What is an OBD Connector?

An On-Board Diagnostics (OBD) connector is a crucial component in modern vehicles, serving as a gateway to access diagnostic information and communicate with the vehicle's onboard computer systems. This standardized connector, mandated for all vehicles produced after 1996, plays a pivotal role in the diagnosis and troubleshooting of engine and vehicle-related issues.

The OBD connector serves as the interface between the vehicle and diagnostic tools, allowing technicians and vehicle owners to retrieve vital information about the vehicle's performance and health. This connector enables the extraction of diagnostic trouble codes (DTCs), which provide insights into the root causes of malfunctions and abnormalities within the vehicle's systems.

Importance of the OBD Connector

The OBD connector facilitates the retrieval of real-time data, including engine RPM, vehicle speed, fuel system status, and emission-related parameters. This wealth of information empowers technicians to identify and address potential issues promptly, ensuring optimal vehicle performance and compliance with emission standards.

Evolution of OBD Connectors

The evolution of OBD connectors has seen a transition from the earlier OBD-I systems, characterized by proprietary connectors and limited diagnostic capabilities, to the standardized OBD-II connector. OBD-II connectors feature a universal 16-pin interface, streamlining diagnostic procedures and enhancing compatibility with diagnostic tools across vehicle makes and models.

Diagnostic Capabilities

The OBD connector enables comprehensive diagnostics, covering a wide array of vehicle systems such as the engine, transmission, anti-lock braking system (ABS), airbag system, and more. This diagnostic capability empowers technicians to pinpoint issues accurately, leading to efficient and cost-effective repairs.

Accessing Diagnostic Information

By accessing the OBD connector, technicians and vehicle owners can obtain valuable insights into the vehicle's performance, emissions, and overall health. This access to real-time data fosters proactive maintenance and timely interventions, ultimately contributing to enhanced vehicle longevity and reliability.

In essence, the OBD connector serves as a vital link between the vehicle's intricate systems and the diagnostic tools essential for maintaining, troubleshooting, and optimizing vehicle performance. Its standardized interface and diagnostic capabilities have revolutionized the automotive industry, enabling efficient and accurate diagnosis of vehicle malfunctions and abnormalities.

Types of OBD Connectors

There are several types of OBD connectors, each designed to accommodate specific vehicle makes and models. These connectors vary in terms of shape, pin configuration, and compatibility, reflecting the diverse requirements of the automotive industry. Understanding the different types of OBD connectors is essential for selecting the appropriate diagnostic tools and ensuring seamless communication with the vehicle’s onboard systems.

OBD-I Connectors

The initial generation of OBD systems, known as OBD-I, featured a range of proprietary connectors specific to individual vehicle manufacturers. These connectors often differed in shape, pin configuration, and communication protocols, posing challenges for technicians and diagnostic tool manufacturers. OBD-I connectors were characterized by their manufacturer-specific nature, necessitating specialized adapters and diagnostic equipment to establish communication with the vehicle’s onboard systems.

OBD-II Connectors

With the introduction of OBD-II systems, a standardized 16-pin connector became the norm across the automotive industry. This universal connector, equipped with a standardized pinout and communication protocol, revolutionized the diagnostic process by ensuring compatibility across various vehicle makes and models. OBD-II connectors streamlined diagnostic procedures, enabling technicians to utilize a single diagnostic tool for a wide range of vehicles, thereby enhancing efficiency and reducing the need for multiple adapters and interfaces.

Enhanced OBD-II Connectors

As automotive technology continues to advance, enhanced OBD-II connectors have emerged to cater to the evolving diagnostic requirements of modern vehicles. These connectors may feature additional pins and functionalities, accommodating advanced diagnostic capabilities and specialized communication protocols. Enhanced OBD-II connectors play a crucial role in facilitating comprehensive diagnostics for complex vehicle systems, including advanced electronic controls and integrated sensor networks.

