What is a Power Connector?

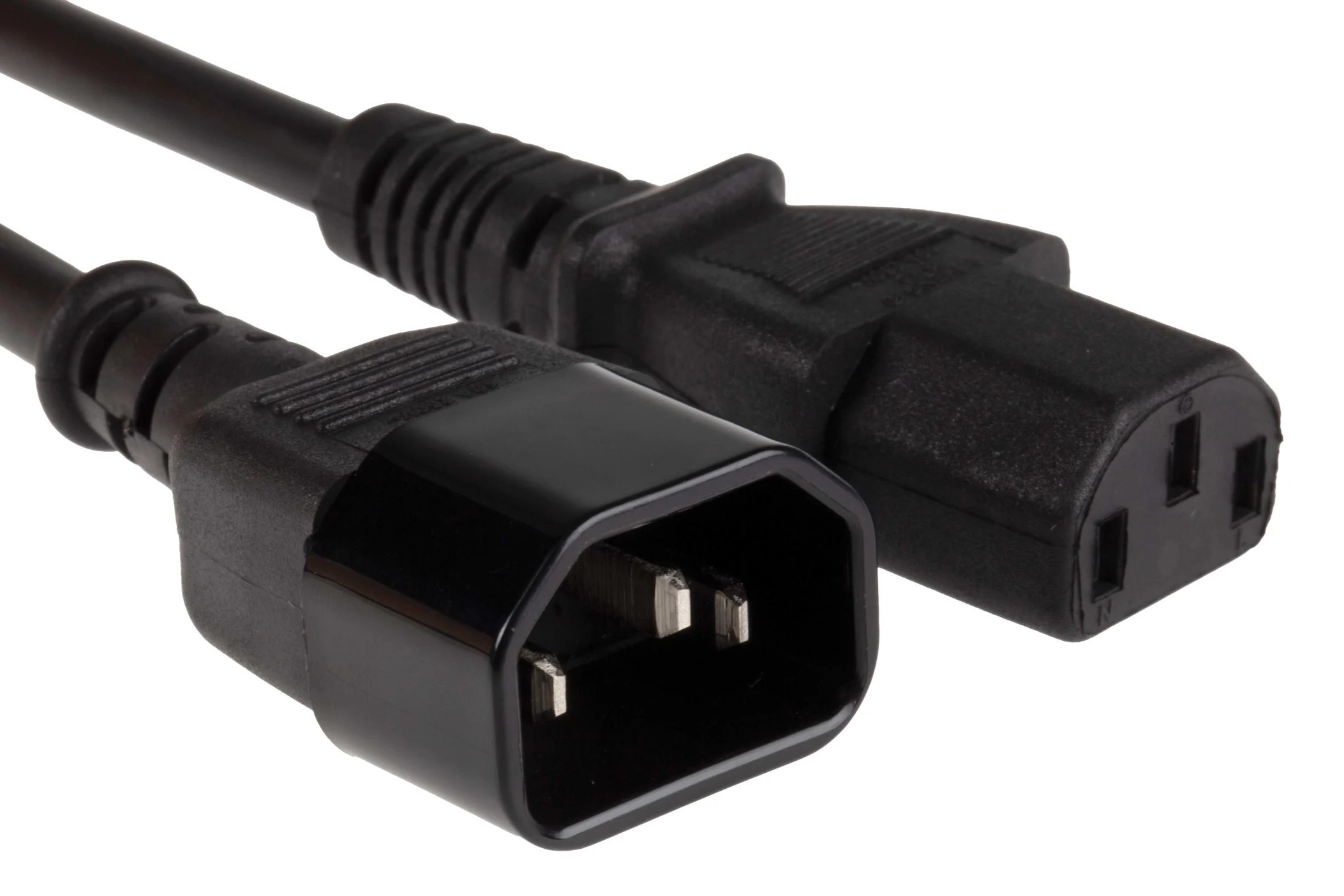

A power connector, also known as an electrical connector, is a crucial component used to transmit electrical power from one device to another. These connectors come in a variety of shapes and sizes, and they play a pivotal role in ensuring the seamless transfer of power between electronic devices. Essentially, a power connector serves as the interface between a power source and the device that requires power, enabling the flow of electricity to power the device's functionality.

