History and Evolution of Electronic Control Modules

Automotive technology has come a long way in the past few decades, and one of the most significant advancements has been the introduction of electronic control modules (ECMs). These small but powerful devices have revolutionized the way vehicles operate, optimizing performance, improving fuel efficiency, and enhancing overall driving experience.

The history of ECMs dates back to the 1970s when the automotive industry began exploring ways to replace traditional mechanical systems with electronic counterparts. This shift was driven by the need for finer control over vehicle functions and the desire to meet increasingly stringent emission and fuel efficiency standards.

Early ECMs, also known as engine control units (ECUs), were rudimentary compared to the sophisticated systems we see in modern vehicles. They primarily focused on controlling the fuel injection and ignition timing to ensure efficient combustion. Over time, ECMs started to incorporate additional functionalities, such as monitoring and adjusting throttle position, exhaust gas recirculation, and even transmission shifting.

As technology advanced, so did ECMs. The integration of microprocessors and sensors facilitated more precise control over engine parameters and allowed for real-time monitoring of various vehicle systems. This paved the way for the development of comprehensive engine management systems capable of adapting to different driving conditions and maximizing performance.

In the 1990s, the advent of onboard diagnostics (OBD) further revolutionized ECM technology. OBD systems enabled technicians to easily access and interpret diagnostic trouble codes (DTCs) stored within the ECM, simplifying the troubleshooting and repair process. This standardized approach to diagnostics also made it easier for vehicle manufacturers to comply with emission regulations.

With the dawn of the 21st century, ECMs became even more sophisticated, integrating with other vehicle systems like transmission control, traction control, and even advanced driver assistance systems (ADAS). The introduction of CAN (Controller Area Network) bus systems allowed for seamless communication between different modules, enabling better coordination and synchronization of vehicle functions.

The future of ECMs holds even more exciting possibilities. With the rise of electric and hybrid vehicles, ECMs will play a crucial role in managing battery power, motor control, and regenerative braking. As autonomous driving technology becomes mainstream, ECMs will need to adapt to new challenges, ensuring the seamless integration of artificial intelligence and sensor data for safe and efficient self-driving vehicles.

How Does an Electronic Control Module Work?

An electronic control module (ECM) is the brain of a vehicle’s electrical system. It is responsible for controlling and coordinating various functions and subsystems, ensuring optimal performance and efficiency. Understanding how ECMs work is essential to comprehend their importance in modern vehicles.

The ECM receives inputs from various sensors placed throughout the vehicle, such as the throttle position sensor, oxygen sensor, coolant temperature sensor, and many others. These sensors collect data on parameters like engine speed, air intake, fuel mixture, and exhaust gases. The ECM processes this data to determine the appropriate actions to take.

Using complex algorithms and pre-programmed maps, the ECM calculates the ideal fuel injection timing, ignition timing, and other parameters based on the collected sensor data. It then sends signals to actuators, such as fuel injectors, ignition coils, and electronic throttle bodies, to execute these calculated actions.

The ECM continuously monitors the engine’s performance and adjusts its operations in real-time to ensure optimal efficiency and emissions control. It makes rapid decisions based on current driving conditions, such as throttle position, engine load, and vehicle speed. By adjusting fuel delivery, timing, and other parameters, the ECM can optimize power output and fuel consumption.

In addition to engine control, modern ECMs often integrate with other vehicle systems, such as the transmission, ABS (anti-lock braking system), and stability control. This integration allows for better coordination and synchronization of various functions, resulting in smoother operation and improved safety.

The ECM also plays a vital role in diagnostics. It continuously monitors the vehicle’s systems and stores relevant data in its memory. If a fault or anomaly is detected, the ECM generates diagnostic trouble codes (DTCs) to indicate the issue. These codes can be retrieved using a diagnostic scanner, allowing technicians to pinpoint the problem and initiate the necessary repairs.

Overall, the functionality of an ECM is extensive and complex. It requires a combination of hardware, such as microprocessors and memory modules, and software with intricate algorithms to perform its tasks effectively. The continuous advancements in technology have made ECMs increasingly capable of managing and optimizing vehicle systems, ensuring optimal performance, fuel efficiency, and overall driving experience.

