Assessing the Damage

Before diving into the repair process, it’s crucial to thoroughly assess the damage to your stylus. Begin by carefully examining the exterior for any visible cracks, dents, or signs of wear and tear. Take note of any irregularities in the stylus’s performance, such as unresponsiveness or erratic behavior on the touchscreen.

Next, inspect the stylus tip for any signs of damage or deformation. A damaged tip can significantly impact the stylus’s functionality and precision. Look for wear patterns or unevenness on the tip’s surface, as these could indicate the need for repairs.

Additionally, test the stylus on a compatible device to gauge its responsiveness and accuracy. Pay close attention to any inconsistencies in the stylus’s performance, such as lagging input or imprecise tracking. These observations will help you pinpoint the specific areas that require attention during the repair process.

By thoroughly assessing the damage, you’ll gain valuable insights into the condition of your stylus, allowing you to proceed with the repair process with a clear understanding of the issues at hand.

Gathering the Necessary Tools

Before embarking on the stylus repair journey, it’s essential to gather the requisite tools to ensure a smooth and efficient process. Here’s a comprehensive list of the essential tools you’ll need:

- Microfiber Cloth: A soft, lint-free microfiber cloth will be indispensable for gently cleaning the stylus and its components without causing scratches or abrasions.

- Small Screwdriver Set: Invest in a precision screwdriver set with various head types to accommodate the different screws commonly found in stylus assemblies.

- Tweezers: Fine-tipped tweezers will aid in handling small components and delicate parts during disassembly and reassembly.

- Replacement Tips (if applicable): If your stylus model permits tip replacement, ensure you have the appropriate replacement tips on hand.

- Isopropyl Alcohol: This will be useful for cleaning the stylus components and removing any stubborn debris or adhesive residue.

- Replacement Adhesives (if applicable): If your repair involves reattaching components, having the appropriate adhesive, such as double-sided tape or adhesive glue, is crucial.

- Magnifying Glass or Loupe: A magnifying tool can aid in inspecting intricate components and identifying minute damages that may be overlooked with the naked eye.

- Work Surface Mat: Protect your work surface and prevent small parts from rolling away by utilizing a non-slip work mat with compartments for organizing screws and components.

By ensuring you have these essential tools at your disposal, you’ll be well-prepared to tackle the stylus repair process with confidence and precision.

