The Basics of Circuit Size

When it comes to the world of technology, size truly matters. In the realm of electronics, the size of circuits plays a crucial role in determining the overall efficiency and functionality of devices. The smaller the circuits, the more advanced and compact the technology can become.

At its most fundamental level, a circuit is a network of electronic components such as resistors, capacitors, and transistors that work together to perform a specific function. The size of these components, as well as the arrangement and interconnection of the circuit, directly affects its size.

The miniaturization of circuits has been a continuous goal in the field of electronics. Over the years, advancements in manufacturing processes and materials have allowed for increasingly smaller electronic components. These advancements have paved the way for the development of smaller, more powerful electronic devices that we use in our daily lives.

One groundbreaking technology that has contributed to the miniaturization of circuits is Microelectromechanical Systems (MEMS). MEMS combines both mechanical and electrical components on a microscopic scale. This integration allows for the creation of tiny sensors and actuators that can be used in a wide range of applications, such as automotive, healthcare, and consumer electronics.

Another important concept in the miniaturization of circuits is the System-on-a-Chip (SoC) design. SoC refers to the integration of various components, such as the processor, memory, and communication modules, onto a single chip. This integration results in highly compact devices that have the power to perform complex tasks while occupying minimal space.

With the rise of the Internet of Things (IoT), the demand for smaller circuits has become even more crucial. IoT devices, such as wearable technology, rely on compact and lightweight components to seamlessly integrate into our daily lives. These devices collect and transmit data, allowing for the automation and monitoring of various aspects of our environment.

Despite the incredible advancements in circuit miniaturization, there are still challenges to overcome. One of the main challenges is ensuring that the smaller components still maintain their functionality and reliability. The size reduction can lead to increased susceptibility to environmental factors such as heat and vibrations, which can impact the performance of the circuits.

Miniaturization of Electronics

The miniaturization of electronics has revolutionized the way we interact with technology. From smartphones and laptops to smartwatches and fitness trackers, our devices are becoming smaller, sleeker, and more powerful than ever before.

Advancements in manufacturing processes and the development of new materials have been key factors driving the miniaturization of electronics. These advancements have allowed for the creation of smaller components, such as transistors and integrated circuits, that can perform complex tasks in a fraction of the space they once occupied.

One of the primary driving forces behind the miniaturization of electronics is Moore’s Law. Coined by Intel co-founder Gordon Moore, Moore’s Law states that the number of transistors on a chip doubles approximately every two years. This exponential growth in transistor density has allowed for the continuous improvement of computing power while reducing the overall size of devices.

Another crucial aspect of miniaturization is the development of new materials with unique properties. For example, the introduction of semiconductors made from materials like silicon revolutionized the electronics industry. These semiconductors can conduct electricity under certain conditions while acting as an insulator in others, enabling the creation of smaller and more efficient electronic components.

The miniaturization of electronics has also benefited from advancements in microfabrication techniques. These techniques allow for the precise manufacturing of intricate electronic components at the micro and nanoscale, enabling the creation of ultra-compact devices with enhanced functionality.

Furthermore, the demand for smaller and more portable devices has fueled the drive to miniaturize electronics. Consumers now expect their devices to be lightweight and easily carried in a pocket or bag. This demand has pushed manufacturers to develop innovative solutions that pack more functionality into smaller form factors.

One significant example of miniaturized electronics is the development of wearable technology. These devices, such as smartwatches and fitness trackers, are designed to be worn on the body and seamlessly integrate into our daily lives. The miniaturization of components allows for the creation of sleek and stylish wearables that can track our fitness, monitor our health, and connect us to the digital world.

Despite the incredible progress in miniaturizing electronics, there are still challenges to overcome. These challenges include managing heat dissipation in compact devices, ensuring the durability and reliability of small-scale components, and effectively integrating complex functionalities within limited space.

As technology continues to advance, we can expect the miniaturization of electronics to play a significant role in shaping the future of our devices. From smaller and more powerful smartphones to wearable devices that seamlessly blend into our daily lives, the possibilities are endless.

Microelectromechanical Systems (MEMS)

In the world of miniaturization, Microelectromechanical Systems (MEMS) have emerged as a groundbreaking technology that combines mechanical and electrical components on a microscopic scale. MEMS refer to the integration of small sensors, actuators, and microelectronics onto a single chip, enabling the creation of powerful and compact devices.

MEMS devices are revolutionizing various industries, from automotive and healthcare to consumer electronics and aerospace. These devices leverage the principles of microfabrication and microelectronics to create sensors and actuators that can detect, measure, and respond to changes in the environment.

One of the key advantages of MEMS technology is its size. The components used in MEMS devices can be as small as a few micrometers, allowing for unprecedented levels of miniaturization. This size reduction has numerous benefits, including lower production costs, increased functionality, and the ability to create devices that were once unimaginable.