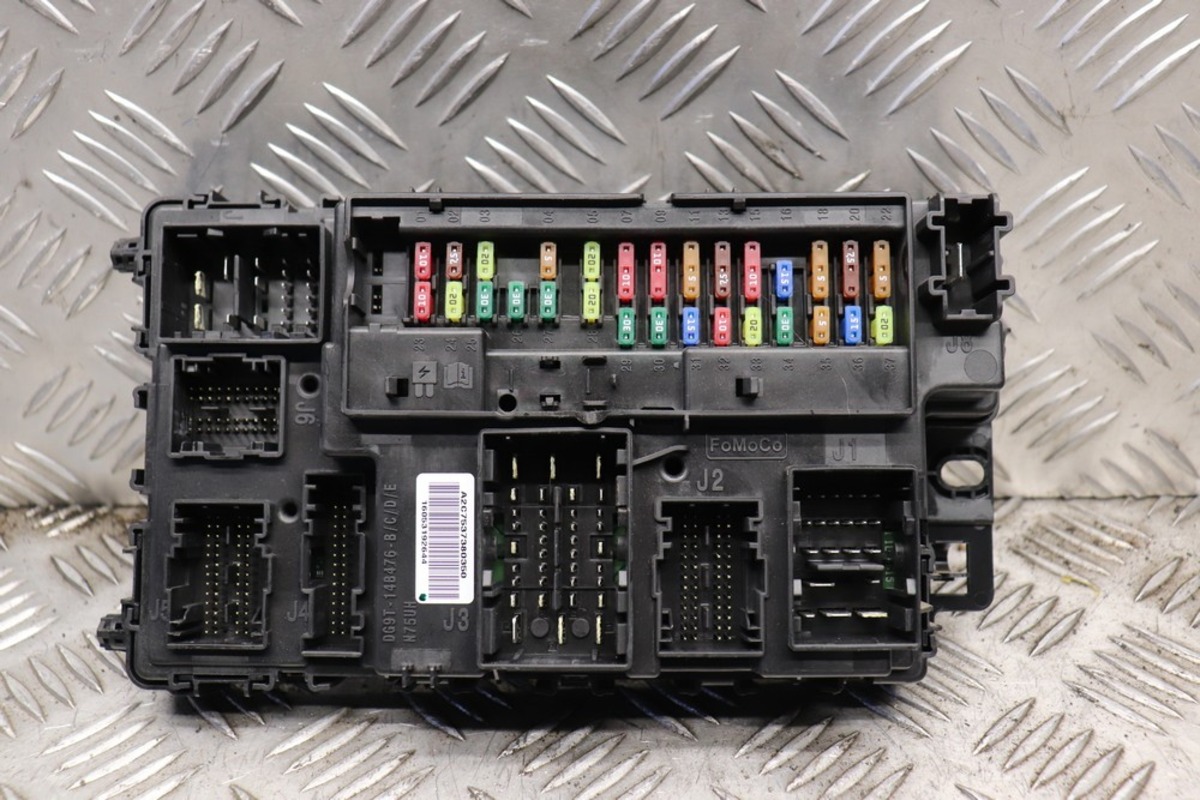

Components of an Electronic Control Module

An electronic control module (ECM) is a sophisticated electronic device that consists of several key components, working in harmony to manage and control various functions within a vehicle. These components play a crucial role in ensuring the ECM’s functionality and reliability.

1. Microprocessor: The microprocessor is the heart of the ECM, responsible for executing the complex calculations and algorithms required to control the vehicle’s systems. It processes the data received from the sensors, performs calculations, and sends instructions to the actuators.

2. Memory: The ECM has two types of memory – read-only memory (ROM) and random-access memory (RAM). ROM stores the ECM’s software and programming code, while RAM is used for temporary storage of data and variables during operation.

3. Input Sensors: The ECM receives inputs from various sensors placed throughout the vehicle. These sensors include the throttle position sensor, oxygen sensor, coolant temperature sensor, mass airflow sensor, and many others. They collect data on critical parameters such as engine speed, air intake, fuel mixture, and exhaust gases.

4. Output Actuators: The ECM sends signals to output actuators based on the processed sensor data to control various vehicle functions. These actuators include fuel injectors, ignition coils, electronic throttle bodies, and others. They execute the instructions from the ECM to ensure efficient fuel delivery, ignition timing, and other critical operations.

5. Power Supply: The ECM requires a stable power supply to function correctly. It is typically connected to the vehicle’s main power source, such as the battery or alternator. The power supply ensures that the ECM has the necessary energy to perform its tasks reliably.

6. Communication Interfaces: Modern ECMs often feature communication interfaces such as CAN (Controller Area Network) or LIN (Local Interconnect Network). These interfaces enable the ECM to exchange data with other vehicle systems and modules, promoting seamless integration and coordination.

