What Is a Robot?

A robot is a programmable machine that can interact with its environment and perform tasks autonomously or semi-autonomously. It is equipped with sensors, actuators, and a control system to perceive and manipulate its surroundings.

Robots are designed to mimic human actions or improve efficiency in various industries and everyday life. They can be programmed to perform repetitive tasks, handle complex operations, or assist humans in hazardous or physically demanding situations.

At their core, robots are machines that can gather information from their environment through sensors, process that information through algorithms, and act on it by using actuators. This allows them to make decisions and execute actions without direct human intervention.

Robots come in various forms and sizes, from large industrial robots used in manufacturing to small autonomous drones. They can be found in factories, hospitals, homes, and even outer space.

While some robots are designed to look and move like humans, known as humanoid robots, others have specialized functions. For instance, industrial robots are commonly used in assembly lines for tasks such as welding, painting, and packaging. Service robots, on the other hand, are used in settings like healthcare and hospitality to assist with customer service and support.

Advancements in robotics have been made possible through the integration of artificial intelligence (AI) technologies. AI enables robots to learn, adapt, and make decisions based on data and experience. This allows them to perform more complex tasks and interact with humans more intuitively.

The field of robotics and its applications continue to evolve, with new uses and advancements constantly emerging. From self-driving cars to space exploration, robots are transforming industries and pushing the boundaries of what is possible.

Definition of a Robot

A robot is a complex machine designed to perform tasks autonomously or semi-autonomously. It is typically composed of a mechanical body, sensors, actuators, and a control system. The term “robot” was first coined by Czech writer Karel Čapek in his 1920 play “R.U.R.” (Rossum’s Universal Robots).

There are several key components that define a robot:

- Autonomy: A robot is capable of executing tasks without continuous human guidance. It can make decisions based on its programming and interact with its environment.

- Sensors: Robots are equipped with various sensors, such as cameras, microphones, and touch sensors, to gather information about their surroundings.

- Actuators: These are the mechanisms that allow robots to physically interact with the world. Actuators can include motors, hydraulic systems, and grippers.

- Control System: The control system is the brain of the robot, processing information from sensors and sending commands to the actuators. It is responsible for the robot’s behavior and decision-making.

Robots can be classified into different categories based on their capabilities and areas of application. For example, industrial robots are commonly found in manufacturing settings, performing tasks such as assembly, welding, and material handling. Service robots, on the other hand, are designed to assist humans in various industries, such as healthcare, hospitality, and agriculture.

While the concept of a robot typically brings to mind a machine that mimics human actions, it is important to note that robots can come in various forms. This includes humanoid robots, which are built to resemble human features and movements, as well as specialized robots designed for specific tasks, like underwater exploration or space missions.

As technology continues to advance, the definition of a robot continues to evolve. Modern robots are now equipped with advanced features, such as artificial intelligence and machine learning, allowing them to adapt, learn, and improve their performance over time.

History of Robotics

The history of robotics dates back thousands of years, with early examples of automated machines found in ancient civilizations. However, the modern era of robotics began in the 20th century, marked by significant advancements in technology and the birth of the field of robotics.

Ancient civilizations, such as the ancient Egyptians and Greeks, developed mechanical devices for various purposes. One notable example is the ancient Greek engineer Hero of Alexandria, who created a steam-powered device called the aeolipile in the first century AD. This device is considered an early precursor to the modern steam engine.

In the 18th and 19th centuries, inventors and engineers continued to create automated machines. The Industrial Revolution saw the rise of mechanized factories, where machines were used to perform tasks previously done by hand. However, these machines were not considered robots in the modern sense, as they lacked autonomy and programmability.

The term “robot” was first used in 1920 by Czech writer Karel Čapek in his play “R.U.R.” (Rossum’s Universal Robots), which introduced the concept of artificial beings created to serve humans. This play popularized the term and sparked interest in the field of robotics.

In the 1950s and 1960s, significant progress was made in robotics research. The development of the digital computer and advances in electronics laid the foundation for the modern robots we know today. One of the earliest programmable robots was the Unimate, created by George Devol and Joseph Engelberger in the late 1950s. This industrial robot was used for tasks such as welding and material handling in manufacturing plants.

Throughout the following decades, robotics technology continued to advance. In the 1970s, robots began to be used in industries beyond manufacturing, including healthcare and space exploration. The first mobile robot, Shakey, was developed at Stanford Research Institute in 1970 and was capable of navigating its environment using a combination of cameras and sensors.

The turn of the 21st century brought about even more advancements in robotics. The integration of artificial intelligence and machine learning technologies has allowed robots to learn, adapt, and make decisions autonomously. This has led to the development of advanced robotic systems, such as self-driving cars and humanoid robots.

Today, robotics is a rapidly growing field with applications in various industries, including healthcare, agriculture, construction, and entertainment. With ongoing advancements in technology, robots are expected to play an increasingly significant role in shaping the future of human society.

Different Types of Robots

Robots come in a wide range of types and forms, each designed to perform specific tasks and functions. From industrial robots to service robots, the diversity of robots allows them to cater to various industries and applications.

Here are some of the different types of robots:

- Industrial Robots: These robots are widely used in manufacturing and industrial environments. They are designed to perform repetitive and precise tasks, such as welding, painting, assembly, and material handling. Industrial robots are typically large and operate within structured and controlled environments.

- Service Robots: Service robots are designed to interact with and assist humans in a variety of settings. They can be found in industries such as healthcare, hospitality, retail, and agriculture. These robots are often equipped with advanced sensors and communication capabilities to provide services such as cleaning, delivery, customer assistance, and caregiving.

- Mobile Robots: Mobile robots have the ability to move and navigate autonomously. They are commonly used in applications such as logistics, warehousing, and agriculture. Mobile robots can operate in indoor and outdoor environments and use sensors, cameras, and mapping technologies to navigate and avoid obstacles.

- Humanoid Robots: Humanoid robots are designed to resemble human features and movements. They have a human-like appearance and can mimic human actions to some extent. Humanoid robots are often used in research, entertainment, and social interactions. They can be programmed to perform tasks that require human-like dexterity and communication.

