Understanding Short Circuits

A short circuit is a common problem in electronic devices that occurs when a current takes an unintended path, bypassing the normal flow of electricity. Understanding what a short circuit is and how it can affect your electronics is crucial for diagnosing and resolving issues related to electrical malfunctions.

Essentially, a short circuit happens when there is a low resistance connection between two points in an electrical circuit that are not meant to be connected. This results in a sudden surge of electrical current and potentially causes damage to the components involved.

Short circuits can occur due to various reasons, such as damaged wiring, faulty connections, or defective components. These issues can lead to the unintended flow of electrical current and pose a risk of overheating, fires, or even explosions.

When a short circuit occurs, it disrupts the normal functioning of the device, causing it to malfunction or stop working altogether. In some cases, a short circuit may trigger fuses or circuit breakers, cutting off the power supply to prevent further damage.

It is important to note that short circuits can happen in any electronic device, from small household appliances to complex industrial machinery. Thus, being familiar with the causes and signs of short circuits can help you address the issue promptly and effectively.

In the next sections, we will explore what the term “shorted” means in the context of electronics, the common causes of short circuits, how to identify them, and the necessary steps for fixing and preventing short circuits.

What Does “Shorted” Mean?

When we say that a component or circuit has “shorted,” it means that there is a direct electrical connection between two points where there should not be. This unintended connection allows the flow of electrical current to bypass the intended path, leading to various issues.

In simple terms, when a component or circuit is shorted, it creates a low-resistance pathway for the electrical current to flow, without going through the necessary load or other components in the circuit. As a result, the excessive current can cause damage to the components involved, leading to equipment malfunction or failure.

A short circuit can occur due to a variety of reasons, such as a manufacturing defect, physical damage to the wiring or components, or improper installation. For example, a damaged insulation on a wire could cause it to come into contact with other wires, creating a short circuit.

When a short circuit occurs, it often results in the activation of protective devices like fuses or circuit breakers. These safety mechanisms are designed to detect and interrupt the flow of current to prevent further damage, overheating, or fire hazards.

It is important to note that identifying a shorted component or circuit requires proper diagnosis and troubleshooting. Skilled technicians or electricians often use specialized tools and techniques to locate the exact point of the short and rectify the issue.

In the following sections, we will delve into the common causes of shorted components, how to identify a short circuit, and the steps involved in fixing and preventing them. Understanding these aspects will empower you to address short circuit problems effectively and protect your electronic devices from potential harm.

Causes of Shorted Components

Shorted components can be a result of various factors, ranging from manufacturing defects to external influences. Understanding these causes can help you diagnose and prevent short circuits more effectively.

1. Manufacturing Defects: Faulty manufacturing processes can lead to components being improperly formed or connected. This can result in internal short circuits or weak points within the component structure.

2. Physical Damage: Components can be damaged during handling, installation, or due to external forces. Physical damage, such as a cracked circuit board or a pinched wire, can create unintended connections and cause short circuits.

3. Overheating: Excessive heat can cause components to expand and come into contact with neighboring components or traces on the circuit board, resulting in shorts. Overheating can occur due to inadequate cooling systems or excessive power load.

4. Moisture and Corrosion: Exposure to moisture or corrosive substances can lead to the degradation of component materials, resulting in short circuits. This is particularly common in environments with high humidity or chemical exposure.

5. Improper Wiring: Incorrect wiring or improper connections during installation can create shorts. This can include crossed wires, loose connections, or misaligned terminals.

6. Faulty Power Supply: Fluctuations in the power supply, such as voltage spikes or power surges, can overload components and cause short circuits.

7. Aging and Wear: Over time, components can degrade or wear out, resulting in shorts. This can be due to the breakdown of insulation materials, fatigue of conductive elements, or the accumulation of debris.

