The Importance of Waterproof Adhesive in Phone Manufacturing

Waterproof adhesive plays a pivotal role in the manufacturing of phones, ensuring the durability and longevity of these devices. As smartphones have become an indispensable part of modern life, the need for reliable and long-lasting construction has never been greater. Waterproof adhesive is essential in this regard, as it provides a protective barrier against moisture, dust, and other environmental factors that could potentially damage the internal components of a phone.

One of the primary reasons for the importance of waterproof adhesive in phone manufacturing is the need to safeguard delicate electronic circuitry from water and other liquids. Without this crucial protective layer, phones would be highly susceptible to water damage, leading to malfunctions and ultimately rendering the devices inoperable. Moreover, waterproof adhesive also prevents the ingress of dust and other contaminants, which could compromise the functionality of the phone over time.

Furthermore, the use of waterproof adhesive enhances the overall resilience of phones, making them more resistant to everyday wear and tear. This is particularly significant given the portable nature of smartphones, which are constantly exposed to various environmental hazards. By effectively sealing the internal components, waterproof adhesive contributes to the structural integrity of the device, thereby prolonging its lifespan and ensuring a reliable performance throughout its use.

In addition to protecting the internal circuitry, waterproof adhesive also contributes to the aesthetic appeal of phones. By creating a seamless and impermeable bond between components, it enables manufacturers to design sleek and slim devices without compromising on durability. This is crucial in meeting consumer demands for stylish and robust smartphones that can withstand the rigors of daily use.

Moreover, the incorporation of waterproof adhesive in phone manufacturing aligns with the industry's commitment to sustainability. By extending the lifespan of phones and reducing the likelihood of premature device failure, this adhesive helps minimize electronic waste, thereby supporting environmental conservation efforts.

In essence, the importance of waterproof adhesive in phone manufacturing cannot be overstated. Its role in protecting internal components, enhancing device resilience, maintaining aesthetic appeal, and promoting sustainability underscores its indispensable nature in the production of modern smartphones. As technology continues to advance, the significance of waterproof adhesive will only grow, further solidifying its position as a fundamental component in phone manufacturing.

Properties of Waterproof Adhesive

Waterproof adhesives used in phone manufacturing possess a diverse range of properties that are essential for ensuring the integrity and functionality of the devices. These properties not only contribute to the effective sealing of internal components but also play a crucial role in enhancing the overall performance and durability of smartphones.

One of the primary properties of waterproof adhesive is its ability to form a strong and resilient bond between different materials. This ensures that the internal components of the phone remain securely in place, even when subjected to external stresses and environmental factors. Additionally, the adhesive’s capacity to adhere to various surfaces, including metal, plastic, and glass, is vital for creating a comprehensive seal within the device.

Furthermore, waterproof adhesives exhibit exceptional resistance to moisture and other liquid substances. This impermeability is essential for safeguarding the internal circuitry of the phone, preventing water intrusion that could lead to corrosion and electrical damage. By effectively repelling liquids, the adhesive helps maintain the operational integrity of the device, even in challenging environmental conditions.

In addition to being waterproof, these adhesives often demonstrate high thermal stability, with the ability to withstand a wide range of temperatures without compromising their adhesive properties. This characteristic is crucial for ensuring that the adhesive remains effective in diverse operating environments, including both extreme cold and heat. Moreover, the thermal stability of the adhesive contributes to the overall resilience of the phone, allowing it to function reliably under varying climatic conditions.

Another important property of waterproof adhesive is its flexibility and impact resistance. These adhesives are engineered to absorb and distribute mechanical stresses, thereby providing a degree of cushioning and protection for the internal components of the phone. This flexibility is particularly significant in mitigating the effects of physical shocks and vibrations, which the device may encounter during everyday use.

Moreover, many waterproof adhesives exhibit excellent chemical resistance, ensuring that they remain unaffected by exposure to common substances such as oils, solvents, and cleaning agents. This resistance contributes to the long-term stability of the adhesive bond, further enhancing the durability of the phone’s construction.