- Medical Robots: Medical robots are used in healthcare settings to assist in surgical procedures, rehabilitation, and patient care. These robots can perform delicate and precise tasks, reducing the risk of human error and improving patient outcomes. Examples of medical robots include surgical robots used in minimally invasive surgeries and robotic exoskeletons used for rehabilitation.

- Agricultural Robots: Agricultural robots, also known as agribots or agrobots, are used in farming and agriculture. They can perform tasks such as planting, harvesting, spraying, and monitoring crops. Agricultural robots enable increased efficiency and precision in farming, optimizing yields and reducing the need for manual labor.

These are just a few examples of the many types of robots that exist today. As technology continues to advance and new challenges emerge, we can expect to see even more diverse and specialized robots being developed to address various needs and improve our daily lives.

Industrial Robots

Industrial robots play a vital role in the manufacturing and production sectors, revolutionizing the way goods are produced. These robots are designed to perform repetitive and precise tasks with high speed, accuracy, and efficiency. They have significantly improved productivity and quality in industries across the globe.

One of the key advantages of industrial robots is their ability to automate labor-intensive tasks, reducing the need for human workers in hazardous or monotonous environments. These robots can perform tasks such as welding, painting, assembly, material handling, and packaging. By automating these processes, industrial robots improve the speed and consistency of production, resulting in higher output and cost savings.

Industrial robots are equipped with various advanced technologies that enable them to perform their tasks effectively. They are often equipped with different types of sensors such as vision systems, force sensors, and proximity sensors to ensure accurate perception of the environment. This allows them to make real-time adjustments and adaptations to their movements and actions.

Furthermore, industrial robots can be programmed to work collaboratively with human workers in what is known as human-robot collaboration (HRC). This approach ensures that humans and robots can work side by side, with each leveraging their unique capabilities. HRC allows for enhanced efficiency and safety in the workplace.

The impact of industrial robots spans numerous industries, including automotive, electronics, aerospace, and consumer goods. In the automotive industry, robots are widely used on assembly lines for tasks such as welding, painting, and installing components. In electronics manufacturing, robots handle delicate tasks like circuit board assembly and testing. These robots are programmed to work with precision in order to meet the stringent quality requirements of these industries.

Industrial robots have also brought about improvements in workplace safety. By taking over dangerous or physically demanding tasks, they help minimize the risk of accidents and injuries for human workers. Robots excel at tasks that involve heavy lifting, repetitive motions, or exposure to hazardous substances, allowing employees to focus on higher-level tasks that require critical thinking and problem-solving skills.

As technology continues to advance, industrial robots are becoming even more sophisticated. They are now equipped with advanced artificial intelligence and machine learning capabilities that enable them to adapt to changing conditions, learn from experience, and optimize their performance over time.

Industrial robots have undoubtedly transformed the manufacturing landscape, making production processes faster, safer, and more efficient. As they continue to evolve, they hold the potential to drive further advancements in industries worldwide.

Service Robots

Service robots are a type of robot designed to interact with and assist humans in various industries and everyday life. They are equipped with advanced sensors, communication capabilities, and artificial intelligence to perform specific tasks and provide valuable services.

One of the key areas where service robots are used is in the healthcare industry. These robots can assist healthcare professionals by delivering medications, transporting medical supplies and equipment, and providing support to patients. They can also perform tasks such as monitoring vital signs and providing companionship to patients, particularly in settings like nursing homes or rehabilitation centers.

In the hospitality industry, service robots are being employed to enhance customer experiences. For instance, hotels are now utilizing robots as concierges, providing information about hotel services, offering room service, and even providing entertainment. These robots can navigate through hotel corridors, interact with guests, and perform various tasks, making guests’ stays more convenient and enjoyable.

Another area where service robots are making an impact is in retail and customer service. Robots can assist with inventory management, restocking shelves, and guiding customers to products in large retail stores. These robots can also engage in personalized interactions with customers, providing information about products and promotions.

Service robots are also being used in the agricultural sector to improve efficiency and optimize crop production. These robots can assist in tasks such as planting, spraying pesticides, and harvesting crops. They can navigate fields autonomously, collect data on crop health, and provide insights to farmers for better decision-making.

In addition to these industries, service robots are also utilized in other areas such as security and surveillance, cleaning and maintenance, and even in entertainment and amusement parks. They can perform tasks that improve safety, reduce human effort, and enhance productivity.

Service robots are designed to be user-friendly and adaptable for different environments. They often have interfaces that allow users to interact with them through touchscreens, voice commands, or mobile applications. Some of these robots are even equipped with natural language processing capabilities, enabling them to understand and respond to human speech.

As technology continues to advance, the capabilities of service robots are expected to expand. They will become more intelligent, intuitive, and capable of complex tasks. The integration of machine learning and artificial intelligence algorithms will enable these robots to learn from data, adapt to changing environments, and better understand human needs and preferences.

Service robots are revolutionizing numerous industries by improving efficiency, enhancing customer experiences, and providing valuable assistance. With further advancements in robotics, these robots will continue to play an increasingly crucial role in our everyday lives.

Mobile Robots

Mobile robots are a type of robot designed to move and navigate autonomously or semi-autonomously. They are equipped with mobility systems, sensors, and on-board processing capabilities to navigate through different environments and perform various tasks. Mobile robots have found applications in a wide range of industries, from logistics and warehousing to healthcare and exploration.

One of the key characteristics of mobile robots is their ability to move and operate in both indoor and outdoor environments. They utilize different types of locomotion systems, including wheels, tracks, and legs, depending on the terrain and the tasks they are designed for.

In the field of logistics and warehousing, mobile robots play a crucial role in streamlining operations and increasing efficiency. They can be used for tasks such as inventory management, order fulfillment, and goods transportation within warehouses. These robots navigate autonomously through the aisles, picking up and delivering items to their designated locations, ultimately reducing the need for human intervention and minimizing errors.

Mobile robots are also increasingly being used in healthcare settings to enhance patient care and improve efficiency. They can assist with tasks such as medication delivery, equipment transportation, and waste management. These robots can navigate through hospital corridors, interact with staff, and ensure timely and reliable service delivery.

