What Is a Crystal?

A crystal, in the context of electronics, refers to a specialized component that plays a vital role in various electronic devices and circuits. It is a solid-state structure made up of a specific arrangement of atoms or molecules. These atoms or molecules are repeated in a regular and symmetric pattern, creating a crystal lattice structure.

The crystal lattice structure gives crystals their unique properties, such as high mechanical strength, electrical conductivity, and piezoelectricity. Moreover, crystals exhibit an inherent ability to vibrate with high precision, which is why they are extensively used in electronic circuits as frequency-determining elements.

Crystals are commonly used in various applications, including radios, oscillators, watches, and microprocessors. They act as a reliable source of precise and stable frequencies that are crucial for the accurate functioning of electronic devices.

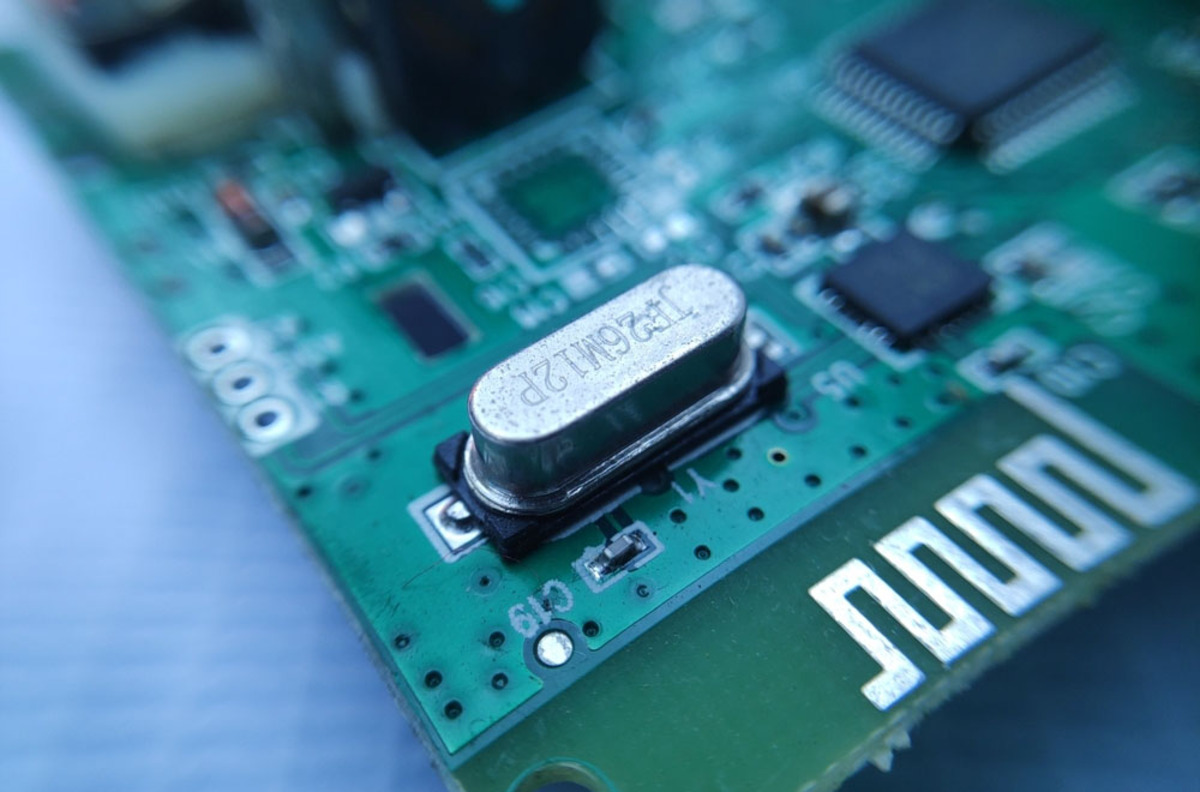

It’s important to note that crystals come in different sizes and shapes, but the most commonly used type is the quartz crystal. Quartz crystals are widely preferred due to their excellent stability, high accuracy, and low cost.