Wireless OBD Connectors

Wireless OBD connectors represent a contemporary innovation, leveraging wireless communication protocols to establish a connection between the vehicle’s onboard systems and diagnostic tools. These connectors eliminate the need for physical cable connections, offering greater convenience and flexibility during diagnostic procedures. Wireless OBD connectors enable seamless communication with the vehicle’s onboard computer systems, providing real-time data and diagnostic capabilities without the constraints of traditional wired connections.

Understanding the diverse types of OBD connectors is pivotal for navigating the intricate landscape of automotive diagnostics. By recognizing the characteristics and functionalities of these connectors, technicians and vehicle owners can make informed decisions regarding diagnostic tool selection and ensure efficient communication with the vehicle’s onboard systems.

OBD Connector Pinout

The OBD connector pinout, also known as the OBD pin assignment, delineates the specific functions and assignments of each pin within the standardized 16-pin OBD-II connector. Understanding the pinout is essential for establishing communication with the vehicle’s onboard systems and accessing diagnostic information effectively. The pinout configuration facilitates the interpretation of diagnostic trouble codes (DTCs), real-time data retrieval, and the seamless integration of diagnostic tools with the vehicle’s OBD system.

Standardized Pin Configuration

The OBD-II connector features a standardized pin configuration, ensuring consistency across vehicles and diagnostic tools. The 16-pin connector comprises specific pins allocated for power, ground, communication protocols, and various signal inputs and outputs. This standardized pinout simplifies the diagnostic process by providing a uniform interface for diagnostic tools and ensuring compatibility across different vehicle makes and models.

Diagnostic Communication Protocols

Within the OBD connector pinout, certain pins are dedicated to diagnostic communication protocols such as the Controller Area Network (CAN) bus, which facilitates high-speed communication between the vehicle’s electronic control units (ECUs) and the diagnostic tool. The allocation of pins for specific communication protocols enables seamless data exchange and diagnostic operations, allowing technicians to retrieve comprehensive vehicle information and perform targeted diagnostics.

Power and Ground Pins

Crucial to the OBD connector pinout are the designated pins for power and ground connections. These pins provide the necessary electrical power and grounding for the diagnostic tool to interface with the vehicle’s OBD system. The standardized allocation of power and ground pins ensures consistent power delivery and establishes a stable electrical connection, essential for reliable communication and diagnostic operations.

Signal Inputs and Outputs

Various pins within the OBD connector pinout are dedicated to signal inputs and outputs, facilitating the exchange of data between the vehicle’s onboard systems and the diagnostic tool. These pins enable the retrieval of real-time sensor data, diagnostic trouble codes, and system status information, empowering technicians to conduct comprehensive diagnostics and address vehicle malfunctions accurately.

Adherence to OBD-II Standards

The adherence to OBD-II standards in the pinout configuration ensures interoperability and compatibility across diagnostic tools and vehicles. This standardized pinout designates specific functions to each pin, promoting uniformity and simplifying the integration of diagnostic equipment with the vehicle’s OBD system.

The OBD connector pinout serves as a foundational element in the diagnostic process, dictating the interface between the vehicle’s onboard systems and diagnostic tools. By comprehending the pinout configuration and its significance, technicians and vehicle owners can harness the full potential of OBD diagnostics, enabling efficient troubleshooting and maintenance of vehicle systems.