In agriculture, mobile robots are utilized for tasks like crop monitoring, planting, and harvesting. They can be equipped with sensors to collect data on crop health, soil conditions, and other vital parameters. Mobile robots are especially beneficial in large-scale farming operations where they can optimize the use of resources and improve overall crop productivity.

Another prominent application of mobile robots is in exploration and reconnaissance in environments that are hazardous or inaccessible to humans. For example, robots are used in space exploration to gather data, conduct experiments, and assist with tasks that would otherwise be challenging for astronauts. They can also be deployed for search and rescue operations, providing valuable assistance in locating survivors in disaster-stricken areas.

The advancement of sensor technologies and perception capabilities has greatly contributed to the capabilities of mobile robots. They are equipped with various sensors, such as cameras, lidar, and ultrasonic sensors, to perceive their surroundings and navigate through obstacles. These sensors allow mobile robots to adapt to changing environments and make real-time decisions to ensure safe and efficient navigation.

Mobile robots are expected to continue advancing in their capabilities, with ongoing developments in artificial intelligence and machine learning. These technologies enable mobile robots to learn from their experiences, optimize their paths, and make intelligent decisions based on gathered data.

The versatility and adaptability of mobile robots make them an invaluable asset across multiple industries. As technology continues to evolve, we can expect mobile robots to play an increasingly significant role in transforming work environments and enhancing our daily lives.

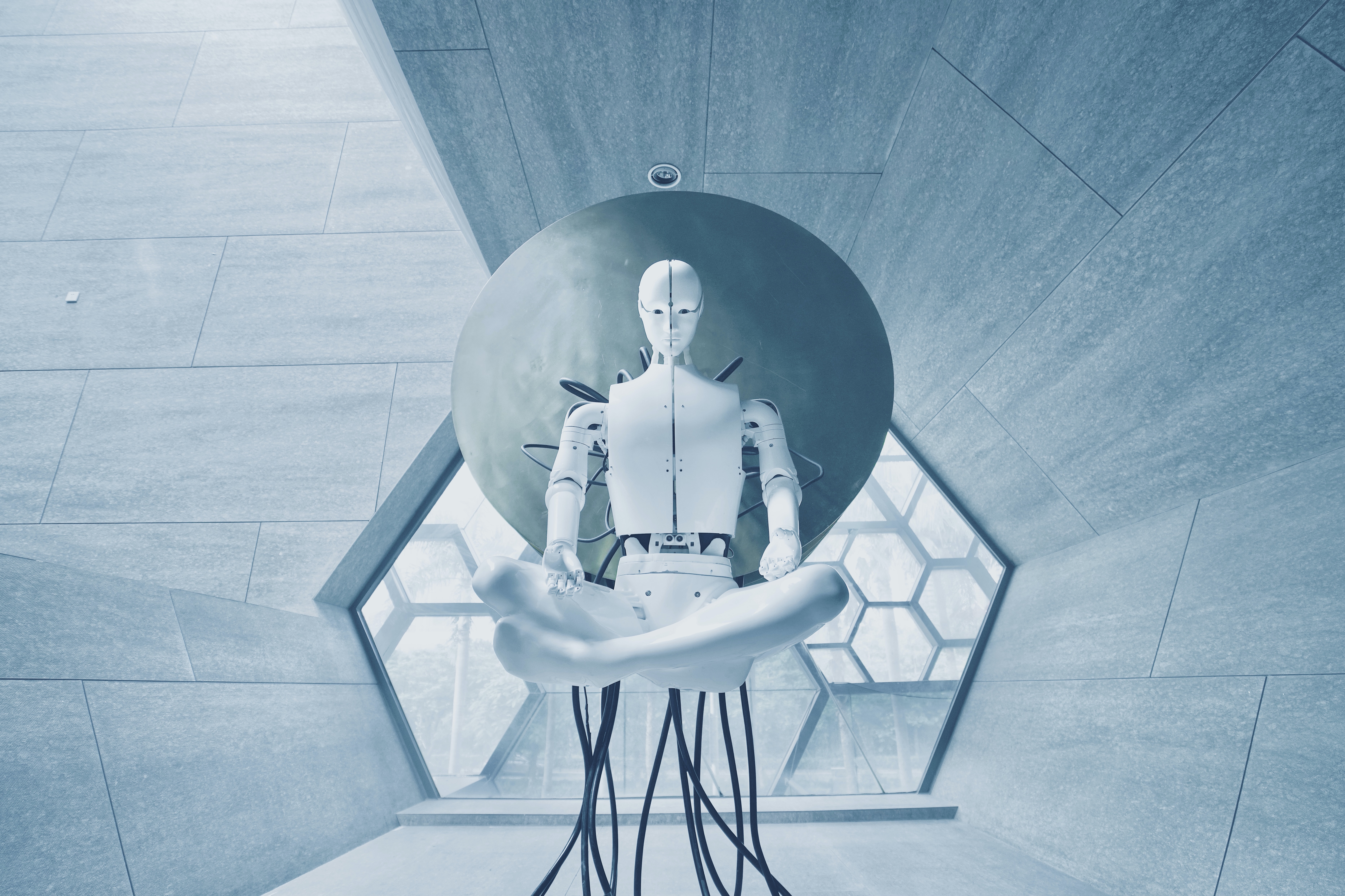

Humanoid Robots

Humanoid robots are robots designed to resemble humans in appearance and mimic human movements. These robots are built with a humanoid body structure that includes a head, torso, arms, and legs. The development of humanoid robots aims to create machines that can interact with humans in a more natural and intuitive manner.

One of the primary objectives of humanoid robots is to replicate human actions and behaviors. They are equipped with various components, such as joints, sensors, and actuators, that allow them to move and imitate human gestures and expressions. By emulating human features, humanoid robots can interact and communicate with humans in a more relatable and familiar way.

Humanoid robots have a wide range of potential applications. In research and development, they serve as a platform for studying various aspects of human movement, behavior, and cognition. Researchers can use them to explore topics like human-robot interaction, social robotics, and artificial intelligence.

In healthcare, humanoid robots can be used as companions for the elderly or individuals with disabilities. These robots can provide social interaction, remind users to take medication, or assist with daily activities. Humanoid robots can offer emotional support and enhance quality of life for those in need of companionship.

