Precautions Before Removing the Airbag Connector

Precautions Before Removing the Airbag Connector

Before attempting to remove an airbag connector, it is crucial to prioritize safety and adhere to specific precautions to prevent accidental deployment of the airbag. Airbags are designed to inflate rapidly upon impact, and mishandling the airbag connector can lead to serious injury or damage to the vehicle. Therefore, it is imperative to take the following precautions before initiating the removal process:

-

Disable the Vehicle Battery: Always start by disconnecting the vehicle battery to eliminate the risk of electrical surges that could trigger the airbag system. This step is vital in ensuring that the airbag remains inactive during the connector removal process.

-

Wait for a Minimum of 15 Minutes: After disconnecting the battery, it is essential to wait for at least 15 minutes before proceeding with the removal. This waiting period allows the residual electrical charge in the airbag system to dissipate, reducing the risk of accidental deployment.

-

Handle the Airbag Connector with Care: When working with the airbag connector, it is crucial to exercise extreme caution and handle the connector gently to avoid inadvertently triggering the airbag. Any rough handling or excessive force applied to the connector can lead to unintended deployment.

-

Use Anti-Static Measures: Employing anti-static measures, such as wearing an anti-static wrist strap, can help mitigate the risk of static electricity discharge, which could potentially activate the airbag system.

-

Refer to Vehicle-Specific Guidelines: Different vehicle models may have specific instructions or precautions related to airbag connector removal. It is essential to consult the vehicle's manual or manufacturer's guidelines to ensure compliance with recommended safety procedures.

-

Seek Professional Assistance if Uncertain: If there is any uncertainty or lack of experience in dealing with airbag connectors, it is advisable to seek assistance from a qualified automotive professional. Safety should always be the top priority when working with airbag systems.

By diligently observing these precautions, individuals can significantly reduce the likelihood of accidental airbag deployment and ensure a safe environment for removing the airbag connector.

Remember, safety should always be the foremost consideration when working with airbag connectors, and strict adherence to these precautions is paramount to prevent potential harm or injury.

Tools and Equipment Needed

Before embarking on the process of removing an airbag connector, it is essential to gather the necessary tools and equipment to facilitate a safe and efficient procedure. The following items are indispensable for this task:

- Socket Wrench Set: A socket wrench set with the appropriate socket sizes is crucial for disconnecting the vehicle battery terminals. Ensure that the socket sizes match the battery terminal connectors to facilitate a secure and proper fit.

- Anti-Static Wrist Strap: An anti-static wrist strap is essential for dissipating any static charge from the body, minimizing the risk of accidental activation of the airbag system due to electrostatic discharge.

- Vehicle Manual or Guidelines: It is imperative to have access to the vehicle’s manual or specific guidelines pertaining to the airbag system and connector removal. This resource provides crucial information on the location of the airbag connector and any model-specific instructions.

- Insulated Gloves: Insulated gloves serve as an additional safety measure, providing protection against potential electrical hazards when working with the vehicle’s battery and electrical connections.

- Flashlight: A reliable flashlight is indispensable for illuminating the area around the airbag connector, especially in dimly lit or confined spaces within the vehicle.

- Flat-Head Screwdriver: A flat-head screwdriver is useful for releasing the locking mechanism of the airbag connector, allowing for safe disconnection without causing damage to the connector or surrounding components.

- Protective Eyewear: Wearing protective eyewear is recommended to shield the eyes from any debris or accidental dislodgment of components during the airbag connector removal process.

By ensuring the availability of these tools and equipment, individuals can approach the task of removing an airbag connector with the necessary preparation and readiness to maintain safety and precision throughout the procedure.

Step 1: Disconnect the Vehicle Battery

Prior to initiating the removal of an airbag connector, the first crucial step is to disconnect the vehicle’s battery to ensure the deactivation of the airbag system and minimize the risk of electrical hazards. Follow these detailed instructions to safely disconnect the vehicle battery:

- Locate the Vehicle Battery: Identify the location of the vehicle’s battery within the engine compartment or the designated battery compartment in the vehicle. It is typically secured with a bracket and covered by a protective casing.