Application of Waterproof Adhesive in Phone Manufacturing

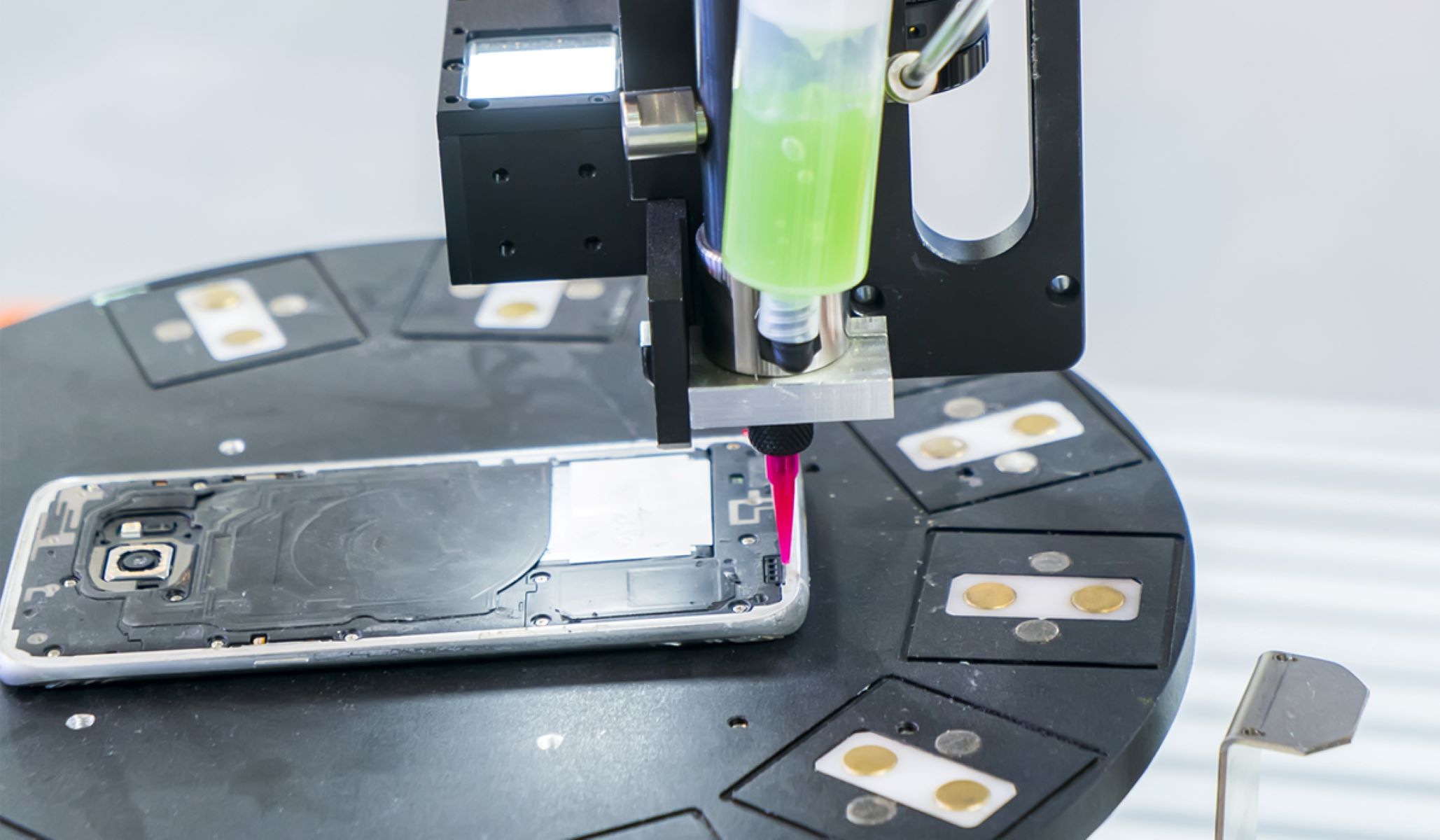

The application of waterproof adhesive in phone manufacturing is a critical process that involves precise techniques to ensure the effective sealing and protection of internal components. This adhesive is strategically applied at various stages of the manufacturing process, playing a pivotal role in enhancing the durability and reliability of smartphones.

One of the primary applications of waterproof adhesive is in securing the display assembly to the phone’s frame. This process involves the precise application of the adhesive along the edges of the display, creating a secure bond that not only prevents moisture ingress but also contributes to the structural integrity of the device. The adhesive’s ability to adhere to both glass and metal surfaces is crucial in this application, ensuring a robust and enduring connection.