To avoid or minimize the risk of shorted components, it is important to handle and install electronic devices with care, follow manufacturer guidelines for proper wiring and maintenance, and ensure reliable power supply. Regular inspections and preventive maintenance can also help identify potential issues before they lead to short circuits.

In the next section, we will discuss how to identify a short circuit and the signs to look out for when troubleshooting electronic devices.

How to Identify a Short Circuit

Identifying a short circuit is essential for effectively troubleshooting and resolving electrical issues in electronic devices. Here are some signs and methods that can help you identify a short circuit:

1. Circuit Breaker Tripping: If the circuit breaker trips frequently or instantly when you turn on a specific device, it could indicate a short circuit. The breaker detects the excessive current caused by the short and shuts off the power supply to prevent damage.

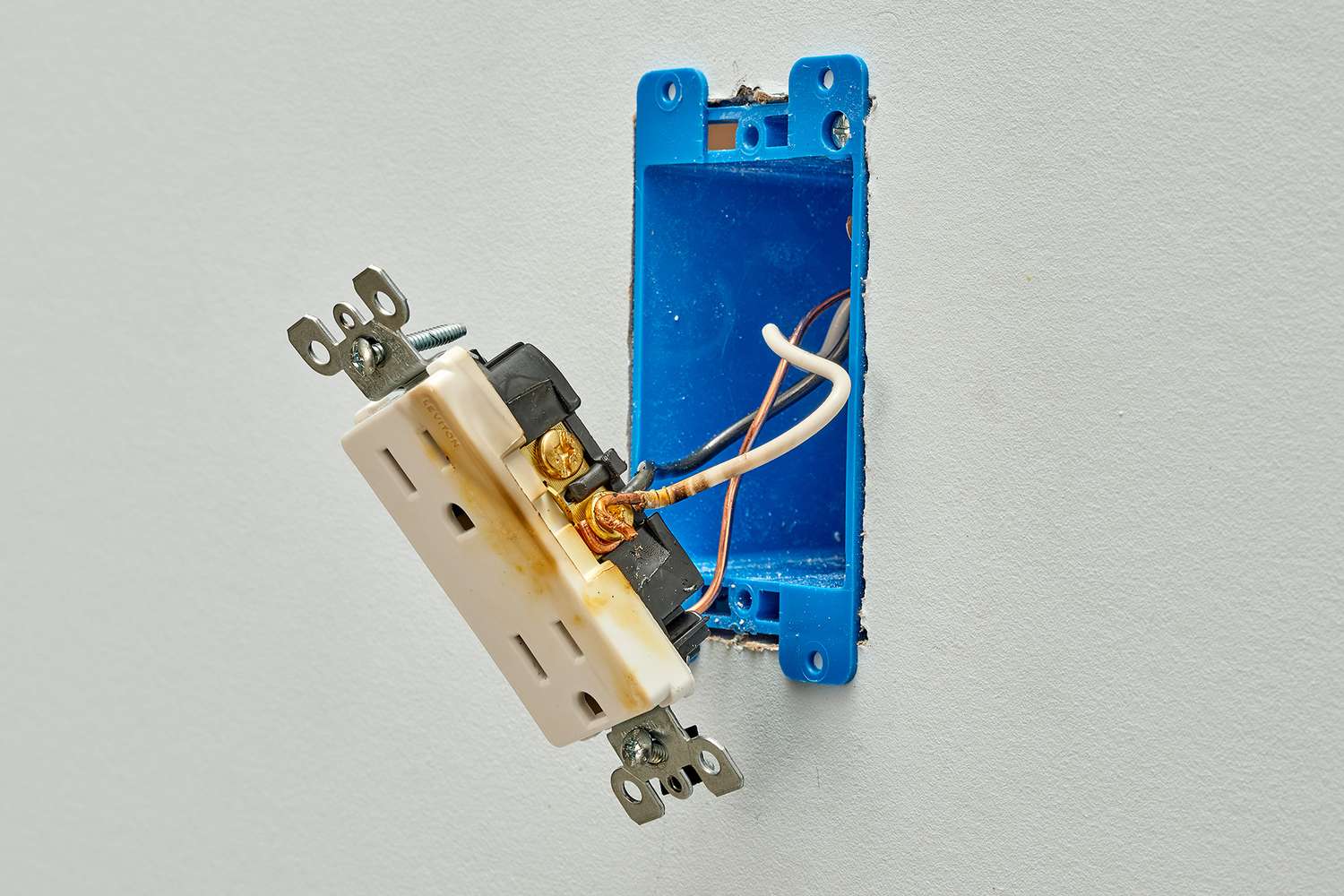

2. Burning Smell or Smoke: A distinct burning smell or smoke coming from your electronic device is a clear indicator of a short circuit. It suggests that the excessive current has caused overheating and potentially damaged wiring or components.

3. Sparks or Arcing: If you see sparks or hear crackling sounds when you plug in or turn on a device, it could be a sign of a short circuit. These sparks occur due to the electrical arcing caused by the undesired flow of current.

4. Non-Functional Parts: When certain parts of a device, such as buttons, switches, or specific functions, stop working, it may indicate a short circuit in the corresponding circuitry.

5. Visual Inspection: Carefully inspect the wiring, circuit boards, and components for any physical damage, loose connections, or signs of burn marks. Look for melted insulation, charred marks, or blackened areas, as these can indicate the presence of a short circuit.

6. Using a Multimeter: A multimeter is a handy tool for measuring electrical values. By checking the resistance between different points in a circuit, you can identify if there is a path with very low resistance, indicating a short circuit.

7. Professional Assistance: If you are unable to locate the short circuit or the issue persists, it is advisable to seek help from a qualified technician or electrician. They have the expertise and specialized equipment to diagnose and resolve complex electrical problems.

Remember to exercise caution when dealing with electrical devices and components. Ensure that the power is turned off before conducting any visual inspections or using a multimeter.

