What Is an MOV?

An Metal Oxide Varistor (MOV) is a type of electronic component used to protect electrical circuits from voltage surges and transient events. It is a semiconductor device that behaves like a resistor under normal operating conditions but exhibits a nonlinear response when subjected to high voltage levels. MOVs are commonly used in a variety of electronic devices and equipment to safeguard against sudden voltage spikes that could cause damage or malfunction.

When an MOV is connected in parallel across a circuit or device, it constantly monitors the voltage levels. In normal conditions, it remains in a high impedance state, allowing the normal flow of current. However, when the voltage exceeds a pre-determined threshold, typically around 120-150% of the device’s rated voltage, the MOV reacts by effectively shorting itself and diverting the excess current away from the circuit.

The primary mechanism that allows an MOV to provide surge protection lies in its composition. It is made up of zinc oxide grains pressed together tightly, making it a highly resistive material. When exposed to a voltage surge, the energy is absorbed by the MOV, causing the zinc oxide grains to break down and create a low impedance path for the excess current to flow.

The ability of an MOV to suppress voltage surges makes it an essential component in various applications, including power distribution systems, consumer electronics, telecommunications equipment, and industrial machinery. Its widespread use stems from the fact that it provides an effective and affordable solution for protecting sensitive electronic components from potentially destructive transient events.

How Does an MOV Work?

An MOV operates on the principle of voltage-dependent resistance, utilizing its nonlinear characteristics to protect electronic circuits from voltage surges. When voltage is below a certain threshold, the MOV behaves as an insulator, allowing current to flow through the circuit as normal. However, when the voltage exceeds the specified threshold, the MOV undergoes a rapid change in resistance, effectively becoming conductive and diverting the excess voltage away from the circuit.

Inside an MOV, there are numerous zinc oxide (ZnO) grains packed tightly together. In a normal operating state, the ZnO grains have a high resistance, preventing any significant current flow. But when a high voltage surge occurs, the energy is absorbed by the MOV, causing the ZnO grains to release electrons. This creates a conductive path between the MOV’s electrodes, facilitating the flow of excess current and redirecting it away from the circuit.

The response time of an MOV is one of its crucial characteristics. When a voltage surge is detected, the MOV needs to react swiftly to divert the excess current. The response time depends on factors such as the size of the MOV and the magnitude of the voltage surge. However, generally, MOVs have response times in nanoseconds, providing rapid protection for electronic devices.

It is important to note that MOVs have a finite lifespan and are designed to withstand a specific number of voltage surges before their performance begins to degrade. Therefore, it is essential to regularly check and replace MOVs in applications where they are employed for surge protection.

Characteristics of an MOV

Metal Oxide Varistors (MOVs) possess several important characteristics that make them suitable for surge protection applications in electronic circuits. Understanding these characteristics is crucial for using MOVs effectively and ensuring their proper operation:

1. Nonlinear Voltage-Current Relationship: MOVs exhibit a nonlinear response to voltage changes. In normal operating conditions, they have a high resistance, but when the voltage exceeds a specific threshold, their resistance drops significantly, allowing excess current to flow away from the circuit.

2. Clamping Voltage: The clamping voltage is the voltage level above which the MOV starts to conduct significantly. It is an essential parameter to consider when selecting an MOV for a specific application, as it determines the level at which the MOV will begin to protect against voltage surges.

3. Surge Current Handling Capability: MOVs can handle large surge currents generated by voltage spikes. The surge current rating indicates the maximum current that an MOV can handle without being damaged. It is crucial to choose an MOV with an appropriately high surge current rating to ensure its effectiveness in protecting the circuit.

4. Voltage Protection Level: MOVs provide protection by clamping the voltage surge to a safe level. The voltage protection level is the maximum voltage that an MOV can withstand without failing or becoming permanently conducting. It is important to select an MOV with a voltage protection level suitable for the application’s requirements.

5. Response Time: MOVs respond rapidly to voltage surges, diverting excess current away from the circuit. The response time is the time it takes for the MOV to transition from a high resistance to a low resistance state. Shorter response times indicate quicker protection against voltage spikes.

6. Endurance: MOVs have a finite lifespan and are designed to handle a specific number of surges. Over time and with repeated exposure to voltage surges, their performance may degrade, reducing their ability to protect against future surges. Regular testing and replacement of MOVs are necessary to maintain effective surge protection.

7. Size: MOVs are available in various sizes to accommodate different applications. Smaller MOVs are suitable for protecting sensitive electronic devices, while larger MOVs can handle higher surge currents in industrial applications.