Humanoid robots are also utilized in education and entertainment. They can be employed as educational tools to teach subjects such as science, technology, engineering, and mathematics (STEM). Moreover, humanoid robots have been featured in various performances and shows, bringing entertainment value and excitement to audiences.

Research into artificial intelligence and machine learning has enabled humanoid robots to become more intelligent and responsive. They can recognize and interpret human gestures, facial expressions, and voice commands. This allows for more natural and intuitive communication between humans and robots.

Despite progress, there are still challenges in perfecting humanoid robots. Designing and constructing a humanoid robot that can replicate all the nuances and complexities of human movement and behavior remains a significant undertaking. Additionally, achieving robust and reliable balance and stability is a technical challenge due to the complex dynamics involved.

Nonetheless, humanoid robots continue to evolve, with ongoing advancements being made in materials, sensors, and control systems. With further developments, humanoid robots hold the potential to play more significant roles in various industries and everyday life, enhancing human-robot interaction and improving our overall human-like experiences with machines.

Robotic Process Automation

Robotic Process Automation (RPA) is a technology that uses software robots or bots to automate repetitive and rule-based tasks in business processes. RPA is designed to mimic human interactions with digital systems by utilizing user interfaces, data entry, and other actions typically performed by humans.

RPA is distinct from traditional automation in that it does not require extensive integration with underlying systems or modifications to existing infrastructure. Instead, it operates by interacting with applications and systems through their user interfaces, allowing for faster implementation and flexibility.

Organizations across various industries are implementing RPA to streamline their operations, reduce human errors, and increase efficiency. RPA can handle routine and mundane tasks such as data entry, report generation, invoice processing, and data validation. By automating these tasks, employees can focus on more strategic and high-value activities that require critical thinking and creativity.

Implementing RPA involves analyzing and mapping business processes to identify areas that can be automated. Software robots are then developed and trained to perform specific tasks within the defined processes. These robots can work 24/7, ensuring continuous operation and faster execution of tasks compared to manual efforts.

RPA offers several benefits to organizations. It significantly reduces the likelihood of errors that can occur due to manual data entry or repetitive tasks. Moreover, it improves accuracy and data quality by eliminating human mistakes and inconsistencies.

Another advantage of RPA is its scalability. As the volume of tasks increases, organizations can easily deploy more software robots to handle the workload. This flexibility allows for efficient resource allocation and ensures smooth operations during peak demands.

Additionally, RPA integrates well with existing systems and applications, without requiring significant changes to underlying infrastructure. This means that organizations do not need to replace their current IT systems but can leverage RPA to automate specific parts of the workflow. This adaptability makes RPA a cost-effective solution with a relatively short implementation time.

While RPA offers significant benefits, it is important to consider the limitations. RPA is most effective when applied to standardized and rule-based processes. Processes with a high degree of variability or requiring complex decision-making may be less suitable for automation with RPA alone.

Looking ahead, RPA is expected to continue evolving with advancements in artificial intelligence and machine learning. By incorporating cognitive capabilities, such as natural language processing and machine vision, RPA can handle more complex tasks and make intelligent decisions based on analyzed data.

Robotic Process Automation is playing a transformative role in businesses, driving efficiency and improving productivity by automating repetitive tasks. As technology continues to advance, the potential for RPA to optimize processes and free up human resources for more valuable work will only continue to grow.

Robot Programming

Robot programming is the process of instructing a robot on how to perform tasks and interact with its environment. It involves writing code and creating algorithms that enable robots to carry out specific actions, make decisions, and respond to different situations.

There are various programming languages and approaches used for robot programming, depending on the specific robot and its capabilities. Some robots are programmed using high-level languages such as Python, Java, or C++, while others may use domain-specific languages specifically designed for robotics.

Robot programming involves several key steps:

- Task Analysis: This step involves analyzing the desired task or behavior of the robot. It includes breaking down the task into smaller subtasks and determining the necessary inputs, outputs, and interactions with the environment.

- Algorithm Design: In this step, algorithms are developed to define the sequence of actions and decisions that the robot needs to take to complete the task. The algorithms may incorporate sensor inputs, logical conditions, and mathematical calculations.

- Coding: The algorithm is translated into code using a programming language. This involves writing the specific instructions that the robot will follow, including control structures, loops, and functions.

- Simulation and Testing: Before deploying the code on the actual robot, simulation environments may be used to test the program. This allows for verification and validation of the program’s behavior without the risk of potential damage or errors in a real-world scenario.

- Deployment and Execution: Once the program has been tested and verified, it is deployed onto the robot. The robot then executes the program to perform the intended tasks and interact with its surroundings.

Robot programming requires a solid understanding of the robot’s capabilities, sensors, and actuators. Knowledge about the programming language and relevant programming concepts is also crucial.

As robots become more advanced, there is a growing trend towards making robot programming more accessible and user-friendly. This includes the development of visual programming interfaces, drag-and-drop tools, and intuitive frameworks that simplify the process for users who may not have a strong programming background.

Furthermore, with the emergence of machine learning and artificial intelligence, there is a shift towards enabling robots to learn from data and adapt their behavior. This involves training the robots using techniques such as reinforcement learning or imitation learning, where they observe and imitate human demonstrations.

Robot programming is a dynamic field that continues to evolve with advancements in technology. As robots become more intelligent, adaptable, and capable of autonomous decision-making, the programming techniques and methodologies will also advance, enabling robots to perform more complex tasks and interact with humans in increasingly intuitive ways.

How Robots Work

Robots are complex machines that are designed to perform tasks autonomously or semi-autonomously. They work by combining various components, technologies, and algorithms to perceive and interact with the world around them. Here’s a simplified breakdown of how robots work:

Sensors and Perception: Robots are equipped with sensors that allow them to perceive their environment. These sensors can include cameras, microphones, touch sensors, proximity sensors, and more. The data collected by these sensors is processed to provide information about the robot’s surroundings, including objects, people, and environmental conditions.

Processing and Decision-making: Once the sensory information is collected, it is sent to the robot’s control system for processing. The control system consists of a combination of hardware and software that enables the robot to make decisions based on the data it receives. Algorithms and logic are implemented to analyze the sensory data and determine the appropriate actions to take.