7. Diagnostic Connector: The ECM has a diagnostic connector that allows access to its onboard diagnostics system. Through this connector, technicians can connect diagnostic tools to retrieve diagnostic trouble codes (DTCs) and perform troubleshooting and diagnostics.

Each component within an ECM works together to enable precise control over various vehicle systems. The microprocessor processes the sensor data, the memory stores necessary programming code and temporary data, the input sensors provide critical information, and the output actuators execute instructions. The power supply ensures proper energy delivery, communication interfaces facilitate system integration, and the diagnostic connector assists in troubleshooting and maintenance.

Types of Electronic Control Modules

Electronic control modules (ECMs) come in various types, each designed to control specific vehicle systems or subsystems. The different types of ECMs serve specific purposes and play a vital role in the overall operation and performance of a vehicle.

1. Engine Control Module (ECM): The engine control module, also known as the powertrain control module (PCM) in some vehicles, is one of the most critical ECMs. It is responsible for overseeing and controlling the engine’s performance, including fuel injection, ignition timing, air-fuel ratio, and exhaust emissions. The ECM continuously monitors various engine parameters and adjusts its operations to optimize power output, fuel efficiency, and emissions control.

2. Transmission Control Module (TCM): The transmission control module is dedicated to managing the operation of the transmission system. It receives input data from sensors such as vehicle speed, throttle position, and gear position, and uses this data to determine the optimal shifting points and engagement of clutches or bands. The TCM ensures smooth gear changes and efficient transmission performance.

3. Anti-Lock Braking System (ABS) Control Module: The ABS control module is responsible for monitoring and controlling the anti-lock braking system in a vehicle. It receives input data from wheel speed sensors and activates the ABS pump to modulate braking pressure on individual wheels, preventing wheel lock-up and allowing for effective braking in emergency situations.

4. Body Control Module (BCM): The body control module is primarily concerned with managing the electrical components and systems related to the vehicle’s body and interior. It controls functions such as power windows, central locking, lighting systems, climate control, and security features. The BCM ensures proper operation and coordination of these systems, enhancing comfort, convenience, and safety.

5. Airbag Control Module (ACM): The airbag control module is responsible for the deployment of airbags in the event of a collision. It monitors impact sensors and other relevant data to determine the severity of an impact and triggers the deployment of airbags, seat belt pretensioners, and other safety measures to protect the vehicle occupants.

6. Electronic Stability Control (ESC) Module: The ESC module is essential for maintaining vehicle stability and traction control. It constantly monitors sensors, including wheel speed sensors, yaw rate sensors, and steering angle sensors, to detect any loss of control or instability. The ESC module intervenes by selectively applying brakes to specific wheels or adjusting engine power to bring the vehicle back in line and prevent skidding or sliding.

These are just a few examples of the types of ECMs found in modern vehicles. Other ECMs may exist for specific subsystems like the fuel system, climate control system, or entertainment system. The integration of these ECMs allows for precise control and coordination of various vehicle functions, ensuring optimal performance, safety, and comfort.

Common Symptoms of a Failing Electronic Control Module

The electronic control module (ECM) is a crucial component of a vehicle’s electrical system. Like any other electronic device, it can experience issues over time. Recognizing the common symptoms of a failing ECM is essential to address problems promptly and avoid more significant vehicle issues.

1. Engine Performance Problems: A failing ECM can lead to various engine performance issues. These may include rough idling, misfires, hesitation during acceleration, reduced power, or even stalling. The ECM’s inability to deliver the correct signals to the engine components can disrupt fuel delivery, ignition timing, and other critical functions.

2. Inconsistent Starting or Drivability Issues: A faulty ECM can cause difficulties when starting the engine or erratic behavior while driving. You may experience intermittent starting problems, where the engine takes longer to start or requires multiple attempts. Erratic drivability issues, such as sudden loss of power or irregular acceleration, can also indicate an ECM problem.

3. Illuminated Check Engine Light: A failing ECM often triggers the check engine light on the vehicle’s dashboard. This warning light indicates that a problem has been detected within the various systems managed by the ECM. It is essential to have the vehicle diagnosed by a qualified technician to retrieve diagnostic trouble codes (DTCs) stored in the ECM and identify the underlying issue.

4. Unresponsive or Inoperative Systems: A failing ECM can cause the malfunction or complete failure of certain vehicle systems. For example, you may notice that the electronic throttle control is unresponsive or that the transmission shifts abruptly or not at all. Other affected systems may include the ABS, airbags, and even the vehicle’s electrical components controlled by the body control module.