In the next section, we will discuss various methods for testing and locating shorted components, helping you pinpoint the source of the short circuit accurately.

Testing for Shorted Components

Once you have identified signs of a short circuit, the next step is to test and locate the specific component or area that is causing the issue. Here are some methods for testing and determining shorted components:

1. Visual Inspection: Start by examining the circuit board, wires, and components for any visible signs of damage or anomalies. Look for burnt or charred marks, melted insulation, or any loose connections. These visual cues can help pinpoint the area or component that may be shorted.

2. Continuity Testing: Use a digital multimeter set to the continuity or resistance mode to test the electrical continuity of various components or traces on the circuit board. Continuity testing helps identify any closed circuits or unintended connections that may be causing the short. If the multimeter beeps or shows a low resistance reading when probing two points, it indicates that they are shorted.

3. Insulation Resistance Testing: Insulation resistance testing measures the resistance between a conductor and its surrounding insulation. It helps identify weak or damaged insulation that may result in short circuits. Specialized insulation resistance testers are used for this purpose, providing accurate measurements and indicating potential shorts.

4. Component Isolation: If the short circuit is not evident through visual inspection or continuity testing, you can isolate specific components or sections of the circuit to narrow down the problem. This can be done by disconnecting or removing components one by one and retesting for the short circuit. The component that, when removed, eliminates the short, is likely the culprit.

5. Thermal Imaging: In some cases, short circuits can cause excessive heat buildup in specific areas. Using a thermal imaging camera, you can identify these hot spots, which may indicate the presence of a short circuit. This method is particularly useful for large-scale systems or complex assemblies where visual inspection may be challenging.

Remember to follow safety procedures and guidelines when conducting these tests. Ensure that the power is disconnected, and take precautions to prevent accidental contact with live circuits.

Identifying the exact component or area causing the short circuit is crucial for effective troubleshooting and repair. Once you have located the source of the short, you can proceed to fix or replace the affected component, as we will discuss in the following section.