Overall, crystals serve as essential components in the world of electronics, providing accurate timing signals and stable frequencies that enable the proper operation of electronic devices and circuits.

How Does a Crystal Work in Electronics?

A crystal works in electronics by leveraging its unique physical properties to generate a stable and precise frequency. The crystal’s ability to vibrate at a specific frequency is the key to its functionality.

When an electrical voltage is applied to a crystal, it undergoes a phenomenon known as the piezoelectric effect. This effect causes the crystal to deform or vibrate at its natural or resonant frequency. The resonant frequency is determined by the physical characteristics of the crystal, such as its shape, size, and crystal lattice structure.

The vibrating crystal generates electrical signals with a precise frequency, which can be harnessed to regulate the timing of electronic circuits. These signals are commonly used as clock signals in digital circuits, ensuring synchronous operations and precise timing intervals.

The crystal’s inherent frequency stability is crucial for its reliable operation. Even under varying environmental conditions such as temperature and pressure, the crystal maintains its resonant frequency with minimal deviation. This stability is vital for accurate timekeeping and synchronization in electronic devices.

By integrating a crystal into electronic circuits, it acts as a reference point for generating stable and predictable frequencies. The crystal oscillates at a frequency determined by its physical characteristics, such as the thickness and cut of the crystal. This frequency can be further adjusted using external components to meet the specific requirements of the electronic device.

Overall, the precise vibrations of a crystal enable it to function as a reliable and accurate frequency-determining element in electronic circuits. Its ability to maintain stable frequencies makes it an indispensable component for various applications that rely on precise timing and synchronization.

The Crystal Structure

The crystal structure refers to the unique arrangement of atoms or molecules within a crystal lattice. It is this highly organized structure that gives crystals their distinctive physical and electrical properties.

Crystals are made up of repeating units called unit cells. These unit cells are stacked together in a three-dimensional pattern, creating a lattice structure that extends throughout the crystal. The arrangement of atoms or molecules within the unit cell determines the overall crystal structure.

There are various types of crystal structures, each with its own characteristics. One commonly found crystal structure is the cubic structure, where the unit cells are arranged in a cube-like pattern. Another example is the hexagonal structure, characterized by a repeating hexagonal arrangement of unit cells.

The crystal lattice structure influences the properties of the crystal, such as its electrical conductivity, mechanical strength, and optical properties. The regular and symmetric arrangement of atoms or molecules enables efficient transmission of electrical signals and vibrations within the crystal.

Furthermore, the crystal structure affects how the crystal interacts with electromagnetic fields. For example, piezoelectric crystals have a specific crystal structure that allows them to convert electrical energy into mechanical motion or vice versa.

It is worth mentioning that the crystal structure can be altered by factors such as temperature, pressure, and impurities. These changes can affect the crystal’s performance and introduce variations in its electrical properties.

How are Crystals Made?

Crystals can be artificially manufactured through a process known as crystal growth. This process involves creating conditions that promote the formation of a well-defined crystal lattice structure.

One common method of crystal growth is the melt method. In this method, a pure material, such as silicon or quartz, is melted at high temperatures until it becomes a molten liquid. The molten material is then cooled slowly, allowing the atoms or molecules to arrange themselves in a regular pattern as they solidify. This slow cooling process ensures the formation of a single crystal with a well-defined lattice structure.

Another method is the solution method, where a solute (the material from which the crystal is formed) is dissolved in a solvent. As the solution cools or evaporates, the solute molecules start to come together and form a crystalline structure. By controlling factors such as temperature, concentration, and cooling rate, crystals of different sizes and shapes can be obtained.

Additionally, crystal growth can also occur through a process called vapor deposition. In this method, vaporized molecules of the desired material are condensed onto a substrate, resulting in the growth of a crystalline film.

It’s important to note that different crystal growth methods are employed depending on the specific material and desired crystal characteristics. The process may require precise control of temperature, pressure, and other parameters to achieve the desired crystal structure and quality.