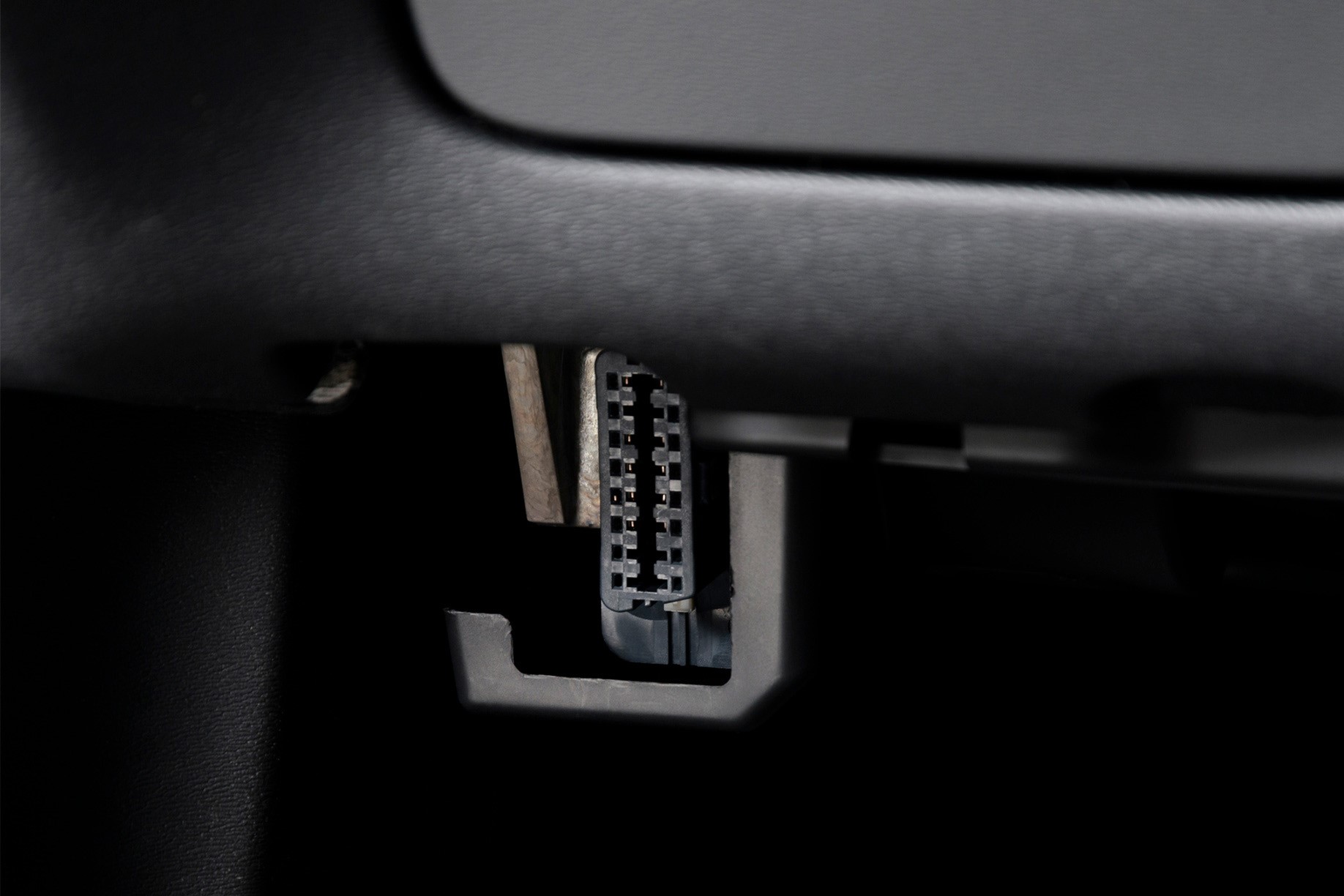

OBD Connector Location

The location of the OBD connector within a vehicle is a critical factor in accessing the onboard diagnostic information and conducting comprehensive vehicle diagnostics. The OBD connector, mandated for all vehicles produced after 1996, is strategically positioned to facilitate convenient access for diagnostic procedures while ensuring compatibility with standard diagnostic tools. Understanding the OBD connector’s location within a vehicle is essential for technicians and vehicle owners seeking to retrieve diagnostic data and perform troubleshooting effectively.

Driver’s Compartment

Commonly, the OBD connector is situated within the driver’s compartment, typically beneath the dashboard or near the vehicle’s center console. This placement ensures easy accessibility for diagnostic purposes, allowing technicians and vehicle owners to connect diagnostic tools without the need for extensive disassembly or vehicle elevation. The proximity of the OBD connector to the driver’s compartment enhances convenience during diagnostic operations, enabling swift and efficient access to the vehicle’s onboard systems.

