What is an IDC Connector?

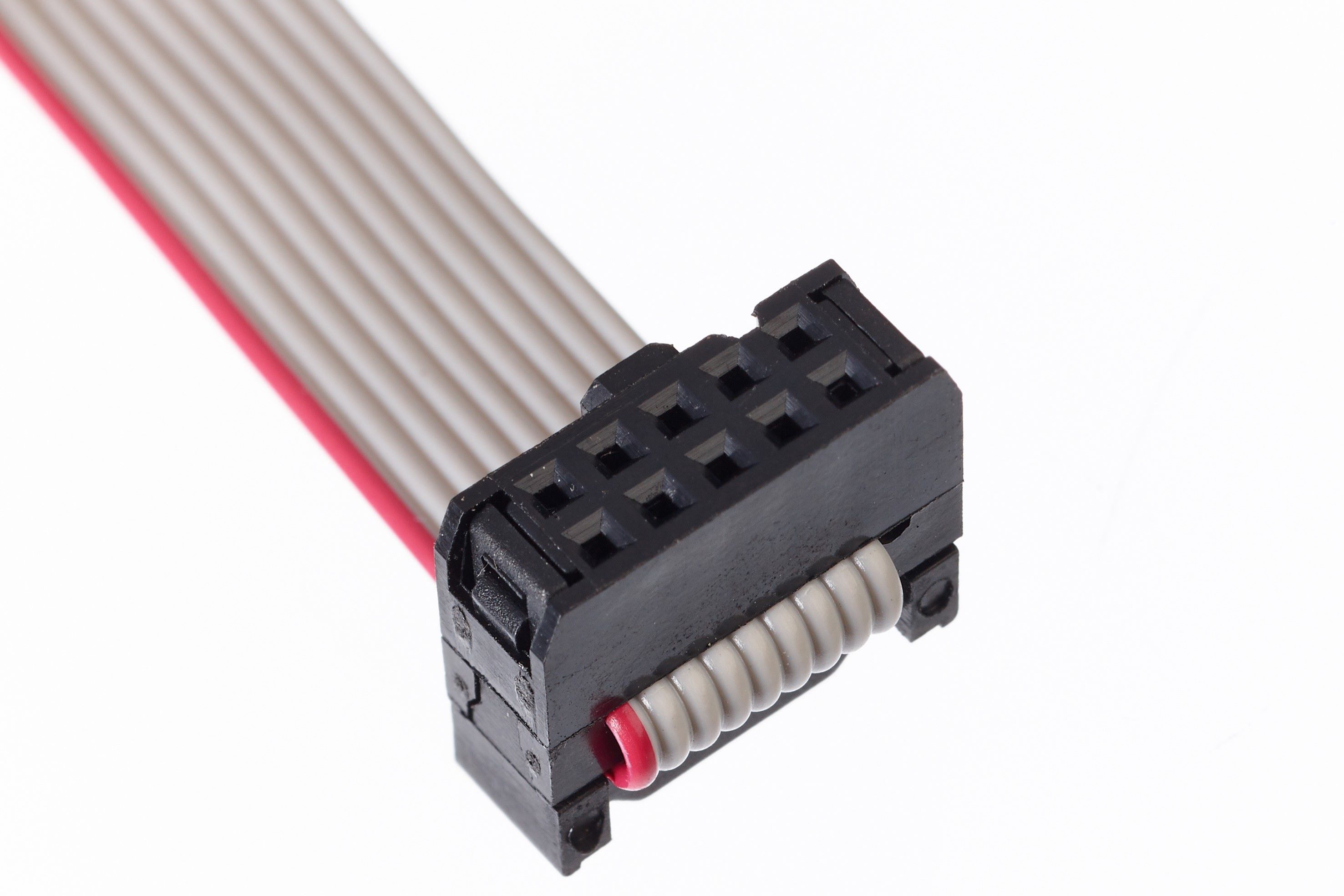

An Insulation Displacement Connector (IDC) is a type of electrical connector that is commonly used to terminate flat cables. It is designed to make the process of connecting wires to the connector easier and more efficient. The IDC connector features sharp, specially shaped contacts that displace the insulation of the cable to make a connection, eliminating the need for stripping the insulation before termination.