5. Poor Fuel Efficiency: A malfunctioning ECM can disrupt the precise control over fuel injection and other engine parameters. As a result, the vehicle’s fuel efficiency may decrease noticeably. If you find that you are getting significantly fewer miles per gallon than usual, it could be an indication of an ECM problem.

6. Difficulty Passing Emission Tests: Since the ECM plays a crucial role in controlling and monitoring emissions, a failing ECM can lead to increased emissions and difficulty passing emission tests. If you notice that your vehicle consistently fails emissions testing or emits excessive smoke from the exhaust, it could be due to an ECM issue.

It is important to note that these symptoms may also be caused by other vehicle issues, so a proper diagnosis by a qualified technician is necessary. They will use diagnostic tools to retrieve DTCs and perform further tests to pinpoint the exact cause of the problem. Timely identification and resolution of ECM issues can prevent further damage and ensure optimal vehicle performance.

Diagnosis and Troubleshooting of Electronic Control Module Issues

When experiencing problems with the electronic control module (ECM) of a vehicle, diagnosis and troubleshooting are crucial steps to identify and resolve the underlying issues. While it is recommended to consult a qualified technician for accurate diagnosis, understanding the basic steps involved can help vehicle owners understand the process better.

1. Retrieve Diagnostic Trouble Codes (DTCs): The first step in diagnosing ECM issues is to retrieve the diagnostic trouble codes stored in the ECM. These codes provide valuable information about the specific problem areas. Using a diagnostic scanner, the technician can access the ECM’s memory and retrieve the codes for further analysis.

2. Interpret Diagnostic Trouble Codes (DTCs): Once the DTCs are retrieved, the technician will interpret them to identify the potential causes of the problem. Each code corresponds to a specific issue within the vehicle’s systems, such as fuel delivery, ignition timing, or sensor malfunctions. Interpretation of the codes helps narrow down the troubleshooting process.

3. Perform Visual Inspection: A visual inspection of the ECM and its associated components can reveal signs of physical damage or loose connections. The technician will check for corroded or damaged wiring, loose connectors, or any signs of water damage that could affect the ECM’s functionality.

4. Functional Testing: The technician will perform various functional tests to assess the ECM’s operation. These tests may include checking input and output signals from the ECM using specialized equipment and tools. The goal is to determine if the ECM is sending the correct signals to the vehicle’s systems and if the output actuators are functioning properly.

5. Check Power and Ground Connections: The ECM requires a stable power and ground connection to function correctly. The technician will verify the voltage and continuity of the power and ground connections to ensure they meet specifications. Loose or faulty connections can cause ECM malfunctions and other related issues.

6. Component Testing: In some cases, specific components, such as sensors or actuators, may be the root cause of ECM issues. The technician will perform individual component tests to check for proper functionality. This may involve using specialized tools or equipment to measure sensor outputs or actuator responses.

7. Reprogramming or Updating: Sometimes, ECM issues can be resolved through reprogramming or updating the ECM’s software. The technician will check for any available manufacturer updates or fixes that address known ECM issues. Reprogramming or updating the ECM may require specialized software and equipment.

8. Replacement: If all troubleshooting steps fail to resolve the ECM issues, the technician may recommend replacing the ECM. This should only be done after all other potential causes have been ruled out. Replacement may require programming or syncing with the vehicle’s systems to ensure compatibility and functionality.

It is important to note that diagnosis and troubleshooting ECM issues can be complex. It is always recommended to seek the expertise of a qualified technician who has experience with ECMs and the necessary diagnostic tools. Their knowledge and skills will ensure proper diagnosis and effective resolution of ECM-related problems.

When Should You Replace an Electronic Control Module?

The decision to replace an electronic control module (ECM) in a vehicle is not one to be taken lightly. While ECM issues can cause significant disruptions and performance problems, it is essential to consider certain factors before opting for a replacement.

1. Diagnostic Trouble Codes (DTCs): When diagnostic trouble codes are retrieved from the ECM, they offer valuable insight into the specific problems affecting the vehicle. If multiple critical DTCs related to the ECM or its associated components are present and cannot be resolved through troubleshooting and repairs, replacement may be necessary.

2. Irreparable Damage: Physical damage to the ECM, such as corrosion, water damage, or burnt circuits, may render it unrepairable. If the damage is extensive and affects the ECM’s functionality, replacement is often the more practical and cost-effective solution.

3. Software or Firmware Issues: In some cases, ECM issues may be due to software or firmware corruption. If reprogramming or updating the ECM does not resolve these issues, replacement may be necessary to ensure proper operation and compatibility with the vehicle’s systems.