Action and Execution: After processing the sensory data and making decisions, the robot takes action through its actuators. Actuators are the mechanisms or devices that allow the robot to physically interact with the environment. Depending on the design of the robot, actuators can include motors, hydraulic systems, grippers, or other tools specific to the robot’s intended tasks.

Feedback and Adjustment: Robots often have feedback mechanisms to monitor the effectiveness of their actions. This feedback can come from sensors that detect changes in the environment or from internal sensors that measure the robot’s own state. Based on this feedback, the robot can make adjustments to its actions or behavior in real-time.

While this is a simplified explanation, the workings of robots can vary greatly depending on their specific design and purpose. Some robots may rely more on pre-programmed instructions, while others utilize artificial intelligence and machine learning algorithms to adapt and learn from their experiences.

Additionally, the integration of robotics with other technologies, such as artificial intelligence, computer vision, and natural language processing, further enhances a robot’s capabilities. By leveraging these technologies, robots can recognize patterns, interpret data, understand human commands, and even learn from their interactions with users and the environment.

Overall, robots are complex systems that bring together various components, sensing capabilities, decision-making algorithms, and actuation mechanisms. Their ability to perceive, process, and interact with the world allows them to perform tasks autonomously, making them valuable assets across industries ranging from manufacturing and healthcare to exploration and entertainment.

Sensors and Actuators

Sensors and actuators are integral components of robots that enable them to perceive their environment and physically interact with it. Sensors provide robots with the ability to gather information about their surroundings, while actuators allow them to execute actions based on that information. Let’s take a closer look at sensors and actuators in robotics:

Sensors: Sensors are devices that detect and measure physical or environmental parameters. They capture data from the robot’s surroundings and convert it into electrical signals. Robots can be equipped with a variety of sensors, including:

- Cameras: Cameras capture visual information about the environment. They can be used to recognize objects, detect movement, or track changes.

- Microphones: Microphones capture audio signals, allowing robots to process and interpret sound. This enables speech recognition, sound localization, and even voice commands.

- Infrared Sensors: Infrared sensors detect infrared radiation to identify temperature variations and proximity to objects. They are commonly used for navigation and obstacle avoidance.

- Touch Sensors: Touch sensors provide robots with the ability to detect physical contact with objects or surfaces. They are used for tasks that require delicate handling or tactile feedback.

- Force Sensors: Force sensors measure the applied force or pressure during interactions with objects. They aid in tasks that require precise force control, such as gripping or assembly.

Actuators: Actuators are devices that enable robots to physically interact with the environment and execute actions. They convert electrical signals into mechanical motion. Common types of actuators found in robots include:

- Electric Motors: Electric motors produce rotational or linear motion in response to electrical signals. They are used for tasks such as joint movement, locomotion, or manipulating objects.

- Hydraulic Actuators: Hydraulic actuators use pressurized fluid to generate force and motion. They provide high force capabilities and are used in applications that require significant strength, such as heavy lifting.

- Pneumatic Actuators: Pneumatic actuators use compressed air or gas to create mechanical motion. They are lightweight and often used in applications requiring rapid movements, like gripping or positioning.

- Grippers and Manipulators: Grippers and manipulators are specialized actuators that enable robots to grasp and manipulate objects. They can have various designs, including robotic hands, clamp-like mechanisms, or suction cups.

By combining sensors and actuators, robots can perceive their environment and react accordingly. Sensors provide crucial data that informs the robot’s decision-making processes and enables it to adapt to different situations. Actuators, on the other hand, allow robots to perform physical tasks, manipulate objects, or move through their surroundings.

Advances in sensor and actuator technology have greatly expanded the capabilities of robots. With more sophisticated sensors, robots can perceive with greater accuracy, recognizing objects, detecting obstacles, and even interpreting human gestures or facial expressions. Similarly, advancements in actuators have resulted in robots with improved dexterity, strength, speed, and precision.

As robotics progresses, innovations in sensors and actuators continue to shape the field. This drives the development of robots that can interact more seamlessly with humans, perform complex tasks autonomously, and navigate challenging environments with increased efficiency and safety.

Artificial Intelligence in Robots

Artificial Intelligence (AI) plays a pivotal role in enhancing the capabilities of robots, enabling them to perceive, learn, reason, and make intelligent decisions. By incorporating AI technologies, robots become more adaptable, autonomous, and capable of interacting with humans and their environment. Here’s how AI is integrated into robots:

Sensor Data Processing: AI algorithms process data from various sensors, such as cameras and microphones, allowing robots to perceive and interpret their surroundings. Computer vision algorithms, for example, analyze visual data to recognize objects, detect features, and understand the spatial layout of the environment. Natural Language Processing (NLP) algorithms enable robots to understand and respond to human speech.

Machine Learning: Machine learning algorithms enable robots to learn from data and improve their performance over time. They can recognize patterns, make predictions, and adapt their behaviors based on past experiences. Reinforcement learning algorithms, for instance, help robots learn optimal actions by rewarding positive outcomes and penalizing negative ones.

Autonomous Decision-making: AI empowers robots to make decisions autonomously. Through AI planning and reasoning algorithms, robots can evaluate possible actions and select the most appropriate course of action based on their objectives and the information available. This allows robots to handle complex tasks with multiple variables and uncertainties.

Natural Interactions: AI facilitates natural interactions between humans and robots. By analyzing human gestures, facial expressions, and speech patterns, robots can better understand and respond to human communication. Intelligent virtual assistants, like those found in household devices, utilize AI to interpret voice commands, provide information, and perform tasks based on user inquiries.

Cognitive Abilities: AI algorithms enable robots to exhibit cognitive capabilities such as learning, reasoning, and problem-solving. These abilities allow robots to understand context, adapt to dynamic environments, and improve their performance over time. Robots with cognitive abilities are well-suited for tasks requiring complex decision-making or those that involve human-like interaction.

The integration of AI into robots has led to significant advancements in various fields. In healthcare, AI-powered robots assist in patient care, helping with medication reminders, monitoring vital signs, and providing companionship. In manufacturing, robots equipped with AI can recognize product defects, optimize production processes, and perform intricate tasks with speed and precision.