IDC connectors are widely utilized in various electronic and electrical applications due to their convenience and reliability. They are commonly found in telecommunications equipment, computer peripherals, automotive electronics, and other consumer electronic devices.

The design of the IDC connector allows for quick and secure terminations, making it a popular choice for both professionals and hobbyists working on electronic projects. Its ease of use and robust connection make it an essential component in many electronic systems.

The IDC connector is available in various configurations to accommodate different cable sizes and pin counts, making it versatile for a wide range of applications. Its simple yet effective design has made it a go-to choice for connecting flat cables in various electronic devices and systems.

In summary, the IDC connector is a specialized electrical connector designed to simplify the process of terminating flat cables. Its unique design and ease of use have made it an indispensable component in a wide array of electronic applications.

How Does an IDC Connector Work?

The operation of an Insulation Displacement Connector (IDC) is based on a simple yet ingenious principle. When a flat cable is inserted into the connector, the sharp, specially shaped contacts within the connector pierce through the insulation of the individual conductors, establishing a direct connection with the metal conductor inside the cable. This displacement of insulation creates a secure and reliable electrical connection without the need for stripping the cable beforehand.

The IDC connector’s contacts are precisely engineered to ensure proper contact with the conductors while maintaining the insulation displacement mechanism. This design allows for consistent and reliable terminations, minimizing the risk of poor connections or signal interference.

One of the key advantages of IDC connectors is their ability to accommodate multiple conductors within a single connector, simplifying the process of connecting cables with numerous conductors. This feature makes IDC connectors particularly useful in applications where space is limited, and a high density of connections is required.

Furthermore, the IDC connector’s design enables quick and easy termination, reducing the time and effort required to connect flat cables. This efficiency is especially valuable in mass production or assembly line environments, where speed and accuracy are essential.

In essence, the IDC connector works by utilizing insulation displacement contacts to establish secure electrical connections with the conductors of flat cables. Its straightforward operation, combined with its reliability and efficiency, makes it a preferred choice for a wide range of electronic and electrical applications.

Types of IDC Connectors

There are several types of Insulation Displacement Connectors (IDC) designed to accommodate different cable configurations and applications:

- Ribbon Cable IDC Connectors: These connectors are specifically tailored for ribbon cables, which consist of multiple conductors arranged in parallel. Ribbon cable IDC connectors come in various configurations to match the pin counts and spacing of ribbon cables, providing a reliable and efficient means of terminating these types of cables.

- D-sub IDC Connectors: D-sub connectors, commonly used in computer and data communication applications, are also available in IDC configurations. These connectors are designed to terminate flat cables in D-sub formats, offering a convenient solution for connecting flat cables to D-sub interfaces.

- Modular IDC Connectors: Modular connectors, such as RJ45 connectors used in Ethernet networking, are available in IDC versions. These connectors simplify the termination of flat cables in networking and telecommunications applications, ensuring consistent and secure connections for data transmission.

- Boxed IDC Connectors: Boxed IDC connectors feature a protective housing that encloses the termination area, providing added protection and strain relief for the terminated cables. These connectors are commonly used in industrial and harsh environment applications where cable integrity and durability are crucial.

Each type of IDC connector is designed to cater to specific cable types and applications, offering efficient and reliable termination solutions for different electronic and electrical systems.

Additionally, IDC connectors come in various pin counts and configurations to accommodate different cable sizes and connection requirements. This versatility makes IDC connectors suitable for a wide range of applications, from consumer electronics to industrial machinery.

Applications of IDC Connectors

Insulation Displacement Connectors (IDC) find widespread use in a diverse array of electronic and electrical applications due to their efficiency and reliability. Some common applications of IDC connectors include:

- Telecommunications Equipment: IDC connectors are extensively used in telecommunications equipment, such as modems, routers, and telephone systems, for terminating flat cables in data and voice communication applications. Their ability to quickly and securely terminate multiple conductors makes them ideal for telecommunications infrastructure.