- Put on Insulated Gloves and Safety Glasses: Before proceeding, it is essential to prioritize safety by wearing insulated gloves to protect against potential electrical shocks and safety glasses to shield the eyes from any debris or accidental contact with battery components.

- Use a Socket Wrench to Loosen the Battery Terminals: Select the appropriate socket size from the wrench set and carefully loosen the nut securing the negative (black) terminal first, followed by the positive (red) terminal. Ensure that the wrench makes full contact with the nut to prevent slippage and potential damage to the terminals.

- Remove the Battery Terminals: Once the nuts are sufficiently loosened, carefully remove the battery terminals from their respective posts, starting with the negative terminal and then the positive terminal. Gently wiggle the terminals if they are firmly attached to the posts to facilitate safe removal without excessive force.

- Secure the Battery Terminals: After removing the terminals, carefully tuck them away from the battery posts to prevent accidental contact and re-securing. This step is crucial to avoid unintentional reconnection of the battery while working on the airbag connector.

- Wait for 15 Minutes: Allow a minimum of 15 minutes for the residual electrical charge to dissipate from the vehicle’s electrical system. This waiting period is critical to ensure the deactivation of the airbag system and mitigate the risk of accidental deployment during the airbag connector removal process.

By meticulously following these steps to disconnect the vehicle battery, individuals can effectively deactivate the airbag system and create a safe working environment for the subsequent removal of the airbag connector.