While AI offers immense potential for robotics, challenges remain. Developing AI algorithms that are robust, reliable, and capable of handling real-world complexities is an ongoing endeavor. Ensuring the ethical use of AI in robots is also a critical consideration, as it involves issues such as privacy, bias, and accountability.

As AI technologies continue to evolve, robots will become more intelligent, adaptable, and capable of understanding and responding to human needs. The integration of AI with robotics has the potential to drive further advancements, opening up new possibilities for robots to assist and collaborate with humans in various domains.

Ethics of Robotics

The growing prominence of robotics raises important ethical considerations that need to be addressed. These ethical concerns revolve around the impact of robots on society, their interactions with humans, and the potential consequences of their actions. Here are some key ethical considerations related to robotics:

Human Safety: Ensuring the safety of humans is a primary ethical concern in robotics. As robots become more autonomous and capable of physical interaction, measures must be taken to prevent harm to humans. Safety protocols, fail-safe mechanisms, and thorough testing are crucial to mitigating risks associated with robot operations.

Privacy and Data Security: Robots equipped with sensors and cameras have the potential to collect vast amounts of personal data. It is vital to ensure that this data is collected and used responsibly, respecting privacy rights and adhering to data protection regulations. Implementing secure data storage and transmission protocols is necessary to safeguard sensitive information.

Transparency and Accountability: The decision-making processes of autonomous robots must be transparent and understandable. The complex algorithms and machine learning models used by robots should be explainable to prevent biased or discriminatory actions. Establishing clear lines of responsibility and accountability for robot actions is essential, particularly in cases of unforeseen consequences or accidents.

Social Impact and Inequality: Widespread use of automation and robotics can have significant societal impact, including job displacement and income inequality. It is crucial to address these effects through measures such as retraining programs, ensuring fair employment practices, and promoting equitable access to opportunities created by robotics.

Ethical Design and Use: Ethical considerations should be integrated into the design and development of robots from the early stages. This includes considering the potential misuse of robots, building in mechanisms for ethical decision-making, and conducting thorough risk assessments. Ethical guidelines and frameworks should be established to govern the design, deployment, and use of robots across various domains.

Human-Robot Interaction: Maintaining appropriate human-robot interaction is an ethical concern in robotics. Robots should be designed to respect human dignity, cultural diversity, and individual preferences. Clear communication channels should be established to empower humans to interact and collaborate with robots effectively. Ensuring robots do not replace essential human interactions, particularly in care and social settings, is also crucial.

Environment and Sustainability: Robotics should contribute to sustainable practices and environmental preservation. Ensuring responsible manufacturing, recycling of robot components, and reduced energy consumption are essential for minimizing the ecological footprint associated with the production and use of robots.

Addressing these ethical concerns requires collaboration between stakeholders, including robotics engineers, policymakers, ethicists, and the public. Ethical codes and standards can guide the development and use of robotics, promoting responsible practices and safeguarding the well-being of society.

Continued discussions and regulations around the ethics of robotics are necessary as technology advances. By fostering a culture of responsible development and deployment, we can harness the potential of robotics while upholding ethical principles and ensuring a positive impact on society.

Uses of Robots

Robots have become integral to various industries and applications, transforming the way we live, work, and interact. With their ability to perform tasks efficiently, accurately, and tirelessly, robots have found diverse applications across different sectors. Here are some key uses of robots:

Manufacturing and Assembly: Industrial robots are widely used in manufacturing and assembly processes. They can handle repetitive tasks, such as welding, painting, and quality inspection, with precision and consistency. Robots improve efficiency and productivity, ultimately reducing production costs and improving product quality.

Healthcare and Medical Assistance: Robots have made significant advancements in healthcare. They can assist in surgeries, perform delicate procedures with higher precision, and aid in rehabilitation. Robots can also be utilized in patient care, helping with tasks like medication delivery, monitoring vitals, and providing companionship for the elderly.

Logistics and Warehousing: Robots are increasingly being used in logistics, warehousing, and distribution centers. They can automate the movement of goods, inventory management, and order fulfillment. This improves efficiency in supply chain operations, reduces errors, and enhances overall logistics performance.

Agriculture and Farming: Robots are transforming the agricultural sector. Agricultural robots can perform tasks such as planting, harvesting, and monitoring crops. They can optimize resource usage, improve crop yields, and reduce the need for manual labor in large-scale farming operations.

Exploration and Space Missions: Robots play a vital role in space exploration. Robotic rovers and spacecraft are sent to explore planetary surfaces, analyze samples, and gather scientific data. These robots enable us to explore distant places that are inaccessible or too dangerous for humans.

Construction and Infrastructure: Robots are increasingly utilized in the construction industry to perform tasks like bricklaying, concrete pouring, and demolition. These robots improve efficiency, safety, and precision in construction processes. They can take on physically demanding tasks and work in hazardous environments.

Service and Hospitality: Service robots are being deployed in various service industries. In hotels, robots can act as concierges or room service assistants. In restaurants, robots can perform tasks like food delivery and customer service. These robots enhance customer experiences and provide personalized service.

Educational and Research: Robots have found applications in education and research. They are utilized as educational tools to teach programming, engineering, and other subjects. Research robots provide platforms for studying human-robot interaction, artificial intelligence, and exploring new technologies and algorithms.

Entertainment and Amusement: Robots are also employed for entertainment purposes. From amusement parks to exhibitions, robots can serve as performers, mascots, or interactive companions. They captivate audiences with their unique abilities, human-like movements, and engaging performances.

These are just a few examples of the many uses of robots in today’s society. As technology continues to advance, robots will continue to find new applications, providing value in industries and domains we have yet to imagine.

Impact of Robots in Various Industries

Robots have had a significant impact across various industries, revolutionizing workflows, improving productivity, and driving innovation. By automating tasks, robots have transformed the way business operations are carried out. Here’s a look at the impact of robots in some key industries:

Manufacturing and Production: Robotics has revolutionized the manufacturing industry. Industrial robots streamline assembly lines and perform tasks such as welding, painting, and packaging with speed and precision. They have improved productivity, reduced errors, and enhanced product quality in manufacturing processes.