- Computer Peripherals: In the realm of computer hardware, IDC connectors are employed in various peripherals, including disk drives, printers, and internal cabling within computer systems. Their ease of use and consistent performance make them a preferred choice for connecting flat cables in these devices.

- Automotive Electronics: IDC connectors play a vital role in automotive electronics, where they are utilized for connecting flat cables in vehicle control systems, infotainment systems, and onboard diagnostic interfaces. Their reliability and space-saving design make them well-suited for automotive applications.

- Consumer Electronics: From home entertainment systems to kitchen appliances, IDC connectors are integrated into a wide range of consumer electronics for connecting internal components and peripherals. Their efficient termination process and secure connections contribute to the overall reliability of these devices.

- Industrial Machinery: In industrial settings, IDC connectors are employed in machinery and equipment for connecting control panels, sensors, and other electrical components. Their ability to accommodate multiple conductors and provide secure terminations makes them valuable in industrial automation and control systems.

These applications represent just a few examples of the diverse uses of IDC connectors across various industries. Their versatility and reliability make them indispensable in the design and manufacturing of electronic and electrical systems.

Advantages of IDC Connectors

Insulation Displacement Connectors (IDC) offer several distinct advantages that make them a preferred choice for terminating flat cables in electronic and electrical systems:

- Efficient Termination: IDC connectors allow for quick and efficient termination of flat cables without the need for stripping insulation, saving time and effort during the assembly process.

- Reliable Connections: The insulation displacement mechanism of IDC connectors ensures consistent and secure electrical connections, minimizing the risk of signal interference or connection failures.

- Space-saving Design: IDC connectors are compact and can accommodate multiple conductors within a single connector, making them suitable for applications where space is limited.

- Versatility: IDC connectors are available in various configurations to accommodate different cable sizes, pin counts, and formats, allowing for flexibility in design and application.

- Ease of Use: The straightforward termination process of IDC connectors makes them accessible to both professionals and hobbyists, contributing to their widespread adoption in electronic projects and systems.

- Cost-effective Solution: The efficiency and reliability of IDC connectors result in cost savings during assembly and maintenance, making them an economical choice for connecting flat cables.

These advantages collectively position IDC connectors as a practical and reliable solution for terminating flat cables in a wide range of electronic and electrical applications. Their ease of use, space-saving design, and consistent performance make them indispensable components in modern electronic systems.

Considerations for Using IDC Connectors

While Insulation Displacement Connectors (IDC) offer numerous benefits, there are important considerations to keep in mind when using them in electronic and electrical applications:

- Cable Compatibility: It is crucial to ensure that the IDC connector is compatible with the specific type and size of flat cable being used. Different IDC connectors are designed to accommodate varying cable configurations, and selecting the appropriate connector is essential for reliable terminations.

- Termination Tools: Using the correct termination tools is essential for achieving secure and reliable connections with IDC connectors. Employing proper tools and following manufacturer guidelines for termination procedures is imperative to ensure optimal performance.

- Environmental Conditions: Consider the environmental factors in which the IDC connectors will be utilized. In harsh or demanding environments, such as industrial settings or automotive applications, it may be necessary to select IDC connectors with enhanced durability and resistance to environmental stressors.

- Connector Orientation: Pay attention to the orientation and positioning of IDC connectors within the system. Proper alignment and secure mounting of the connectors contribute to the overall integrity and longevity of the connections.

- Quality and Reliability: Selecting high-quality IDC connectors from reputable manufacturers is essential to ensure long-term reliability and performance. Prioritizing quality components contributes to the overall dependability of the electrical connections.

- Testing and Validation: Conducting thorough testing and validation of IDC connections is critical to verify their integrity and functionality. Regular inspections and testing procedures help identify and address any potential issues before they impact the system’s performance.

By carefully considering these factors and adhering to best practices for the selection and installation of IDC connectors, engineers and technicians can maximize the effectiveness and reliability of these connectors in their electronic and electrical designs.