Overall, the production of crystals requires carefully controlled conditions and processes to encourage the formation of a well-defined crystal lattice structure. These artificially created crystals exhibit similar properties to naturally occurring crystals and are widely used in various applications in electronics and other industries.

Types of Crystals Used in Electronics

In electronics, various types of crystals are used, each with its own unique properties and applications. Let’s explore some of the commonly used crystals:

- Quartz Crystals: Quartz is the most widely used crystal in electronics due to its excellent stability and reliability. Quartz crystals can provide accurate and precise frequencies, making them suitable for applications such as oscillators, clocks, and timers.

- Crystal Oscillators: Crystal oscillators are integrated circuits that utilize crystals to generate stable and precise frequencies. They are widely used in electronic devices that require accurate timing, such as microcontrollers, communication systems, and digital watches.

- Surface Acoustic Wave (SAW) Crystals: SAW crystals utilize acoustic waves to transmit and receive signals. They are commonly used in wireless communication systems, including cellular phones, GPS devices, and wireless transceivers.

- Temperature Compensated Crystal Oscillators (TCXO): TCXOs are designed to provide stable frequencies despite changes in temperature. They are commonly used in applications where temperature variations can impact the accuracy of the timing signal, such as aerospace, telecommunications, and navigation systems.

- Oven-Controlled Crystal Oscillators (OCXO): OCXOs are highly stable crystal oscillators that maintain a precise frequency by controlling the temperature of the crystal using an oven. They are used in applications that require extremely accurate timing, such as frequency standards, scientific instruments, and satellite communication systems.

- Silicon-Controlled Rectifier (SCR) Crystals: SCR crystals are specifically designed for use in power control systems and applications. They provide precise timing for switching operations in devices like semiconductor switches, motor drives, and power supplies.

These are just a few examples of the types of crystals used in electronics. Each crystal has its own set of characteristics and specifications, making it suitable for different applications. The choice of crystal depends on factors such as required frequency stability, operating temperature range, power consumption, and cost.

Importance of Crystals in Electronics

Crystals play a crucial role in the field of electronics, offering several important benefits and functions. Let’s explore the significance of crystals in electronic devices:

- Precision and Accuracy: The primary function of crystals in electronics is to provide precise and accurate timing signals. The regular vibrations of crystals generate stable frequencies that are essential for synchronizing various electronic components. This precision ensures reliable operation of devices and prevents timing errors.

- Frequency Control: Crystals allow for precise frequency control in electronic circuits. By selecting crystals with specific resonant frequencies, designers can ensure that circuits operate at the desired frequencies, improving signal integrity and preventing interference between different circuits.

- Stable Timekeeping: Crystals are used in clocks, watches, and timing circuits to maintain accurate timekeeping. The constant and stable vibrations of crystals enable consistent timekeeping over long periods, ensuring accurate synchronization of various time-dependent functions in electronic devices.

- Communication Systems: Crystals are essential in communication systems, providing stable frequencies for transmitting and receiving signals. They enable precise modulation and demodulation of signals, improving the overall performance and reliability of communication devices.

- Microprocessor Clocking: Crystals are integral components in microprocessors and digital systems. They provide the clock signal that synchronizes the operation of the entire system, ensuring accurate execution of instructions and enabling precise timing for data processing.

- Frequency Reference: Crystals act as reliable frequency references in electronic systems. By providing a stable and precise frequency, they serve as a reference for analog-to-digital converters, data sampling, and other time-sensitive operations.

- Filtering and Frequency Manipulation: Crystals are utilized in filters and resonant circuits to manipulate and filter specific frequencies. By selecting crystals with specific characteristics, unwanted frequencies can be attenuated, allowing for enhanced signal quality and improved performance.

The importance of crystals in electronics cannot be overstated. They facilitate accurate timing, stable frequencies, and reliable operation of various electronic devices, ensuring seamless communication, precise data processing, and accurate timekeeping.