Power connectors are designed to establish a secure and reliable electrical connection, typically comprising male and female components that fit together to form a complete circuit. They are commonly found in electronic devices, computer systems, industrial equipment, and various other applications where a stable power supply is essential.

Types of Power Connectors

Power connectors encompass a diverse range of types, each tailored to specific applications and requirements. Some of the most common power connector types include:

-

AC Power Connectors: These connectors are used for alternating current (AC) power transmission, commonly found in household appliances and electrical equipment.

-

DC Power Connectors: Designed for direct current (DC) power transmission, these connectors are prevalent in electronic devices, power supplies, and renewable energy systems.

-

Battery Connectors: Specifically crafted for connecting batteries to devices, these connectors are vital in portable electronics, electric vehicles, and energy storage systems.

-

Coaxial Power Connectors: Utilized for transmitting high-frequency signals and power, these connectors are widely used in telecommunications, medical devices, and aerospace applications.

-

Circular Connectors: These connectors feature a circular interface and are employed in industrial machinery, military equipment, and audio-visual devices.

-

Rectangular Connectors: Known for their rectangular shape, these connectors are commonly used in computer systems, automotive applications, and consumer electronics.

Understanding the purpose and functionality of these diverse power connectors is essential for selecting the most suitable option for a specific application.

In essence, power connectors serve as the vital link in the electrical circuit, enabling the seamless transfer of power to drive the functionality of various electronic devices and equipment. Their diverse types cater to specific needs, making them indispensable in numerous industries and applications.

[Include a brief transition to the next section to maintain the flow of the article.]Types of Power Connectors

Power connectors come in a diverse array of types, each tailored to specific applications and requirements. Understanding the distinctions between these types is crucial for selecting the most suitable connector for a particular use case. Here are some of the most common power connector types:

- AC Power Connectors: These connectors are designed for transmitting alternating current (AC) power and are commonly found in household appliances, industrial equipment, and electrical devices. They are crucial for ensuring a reliable power supply to a wide range of electrical systems.

- DC Power Connectors: Specifically crafted for transmitting direct current (DC) power, these connectors are prevalent in electronic devices, power supplies, and renewable energy systems. They play a vital role in facilitating the efficient transfer of DC power to drive the functionality of various devices.

- Battery Connectors: These connectors are designed to establish a secure connection between batteries and electronic devices. They are essential components in portable electronics, electric vehicles, and energy storage systems, enabling the seamless transmission of power from the battery to the device.

- Coaxial Power Connectors: Widely used for transmitting high-frequency signals and power, coaxial power connectors find applications in telecommunications, medical devices, aerospace systems, and other industries where the reliable transmission of power and signals is critical.

- Circular Connectors: Featuring a circular interface, these connectors are employed in industrial machinery, military equipment, and audio-visual devices. Their robust design and versatility make them suitable for demanding applications where a secure and reliable power connection is essential.

- Rectangular Connectors: Known for their rectangular shape, these connectors are commonly used in computer systems, automotive applications, and consumer electronics. Their distinct form factor and compatibility with various devices make them integral components in modern electronic systems.

Each type of power connector serves a specific purpose and is engineered to meet the unique demands of different applications. Understanding the characteristics and applications of these connectors is essential for making informed decisions when selecting the most appropriate connector for a particular electrical system.

By familiarizing oneself with the diverse types of power connectors, individuals and businesses can ensure the seamless and efficient transmission of power in various electronic devices and equipment, contributing to the optimal performance and reliability of electrical systems.

[Include a brief transition to the next section to maintain the flow of the article.]Importance of Power Connectors

Power connectors play a pivotal role in ensuring the reliable and efficient transmission of electrical power in a wide range of electronic devices and systems. Their significance extends across various industries and applications, making them indispensable components in modern technology. Here are key reasons highlighting the importance of power connectors:

- Reliable Power Transmission: Power connectors are essential for establishing a secure and reliable electrical connection, ensuring the uninterrupted transmission of power from a source to a device. This reliability is crucial for maintaining the consistent operation of electronic equipment and preventing power interruptions that could lead to system failures.