Step 2: Locate the Airbag Connector

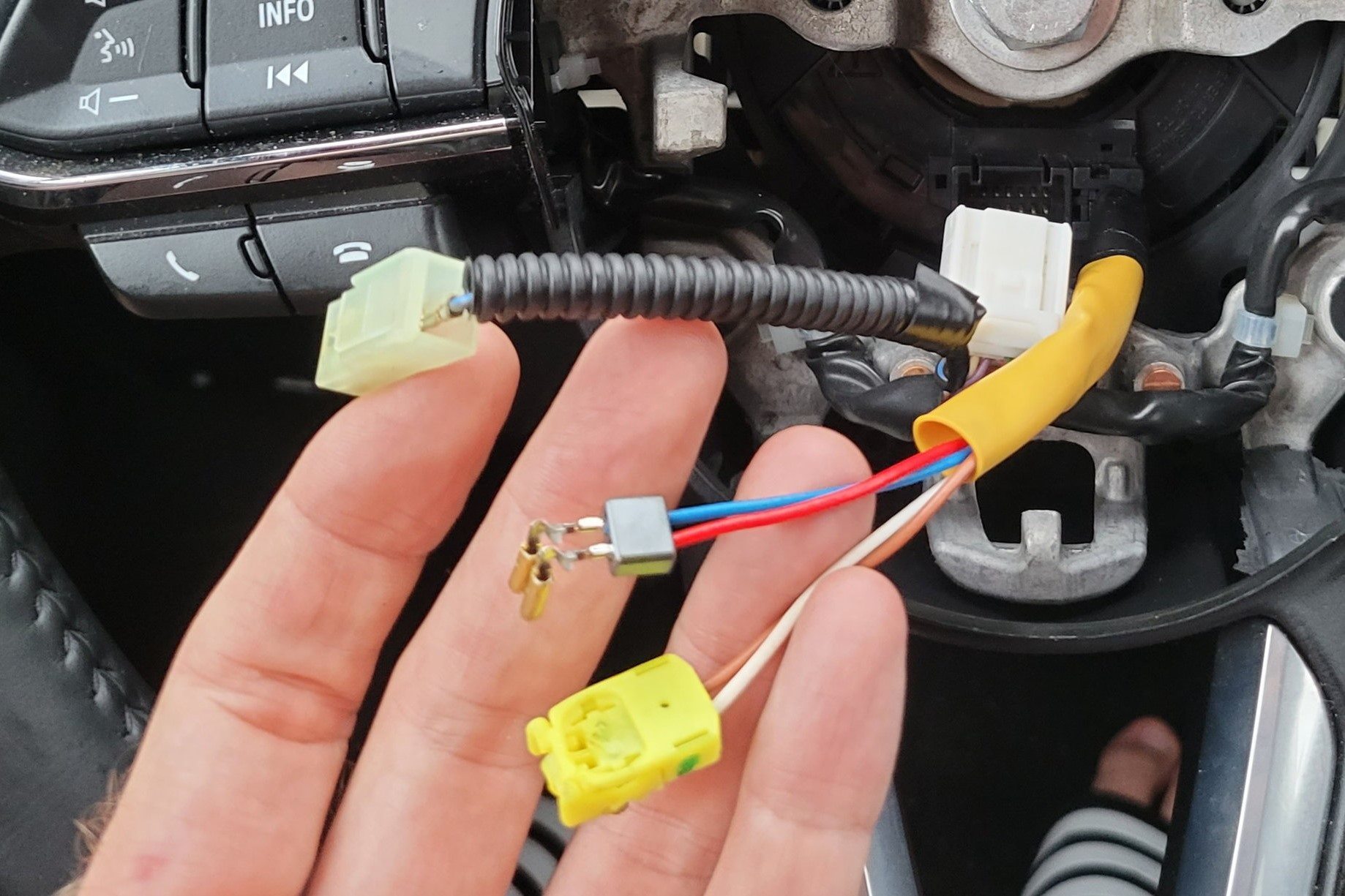

After safely disconnecting the vehicle’s battery, the next pivotal step in the process of removing an airbag connector is to locate the precise position of the connector within the vehicle. The airbag connector is typically situated within the vicinity of the steering column, dashboard, or the vehicle’s interior panels. To effectively locate the airbag connector, follow these systematic guidelines:

- Refer to the Vehicle Manual: Consult the vehicle’s manual or manufacturer’s guidelines to obtain specific details regarding the location of the airbag connector. The manual often provides comprehensive diagrams and descriptions to assist in identifying the precise position of the connector.

- Examine the Steering Column and Dashboard: Inspect the area around the steering column and dashboard, as the airbag connector is commonly positioned within these regions. Look for any visible wiring harnesses leading to the airbag module, which can guide you towards the location of the connector.

- Check Behind Interior Panels: In some vehicle models, the airbag connector may be concealed behind interior panels. Carefully remove the panels as per the vehicle manual’s instructions and visually examine the area for the presence of the airbag connector and its associated wiring.

- Utilize a Flashlight: In dimly lit areas or confined spaces within the vehicle, use a reliable flashlight to illuminate the surroundings and effectively identify the airbag connector. Proper lighting is essential for a clear and accurate inspection of the connector’s location.

- Exercise Caution and Patience: While locating the airbag connector, exercise patience and caution to avoid unnecessary force or manipulation of surrounding components. The connector may be secured in a manner that requires careful handling to prevent damage during the removal process.

By meticulously following these steps and exercising diligence in the search for the airbag connector, individuals can effectively pinpoint its location, laying the groundwork for the subsequent steps involved in safely disconnecting the connector from the airbag system.

Step 3: Identify the Locking Mechanism

Once the airbag connector is located, the next crucial step in the process of removing the connector is to identify and understand the locking mechanism that secures the connector in place. The locking mechanism may vary depending on the vehicle model and connector type. To effectively identify the locking mechanism, follow these systematic guidelines:

- Visual Inspection: Carefully examine the airbag connector to identify any visible locking components or mechanisms. These may include tabs, levers, or sliding locks that are designed to secure the connector firmly in place.

- Refer to the Vehicle Manual: Consult the vehicle’s manual or manufacturer’s guidelines to obtain specific details regarding the type of locking mechanism employed in the airbag connector. The manual often provides detailed illustrations and descriptions of the locking mechanism, aiding in its identification.

- Observe Surrounding Components: Take note of any adjacent components or structures near the airbag connector that may indicate the presence of a locking mechanism. Some connectors may be integrated into a larger housing or assembly, requiring careful observation to discern the locking mechanism.

- Exercise Caution: While inspecting the locking mechanism, exercise caution to avoid applying excessive force or inadvertently triggering the connector. Delicate handling is essential to prevent damage to the locking components and the connector itself.

- Document Findings: If necessary, document the specific details of the locking mechanism, including its location, type, and any unique features that may influence the removal process. This documentation can serve as a reference during the subsequent steps of disconnecting the airbag connector.