How to Fix a Short Circuit

Fixing a short circuit involves locating and addressing the component or area causing the unintended electrical connection. Here are some steps to help you fix a short circuit:

1. Disconnect Power: Before attempting any repairs, ensure that the power supply to the affected circuit or device is disconnected. This will eliminate the risk of electrical shock and further damage.

2. Identify the Source: Utilize the testing methods discussed earlier to pinpoint the specific component, wire, or circuit board area that is causing the short circuit. Visual inspection, continuity testing, and isolation techniques can help determine the source of the problem.

3. Repair or Replace: Once you have identified the shorted component, you can proceed with repairing or replacing it. This may involve soldering broken connections, replacing damaged components, or fixing or replacing sections of damaged wiring or circuitry.

4. Check Wiring and Connections: Inspect the wiring and connections in the affected area. Look for loose connections, frayed wires, or damaged insulation. Repair or replace any faulty wiring or connections to prevent future short circuits.

5. Test for Continuity: After performing the necessary repairs, retest the circuit or device for continuity to ensure that the short circuit has been resolved. Use a multimeter in the continuity or resistance mode to check for any unintended connections or closed circuits.

6. Restore Power and Verify: Once you are confident that the short circuit has been fixed, reconnect the power supply and test the device or circuit. Verify that it is functioning properly without any signs of overheating, smoke, or abnormal behavior.

If you are unsure about your abilities or if the short circuit is in a complex or sensitive system, it is always recommended to seek professional help from a qualified technician or electrician. They will have the expertise and experience to safely diagnose and repair short circuit issues.

Remember, prevention is key to avoiding future short circuits. Following proper installation guidelines, performing regular maintenance checks, and using surge protectors or circuit breakers can help minimize the risk of short circuits in electrical devices.

In the next section, we will discuss some preventive measures you can take to reduce the likelihood of encountering short circuit problems.

Preventing Future Shorts

Taking proactive measures to prevent short circuits can help protect your electronic devices and ensure their long-term reliability. Here are some preventive measures to consider:

1. Proper Installation: When installing electronic devices or wiring, ensure that you follow the manufacturer’s guidelines and recommendations. This includes correctly connecting wires, securing connections, and using appropriate insulation materials.

2. Regular Maintenance: Perform routine maintenance checks on your electronic devices, especially those in critical systems or high-risk environments. Inspect wiring, connectors, and components for signs of wear, damage, or corrosion. Address any issues promptly to prevent short circuits.

3. Surge Protection: Install surge protectors or surge suppressors in electrical circuits to safeguard against voltage spikes or power surges. These devices help limit the voltage supplied to electronic devices and can prevent damage caused by sudden electrical fluctuations.

4. Adequate Ventilation: Ensure that electronic devices have proper ventilation to prevent overheating. Excessive heat can degrade components and insulation, increasing the risk of short circuits. Keep devices in well-ventilated areas and avoid obstructing air vents or cooling systems.

5. Proper Cable Management: Organize and secure cables to minimize the risk of accidental damage or interference. Avoid tightly bending or stressing cables, as this can lead to insulation damage and short circuits. Use cable ties or organizers to keep cables neat and secure.

6. Environment Awareness: Be mindful of the environment in which electronic devices are used. High humidity, extreme temperatures, or exposure to corrosive substances can accelerate component degradation and increase the likelihood of short circuits. Take appropriate measures to protect devices in these environments.

7. Professional Inspection: Consider scheduling periodic inspections by qualified technicians or electricians. They can conduct comprehensive assessments of your electrical systems, identifying and addressing potential issues before they lead to short circuits or other electrical problems.

By implementing these preventive measures, you can significantly reduce the risk of encountering short circuits in your electronic devices. Taking proactive steps to protect your equipment not only improves performance but also extends their lifespan.

In the next section, we will provide a summary of the key points discussed throughout this article, emphasizing the importance of understanding and addressing short circuit issues.