Understanding these characteristics enables engineers and technicians to select and deploy MOVs appropriately, ensuring the effective protection of electronic circuits from damaging voltage surges and transient events.

Types of MOVs

Metal Oxide Varistors (MOVs) come in various types to suit different applications and requirements. The different types of MOVs include:

1. Standard MOVs: These are the most common type of MOVs, widely used in a range of applications. Standard MOVs provide basic surge protection and are available in different voltage ratings and sizes to accommodate various circuit requirements.

2. High Energy MOVs: These MOVs are specifically designed to handle larger surge currents and higher energy levels. They are commonly used in industrial and high-power applications where the potential for large voltage spikes is significant.

3. Surface Mount MOVs: Surface mount MOVs, abbreviated as SMD MOVs, are designed for surface mounting on printed circuit boards (PCBs). They are compact in size and enable easy integration into space-constrained electronic devices. SMD MOVs are commonly used in consumer electronics and telecommunications equipment.

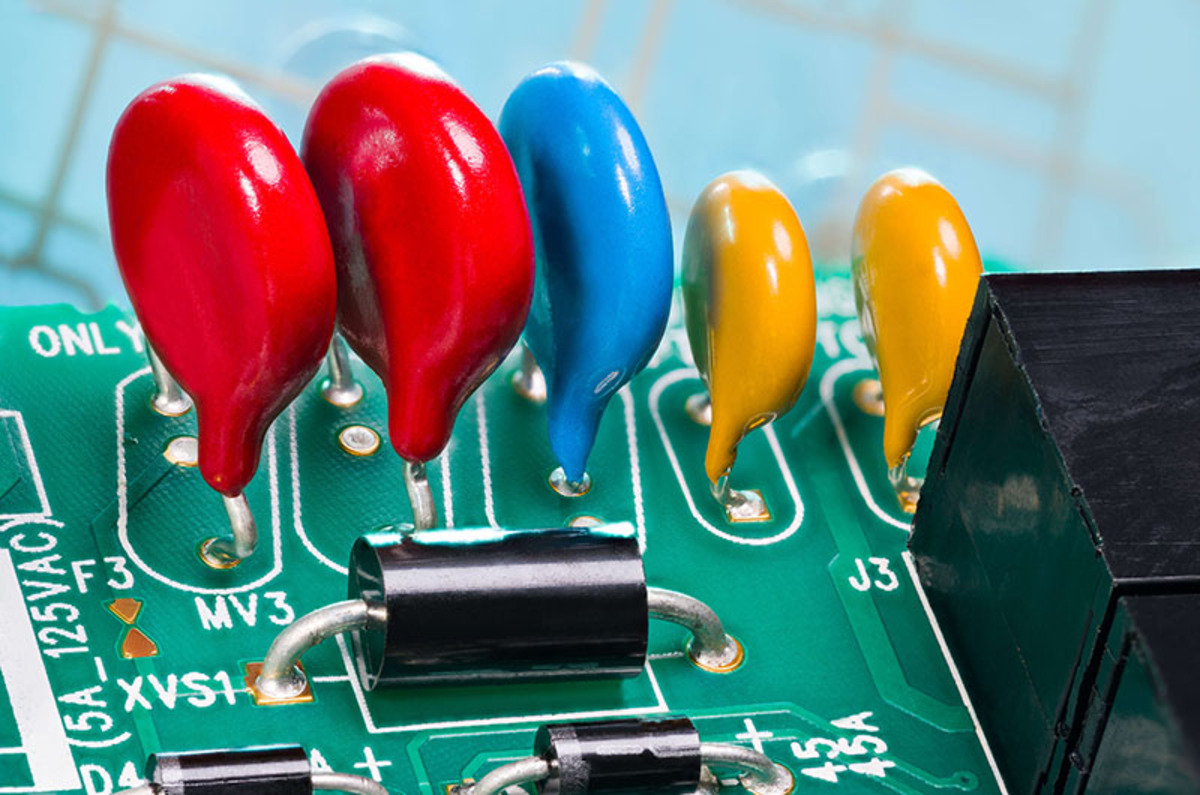

4. Radial Lead MOVs: Radial lead MOVs have leads that extend from the sides of the component, making them suitable for through-hole mounting on PCBs or for integration in larger electronic systems. They are widely used in industrial applications, power distribution systems, and power supplies.

5. Automotive MOVs: Automotive MOVs are specifically designed to meet the stringent requirements of the automotive industry. They provide surge protection for various automotive electronics, including engine control units (ECUs), lighting systems, and in-vehicle entertainment systems.