4. Age and Mileage: ECMs, like any other electronic component, have a lifespan. As the vehicle ages and accumulates mileage, the ECM may become more prone to failure or issues. If the ECM is approaching its expected lifespan, replacing it proactively can prevent unexpected failures and subsequent vehicle malfunctions.

5. Performance and Drivability Problems: If the ECM’s issues significantly impact the vehicle’s performance, drivability, or safety, replacement may be the most appropriate course of action. Persistent engine misfires, stalling, fuel delivery problems, or other critical issues that cannot be resolved through repairs may justify ECM replacement.

6. Lack of Availability or Compatibility: In some cases, older vehicle models may no longer have ECM replacements readily available from the original manufacturer. In such instances, aftermarket ECMs may be an option, but compatibility must be carefully considered to ensure proper functionality and integration with the vehicle’s systems.

7. Expert Recommendations: It’s important to consult with qualified technicians or specialists with expertise in ECMs. They can provide valuable insights and recommendations based on their knowledge and experience. Their expertise can guide the decision-making process regarding ECM replacement.

Keep in mind that ECM replacement should be pursued after all other potential causes have been ruled out through thorough diagnostics and troubleshooting. It is also crucial to use genuine or reliable replacement ECMs and ensure proper programming and syncing with the vehicle’s systems to maintain compatibility and functionality.

Ultimately, the decision to replace an ECM should be based on careful consideration of the specific circumstances, including the severity and persistence of the ECM issues, the age and mileage of the vehicle, and expert recommendations. Replacing an ECM can restore proper functionality and improve the overall performance and reliability of the vehicle.

The Role of Reprogramming and Updating in Electronic Control Modules

Reprogramming and updating electronic control modules (ECMs) play a vital role in ensuring optimal performance, functionality, and compatibility with modern vehicles. As technology advances, ECMs may require reprogramming or updating to address known issues, enhance features, or improve overall operation.

1. Resolving Known Issues: Vehicle manufacturers may discover specific issues or bugs in the ECM software or programming after the vehicle’s release. Reprogramming or updating the ECM allows manufacturers to address these known issues and provide corrective measures. This helps ensure that the ECM operates as intended, minimizing potential performance problems or failures.

2. Enhancing Features and Functionality: Reprogramming or updating the ECM can introduce new features or enhance existing ones. This allows for improved performance, better fuel efficiency, and enhanced driving experience. Manufacturers may release updates to optimize engine performance, refine transmission shifting patterns, or add compatibility with new technology.

3. Compatibility with Vehicle Systems: Electronic control modules need to be compatible with other vehicle systems and modules to ensure seamless integration and functionality. Reprogramming or updating the ECM can address compatibility issues, ensuring proper communication and coordination between the ECM and other systems. This is particularly important when adding aftermarket components or making modifications to a vehicle.

4. Adapting to Environmental Conditions: Reprogramming or updating the ECM can enable vehicles to operate optimally in different environmental conditions. For example, ECM updates may adjust engine parameters to account for varying altitudes or extreme temperatures, improving performance and efficiency. This adaptability allows vehicles to optimize operation regardless of the climate or location.

5. Compliance with Regulatory Standards: ECM reprogramming or updates can also ensure that vehicles comply with changing regulatory standards. As emission regulations become stricter, manufacturers may issue ECM updates to improve emissions control, reducing pollutants and meeting updated requirements. Updating the ECM can help ensure vehicles remain compliant with environmental regulations.

6. OEM Service Bulletins and Recalls: Original Equipment Manufacturers (OEMs) may release service bulletins or recalls for specific ECM-related issues. These bulletins or recalls typically involve reprogramming or updating the ECM to address safety concerns, performance problems, or other issues. It is crucial to stay informed about any applicable bulletins or recalls to ensure proper ECM functionality and vehicle safety.

Reprogramming or updating an ECM is typically done by authorized dealerships or qualified technicians using specialized equipment and software. This process ensures that the appropriate updates or modifications are performed accurately and safely. It is important to note that ECM reprogramming or updating should be performed following the recommended procedures and using authorized software to avoid potential complications or compatibility issues.

Overall, reprogramming and updating ECMs are essential maintenance procedures that facilitate optimal performance, address known issues, ensure compatibility, and maximize the lifespan of the vehicle’s electronic control module. It is advisable to consult with authorized service centers or qualified technicians to stay up-to-date with any ECM-related updates or recommendations from the vehicle manufacturer.

Cost of Replacing an Electronic Control Module

Replacing an electronic control module (ECM) can be a significant expense for vehicle owners. The cost involved in ECM replacement can vary depending on several factors, including the make and model of the vehicle, the source of the replacement ECM, and additional expenses associated with the replacement process.