Additionally, waterproof adhesive is utilized in the sealing of the phone’s housing, encompassing the areas where the front and back panels meet the frame. This sealing process is essential for creating a barrier against water, dust, and other contaminants, thereby safeguarding the internal circuitry of the device. The adhesive’s impermeability and resistance to environmental factors are instrumental in maintaining the phone’s operational functionality under diverse conditions.

Moreover, the application of waterproof adhesive extends to the assembly of internal components within the phone. This includes securing delicate circuit boards, connectors, and other electronic elements in place, ensuring that they remain protected from moisture and mechanical stresses. The adhesive’s ability to form strong and reliable bonds is critical in this application, as it contributes to the long-term stability and performance of the device.

Furthermore, waterproof adhesive is employed in the construction of camera modules, speakers, and other specialized components within the phone. These applications demand precise and controlled dispensing of the adhesive to achieve optimal sealing and adhesion, thereby enhancing the overall resilience and functionality of the device’s auxiliary features.

Additionally, the application of waterproof adhesive is integrated into the manufacturing of specialized phone models designed for rugged or outdoor use. In these instances, the adhesive plays a crucial role in fortifying the device against environmental hazards, including water immersion, extreme temperatures, and mechanical impacts, thereby ensuring the phone’s suitability for challenging operating conditions.

Overall, the application of waterproof adhesive in phone manufacturing encompasses a diverse array of processes, each contributing to the robustness, reliability, and longevity of the devices. Through meticulous application and integration into various assembly stages, waterproof adhesive serves as a cornerstone in ensuring the durability and resilience of modern smartphones.

Benefits of Using Waterproof Adhesive in Phone Manufacturing

The utilization of waterproof adhesive in phone manufacturing yields a multitude of benefits that significantly enhance the quality, durability, and reliability of smartphones. These advantages extend beyond mere water resistance, encompassing various aspects that contribute to the overall performance and longevity of the devices.

One of the primary benefits of using waterproof adhesive is the enhanced durability it provides to smartphones. By effectively sealing the internal components and creating a protective barrier against moisture and dust, the adhesive ensures that the devices remain resilient in the face of environmental challenges. This durability translates to a longer lifespan for the phones, reducing the likelihood of premature failure and the associated need for repairs or replacements.

Moreover, the incorporation of waterproof adhesive contributes to the overall reliability of smartphones. The impermeable seal created by the adhesive safeguards the internal circuitry from water damage, thereby minimizing the risk of malfunctions and operational disruptions. This reliability is crucial for ensuring consistent performance and functionality, especially in situations where the phone is exposed to moisture or humid conditions.

Additionally, using waterproof adhesive enhances the resistance of smartphones to environmental factors, including water immersion, humidity, and dust. This expanded resilience makes the devices suitable for a wider range of operating environments, allowing users to confidently use their phones in various outdoor settings without concerns about potential damage due to exposure to water or other elements.

Furthermore, the application of waterproof adhesive enables phone manufacturers to design sleek and aesthetically appealing devices without compromising on durability. The adhesive’s ability to create a seamless and impermeable bond between components facilitates the production of slim and stylish smartphones that meet consumer demands for both elegance and robustness. This balance between form and function is a significant benefit in the competitive smartphone market.

Moreover, the use of waterproof adhesive aligns with sustainability efforts in the electronics industry. By extending the lifespan of smartphones and reducing the incidence of water-related damage, the adhesive contributes to minimizing electronic waste. This aligns with the growing emphasis on environmental responsibility and the reduction of the industry’s ecological footprint.

In essence, the benefits of using waterproof adhesive in phone manufacturing extend far beyond water resistance, encompassing enhanced durability, reliability, environmental resilience, design flexibility, and sustainability. These advantages collectively contribute to the production of smartphones that not only meet the evolving needs of consumers but also demonstrate a commitment to quality, longevity, and environmental consciousness.

Challenges in Using Waterproof Adhesive in Phone Manufacturing

While the application of waterproof adhesive in phone manufacturing offers numerous benefits, it also presents several challenges that manufacturers must address to ensure the successful integration of this crucial component in smartphone construction.

One of the primary challenges lies in achieving a balance between effective sealing and maintaining the desired aesthetic appeal of the device. The application of waterproof adhesive must not compromise the sleek and stylish design of modern smartphones, necessitating meticulous engineering and precision in the adhesive application process. Manufacturers face the challenge of seamlessly integrating the adhesive while preserving the visual attractiveness of the device, as any imperfections or excess adhesive can detract from the overall aesthetic appeal.