- Compatibility and Versatility: Power connectors are designed to accommodate diverse voltage and current requirements, catering to the specific needs of different devices and systems. Their versatility allows them to be utilized in a wide array of applications, ranging from consumer electronics to industrial machinery, contributing to the seamless integration of power sources with various electrical systems.

- Safety and Protection: High-quality power connectors are engineered with safety features to prevent electrical hazards such as short circuits, overloading, and voltage fluctuations. By incorporating protective mechanisms, power connectors safeguard both the devices they power and the individuals interacting with the equipment, enhancing overall safety in electrical systems.

- Efficient Power Management: Power connectors enable efficient power distribution and management, ensuring that electrical devices receive the appropriate power supply for optimal performance. By facilitating efficient power transfer, these connectors contribute to energy conservation and the effective utilization of electrical resources.

- Interconnectivity and Integration: In complex electronic systems, power connectors serve as the interface that enables the seamless interconnection of various components and subsystems. Their ability to facilitate integration and interconnectivity is vital for the overall functionality and performance of interconnected electronic devices and equipment.

The importance of power connectors lies in their ability to provide a stable and secure electrical interface, ensuring the reliable transmission of power while addressing compatibility, safety, and efficiency considerations. Their role in powering and safeguarding electronic systems underscores their significance in modern technology and industrial applications.

Understanding the critical importance of power connectors is essential for individuals and businesses seeking to optimize the performance, safety, and reliability of their electrical systems, thereby underscoring the pivotal role of these connectors in the realm of technology and engineering.

[Include a brief transition to the next section to maintain the flow of the article.]How to Choose the Right Power Connector

Choosing the right power connector is crucial for ensuring optimal performance, reliability, and safety in electrical systems. Given the diverse types and specifications of power connectors available, selecting the most suitable connector requires careful consideration of several key factors. Here are essential guidelines for choosing the right power connector:

- Electrical Specifications: Assess the voltage, current, and frequency requirements of the electrical system to determine the appropriate electrical specifications for the power connector. Matching the connector’s electrical ratings with the system’s requirements is crucial for safe and efficient power transmission.

- Mechanical Compatibility: Consider the physical dimensions, form factor, and mounting requirements of the power connector to ensure compatibility with the device or equipment it will be connected to. Mechanical compatibility is essential for seamless integration and reliable operation of the connector within the system.

- Environmental Considerations: Evaluate the environmental conditions in which the electrical system will operate, including factors such as temperature, moisture, and exposure to chemicals or contaminants. Select a power connector with appropriate environmental ratings and protective features to ensure resilience in challenging operating environments.

- Connector Type and Configuration: Determine the most suitable connector type based on the specific application, such as AC or DC power transmission, battery connections, or high-frequency signal transmission. Additionally, consider the connector’s configuration, such as the number of pins or contacts, to accommodate the system’s connectivity requirements.

- Reliability and Durability: Prioritize power connectors known for their reliability, durability, and long-term performance. Look for connectors with robust construction, secure locking mechanisms, and proven track records of withstanding mechanical stress and environmental factors, ensuring the longevity of the electrical connection.

By carefully evaluating these factors and considering the specific requirements of the electrical system, individuals and businesses can make informed decisions when selecting the right power connector. Choosing a connector that aligns with the system’s electrical, mechanical, and environmental needs is essential for achieving optimal performance and safety.

Ultimately, the process of choosing the right power connector involves a comprehensive assessment of technical specifications, compatibility, environmental resilience, and reliability, culminating in the selection of a connector that meets the unique demands of the electrical system it will power.

[Include a brief transition to the next section to maintain the flow of the article.]Common Issues with Power Connectors

Power connectors, despite their critical role in electrical systems, are susceptible to several common issues that can affect their performance and reliability. Understanding these issues is essential for proactive maintenance and troubleshooting. Here are some prevalent problems associated with power connectors:

- Loose Connections: One of the most frequent issues is the development of loose connections, which can lead to intermittent power supply, voltage fluctuations, and system malfunctions. Loose connections may result from wear and tear, improper installation, or inadequate locking mechanisms, necessitating timely inspection and re-securing of the connectors.

