologies will drive the development of intelligent automation systems. These systems will have the ability to learn on their own, adapt to changing conditions, and make intelligent decisions. Intelligent automation will unlock new possibilities in autonomous vehicles, drones, smart buildings, and personalized customer experiences.

Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are increasingly being integrated with automation systems. AR can enhance worker performance by providing real-time information and instructions overlaid on the physical environment. VR enables immersive training experiences and simulations, improving skill development for complex tasks. These technologies will play a significant role in training, maintenance, and collaboration in the automation industry.

Ethical and Social Implications: As automation becomes more pervasive, issues surrounding ethics and social impact will come to the forefront. Discussions on job displacement, income inequality, data privacy, and algorithm bias will continue to shape the future of automation. Stakeholders must work together to address these ethical concerns and ensure that automation benefits society as a whole.

The future of the automation industry holds immense potential for innovation and transformation. By embracing these trends, industries can unlock new opportunities, drive productivity, and create a more efficient and sustainable future.

Careers and Skills in the Automation Industry

The automation industry is experiencing significant growth, creating a demand for skilled professionals who can design, implement, and manage automated systems. Careers in this field offer exciting opportunities. Here are some key roles and skills in the automation industry:

Automation Engineer: Automation engineers are responsible for designing, developing, and maintaining automated systems. They have a strong background in engineering principles and expertise in specific automation technologies, such as PLC programming, robotics, or AI. Automation engineers analyze processes, identify automation opportunities, and implement solutions to improve efficiency and productivity.

RPA Developer: RPA developers specialize in developing and implementing robotic process automation solutions. They have expertise in RPA tools and programming languages, such as UiPath, Automation Anywhere, or Blue Prism. RPA developers work closely with business teams to identify process automation opportunities and design and deploy the necessary software robots.

Industrial Robot Programmer: Industrial robot programmers specialize in programming and configuring robots to perform specific tasks. They have knowledge of robot programming languages, such as Robot Operating System (ROS) or proprietary robot programming languages. Industrial robot programmers collaborate with engineers and production teams to optimize robot movements, troubleshoot issues, and ensure efficient and safe operation.

Data Analyst: Data analysts play a crucial role in the automation industry by collecting, analyzing, and interpreting data generated by automated systems. They have expertise in data mining, statistical analysis, and data visualization techniques. Data analysts identify trends, patterns, and anomalies in the data, providing insights for process optimization, quality improvement, and decision-making.

AI Specialist: AI specialists focus on developing and implementing artificial intelligence solutions in automation systems. They have a deep understanding of machine learning algorithms, neural networks, and natural language processing. AI specialists train AI models, fine-tune algorithms, and develop applications that leverage AI for autonomous decision-making, predictive maintenance, or intelligent data analysis.

IoT Engineer: IoT engineers specialize in designing, implementing, and managing the integration of automation systems with the Internet of Things (IoT). They have expertise in sensor technology, connectivity protocols, and cloud platforms. IoT engineers develop and deploy IoT-enabled devices, optimize data transmission and storage, and ensure secure and reliable communication between devices and systems.

Cybersecurity Specialist: In the automation industry, cybersecurity specialists focus on protecting automated systems from cyber threats and ensuring data privacy. They have expertise in network security, vulnerability assessment, and access control. Cybersecurity specialists analyze system vulnerabilities, design and implement security protocols, and monitor and respond to security incidents.

Key skills for individuals pursuing careers in the automation industry include proficiency in automation technologies, strong problem-solving and analytical skills, adaptability to new technologies, and a continual learning mindset. Communication and teamwork skills are also essential as automation professionals collaborate with cross-functional teams and stakeholders.

Continual professional development and staying updated with the latest trends and advancements in automation technologies are crucial for success in this field. Certifications, workshops, and industry conferences can provide additional knowledge and opportunities for networking.

The automation industry offers a diverse range of career paths and opportunities for professionals to contribute to the transformation of industries through the adoption of cutting-edge automation technologies.

Key Players and Companies in the Automation Industry

The automation industry is fueled by the expertise and innovation of numerous key players and companies. Let’s explore some of the prominent names shaping the automation landscape:

ABB: ABB is a global leader in robotics, automation, and electrification technologies. The company provides a wide range of automation solutions, including industrial robots, control systems, and intelligent manufacturing software. ABB’s expertise spans industries such as manufacturing, utilities, and transportation.

Fanuc: Fanuc is renowned for its industrial robots and factory automation systems. The company offers a comprehensive range of robotic solutions, including assembly robots, handling robots, and CNC systems. Fanuc’s products are widely used in industries such as automotive, electronics, and food processing.

Siemens: Siemens is a global technology powerhouse with a focus on electrification, automation, and digitalization. The company offers a wide range of automation solutions, including industrial automation systems, motion control systems, and process control technology. Siemens serves industries such as manufacturing, energy, and transportation.

Rockwell Automation: Rockwell Automation specializes in industrial automation and information solutions. The company provides a comprehensive portfolio of automation products and services, including control systems, motor control devices, and industrial software. Rockwell Automation serves industries such as automotive, oil and gas, and pharmaceuticals.

Mitsubishi Electric: Mitsubishi Electric is a global leader in automation technology, offering a diverse range of products, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial robots. The company’s automation solutions cater to industries such as manufacturing, energy, and transportation.

Yaskawa Electric: Yaskawa Electric is a key player in robotics and motion control systems. The company manufactures industrial robots, servo motors, and drives, with a focus on enhancing automation and efficiency in industries like automotive, electronics, and healthcare. Yaskawa’s robots are known for their precision and reliability.

Festo: Festo is a leading provider of automation solutions, specializing in pneumatic and electrical automation technology. The company offers a wide range of products, including pneumatic actuators, control valves, and industrial control systems. Festo’s solutions cater to industries such as automotive, food processing, and packaging.

Honeywell: Honeywell is a multinational conglomerate that provides automation and control systems for industries such as aerospace, manufacturing, and building automation. The company offers a broad portfolio of products, including process control systems, sensors, and software solutions for industrial automation.

Danaher Corporation: Danaher Corporation is a global science and technology conglomerate that specializes in automation and industrial solutions. The company provides a wide range of automation products and services, including motion control systems, sensors, and quality control instruments. Danaher serves industries such as healthcare, automotive, and electronics.

Schneider Electric: Schneider Electric is a leading provider of automation and energy management solutions. The company offers a comprehensive portfolio of automation products, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial software. Schneider Electric serves industries such as manufacturing, energy, and infrastructure.

These key players and companies are at the forefront of driving innovation and shaping the automation industry. Their solutions and technologies continue to transform industries across the globe, optimizing processes and enhancing productivity.