MEMS sensors play a crucial role in many everyday devices, such as smartphones and wearables. They enable capabilities like touchscreens, motion sensing, and environmental sensing. Accelerometers, gyroscopes, and pressure sensors are some examples of MEMS sensors that have become ubiquitous in modern electronics.

Actuators, on the other hand, are responsible for converting electrical signals into physical movement. MEMS actuators enable various functions like autofocus in cameras, vibration feedback in smartphones, and precise positioning in robotics. These compact actuators provide accurate and efficient control in a wide range of applications.

The applications of MEMS technology extend beyond consumer electronics. In the automotive industry, MEMS accelerometers are used in airbag deployment systems to detect collisions and trigger a rapid inflation response. In healthcare, MEMS sensors can monitor vital signs and provide real-time data for diagnosis and treatment. MEMS devices have even been used in space exploration missions to capture high-resolution images and perform delicate maneuvers.

Despite their small size, MEMS devices are designed to be highly reliable and robust. They undergo rigorous testing to ensure durability and functionality in demanding environments. The microfabrication techniques used in their production allow for precise alignment and integration of various components, ensuring optimal performance.

As technology continues to advance, the potential applications for MEMS devices are growing exponentially. From smart homes and smart cities to the Internet of Things, MEMS technology is poised to play a pivotal role in shaping our future. By enabling the creation of smaller, more efficient, and more capable devices, MEMS have opened up new possibilities for innovation across industries.

System-on-a-Chip (SoC)