6. Varistor Arrays: Varistor arrays consist of multiple MOVs connected in parallel or series to provide enhanced surge protection. They are commonly used in applications where greater reliability and higher surge current handling are necessary, such as in industrial machinery and high-voltage electrical systems.

The selection of the appropriate type of MOV depends on factors such as the application’s voltage requirements, surge current levels, space constraints, and environmental conditions. It is crucial to consider these factors when choosing an MOV to ensure optimal surge protection and reliable operation of electronic circuits.

Applications of MOVs

Metal Oxide Varistors (MOVs) are widely used in various applications to protect electronic circuits and devices from voltage surges and transient events. Some common applications of MOVs include:

1. Power Distribution Systems: MOVs are commonly employed in power distribution systems to protect against voltage spikes from lightning strikes, power grid fluctuations, or switching events. They help prevent damage to sensitive equipment such as transformers, switchgear, and control panels.

2. Consumer Electronics: MOVs play a crucial role in protecting consumer electronic devices from voltage surges caused by lightning strikes, power outages, or electrical faults. They are commonly found in televisions, computers, gaming consoles, home theater systems, and other household appliances.

3. Telecommunications Equipment: MOVs are essential components in telecommunications networks, safeguarding sensitive equipment such as routers, modems, and telecommunication towers from voltage surges that can occur during lightning strikes or sudden power surges.

4. Industrial Machinery: The use of MOVs in industrial machinery protects critical equipment from voltage spikes that can occur due to power fluctuations or electrical disturbances. They are commonly found in motor drives, industrial control systems, robotic systems, and machine tools.

5. Renewable Energy Systems: MOVs are frequently used in renewable energy systems, including solar power and wind power installations. They protect inverters, charge controllers, and other vital components from voltage transients caused by lightning or grid disturbances.

6. Automotive Electronics: Automotive MOVs are specifically designed to protect automotive electronics from voltage fluctuations and transients. They are used in various automotive applications, including engine control units (ECUs), ignition systems, lighting systems, and infotainment systems.

7. Surge Protectors and Power Strips: MOVs are a key component in surge protectors and power strips used in homes and offices. They provide multiple outlets with surge protection, safeguarding connected devices such as computers, televisions, and peripherals from power surges.

8. Medical Equipment: MOVs play a vital role in protecting sensitive medical equipment such as imaging systems, diagnostic devices, and life support systems from voltage surges that could potentially compromise patient safety or damage the equipment.

MOVs are versatile components that find application in numerous fields to protect valuable electronics from voltage surges. Their ability to react quickly and divert excess current makes them an essential part of reliable surge protection systems across various industries.

Advantages of Using MOVs

Metal Oxide Varistors (MOVs) offer several advantages that make them a popular choice for surge protection in electronic circuits. Here are some key advantages of using MOVs:

1. Efficient Surge Protection: MOVs provide effective and reliable surge protection by quickly clamping excessive voltage levels and diverting the excess current away from the circuit. This helps prevent damage to sensitive electronic components and ensures the continued operation of equipment.

2. Compact Size: MOVs are available in small and compact sizes, making them suitable for integration into various electronic devices, circuit boards, and systems without significantly increasing the overall size and weight.

3. Wide Voltage Range: MOVs are available in a wide range of voltage ratings, allowing them to protect circuits operating at different voltage levels. This versatility makes them adaptable to various applications across different industries.

4. Quick Response Time: MOVs have a rapid response time, typically in nanoseconds, which ensures that they can react quickly to voltage surges and provide immediate protection. This quick response time helps minimize the potential damage caused by transient events.

5. Reliability: MOVs are designed to withstand multiple voltage surge events, making them highly reliable for surge protection. They have a long operational life, although it is essential to monitor their performance and replace them when their protective capability may be compromised.

6. Cost-Effective: MOVs are cost-effective compared to other surge protection devices. They provide solid surge protection performance at a reasonable price, making them a practical choice for many applications.

7. Easy Installation: Installing an MOV in a circuit is relatively straightforward, making it convenient for both professionals and enthusiasts. They can be easily soldered onto circuit boards or connected in parallel to protect devices and equipment.

8. Wide Application Range: MOVs are versatile components with applications in various industries and sectors. They are used in power distribution systems, consumer electronics, telecommunications, automotive systems, industrial machinery, and renewable energy systems, among others.

9. Fail-Safe Operation: In the event of an MOV failure, it typically fails in a shorted or open-circuit state, ensuring that the circuit remains protected from transient events. This fail-safe operation enhances the overall reliability of the surge protection system.

In summary, MOVs offer efficient and reliable surge protection, compact size, versatility, and cost-effectiveness. Their benefits make them a valuable component for protecting electronic circuits and devices from voltage surges, ensuring the longevity and proper functioning of valuable equipment across various industries.