Healthcare and Medicine: Robots have made significant advancements in healthcare, impacting areas such as diagnostics, surgery, and patient care. Surgical robots assist in minimally invasive procedures, allowing for greater accuracy and shorter recovery times. Robots also aid in patient monitoring, medication delivery, and rehabilitation, improving patient outcomes and providing support to healthcare professionals.

Logistics and Warehousing: In the logistics and warehousing industry, robots are transforming operations. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are being deployed to move goods, sort packages, and fulfill orders. This reduces manual labor, increases efficiency, and improves inventory management in distribution centers and warehouses.

Agriculture and Farming: Robotics is revolutionizing agriculture. Autonomous robots can perform agricultural tasks such as planting, harvesting, and monitoring crops. These robots optimize resource usage, improve yield, and reduce manual labor dependency in large-scale farming operations. They also enable precision agriculture techniques, ensuring precise application of water, fertilizers, and pesticides.

Construction and Infrastructure: Robots are making an impact in the construction industry by automating various tasks. Robotic arms and drones can perform functions such as bricklaying, concrete pouring, and site inspection. These robots improve efficiency, enhance safety, and reduce construction time and costs. They are especially beneficial in hazardous or hard-to-reach environments.

Retail and Customer Service: Service robots are being utilized in the retail industry, providing interactive and personalized customer experiences. Robots can assist with tasks such as guiding customers to products, providing information, and even acting as self-checkout kiosks. They enhance customer engagement, ease congestion, and streamline operations in retail establishments.

Entertainment and Hospitality: Robots have made a presence in the entertainment and hospitality sectors, providing unique experiences to visitors. Robotic performers, interactive companions, and mascots engage audiences and provide entertainment in amusement parks, hotels, and exhibitions. These robots create memorable experiences and enhance guest satisfaction.

These are just a few examples of how robots have impacted various industries. With their ability to automate repetitive and specialized tasks, robots have optimized processes, increased efficiency, and improved safety. As technology further advances, robots will continue to redefine workflows and contribute to the growth and transformation of industries across the board.

Benefits and Challenges of Robotics

Robotics technology offers a range of benefits across industries, but it also presents certain challenges that need to be addressed. Here is an overview of the benefits and challenges associated with robotics:

Benefits of Robotics:

- Increased Efficiency: Robots are capable of working with speed and precision, leading to improved productivity and efficiency in tasks and processes.

- Improved Safety: By automating hazardous or physically demanding tasks, robots reduce the risk of injuries to human workers, enhancing overall workplace safety.

- Enhanced Precision and Quality: Robots can perform tasks with high accuracy, reducing errors and improving the quality and consistency of output.

- 24/7 Operations: Robots can work around the clock without the need for breaks or rest, ensuring continuous operation and optimized resource utilization.

- Cost Savings: While the initial investment may be significant, robots often result in long-term cost savings through increased productivity, reduced labor costs, and minimized errors.

- Ability to Handle Repetitive Tasks: Robots excel at repetitive and monotonous tasks, freeing up human workers to focus on more complex and creative work.

Challenges of Robotics:

- Initial Investment: Implementing robotics technology can involve substantial upfront costs for procurement, installation, training, and maintenance, making it a significant financial commitment.

- Skills Gap: There is a need for skilled personnel who can effectively develop, program, and maintain robotic systems. Bridging the skills gap is essential for maximizing the potential of robotics technology.

- Job Displacement: The automation of tasks through robotics can lead to job displacement or changes in job requirements, requiring workers to adapt their skills and seek new opportunities.

- Ethical Considerations: The integration of robots raises ethical concerns regarding issues such as privacy, data security, transparency, and the potential impact on human well-being and social dynamics.

- Complexity and Dependence: Robotics systems can be complex, requiring specialized knowledge for implementation, troubleshooting, and maintenance. Organizations may depend heavily on robotics technology, introducing a new set of risks and vulnerabilities.

- Regulatory Challenges: The rapidly evolving nature of robotics technology presents challenges in regulating its use, ensuring safety, ethical practices, and adhering to legal frameworks.

Addressing these challenges requires a comprehensive approach involving collaboration between industry, policymakers, educators, and researchers. It is crucial to ensure responsible implementation, regulation, and training to maximize the benefits of robotics while minimizing any potential risks or negative impacts.

Future of Robotics

The field of robotics is continuously evolving, driven by technological advancements and increasing demand across industries. The future of robotics holds immense potential for further innovation and transformation. Here are some key areas that shape the future of robotics:

Advancements in Artificial Intelligence: Artificial intelligence (AI) will play a crucial role in shaping the future of robotics. The integration of AI algorithms enables robots to learn, reason, and make intelligent decisions. As AI continues to advance, robots will become more autonomous, adaptable, and capable of complex tasks.

Collaborative Robotics: Collaborative robots, or cobots, will see increased adoption in the future. These robots can work safely alongside humans, assisting them in tasks that require collaboration and cooperation. The development of safety features and improved sensor technology is leading to safer and more efficient human-robot interaction.

Soft Robotics and Biomimicry: The future of robotics may see the rise of soft robots that are more flexible and adaptable, mimicking the characteristics of living organisms. Biomimicry, where robots emulate natural principles and designs, can lead to advancements in dexterity, locomotion, and manipulation, expanding the range of tasks robots can perform.

Internet of Things (IoT) Integration: The integration of robotics with the Internet of Things (IoT) will create a connected network of smart robots that can interact and share data with other devices. This connectivity will enable seamless collaboration and coordination between robots, leading to improved efficiency and sophisticated decision-making.

Robotics in Healthcare and Assisted Living: The future will see greater utilization of robots in healthcare and assisted living settings. Robots will assist in patient care, monitoring vital signs, providing companionship, and even supporting rehabilitation. Robotic exoskeletons and prosthetics will further enhance mobility and quality of life for individuals with mobility impairments.

Autonomous Vehicles and Drones: The development of autonomous vehicles and drones will revolutionize transportation and logistics. Self-driving cars and delivery drones will transform the way goods and people are transported, enabling faster and more efficient logistics operations.