Diagnostic Port Accessibility

Vehicle manufacturers prioritize the accessibility of the OBD connector, often positioning it in close proximity to the driver’s seating area to facilitate seamless connection with diagnostic tools. This strategic placement streamlines the diagnostic process, empowering technicians to establish communication with the vehicle’s onboard systems and retrieve vital diagnostic information without encountering accessibility challenges or spatial constraints.

Consistent Location Standards

While the specific placement of the OBD connector may vary slightly among vehicle models, the industry adheres to standardized location guidelines to promote consistency and ease of access. This adherence to consistent location standards ensures that technicians and diagnostic tool manufacturers can anticipate the OBD connector’s position, fostering familiarity and expediting the diagnostic process across diverse vehicle makes and models.

Under-Dash Placement

Under-dash placement of the OBD connector is prevalent in many vehicles, with the connector often located within close proximity to the vehicle’s steering column. This strategic positioning facilitates straightforward access for diagnostic purposes, allowing technicians to connect diagnostic tools and retrieve diagnostic trouble codes (DTCs) and real-time data with minimal effort, enhancing the efficiency of diagnostic operations.

Diagnostic Tool Compatibility

The location of the OBD connector directly influences the compatibility of diagnostic tools, as convenient access to the connector enables seamless integration with a diverse range of diagnostic equipment. The strategic placement of the OBD connector within the driver’s compartment ensures that diagnostic tools can establish communication with the vehicle’s onboard systems, empowering technicians to conduct comprehensive diagnostics and address vehicle malfunctions effectively.

Understanding the location of the OBD connector within a vehicle is pivotal for optimizing the diagnostic process and leveraging the full potential of onboard diagnostic capabilities. By recognizing the strategic placement of the OBD connector and its impact on diagnostic operations, technicians and vehicle owners can streamline vehicle maintenance and troubleshooting, fostering enhanced efficiency and diagnostic precision.

OBD Connector Compatibility

The compatibility of OBD connectors plays a pivotal role in ensuring seamless communication between vehicles and diagnostic tools, facilitating efficient access to onboard diagnostic information. As vehicles evolve and diagnostic technologies advance, the compatibility of OBD connectors with diagnostic tools becomes increasingly crucial for conducting comprehensive vehicle diagnostics and addressing potential malfunctions. Understanding OBD connector compatibility is essential for technicians and vehicle owners seeking to leverage diagnostic capabilities effectively across diverse vehicle makes and models.

OBD-II Standardization

The standardization of OBD-II connectors has significantly enhanced compatibility across vehicles, as the universal 16-pin OBD-II connector has become the industry norm. This standardized connector design, featuring a consistent pinout and communication protocol, ensures compatibility with a wide array of diagnostic tools, irrespective of the vehicle’s make and model. The OBD-II standardization fosters seamless communication and data exchange, empowering technicians to conduct comprehensive diagnostics across diverse vehicle platforms.

Adaptive Diagnostic Tools

Diagnostic tool manufacturers have developed adaptive solutions to enhance OBD connector compatibility, enabling diagnostic tools to communicate effectively with a broad spectrum of vehicles. These adaptive tools encompass versatile connector interfaces, specialized adapters, and software capabilities that cater to the diverse OBD connector configurations encountered across different vehicle makes and models. By incorporating adaptive features, diagnostic tools can establish compatibility with a range of OBD connectors, ensuring comprehensive diagnostic coverage.

Manufacturer-Specific Adapters

For vehicles equipped with manufacturer-specific OBD connectors, specialized adapters and interface modules have been developed to bridge the compatibility gap between the vehicle’s unique connector configuration and standard diagnostic tools. These manufacturer-specific adapters facilitate seamless communication between the vehicle’s onboard systems and diagnostic tools, ensuring that diagnostic capabilities are not hindered by proprietary connector designs. The availability of manufacturer-specific adapters enhances the compatibility of diagnostic tools with a diverse range of vehicles, accommodating unique OBD connector configurations.