1. OEM vs. Aftermarket ECM: The cost of a replacement ECM can vary depending on whether it is sourced from the original equipment manufacturer (OEM) or the aftermarket. OEM ECMs are specifically designed for a particular vehicle model and may come at a higher price. Aftermarket ECMs, on the other hand, are manufactured by third-party companies and may be more affordable, but their compatibility and quality may vary.

2. Labor Costs: The labor costs associated with ECM replacement depend on the complexity of the vehicle’s ECM location and the time required to access and install the replacement unit. The labor rates of the service center or technician performing the replacement will also affect the overall cost. Additionally, if additional diagnostic tests or repairs are necessary, it can add to the labor cost.

3. Programming and Synchronization: After replacing the ECM, programming and synchronization are often required to ensure compatibility with the vehicle’s systems. This process involves using specialized software and equipment to configure the ECM and integrate it properly. The costs associated with programming and synchronization will depend on the service center or technician performing the task.

4. Diagnostic and Troubleshooting Fees: Before determining that an ECM replacement is necessary, vehicle owners often go through a diagnostic and troubleshooting process to identify the root cause of the issues. Diagnostic and troubleshooting fees can vary depending on the complexity of the problem, the time required for diagnosis, and the expertise of the technician.

5. Warranty Coverage: If the vehicle is still under warranty, the cost of ECM replacement may be covered, either partially or in full, depending on the terms of the warranty. It is advisable to check the warranty coverage details to determine if the replacement cost can be mitigated.

It is essential to note that the cost of ECM replacement can range from a few hundred dollars to several thousand dollars, depending on the factors mentioned above. Seeking quotes from different service centers or comparing prices of OEM and aftermarket ECMs can help vehicle owners make informed decisions regarding the replacement cost.

It is recommended to consult with a qualified technician or authorized service center to assess the specific ECM issues, obtain an accurate estimate of the replacement cost, and gain insights into the available options. Additionally, considering the overall value and condition of the vehicle can play a role in determining whether ECM replacement is a cost-effective solution.

Importance of Regular Maintenance and Care for Electronic Control Modules

Electronic control modules (ECMs) are vital components of a vehicle’s electrical system, and their proper functioning is essential for optimal performance and reliability. Regular maintenance and care for ECMs play a crucial role in ensuring their longevity and minimizing the risk of malfunctions or failures.

1. Preventive Measures: Regular maintenance allows for the early detection of potential issues or abnormalities in the ECM. By conducting routine inspections and diagnostics, technicians can identify any signs of wear, loose connections, or other problems. Timely detection and repair of such issues can help prevent more significant problems and extend the life of the ECM.

2. Proper Wiring and Ground Connections: Ensuring the ECM has proper wiring and ground connections is key to its optimal performance. Over time, wiring can become damaged or corroded, leading to poor electrical conductivity and potential ECM malfunctions. Regular inspections can identify any wiring issues, and repairs can be done promptly to maintain reliable connections.

3. Protecting Against Environmental Factors: ECMs are exposed to various environmental factors that can impact their functionality. Extreme temperatures, moisture, and contaminants can cause damage to the ECM. Regular maintenance includes protecting the ECM from these elements by ensuring proper sealing and shielding, as well as keeping the vehicle’s electrical components clean and free from debris.

4. Keeping Software and Firmware Updated: ECMs often require software updates or firmware upgrades released by the manufacturers. These updates address known issues, enhance performance, and improve compatibility with other vehicle systems. Regular maintenance involves staying up-to-date with these updates and ensuring that the ECM’s software is current.

5. Battery Maintenance: The condition of the vehicle’s battery directly affects the ECM’s performance. A low or weak battery can cause voltage fluctuations that can negatively impact the ECM’s operation. Regular battery maintenance, including monitoring battery health, ensuring proper charging, and replacing old or failing batteries, contributes to the optimal functioning of the ECM.

6. Following Manufacturer’s Guidelines: Each vehicle manufacturer provides specific guidelines for ECM maintenance and care. Regular maintenance should adhere to these guidelines, including recommended service intervals, fluid changes, filter replacements, and other scheduled maintenance tasks. Following these guidelines can help prevent ECM-related issues and keep the vehicle running smoothly.

7. Qualified Technicians: It is crucial to entrust ECM maintenance and care to qualified technicians who have the expertise and knowledge in working with ECMs. Technicians with proper training and experience can accurately diagnose issues, perform necessary repairs, and ensure proper programming and synchronization of the ECM. Choosing reputable service centers with qualified technicians is vital for the proper maintenance and care of ECMs.