Moreover, ensuring consistent and uniform application of waterproof adhesive across large-scale production presents a significant challenge. The precise dispensing and distribution of the adhesive require advanced manufacturing techniques and quality control measures to maintain a high standard of sealing effectiveness. Variations in adhesive application can lead to inconsistencies in water resistance, potentially compromising the reliability and durability of the devices.

Another notable challenge in using waterproof adhesive is the need to accommodate the evolving designs and form factors of smartphones. As devices continue to adopt new shapes, sizes, and materials, manufacturers must adapt the adhesive application processes to ensure compatibility with these advancements. This necessitates ongoing research and development to engineer adhesives that can effectively seal diverse device configurations without impeding the design innovations.

Furthermore, the compatibility of waterproof adhesive with other materials and components within the phone poses a challenge. The adhesive must exhibit strong bonding capabilities with a variety of substrates, including glass, metal, and plastic, while also being compatible with electronic components and other adhesives used in the assembly process. Achieving compatibility across these diverse materials without compromising performance remains a complex undertaking for manufacturers.

Additionally, the challenge of maintaining the adhesive’s performance under varying environmental conditions is a critical consideration. The adhesive must retain its waterproof properties and adhesion strength across a wide range of temperatures and humidity levels, ensuring consistent protection for the internal components of the phone. This necessitates rigorous testing and validation to confirm the adhesive’s resilience in diverse operating environments.

Overall, while the utilization of waterproof adhesive offers substantial benefits in phone manufacturing, addressing the challenges related to aesthetic integration, uniform application, design adaptability, material compatibility, and environmental resilience is essential for ensuring the successful implementation of this critical component in the production of reliable and resilient smartphones.

Future Developments in Waterproof Adhesive for Phone Manufacturing

The evolution of waterproof adhesive for phone manufacturing is poised to undergo significant advancements, driven by the ongoing pursuit of enhanced performance, sustainability, and adaptability to emerging technological trends. These future developments hold the potential to revolutionize the construction of smartphones, further elevating their durability, reliability, and environmental resilience.

One of the key areas of advancement in waterproof adhesive technology is the integration of nanomaterials and nanoengineering techniques. By leveraging nanotechnology, manufacturers can develop adhesives with superior water resistance and adhesion properties at the molecular level. This nanoscale engineering enables the creation of adhesives that form exceptionally strong and impermeable bonds, enhancing the overall durability and longevity of smartphones.

Furthermore, the future of waterproof adhesive development encompasses the exploration of bio-based and sustainable formulations. As the industry continues to emphasize environmental responsibility, the use of renewable and biodegradable materials in adhesive formulations is gaining traction. Future adhesives may incorporate bio-based polymers and environmentally friendly additives, reducing the ecological impact of smartphone production while maintaining high-performance waterproofing capabilities.

Moreover, advancements in additive manufacturing and 3D printing technologies are expected to influence the development of customized waterproof adhesives tailored to specific phone designs. These technologies enable the precise fabrication of adhesive structures that conform to intricate device geometries, optimizing the sealing and waterproofing of internal components. This customization contributes to the seamless integration of adhesive solutions in diverse smartphone configurations.

Another area of future development lies in the enhancement of self-healing properties in waterproof adhesives. Researchers are exploring the integration of self-healing mechanisms within adhesives, enabling them to autonomously repair minor cracks or damage caused by mechanical stresses. This self-healing capability can prolong the effectiveness of the adhesive over the phone’s lifespan, contributing to long-term water resistance and device reliability.

Additionally, the future of waterproof adhesive development entails the refinement of multi-material bonding capabilities. Adhesives that can effectively bond dissimilar materials, such as glass to metal or plastic to ceramic, will be instrumental in accommodating the evolving designs and material compositions of future smartphones. This advancement supports the seamless assembly of complex device structures while maintaining robust waterproofing.

Furthermore, the integration of smart adhesive technologies, such as sensors and indicators that detect and signal potential adhesive degradation or water intrusion, is a promising avenue for future development. These intelligent adhesive systems can provide real-time feedback on the integrity of the waterproof seal, enabling proactive maintenance and enhancing the reliability of smartphone waterproofing.