Ethical Guidelines and Regulations: As robotics technology advances, the development of ethical guidelines and regulations will be crucial. Ensuring responsible and ethical use of robots, considering issues such as privacy, data security, transparency, and accountability, will become increasingly important in shaping the future of robotics.

Education and Workforce Development: Future advancements in robotics will require a skilled workforce that can design, program, and maintain robotic systems. Investing in education and workforce development programs will be vital to equip individuals with the necessary skills to thrive in a robotic-centric future.

As technology continues to evolve, the future of robotics holds immense potential for further advancements in automation, AI integration, and human-robot collaboration. Continued research, innovation, and collaboration across industries will drive the development of smarter, more capable, and socially responsible robotics systems.

Advancements in Robotics

Over the years, robotics technology has witnessed significant advancements that have pushed the boundaries of what robots can achieve. These advancements have been driven by breakthroughs in areas such as artificial intelligence, sensing capabilities, materials science, and automation. Here are some key advancements in robotics:

Artificial Intelligence (AI) Integration: The integration of AI has been a game-changer in robotics. AI algorithms enable robots to learn, reason, and make decisions based on data and experiences. Machine learning, deep learning, and reinforcement learning techniques have improved robot autonomy, adaptability, and decision-making capabilities.

Sensing and Perception: Sensing technologies have seen significant advancements, enabling robots to perceive and interact with their environment more effectively. Advanced sensor technologies, such as LiDAR, time-of-flight cameras, and tactile sensors, provide robots with enhanced depth perception, object recognition, and touch sensitivity, enabling them to interact with the world in a more human-like manner.

Soft Robotics: Soft robotics has emerged as an exciting field, leveraging flexible and deformable materials to create robots that can adapt to unpredictable environments. Soft robots can mimic the flexibility and dexterity of living organisms, enabling them to handle delicate objects, navigate complex terrain, and interact safely with humans, opening up new possibilities in various industries.

Collaborative Robots (Cobots): Collaborative robots, or cobots, are designed to work alongside humans, enhancing human-robot collaboration and cooperation. With advanced force sensing and safety features, cobots can perform tasks that require close interaction with humans. They improve productivity and safety by combining the strengths of human workers and robots.

Autonomous Navigation: Advances in perception, machine learning, and mapping technologies have enabled robots to navigate autonomously in complex and dynamic environments. Autonomous robots can create maps, localize themselves, plan paths, and avoid obstacles, making them well-suited for tasks such as exploration, search and rescue, and autonomous vehicles.

Human-Robot Interaction: Human-robot interaction has benefitted from advancements in natural language processing, gesture recognition, and facial expression analysis. Robots are becoming more capable of understanding and responding to human commands, gestures, and emotions, enabling more natural and intuitive interactions.

Exoskeletons and Prosthetics: Advancements in robotics have led to the development of wearable robots, known as exoskeletons, that enhance human capabilities. These robotic suits can assist with rehabilitation, augment strength, and enable individuals with mobility impairments to regain mobility and independence. Similarly, advancements in prosthetic limbs have improved the functionality and control for individuals with limb loss.

Nanorobotics: Nanorobotics involves designing and controlling robots at the nanoscale. These miniature robots have promising applications in areas such as medicine, targeted drug delivery, and microsurgery. They can navigate through intricate environments, interact with biological systems, and perform precise tasks at the cellular level.

These advancements in robotics have paved the way for robots to be more capable, adaptable, and integrated into various domains. Continued research and development in areas such as AI, sensing, and human-robot interaction will further push the boundaries of what robots can achieve, leading to even more remarkable advancements in the future.

Predictions and Speculations

The field of robotics is constantly evolving, and technology advancements continue to shape the future of robotics. While the future is uncertain, several predictions and speculations can be made about the direction robotics may take in the coming years:

Increased Integration with Artificial Intelligence: The integration of robotics with artificial intelligence is expected to intensify. Advancements in machine learning and deep learning algorithms will enable robots to become more intelligent, adaptable, and capable of learning from their experiences. This integration will enhance robots’ ability to understand and respond to human needs, optimize tasks, and make complex decisions.

Rise of Social and Emotional Robotics: The emergence of social and emotional robotics is anticipated, with robots designed to understand and express emotions, allowing for more natural human-robot interactions. These robots may exhibit empathetic behavior, adapt to individual preferences, and provide companionship to individuals in various settings, including healthcare and assisted living.

Growth in Service Robotics: Service robots are projected to see significant growth across industries. From healthcare and hospitality to retail and logistics, robots will continue to assist with tasks that improve productivity, efficiency, and customer experiences. Service robots will further extend their capabilities, offering more personalized and context-aware services.

Advancement in Humanoid Robots: Humanoid robots will become more sophisticated, with advancements in dexterity, mobility, and cognitive abilities. These robots will be designed to interact more naturally with humans, understanding gestures, recognizing emotions, and conversing fluently through advanced natural language processing capabilities. Humanoid robots will find acceptance in various fields, including healthcare, education, and research.

Continued Growth in Autonomous Robots: The growth of autonomous robots, including self-driving cars, delivery drones, and autonomous robots in industries such as agriculture and warehousing, is anticipated. These robots will become more prevalent and will contribute to improved logistics efficiency, enhanced safety, and reduced reliance on human intervention.

Development of Bio-Inspired Robots: Robotics research will likely be influenced by nature, leading to the development of robots that mimic biological systems or behaviors. Bio-inspired robots could replicate features such as locomotion, sensory perception, and adaptability seen in animals, opening new possibilities for robotics in areas such as exploration, search and rescue, and environmental monitoring.

Ethical Considerations: As robotics technology advances, there will be an increased focus on establishing ethical guidelines and regulations. Discussions surrounding responsible AI, transparency, accountability, and privacy will shape the development and use of robots. Ensuring that robotics technologies are developed and deployed in an ethical and socially responsible manner will be paramount.

The aforementioned predictions and speculations provide a glimpse into the potential future of robotics. However, the field of robotics is dynamic and subject to rapid changes. As technology progresses and societal needs evolve, new advancements and opportunities not yet anticipated are likely to arise, shaping the future of robotics in unforeseen ways.