Wireless Diagnostic Solutions

Wireless diagnostic solutions have emerged as a contemporary approach to OBD connector compatibility, leveraging wireless communication protocols to establish a connection between the vehicle’s onboard systems and diagnostic tools. These wireless solutions circumvent the constraints of physical connector compatibility, enabling diagnostic tools to communicate with the vehicle wirelessly, regardless of the OBD connector configuration. Wireless diagnostic solutions offer enhanced flexibility and compatibility, transcending traditional connector limitations and streamlining diagnostic operations.

Universal Compatibility Standards

Efforts to establish universal compatibility standards for OBD connectors and diagnostic tools continue to drive advancements in the field of automotive diagnostics. By promoting uniformity and interoperability, universal compatibility standards aim to eliminate compatibility barriers and ensure that diagnostic tools can effectively communicate with diverse OBD connector configurations, fostering comprehensive diagnostic coverage across the automotive spectrum.

Understanding OBD connector compatibility is instrumental in navigating the complexities of modern vehicle diagnostics and ensuring seamless communication between vehicles and diagnostic tools. By embracing adaptive solutions, standardized interfaces, and wireless diagnostic technologies, technicians and vehicle owners can harness comprehensive diagnostic capabilities, transcending compatibility constraints and optimizing the maintenance and troubleshooting of diverse vehicle systems.

OBD Connector Functions

The OBD connector serves as a gateway to a multitude of essential functions that are integral to the diagnosis, maintenance, and optimization of modern vehicles. Understanding the diverse functions facilitated by the OBD connector is pivotal for technicians and vehicle owners seeking to harness the full potential of onboard diagnostic capabilities and ensure the efficient operation of vehicle systems.

Diagnostic Trouble Code Retrieval

One of the primary functions of the OBD connector is the retrieval of diagnostic trouble codes (DTCs) from the vehicle’s onboard computer systems. These codes provide critical insights into the underlying causes of malfunctions and abnormalities within the vehicle’s various systems, empowering technicians to pinpoint issues accurately and expedite the troubleshooting process.

Real-Time Data Retrieval

The OBD connector facilitates the retrieval of real-time data from the vehicle’s onboard systems, including engine RPM, vehicle speed, fuel system status, and emission-related parameters. This real-time data empowers technicians to monitor the vehicle’s performance, identify anomalies, and make informed decisions regarding maintenance and repairs.

Comprehensive Diagnostics

By accessing the OBD connector, technicians can conduct comprehensive diagnostics covering a wide array of vehicle systems, including the engine, transmission, anti-lock braking system (ABS), airbag system, and more. This diagnostic capability enables the identification and resolution of complex issues, ensuring the optimal performance and safety of the vehicle.

Emission Control Monitoring

The OBD connector plays a crucial role in monitoring and regulating vehicle emissions. By accessing emission-related data through the OBD connector, technicians can ensure compliance with environmental standards and address issues that may impact the vehicle’s emissions control systems, contributing to environmental sustainability and regulatory adherence.

System Status Readouts

Through the OBD connector, technicians and vehicle owners can obtain readouts of various system statuses, including sensor readings, system voltage, and operational parameters. These readouts provide valuable insights into the overall health and functionality of the vehicle’s systems, facilitating proactive maintenance and timely interventions to optimize vehicle performance.

Performance Optimization

The OBD connector serves as a catalyst for performance optimization, enabling the adjustment of vehicle parameters, sensor calibrations, and system configurations to enhance performance and efficiency. By leveraging the diagnostic capabilities facilitated by the OBD connector, technicians can fine-tune vehicle systems and maximize operational performance.

The multifaceted functions of the OBD connector underscore its pivotal role in modern vehicle diagnostics and maintenance. By harnessing these functions, technicians and vehicle owners can proactively address issues, optimize vehicle performance, and ensure the longevity and reliability of their vehicles, ultimately fostering a safer and more efficient driving experience.