Regular maintenance and care for ECMs contribute to the overall reliability, longevity, and performance of the vehicle. By implementing preventive measures, ensuring proper wiring and ground connections, protecting against environmental factors, and following manufacturer’s guidelines, owners can minimize the risk of ECM malfunctions, optimize performance, and maximize the lifespan of these critical components.

Benefits and Advantages of Electronic Control Modules in Vehicles

Electronic control modules (ECMs) have revolutionized the automotive industry, bringing numerous benefits and advantages to vehicles. These sophisticated devices have become a fundamental part of modern vehicles, contributing to improved performance, safety, efficiency, and overall driving experience.

1. Optimized Performance: ECMs play a crucial role in optimizing the performance of a vehicle’s engine and other systems. By precisely controlling fuel injection timing, ignition timing, air-fuel ratio, and other parameters, ECMs ensure efficient combustion, leading to enhanced power output, smoother operation, and improved acceleration.

2. Enhanced Fuel Efficiency: ECMs help optimize fuel consumption by controlling the fuel injection process based on real-time inputs from various sensors. This enables more accurate fuel delivery, reducing wasted fuel and improving overall fuel efficiency. By maximizing the utilization of the fuel, ECMs contribute to cost savings and reduced environmental impact.

3. Improved Emissions Control: Stricter emission regulations require vehicles to minimize their impact on the environment. ECMs play a vital role in achieving this by continuously monitoring and adjusting various engine parameters to optimize emissions control. By ensuring efficient combustion and precise control over fuel delivery, ECMs help vehicles meet emission standards and reduce harmful pollutants.

4. Intelligent Diagnostics: ECMs have advanced diagnostic capabilities that help identify and manage potential issues. By continuously monitoring the vehicle’s systems and collecting data, ECMs can detect faults and generate diagnostic trouble codes (DTCs) that assist technicians in troubleshooting and repairs. This enables timely maintenance and reduces vehicle downtime.

5. Seamless System Integration: ECMs are designed to integrate seamlessly with other vehicle systems. They communicate with components like the transmission control module, anti-lock braking system, and stability control system to ensure coordinated and synchronized operation. This integration improves overall vehicle performance, safety, and drivability.

6. Real-time Adaptability: ECMs have the ability to adapt and adjust based on changing driving conditions. Through input from sensors and continuous monitoring, ECMs can modify engine parameters to optimize performance in various scenarios. This adaptability allows vehicles to perform optimally in different situations, such as high altitudes, extreme temperatures, or heavy loads.

7. Advanced Safety Features: ECMs are integral to the development and implementation of advanced safety features in vehicles. They play a critical role in systems like anti-lock braking, electronic stability control, and airbag deployment. ECMs ensure the correct functioning and coordination of these safety features, enhancing overall vehicle safety and occupant protection.

8. Future Expandability: ECMs provide a platform for future expandability and integration of emerging technologies. As the automotive industry evolves, ECMs can accommodate advancements such as electric drivetrains, hybrid systems, and autonomous driving capabilities. This adaptability enables vehicles to stay current with technological advancements and ensures compatibility with future technologies.

Electronic control modules have transformed the modern vehicle, offering a range of benefits and advantages. From optimizing performance and efficiency to enhancing safety and adaptability, ECMs contribute to a better driving experience and a more sustainable future for the automotive industry.

Implications of a Faulty Electronic Control Module on Vehicle Performance

A faulty electronic control module (ECM) can have significant implications on the performance of a vehicle. The ECM serves as the brain of a vehicle’s electrical system, and any malfunction or failure can disrupt critical functions and negatively impact overall performance.

1. Engine Performance Issues: A faulty ECM can lead to a range of engine performance problems. It may result in rough idling, hesitation during acceleration, misfires, or even complete engine stalling. The ECM controls critical aspects of engine operation, such as fuel injection timing, ignition timing, and air-fuel ratio. Malfunctioning ECM can disrupt these parameters, leading to poor combustion and compromised performance.

2. Reduced Power and Acceleration: A faulty ECM can limit the power output of the engine, resulting in reduced overall performance and acceleration. If the ECM fails to deliver the correct signals to engine components such as fuel injectors or ignition coils, it can cause a decrease in engine power. This can impact the vehicle’s ability to accelerate quickly or perform efficiently during challenging driving situations, such as uphill climbs or overtaking maneuvers.