Role of Crystals in Electronics Devices

Crystals play a vital role in the functionality and performance of various electronic devices. Their precise timing and stable frequencies enable seamless communication, accurate timekeeping, and reliable operation. Let’s explore the key roles of crystals in electronic devices:

- Clock Generation: Crystals serve as the heart of clock generation in electronic devices. They provide a stable and accurate timing reference that synchronizes the operations of different components within a device. This ensures proper coordination and prevents data loss or timing errors.

- Data Communication: Crystals are essential in devices that involve data communication, such as modems, routers, and microcontrollers. They provide the necessary timing signals for transmitting and receiving data, allowing for reliable and efficient data transfer.

- Signal Processing: Crystals are employed in signal processing applications, where precise timing and frequency stability are paramount. They enable accurate sampling rates, precise filtering, and frequency manipulation, ensuring high-quality signal processing and reliable data analysis.

- Wireless Connectivity: Crystals are crucial in wireless devices, such as mobile phones, Wi-Fi routers, and Bluetooth-enabled devices. They provide stable and precise frequencies for signal modulation and demodulation, ensuring reliable wireless communication.

- Precision Measurement Instruments: Crystals are utilized in precision measurement instruments, including frequency counters, oscilloscopes, and scientific equipment. Their stable and accurate frequencies enable precise measurements and data acquisition.

- Timing and Synchronization: Crystals play a critical role in applications where accurate timing and synchronization are necessary. This includes industrial automation systems, audio/video synchronization, and high-speed data transmission, where precise timing ensures optimal performance and coordination.

- Power Management: Crystals are involved in power management circuits, such as voltage regulators and switching power supplies. They provide timing signals for controlling power conversion, ensuring efficient and stable power delivery to various components within a device.

The role of crystals in electronic devices is multifaceted, ranging from providing accurate timing references to enabling reliable communication and signal processing. Without crystals, many electronic devices would struggle to function properly and deliver the level of performance and precision that we have come to expect.

Crystal Oscillators

Crystal oscillators are electronic circuits that use crystals to generate stable and precise frequencies. They play a crucial role in various electronic devices and systems that require accurate timing, synchronization, and frequency control. Crystal oscillators are widely used in applications ranging from consumer electronics to aerospace and telecommunications. Let’s explore the key aspects of crystal oscillators:

Working Principle: Crystal oscillators work based on the piezoelectric effect exhibited by crystals. When an electrical voltage is applied to a crystal, it undergoes mechanical deformation or vibration at its natural or resonant frequency. This vibration generates an electrical signal with a precise frequency determined by the crystal’s physical characteristics.

Oscillation Feedback: Crystal oscillators utilize a feedback mechanism to sustain the oscillation. The output of the oscillating crystal is fed back to the input, reinforcing and maintaining the oscillation. This feedback loop ensures a continuous and stable output frequency.

Types of Crystal Oscillators: There are several types of crystal oscillators, each catering to specific requirements:

- Simple Crystal Oscillators: These are basic crystal oscillator circuits that consist of a crystal, an amplifier, and capacitors. They are commonly used in simple electronics devices where frequency stability isn’t critical.

- Temperature-Compensated Crystal Oscillators (TCXO): TCXOs are designed to overcome the frequency drift caused by temperature variations. They include temperature compensation circuitry that adjusts the crystal’s resonant frequency to maintain stability across temperature changes.

- Oven-Controlled Crystal Oscillators (OCXO): OCXOs provide exceptional frequency stability even in highly temperature-varying environments. The crystal is placed inside an oven-controlled chamber to maintain a precise and constant temperature, minimizing frequency deviations.

- Voltage-Controlled Crystal Oscillators (VCXO): VCXOs incorporate a voltage-controlled circuit to adjust the crystal’s frequency. By applying varying voltages, the frequency can be finely tuned, making VCXOs suitable for applications where frequency modulation is required.

- Phase-Locked Loop (PLL) Oscillators: PLL oscillators utilize a phase-locked loop circuitry to synchronize the output frequency with an external reference signal. This allows for frequency multiplication or division, enabling precise frequency synthesis for various applications.