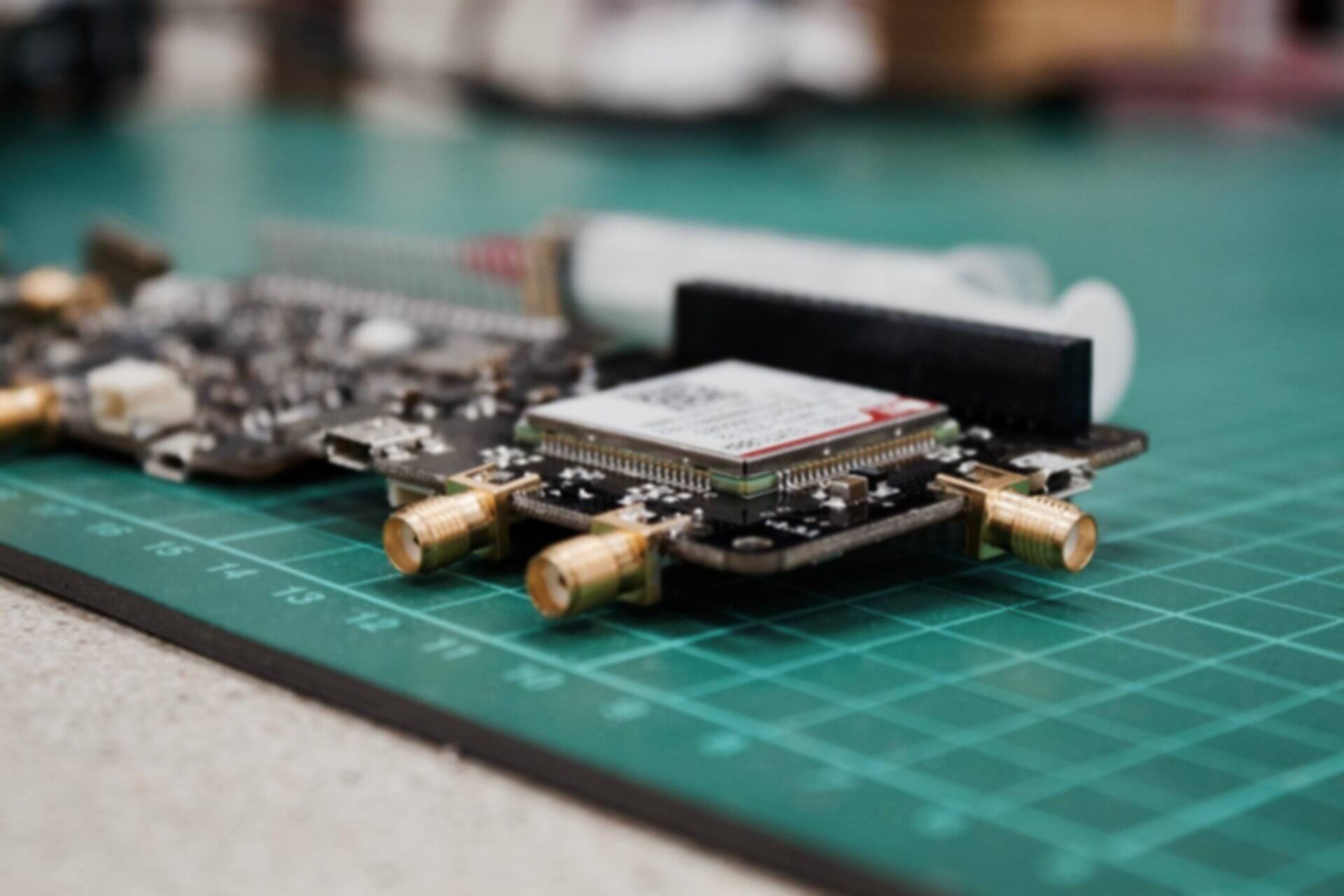

In the quest for smaller and more powerful electronic devices, System-on-a-Chip (SoC) design has emerged as a groundbreaking solution. SoC refers to the integration of various components, including the processor, memory, and communication modules, onto a single chip, resulting in high-performance and compact devices.

The SoC concept has revolutionized the electronics industry by enabling the creation of complex systems in a much smaller form factor. Traditionally, electronic devices consisted of multiple separate chips, each performing a specific function. However, the integration of these components onto a single chip offers numerous advantages.

One of the primary benefits of SoC design is the reduction in size. By combining different components onto a single chip, the overall footprint of the device is drastically decreased. This miniaturization allows for sleeker, more portable devices that can easily fit in our pockets or be worn on our bodies.

Moreover, the integration of components onto a single chip enhances the overall performance and efficiency of the device. The close proximity of the components enables faster data transfer, reduced power consumption, and improved system response time. These factors contribute to a seamless user experience and increased device capabilities.

SoC design also provides cost and manufacturing advantages. With fewer individual chips to assemble and connect, the production process becomes streamlined and more cost-effective. Additionally, the elimination of external connections reduces the risk of signal interference and improves the device’s reliability.

The versatility of SoC design extends to a wide range of applications. From smartphones and tablets to smart home devices and automotive systems, SoC technology is powering the next generation of electronics. The integration of different components, such as processors, memory, graphics, and wireless connectivity, allows for the creation of highly sophisticated and feature-rich devices.

Another notable application of SoC design is in the Internet of Things (IoT) ecosystem. With the proliferation of IoT devices, the demand for compact and efficient SoCs has skyrocketed. These SoCs enable seamless connectivity and intelligent processing capabilities in various IoT devices, enabling them to collect, analyze, and transmit data in real-time.

Despite the many advantages of SoC design, there are challenges to overcome. The integration of multiple components onto a single chip introduces complexities in terms of heat dissipation and power management. Moreover, the design and manufacturing process for SoCs require expertise in various domains, including hardware, software, and system integration.

However, as technology continues to advance, SoC design is expected to become even more pervasive. The relentless pursuit of smaller, more powerful, and energy-efficient devices will continue to drive innovation in SoC technology. With each iteration, SoCs will play an increasingly vital role in shaping the future of electronics.

Wearable Technology and the Internet of Things

In recent years, wearable technology has gained significant traction, becoming an integral part of our daily lives. These innovative devices, ranging from smartwatches and fitness trackers to augmented reality glasses, have revolutionized the way we interact with technology and access information. Wearable technology intersects with the concept of the Internet of Things (IoT), creating a new paradigm where devices seamlessly connect and communicate with each other.

Wearables are designed to be portable, lightweight, and capable of performing a range of functions. They can track our health and fitness metrics, act as communication devices, provide notifications, and even offer virtual reality experiences. These devices offer users a more personalized and immersive experience, enabling them to stay connected and informed on the go.

The integration of wearables into the IoT ecosystem has unlocked new possibilities for connectivity and automation. These devices can communicate with other smart devices and sensor networks, enabling the collection and analysis of data in real-time. For example, a wearable fitness tracker can sync with a smartphone app and cloud-based platforms to provide detailed insights into a user’s health and exercise patterns.

Wearable technology plays a vital role in various sectors, including healthcare, sports, and personal safety. In healthcare, wearables can continuously monitor vital signs, track medication adherence, and alert healthcare providers in case of emergencies. In sports, athletes can utilize wearables to track performance metrics, analyze technique, and prevent injuries. Wearables also enhance personal safety by integrating GPS tracking, emergency alert systems, and automatic fall detection.

Additionally, wearables facilitate a more seamless and intuitive user experience. Through biometric sensors and gesture recognition, these devices can understand and respond to user input. Voice commands, touchscreens, and haptic feedback enable users to interact with wearables intuitively, making them an extension of ourselves.

However, the successful integration of wearables into the IoT ecosystem relies on several factors. Data security and privacy are critical considerations, as wearable devices collect and transmit sensitive personal information. Manufacturers must implement robust security measures to protect user data from breaches and unauthorized access.

Another challenge lies in the power management of wearables. As these devices become more advanced, they require more processing power and battery life. Improvements in power-efficient components, energy harvesting technologies, and wireless charging solutions are crucial for extending the usability of wearables.