- Corrosion and Oxidation: Over time, power connectors can be affected by corrosion and oxidation, especially in environments with high humidity, moisture, or exposure to corrosive substances. The accumulation of corrosion and oxidation can hinder electrical conductivity, leading to increased resistance and potential overheating, necessitating regular cleaning and maintenance to mitigate these effects.

- Mechanical Damage: Power connectors are susceptible to mechanical damage from impacts, bending, or improper handling. Such damage can compromise the structural integrity of the connectors, leading to misalignment, deformation, or breakage, ultimately impacting their electrical performance. Proper handling and protection of connectors are essential to prevent mechanical damage.

- Overheating and Thermal Stress: Inadequate power distribution, high current loads, or environmental factors can contribute to overheating and thermal stress in power connectors. Prolonged exposure to elevated temperatures can degrade the connector’s materials, insulation, and contact surfaces, posing risks of electrical arcing, insulation breakdown, and fire hazards.

- Compatibility Issues: Mismatched connectors, incompatible pin configurations, or improper mating of male and female components can lead to compatibility issues, resulting in poor electrical contact, signal interference, or damage to the connectors. Ensuring proper compatibility and alignment during connector installation is crucial for mitigating these issues.

Addressing these common issues with power connectors requires proactive maintenance, periodic inspections, and adherence to best practices in connector installation and handling. By identifying and mitigating these issues early, individuals and businesses can sustain the optimal performance and reliability of their electrical systems.

Recognizing and addressing these common issues underscores the importance of proactive maintenance and care for power connectors, ultimately contributing to the longevity and effectiveness of electrical connections in various applications.

[Include a brief transition to the next section to maintain the flow of the article.]Maintenance and Care for Power Connectors

Proper maintenance and care are essential for preserving the functionality, reliability, and safety of power connectors in electrical systems. By adhering to best practices and implementing routine maintenance measures, individuals and organizations can mitigate common issues and ensure the longevity of power connectors. Here are key guidelines for the maintenance and care of power connectors:

- Regular Inspection: Conduct periodic visual inspections of power connectors to identify signs of wear, corrosion, or mechanical damage. Inspect the contacts, housings, and locking mechanisms to ensure they are intact and free from debris, corrosion, or other contaminants that may compromise electrical performance.

- Cleaning and Lubrication: Clean power connectors using appropriate methods and solutions to remove dirt, dust, and corrosion. Apply suitable contact lubricants or protective coatings to prevent oxidation and enhance the conductivity of the connector contacts, particularly in environments prone to moisture and corrosion.

- Tightening and Securement: Verify the tightness and securement of power connectors to prevent loose connections that can lead to electrical resistance and intermittent power supply. Follow manufacturer-recommended torque specifications when tightening connectors to ensure proper engagement and electrical continuity.

- Environmental Protection: Shield power connectors from environmental elements such as moisture, chemicals, and excessive heat. Implement protective measures such as gaskets, seals, and enclosures to safeguard connectors from environmental factors that could compromise their electrical integrity and structural durability.

- Proper Handling and Installation: Train personnel on the proper handling, installation, and mating of power connectors to prevent mechanical damage, misalignment, and compatibility issues. Adhere to industry standards and guidelines for connector installation to ensure optimal electrical performance and longevity.

By incorporating these maintenance practices into regular operational procedures, individuals and organizations can uphold the performance and reliability of power connectors, contributing to the overall safety and efficiency of electrical systems.

Emphasizing the significance of proactive maintenance and care for power connectors underscores their critical role in ensuring the seamless transmission of electrical power and signals in diverse applications. By prioritizing maintenance and care, individuals and businesses can optimize the performance and longevity of power connectors, thereby enhancing the reliability and safety of electrical connections.

Implementing these maintenance and care practices is essential for preserving the integrity and functionality of power connectors, ultimately contributing to the sustained reliability and safety of electrical systems across various industries and applications.