Applications: Crystal oscillators find widespread use in numerous applications, including:

– Digital clocks and watches

– Radio transmitters and receivers

– Microcontrollers and processors

– Cellular networks and wireless communication systems

– Aerospace and satellite communication

– Test and measurement instruments

– High-speed data communication networks

Crystal oscillators offer unparalleled accuracy, stability, and reliability in generating precise frequencies for a wide range of electronic devices and systems, making them indispensable components in modern technology.

Crystal Parameters and Specifications

When selecting a crystal for a specific application, various parameters and specifications need to be considered. These parameters determine the crystal’s performance, stability, and compatibility with the desired electronic circuit. Let’s explore some of the key parameters and specifications of crystals:

Frequency (f): The frequency of a crystal refers to the resonant frequency at which it vibrates. It is one of the most critical parameters and is typically specified in Hertz (Hz) or its multiples, such as kilohertz (kHz), megahertz (MHz), or gigahertz (GHz). Choosing a crystal with the correct frequency is essential to ensure proper operation of the electronic circuit.

Frequency Tolerance (Δf): Frequency tolerance is an indication of how closely the actual frequency of the crystal matches the specified frequency. It is expressed as a percentage or parts per million (ppm). A smaller frequency tolerance value indicates a more accurate crystal.

Frequency Stability: Frequency stability represents the ability of a crystal to maintain its specified frequency over time and under varying environmental conditions. It is typically specified in terms of parts per million per degree Celsius (ppm/°C) or parts per billion per degree Celsius (ppb/°C). High-frequency stability is crucial in applications that require precise timekeeping or synchronization.

Load Capacitance (CL): Load capacitance determines the electrical load that should be connected to the crystal to achieve its specified frequency. It is usually specified in picofarads (pF) and is crucial for obtaining optimal performance from the crystal. Choosing the correct load capacitance is vital to ensure the desired oscillation frequency.

Series or Parallel Resonance: Crystals can be operated at either series resonance or parallel resonance, depending on the circuit configuration. Series resonance is when the crystal is used with external capacitors, while parallel resonance is when the crystal is used with external inductors. The selection of series or parallel resonance depends on the specific circuit requirements.

Drive Level: The drive level refers to the power required to maintain oscillations in the crystal. It is typically specified in milliwatts (mW) or microwatts (μW). Operating the crystal within the recommended drive level range ensures proper functioning and longevity.

Aging: Crystals can exhibit aging effects over time, causing small shifts in their frequency. Aging is specified as a frequency deviation over a specified period, often in parts per million per year (ppm/year). Understanding the aging characteristics of a crystal is essential for applications that require long-term frequency stability.

Operating Temperature Range: Crystals have a specified operating temperature range within which they can function reliably. It is crucial to ensure that the operating temperature range of the crystal aligns with the temperature conditions of the intended application.

These are just some of the key parameters and specifications to consider when selecting and using crystals in electronic circuits. Understanding these parameters helps ensure that the chosen crystal meets the requirements of the application in terms of frequency, stability, and compatibility.

Crystal Aging and Frequency Stability

Aging and frequency stability are important considerations when using crystals in electronic circuits. Crystals, despite their stability, may experience slight shifts in frequency over time due to aging effects. Understanding how aging can impact frequency stability is crucial in applications that require long-term precision. Let’s delve into the concepts of crystal aging and frequency stability:

Aging: Crystal aging refers to the phenomenon where the frequency of a crystal undergoes small changes over time. This aging effect is typically caused by factors such as stress, temperature fluctuations, and long-term operation. Although crystals are designed to maintain their stability, they are subject to these environmental factors that can cause slight variations in their resonant frequency.

Frequency Stability: Frequency stability signifies the ability of a crystal to maintain its specified frequency over time and under varying environmental conditions. It is a measure of the crystal’s performance and reliability in generating a precise frequency. A high frequency stability ensures that the crystal will maintain its accuracy and consistency during operation.