Looking ahead, the future of wearable technology and the IoT holds immense potential. Wearables will become more accurate, intelligent, and seamlessly integrated into our lives. They will play a crucial role in monitoring and enhancing our well-being, optimizing workplace productivity, and enabling novel applications in various industries.

Challenges in Miniaturizing Circuits

The miniaturization of circuits has been a remarkable achievement in the field of electronics, but it also comes with its fair share of challenges. As circuits become smaller and more compact, a number of technological and practical obstacles need to be overcome to ensure their functionality and reliability.

One of the main challenges in miniaturizing circuits is the increased susceptibility to environmental factors. Smaller components are more sensitive to heat, vibrations, and electromagnetic interference. These factors can affect the performance and longevity of the circuits, leading to reduced efficiency and even failure in some cases. Designing circuits that can withstand these environmental challenges and provide reliable performance is crucial in the miniaturization process.

Another challenge is managing power consumption. As circuit size decreases, the power requirements may become more demanding. This can be a significant hurdle as smaller devices typically have limited power sources and need to optimize energy consumption. Advanced power management techniques, energy-efficient designs, and the use of low-power components are essential in addressing this challenge.

Manufacturing miniaturized circuits also poses unique challenges. The precision and accuracy required in producing smaller components are more demanding than traditional manufacturing processes. The risk of defects and errors increases, leading to lower yields and increased production costs. Moreover, the intricate nature of small-scale circuitry necessitates specialized equipment and techniques that may be costly or difficult to implement on a large scale.

Another critical challenge is thermal management. As circuits become smaller and more densely packed, the dissipation of heat becomes more challenging. Heat generated during operation can cause performance degradation and even damage delicate components. Effective thermal management solutions, such as heat sinks, thermal vias, and advanced cooling techniques, are necessary to ensure the reliability and longevity of miniaturized circuits.

Additionally, the miniaturization of circuits can pose challenges for design and testing. As components and interconnects become smaller, the design process becomes more complex. Ensuring signal integrity, managing electromagnetic interference, and optimizing circuit layout become crucial tasks. Similarly, testing smaller circuits for functionality and reliability requires specialized testing equipment and techniques that may not be readily available.

While these challenges can be significant, the relentless pursuit of miniaturization and technological advancements continue to drive innovations in circuit design and manufacturing. Through ongoing research and development, engineers and scientists are finding solutions to overcome these obstacles and push the boundaries of what is possible in circuit miniaturization.

Future Trends in Circuit Size

The miniaturization of circuits has been a constant trend in the electronics industry, and this trend is expected to continue in the future. As technology advances and new discoveries are made, several key trends are emerging that will shape the future of circuit size.

One of the future trends in circuit size is the continued development of nanotechnology. Nanotechnology involves the manipulation and control of matter at the nanoscale – at dimensions of less than 100 nanometers. The ability to precisely engineer materials and structures at this scale opens up new possibilities for ultra-small circuits with enhanced performance and functionality.

Another trend is the integration of emerging materials into circuit design. Materials like graphene, which has excellent electrical conductivity and mechanical strength, hold great potential for miniaturized circuits. By incorporating these materials into circuit design, it is possible to achieve higher speeds, lower power consumption, and even flexible or transparent circuitry.

Advancements in additive manufacturing, or 3D printing, are also expected to play a role in circuit miniaturization. 3D printing allows for the precise and efficient production of intricate circuit structures and interconnections. It can enable the creation of multi-layered circuits with complex geometries, reducing the need for traditional fabrication techniques and assembly processes.

Furthermore, the development of new fabrication techniques, such as self-assembly and molecular electronics, holds promise for the creation of even smaller circuits. Self-assembly techniques leverage natural forces to autonomously arrange and position components at the nanoscale. Molecular electronics, on the other hand, aims to use individual molecules as circuit components, leading to circuits that are orders of magnitude smaller than current technology.

The rise of quantum computing also presents an exciting future trend in circuit size. Quantum computing relies on the principles of quantum mechanics to perform calculations. As researchers develop methods for building and controlling quantum circuits, there is a potential for ultra-small circuits capable of executing complex calculations at unprecedented speeds.

Additionally, advances in artificial intelligence (AI) and machine learning may present opportunities for optimizing circuit design. AI algorithms can analyze vast amounts of data and generate designs that are more efficient, compact, and tailored to specific requirements. This can lead to the creation of circuits that make the most efficient use of space while achieving high performance.

While these trends hold promise for the future of circuit miniaturization, they also come with new challenges. Addressing issues such as scalability, reliability, and manufacturing scalability will be crucial to ensure the practical realization of these advancements. Nonetheless, with ongoing research, collaboration, and technological breakthroughs, the future of circuit size looks incredibly promising.