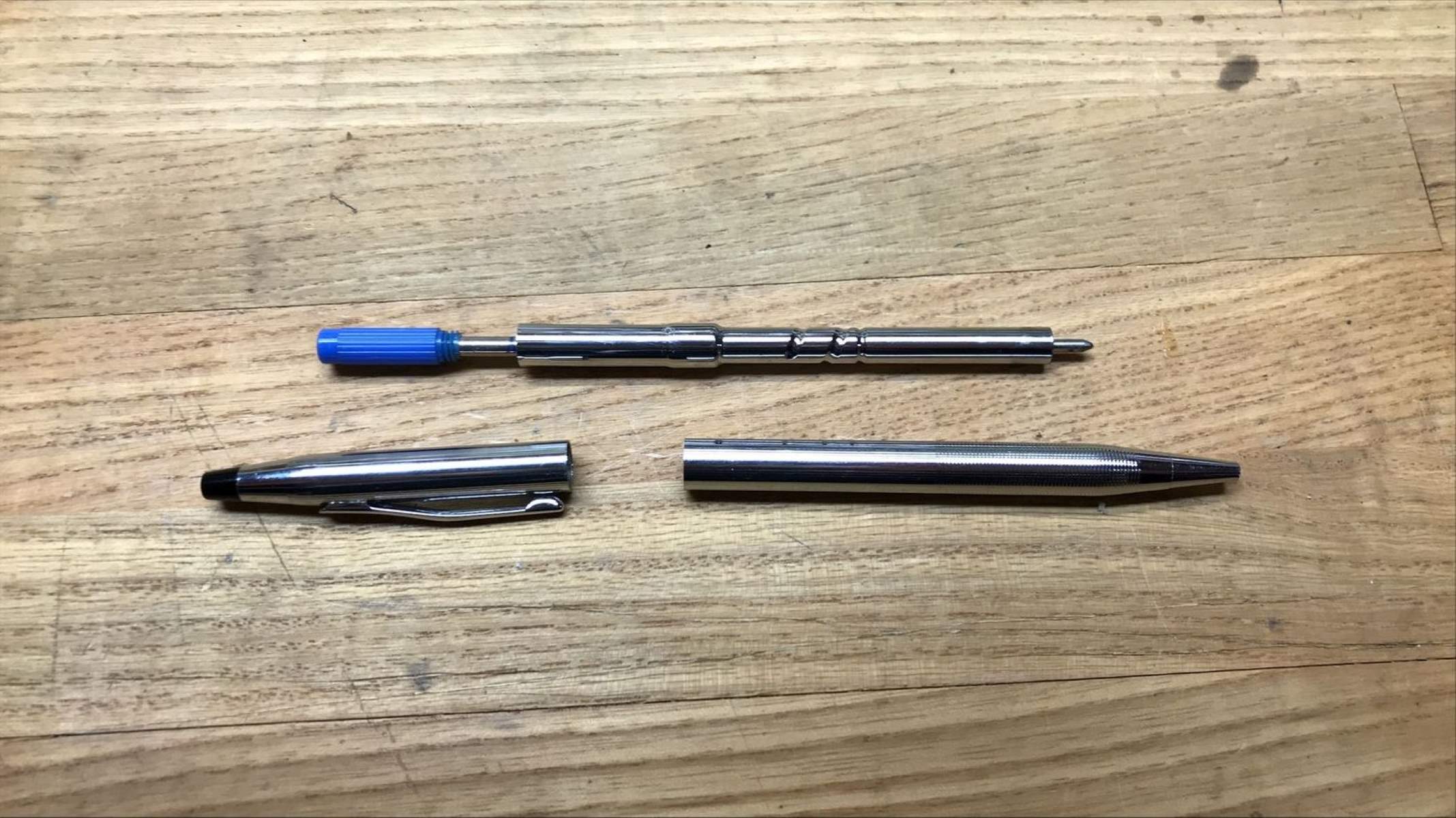

Disassembling the Stylus

Disassembling the stylus is a critical step in the repair process, requiring precision and care to avoid causing further damage. Here’s a step-by-step guide to disassembling the stylus:

- Prepare the Work Area: Find a clean, well-lit workspace and lay down a soft cloth or work mat to prevent the loss of small components and protect the stylus from scratches.

- Refer to Manufacturer Guidelines: If available, consult the manufacturer’s disassembly guidelines or schematics for your specific stylus model. These resources can provide valuable insights into the disassembly process and help prevent damage to delicate components.

- Identify Screws and Fasteners: Use a magnifying glass if necessary to identify and differentiate between various screws and fasteners securing the stylus’s components. Organize these components in a segmented tray to prevent mix-ups during reassembly.

- Remove External Components: Carefully detach any external components, such as buttons or grip covers, using the appropriate tools. Take note of the disassembly sequence to facilitate reassembly later.

- Unscrew the Housing: Use a precision screwdriver to remove the screws securing the stylus housing. Keep track of the screws’ placement and any variations in size or threading.

- Separate Internal Components: Gently separate the internal components, such as the circuit board and battery, from the housing, taking care not to strain or damage delicate wiring or connections.

- Handle with Care: Throughout the disassembly process, handle the components with precision and delicacy, avoiding excessive force or sudden movements that could lead to accidental damage.

By methodically disassembling the stylus and maintaining a keen eye for detail, you’ll lay the groundwork for a successful repair process, setting the stage for identifying and addressing the root cause of the stylus’s issues.

Identifying the Problem

Once the stylus is disassembled, it’s time to closely examine its components and pinpoint the underlying issue. Here’s how to methodically identify the problem:

- Inspect the Stylus Tip: Examine the stylus tip under magnification, looking for signs of wear, deformation, or damage. Uneven wear patterns or visible damage may indicate the need for tip repair or replacement.

- Check Internal Circuitry: Carefully examine the circuit board and wiring for any visible signs of damage, such as frayed wires, loose connections, or burnt components. These issues can adversely affect the stylus’s functionality and responsiveness.

- Test the Pressure Sensitivity: If your stylus features pressure sensitivity, test this functionality to determine if it’s functioning as intended. Inconsistent pressure sensitivity can point to internal issues that require attention.

- Assess Power Supply: If your stylus operates with a battery, inspect the battery compartment and connections for corrosion, leakage, or poor contact. Addressing power supply issues is crucial for ensuring the stylus’s reliable performance.