Initial Frequency Accuracy: Initial frequency accuracy refers to the frequency tolerance at the time of manufacture. It represents the maximum deviation in frequency from the specified value at the start of the crystal’s life cycle. Crystals with a smaller initial frequency accuracy provide better accuracy and require less frequency adjustment or calibration.

Aging Rate: The aging rate quantifies the frequency change over time due to aging. It is typically specified in parts per million (ppm) per year. Crystals with lower aging rates experience minimal frequency drift over extended periods, ensuring long-term stability in applications that require precise and stable timing.

Temperature Compensation: To mitigate the effects of aging and enhance frequency stability, some crystal oscillators incorporate temperature compensation methods. Temperature-compensated crystal oscillators (TCXOs) use circuitry to counteract the variations in frequency caused by temperature changes. The temperature compensation helps maintain the specified frequency of the crystal over a wide range of operating temperatures.

It is important to note that the aging rate and frequency stability are specified by manufacturers and can vary between different crystals. The choice of a crystal with suitable aging characteristics and frequency stability depends on the specific application requirements.

For applications with stringent stability needs, such as precision measurement, navigation systems, and telecommunications, selecting a crystal with low aging and high frequency stability is essential. These crystals ensure accurate and reliable timing over long periods, compensating for any slight frequency deviations caused by aging or environmental factors.

By understanding the aging process and considering frequency stability, engineers can make educated decisions to ensure that the selected crystals meet the long-term precision requirements of their electronic circuits.

Common Issues with Crystals in Electronics

While crystals are crucial components in electronics, they can encounter certain issues that may affect their performance and reliability. Understanding these common issues will help identify and address them effectively. Let’s explore some of the most prevalent issues with crystals in electronics:

Frequency Drift: Crystals can experience frequency drift over time due to aging effects and changes in environmental conditions. This drift can cause a deviation from the desired frequency, potentially affecting the accuracy and synchronization of electronic circuits. Temperature fluctuations, humidity, and mechanical stress can contribute to frequency drift.

Environmental Sensitivity: Crystals can be sensitive to environmental conditions such as temperature, humidity, and pressure. Operating a crystal outside its specified temperature range or exposing it to excessive moisture can generate frequency variations or even damage the crystal. It is essential to consider the environmental limitations and select crystals with appropriate specifications for the intended application.

Mechanical Shock and Vibration: Excessive mechanical shock or vibration can disrupt the crystal’s internal structure or cause it to detach from its mounting. This can lead to frequency instability or complete failure of the crystal. Proper mechanical support and secure mounting techniques must be employed to ensure the crystal’s longevity and performance in high-vibration environments.

Poor Soldering or Connection: Inadequate soldering or improper connection of the crystal can introduce impedance mismatches, resulting in signal reflections and frequency deviations. Careful attention must be given to proper soldering techniques, ensuring good electrical contact and preventing solder bridges or cold joints.

External Interference: Crystals can be susceptible to external electromagnetic interference (EMI), which can disrupt their oscillation and introduce frequency disturbances. Proper shielding, grounding, and EMI mitigation measures must be employed to minimize the impact of external interference on the crystal’s performance.

Incorrect Load Capacitance: Using an incorrect load capacitance can lead to frequency deviations and instability in crystal oscillators. The load capacitance, specified by the crystal manufacturer, must be matched with the external capacitors connected to the crystal to achieve optimal oscillation frequency and stability.

Quality and Manufacturing Issues: Poor quality crystals or manufacturing defects can result in subpar performance, decreased frequency stability, and shortened lifespan. It is crucial to source crystals from reputable manufacturers and ensure they meet the required specifications for the intended application.

By being aware of these common issues, engineers and technicians can take appropriate measures to address and mitigate them. Proper handling, careful installation, adherence to specifications, and regular monitoring can help maintain the performance and reliability of crystals in electronic devices and circuits.

Troubleshooting Crystal Problems

When working with crystals in electronic circuits, it is not uncommon to encounter issues that can affect their performance and functionality. Troubleshooting crystal problems requires a systematic approach to identify and address the root cause of the issue. Here are some steps to troubleshoot common crystal problems:

Step 1: Visual Inspection: Begin by visually inspecting the crystal and its connections. Look for any physical damage, loose connections, or signs of poor soldering. Ensure that the crystal is securely mounted and there are no apparent issues that could impact its performance.