By meticulously following these steps and exercising diligence in identifying the locking mechanism, individuals can gain a comprehensive understanding of the connector’s securing mechanism, paving the way for a safe and successful removal process.

Step 4: Remove the Locking Mechanism

After identifying the locking mechanism securing the airbag connector, the next critical step is to carefully remove the locking components to facilitate the disconnection of the connector from the airbag system. This process requires precision and attention to detail to ensure the safe and effective removal of the locking mechanism. Follow these systematic guidelines to remove the locking mechanism:

- Prepare the Work Area: Clear the surrounding area to create a workspace conducive to performing delicate maneuvers. Ensure that there are no obstructions that may interfere with the removal of the locking mechanism.

- Utilize the Appropriate Tools: Depending on the type of locking mechanism, select the necessary tools, such as a flat-head screwdriver or a specialized release tool, to facilitate the safe removal of the locking components. It is crucial to use tools that match the requirements of the specific locking mechanism without causing damage to the connector.

- Follow Manufacturer’s Guidelines: Refer to the vehicle manual or manufacturer’s guidelines for any specific instructions related to the removal of the locking mechanism. Adhering to recommended procedures ensures compliance with manufacturer specifications and minimizes the risk of errors during the removal process.

- Apply Controlled Force: With the selected tool, apply controlled and deliberate force to disengage the locking mechanism. Exercise caution to avoid excessive pressure that may lead to damage or breakage of the locking components. Some locking mechanisms may require simultaneous manipulation of multiple components for successful removal.

- Observe and Verify Disengagement: As the locking mechanism is being manipulated, carefully observe and verify the gradual disengagement of the components. Ensure that the mechanism is fully released before proceeding to disconnect the airbag connector.

- Document the Removal Process: If necessary, document the steps involved in removing the locking mechanism, including any challenges encountered and the specific techniques employed. This documentation can serve as a reference for future maintenance or reassembly.

By meticulously following these steps and exercising precision in removing the locking mechanism, individuals can effectively prepare the airbag connector for disconnection, setting the stage for the subsequent steps in the safe removal process.

Step 5: Disconnect the Airbag Connector

With the locking mechanism successfully removed, the next pivotal step in the process of removing an airbag connector is to proceed with the disconnection of the connector from the airbag system. This step demands careful handling and adherence to safety protocols to prevent accidental deployment of the airbag. Follow these systematic guidelines to disconnect the airbag connector:

- Confirm Deactivation of the Airbag System: Prior to disconnecting the airbag connector, ensure that the vehicle’s battery remains disconnected and that a minimum of 15 minutes has elapsed since its disconnection. This waiting period allows the residual electrical charge in the airbag system to dissipate, reducing the risk of accidental deployment.

- Handle the Connector Gently: Exercise extreme caution and handle the airbag connector delicately to avoid inadvertently triggering the airbag. Any rough handling or excessive force applied to the connector can lead to unintended deployment, posing a significant safety risk.

- Depressurize the Airbag System (If Applicable): In some vehicle models, it may be necessary to depressurize the airbag system before disconnecting the connector. Refer to the vehicle manual or manufacturer’s guidelines for specific instructions on depressurizing the airbag system, if required.

- Disengage the Connector Locking Tabs or Latches: With the locking mechanism removed, carefully disengage any remaining tabs, latches, or securing features that hold the connector in place. Exercise patience and precision to avoid damage to the connector or its surrounding components.

- Disconnect the Connector: Once the locking tabs or latches are released, gently disconnect the airbag connector by firmly grasping the connector body and carefully separating it from the airbag system. Utilize even pressure and avoid twisting or bending the connector during the disconnection process.

- Secure the Disconnected Connector: After disconnecting the airbag connector, securely tuck it away from the airbag system to prevent accidental contact or reconnection. Take care to position the connector in a manner that ensures it remains isolated from the airbag and its components.

By diligently following these steps and exercising caution during the disconnection of the airbag connector, individuals can successfully remove the connector from the airbag system while prioritizing safety and precision throughout the process.