- Review Manufacturer Documentation: Refer to the stylus’s user manual or technical documentation for troubleshooting guidance and common issues. Manufacturers often provide valuable insights into diagnosing and addressing stylus problems.

By systematically assessing the stylus’s components and functionalities, you’ll be equipped to accurately identify the root cause of the issues plaguing your stylus. This crucial step sets the stage for implementing targeted repairs and restoring the stylus to optimal performance.

Repairing the Stylus Tip

Addressing issues with the stylus tip is a common and crucial aspect of stylus repair. Depending on the type of damage, several approaches can be employed to restore the tip’s functionality:

- Smoothening Rough Edges: If the stylus tip exhibits rough or uneven edges due to wear, carefully sand the tip using fine-grit sandpaper. This process can help restore a smooth and consistent contact surface, improving the stylus’s performance.

- Replacing the Tip: For severely damaged or irreparable tips, consider replacing the tip with a compatible replacement. Follow the manufacturer’s guidelines for tip replacement, ensuring a secure and precise fit.

- Reshaping the Tip: In cases where the tip has become misshapen or deformed, carefully reshape it using precision tools. Ensure that the tip maintains its original dimensions and contours to facilitate accurate touchscreen interaction.

- Applying Conductive Adhesive: If the tip’s conductivity has been compromised, apply a thin layer of conductive adhesive to restore its electrical properties. This approach can help address issues related to erratic or non-responsive stylus behavior.

- Testing and Calibration: After repairing or replacing the stylus tip, thoroughly test the stylus on a compatible device to evaluate its responsiveness and accuracy. If applicable, calibrate the stylus to ensure optimal performance following the repair.

By addressing issues with the stylus tip through meticulous repair or replacement, you can significantly enhance the stylus’s precision and functionality, ultimately prolonging its usability and effectiveness.

Reassembling the Stylus

After completing the necessary repairs and adjustments, reassembling the stylus is a critical step that demands attention to detail and precision. Follow these steps to ensure a successful reassembly process:

- Refer to Documentation: Consult any disassembly notes, manufacturer guidelines, or schematics to guide the reassembly process. Ensure that you have a clear understanding of the sequence and placement of components.

- Organize Components: Lay out the stylus components in a systematic and organized manner, ensuring that screws, fasteners, and small parts are readily accessible and correctly identified.

- Secure Internal Components: Carefully reposition and secure the internal components, such as the circuit board and battery, within the stylus housing, taking care to align and connect them properly.

- Align and Fasten Housing: Position the stylus housing and align it with precision, ensuring that all internal components fit snugly within the housing. Use the appropriate screws and fasteners to secure the housing, following the designated screw sequence if applicable.

- Reattach External Components: Methodically reattach any external components, such as buttons or grip covers, ensuring that they are securely fastened and aligned according to their original configuration.

- Test for Stability: Once the stylus is reassembled, perform a thorough inspection to confirm that all components are securely fastened and aligned. Gently test the stylus for stability and structural integrity.

By meticulously reassembling the stylus with attention to detail and adherence to the correct sequence, you can ensure that the stylus is restored to its original form and functionality, ready to deliver precise and reliable performance.

Testing the Stylus

After the reassembly process, thorough testing is essential to validate the effectiveness of the repairs and ensure the stylus’s optimal functionality. Follow these steps to methodically test the stylus:

- Functional Testing: Test the stylus on a compatible device, such as a touchscreen tablet or digital drawing pad, to evaluate its responsiveness and accuracy. Verify that the stylus registers precise input and pressure sensitivity if applicable.

- Calibration Check: If the stylus features calibration settings, ensure that it is calibrated to the device’s specifications. Verify that the stylus’s tracking and alignment are consistent and accurate across the entire touchscreen surface.

- Multi-Function Testing: If the stylus incorporates additional features, such as programmable buttons or tilt sensitivity, thoroughly test these functions to confirm their proper operation.

- Long-Term Performance Assessment: Use the stylus over an extended period to assess its sustained performance and reliability. Pay attention to any recurring issues or anomalies that may indicate lingering problems.

- User Feedback: Seek feedback from users or colleagues who utilize the stylus, gathering insights into its performance and identifying any residual issues that may require further attention.

By conducting comprehensive testing, you can ascertain the effectiveness of the repairs and adjustments, ensuring that the stylus delivers consistent and precise performance across various tasks and applications. This step is crucial for validating the success of the repair process and instilling confidence in the stylus’s renewed functionality.