Limitations of MOVs

While Metal Oxide Varistors (MOVs) provide effective surge protection in many electronic applications, they also have certain limitations that should be considered. Here are some notable limitations of using MOVs:

1. Single-Use Protection: MOVs are designed to handle a certain number of voltage surges or transient events. Once they have reached their maximum capacity, their ability to provide surge protection may diminish. Regular monitoring and replacement of MOVs may be necessary to maintain optimal surge protection.

2. Voltage Ratings: MOVs have specific voltage ratings, and they are most effective when used within their rated voltage range. Using an MOV below or above its voltage rating can lead to suboptimal surge protection or even failure.

3. Energy Absorption: MOVs have a finite energy absorption capability. In the case of a large energy surge, such as a direct lightning strike, an MOV may not be able to handle the excessive energy, which could result in damage to the protected equipment.

4. Noisy Operation: MOVs can produce a high-frequency noise or ringing when subjected to large voltage surges. This noise can interfere with the normal operation of sensitive electronic devices or audio systems.

5. Limited Response Time: While MOVs have quick response times, there may still be a minimal delay between the occurrence of a surge and the activation of the MOV. In highly sensitive applications, this slight delay could lead to some level of damage before the MOV clamps the voltage.

6. Environmental Considerations: Extreme environmental conditions, such as high temperatures or high humidity, can affect the performance and lifespan of MOVs. It is important to select MOVs specifically designed for the intended environmental conditions.

7. Temperature Dependency: The performance of an MOV can vary with temperature. As temperatures increase, the resistance of the MOV decreases, potentially impacting its surge protection capabilities.

8. Cannot Provide Continuous Protection: MOVs are designed to react quickly to transient events and clamp voltage surges. However, they are not intended to provide continuous protection against sustained overvoltage conditions. Continuous voltage surges can lead to the degradation or failure of an MOV.

It is important to carefully evaluate the specific requirements of an application and consider these limitations when using MOVs for surge protection. In some cases, supplementary surge protection devices or circuit design considerations may be necessary to complement the capabilities of MOVs and provide comprehensive surge protection.

Frequently Asked Questions about MOVs

Here are some commonly asked questions and answers about Metal Oxide Varistors (MOVs):

1. What is the lifespan of an MOV?

The lifespan of an MOV depends on various factors, including the number and intensity of voltage surges it experiences. Typically, MOVs are designed to withstand multiple surges, but their performance may degrade over time. Regular monitoring and replacement are recommended to ensure optimal surge protection.

2. Can an MOV protect against all types of surges?

MOVs are effective in protecting against most common voltage surges and transient events. However, they may not be able to handle extreme energy surges, such as direct lightning strikes, with complete effectiveness. In such cases, additional surge protection measures may be necessary.

3. Can I replace an MOV myself?

Yes, MOV replacements can be done by individuals with knowledge and experience in handling electronic components. It is important to ensure that the replacement MOV has the same voltage and surge current ratings as the original. Proper handling and precautions, such as de-energizing the circuit, should be followed.

4. Can an MOV fail and cause damage to the protected equipment?

In the event of an MOV failure, it typically fails in a shorted or open-circuit state. This ensures that the circuit is protected from voltage surges. However, there is a possibility that an MOV could fail catastrophically, potentially causing damage to the circuit or the protected equipment. Regular testing and monitoring are recommended.

5. Can an MOV protect against power outages?

MOVs are primarily designed to protect against voltage surges and transient events, rather than power outages. However, surge protectors that incorporate MOVs may provide some level of protection against voltage disturbances caused by power outages or electrical faults.

6. Can I use multiple MOVs in parallel for increased surge protection?

Yes, it is possible to use multiple MOVs in parallel to increase surge protection capabilities. This configuration allows for higher surge current handling and can provide redundant protection. However, proper attention should be given to current sharing and ensuring that each MOV’s voltage rating is not exceeded.

7. Can MOVs protect against electromagnetic interference (EMI) and radio frequency interference (RFI)?

While MOVs can provide a minimal level of EMI and RFI filtering due to their inherent characteristics, they are primarily designed for surge protection. For effective EMI and RFI suppression, dedicated filters or shielding methods should be employed alongside surge protection measures.

8. Are MOVs sensitive to polarity?

No, MOVs are not polarity-sensitive. They can be connected in any orientation without affecting their surge protection capabilities.

These FAQs provide a general understanding of MOVs and their application in surge protection. It is always recommended to consult the manufacturer’s guidelines and specifications for specific questions related to individual MOVs and their intended use in different applications.