Step 6: Reconnect the Airbag Connector

After successfully disconnecting the airbag connector and performing necessary maintenance or inspection, the subsequent step involves the safe reconnection of the airbag connector to restore the functionality of the airbag system. This process demands meticulous attention to detail and adherence to safety measures to ensure the secure reattachment of the connector. Follow these systematic guidelines to reconnect the airbag connector:

- Inspect the Connector and Surroundings: Before proceeding with the reconnection, visually inspect the airbag connector and its surrounding components to ensure that no damage has occurred during the disconnection process. Verify that the connector and its terminals are free from debris or any signs of wear or corrosion.

- Align the Connector: Carefully align the airbag connector with the corresponding port or receptacle within the airbag system. Ensure that the connector terminals are correctly positioned for a secure and proper connection, avoiding any forced insertion that may lead to misalignment or damage.

- Apply Even Pressure: With gentle and even pressure, insert the airbag connector into the designated port, ensuring a snug and secure fit. Avoid excessive force or abrupt movements that could compromise the integrity of the connector or the airbag system.

- Engage the Locking Mechanism: If the airbag connector features a locking mechanism, carefully engage the locking tabs, latches, or securing features to firmly secure the connector in place. Verify that the locking mechanism is fully engaged to prevent accidental disconnection during vehicle operation.

- Perform a Visual Check: Conduct a thorough visual inspection to confirm that the airbag connector is securely attached and that all terminals are properly seated within the receptacle. Verify that the connector is free from any obstructions or interference that may impact its functionality.

- Reassemble Surrounding Components: If any interior panels or protective covers were removed during the disconnection process, reassemble them according to the vehicle manual’s instructions. Ensure that all components are securely fastened to maintain the integrity of the airbag system.

By meticulously following these steps and exercising precision during the reconnection of the airbag connector, individuals can ensure the reliable restoration of the airbag system’s functionality while upholding safety standards and proper maintenance practices.

Step 7: Reconnect the Vehicle Battery

Upon completing the reconnection of the airbag connector and ensuring its secure attachment, the final crucial step in the process of working with the airbag system involves the safe and deliberate reconnection of the vehicle’s battery. This step is essential to restore power to the vehicle’s electrical system and reactivate the airbag system while maintaining safety protocols. Follow these systematic guidelines to reconnect the vehicle battery:

- Verify Proper Alignment: Before initiating the reconnection, visually inspect the battery terminals to ensure that they are correctly aligned with their respective posts. Verify that the positive (red) terminal and the negative (black) terminal are positioned accurately for reattachment.

- Remove Insulated Gloves and Safety Glasses: As a precautionary measure, remove insulated gloves and safety glasses to ensure clear visibility and dexterity during the reconnection process. This step minimizes the risk of accidental slippage or mishandling of the battery terminals.

- Clean Battery Terminals (If Necessary): If the battery terminals exhibit signs of corrosion or buildup, gently clean them using a suitable battery terminal cleaning tool or a mixture of baking soda and water. Ensure that the terminals are free from any debris or oxidation that may impede the reconnection process.

- Reattach the Battery Terminals: Starting with the positive (red) terminal, carefully position it over the corresponding post and secure it in place by tightening the terminal nut with a socket wrench. Repeat this process for the negative (black) terminal, ensuring a snug and secure connection without over-tightening.

- Secure Battery Bracket and Casing: If the vehicle’s battery is secured by a bracket or enclosed within a protective casing, ensure that these components are reinstalled and fastened according to the manufacturer’s specifications. Properly securing the battery enhances its stability and minimizes the risk of displacement.

- Perform a Voltage Check: Utilize a multimeter or a voltage tester to verify that the battery is delivering the appropriate voltage after reconnection. This step ensures that the battery is functioning correctly and that the vehicle’s electrical system is operational.

- Conduct a System Check: After reconnecting the battery, perform a comprehensive system check to ensure that all vehicle functions, including the airbag system, are operational. Start the vehicle and verify that the airbag system indicator light behaves as expected, indicating the system’s readiness and functionality.

By diligently following these steps and exercising caution during the reconnection of the vehicle battery, individuals can effectively restore power to the vehicle’s electrical system and reactivate the airbag system while upholding safety standards and proper maintenance practices.