3. Poor Fuel Efficiency: A malfunctioning ECM can also affect fuel efficiency. The ECM controls fuel delivery and other engine parameters to optimize combustion and fuel consumption. A faulty ECM may cause improper fuel delivery or incorrect air-fuel ratios, leading to increased fuel consumption. This not only affects the vehicle’s operational costs but also contributes to higher carbon emissions and a negative impact on the environment.

4. Transmission Issues: In vehicles with electronically controlled transmissions, a faulty ECM can negatively impact transmission performance. The ECM sends signals to the transmission control module to determine shifting points and engage clutches or bands. If the ECM fails to provide accurate signals or commands, it can result in erratic shifting, delays, or harsh gear changes, leading to poor overall drivability.

5. Electrical System Malfunctions: A malfunctioning ECM can disrupt the vehicle’s electrical system, impacting various components and systems. The ECM interface with other modules, including ABS, airbags, stability control, and climate control. If the ECM fails to communicate or send appropriate signals to these systems, it can lead to malfunctions or even complete failure, compromising safety and overall vehicle performance.

6. Increased Emissions: The ECM plays a crucial role in emissions control, ensuring compliance with environmental regulations. A faulty ECM can disrupt emissions-related systems, leading to increased pollutant emissions. This not only contributes to environmental pollution but can also put the vehicle in violation of emission standards, leading to potential legal and regulatory consequences.

It is crucial to address any ECM-related issues promptly to minimize the implications on vehicle performance. Proper diagnosis and repair or replacement of a faulty ECM by qualified technicians are essential in restoring optimal performance, ensuring fuel efficiency, and maintaining overall vehicle reliability and safety.

Future Developments and Advancements in Electronic Control Modules

The field of electronic control modules (ECMs) is constantly evolving, driven by technological advancements and the demand for more efficient, safe, and connected vehicles. As automotive technology continues to progress, several future developments and advancements are expected in ECMs.

1. Integration of Artificial Intelligence: Future ECMs are likely to incorporate artificial intelligence (AI) capabilities. AI algorithms can analyze vast amounts of data from various sensors and systems, allowing ECMs to make more informed decisions in real time. This integration will enhance the adaptability and responsiveness of ECMs, optimizing performance and efficiency.

2. Enhanced Connectivity: ECMs will play an even more significant role in vehicle connectivity. With advancements in wireless communication technologies, ECMs can interact with other vehicles, infrastructure, and cloud-based platforms. This connectivity enables features such as Over-the-Air (OTA) software updates, vehicle-to-vehicle communication, and integration with smart city infrastructure for improved traffic management and safety.

3. Increased Autonomy: As autonomous driving technology continues to advance, ECMs will play a crucial role in managing and coordinating the various systems required for autonomous operation. From sensor fusion to decision-making algorithms, ECMs will integrate with sophisticated perception, planning, and control systems to ensure safe and efficient autonomous driving.

4. Predictive Analytics and Maintenance: Future ECMs will likely leverage predictive analytics to anticipate potential failures or maintenance needs. By continuously monitoring vehicle data, ECMs can detect patterns and anomalies, enabling proactive maintenance. This will result in improved vehicle reliability, reduced downtime, and optimized maintenance schedules.

5. Cybersecurity Measures: As vehicles become more connected and reliant on ECMs, cybersecurity will become increasingly important. Future ECMs will incorporate advanced security measures to protect against cyber threats and unauthorized access. Robust encryption, intrusion detection systems, and secure data communication protocols will be integral components of future ECMs.

6. Energy Management Systems: With the rise of electric and hybrid vehicles, ECMs will adapt to address the unique energy management requirements of these powertrains. Future ECMs will optimize battery usage, manage power flow between different components, and enable regenerative braking to enhance overall energy efficiency and extend the range of electric vehicles.

7. Modular and Scalable Designs: Future ECMs are likely to adopt modular and scalable designs to accommodate various vehicle configurations and customization options. Modular ECM architectures will simplify integration with different vehicle systems and enable easier upgrades and enhancements as technology advances.

8. Improved Diagnostics and Remote Monitoring: Future ECMs will offer advanced diagnostic capabilities and remote monitoring capabilities. By leveraging connectivity and AI, ECMs will enable remote diagnostics, allowing technicians to analyze ECM data and troubleshoot issues remotely. This can lead to faster and more efficient repairs, reducing vehicle downtime.

These future developments and advancements in ECM technology will pave the way for more intelligent, efficient, and connected vehicles. By continuously improving performance, safety, connectivity, and sustainability, ECMs will play a significant role in shaping the future of the automotive industry.