Step 2: Check Power Supply: Verify that the crystal is receiving the correct voltage and current as specified by the crystal datasheet. Ensure the power supply is stable and free from any fluctuations or noise that could impact the crystal’s operation.

Step 3: Environmental Factors: Consider the environmental conditions in which the crystal is operating. Check if the temperature, humidity, or pressure is within the specified range for the crystal. Extreme environmental conditions can cause frequency deviations and instability, so it’s important to ensure that the crystal is used within its specified limits.

Step 4: Frequency Measurement: Use a frequency counter or an oscilloscope to measure the output frequency of the crystal. Compare the measured frequency with the expected frequency specified by the crystal datasheet. If there is a significant deviation, it could indicate a problem with the crystal or its associated circuit components.

Step 5: Load Capacitance: Verify that the load capacitance connected to the crystal matches the specified load capacitance specified by the crystal manufacturer. Incorrect load capacitance can cause frequency deviations and instability. Adjust the load capacitance if necessary, ensuring it matches the crystal’s requirements.

Step 6: External Interference: Check for any potential sources of electromagnetic interference (EMI) that could disrupt the crystal’s operation. Ensure proper shielding and grounding are in place to minimize the impact of external interference on the crystal.

Step 7: Component Replacements: If all the above steps don’t resolve the issue, consider replacing the crystal with a known-good crystal of the same specifications. This will help identify if the problem lies with the crystal itself or with other components in the circuit.

By following these troubleshooting steps, one can identify and resolve common crystal problems. It is important to meticulously test and verify each step before moving on to the next. If the issue persists, consulting the crystal manufacturer or seeking expert advice may be necessary to diagnose and resolve the problem.

Crystal Selection and Soldering Tips

Proper crystal selection and soldering techniques are essential for ensuring reliable performance and longevity of crystals in electronic circuits. Here are some tips to consider when selecting and soldering crystals:

Crystal Selection:

- Frequency Requirement: Choose a crystal with the desired resonant frequency that aligns with the application’s specifications.

- Temperature Range: Select a crystal that can operate within the required temperature range for the intended application.

- Frequency Tolerance and Stability: Consider the required frequency accuracy and stability for the application, ensuring the crystal meets the necessary tolerances.

- Load Capacitance: Determine the appropriate load capacitance specified by the crystal manufacturer and match it with external capacitors for optimal performance.

- Quality and Reliability: Source crystals from reputable manufacturers and ensure they meet quality standards for reliability and longevity.

Soldering Tips:

- Component Handling: Handle crystals with care, avoiding excessive force or mechanical stress that could damage or affect their performance.

- Cleanliness: Ensure the crystal and surrounding area are clean and free from dust, debris, and moisture before soldering.

- Soldering Iron Temperature: Use a temperature-controlled soldering iron set to the appropriate temperature recommended by the crystal manufacturer. Excessive heat can damage the crystal, while insufficient heat can result in poor solder connections.

- Soldering Technique: Apply a small amount of flux to the connections to aid in soldering. Hold the crystal in place securely, ensuring proper alignment with the solder pads. Apply the soldering iron tip to the joint, allowing the solder to flow and form a reliable solder connection. Avoid overheating the crystal during soldering.

- Inspection: Inspect the solder joints to ensure there are no solder bridges, cold joints, or other soldering defects that could impact the crystal’s performance. Use a magnifying glass if necessary to check for any microscopic issues.

- Mechanical Support: Provide appropriate mechanical support for the crystal, such as ensuring it is firmly mounted and protected from excess vibrations or shocks that could damage its connections or internal structure.

By following these crystal selection and soldering tips, you can maximize the performance and reliability of crystals in electronic circuits. Proper selection and soldering techniques are crucial for maintaining the integrity of the crystals and ensuring optimal operation of the circuits in which they are used.