Safety Precautions

When it comes to refining gold from electronic scrap, safety should always be a top priority. The process involves working with hazardous chemicals and potentially dangerous equipment, so it is important to take necessary precautions to protect yourself and others. Here are some essential safety measures to consider:

- Protective Gear: Always wear appropriate protective gear, such as safety goggles, gloves, and a lab coat, to shield yourself from any potential hazards. This will help minimize the risk of chemical splashes, burns, and other accidents.

- Well-Ventilated Area: Choose a well-ventilated area for your refining process. Proper ventilation will help to dissipate any toxic fumes that might be released during the chemical reactions. If working indoors, consider using a fume hood or setting up a fan to ensure good air circulation.

- Fire Safety: Gold refining involves the use of high temperatures, so it is crucial to have appropriate fire safety measures in place. Keep a fire extinguisher nearby and be aware of the location of the nearest emergency exits. It is also advisable to have a fire-resistant surface to work on and to avoid wearing loose clothing that could catch fire.

- Chemical Handling: Handle all chemicals with care and follow the recommended safety guidelines. Store them properly in clearly labeled containers, away from heat or direct sunlight. Be cautious when transferring or mixing chemicals, as some reactions can be highly exothermic or produce toxic gases.

- No Eating or Drinking: Strictly avoid eating, drinking, or smoking while working with chemicals or electronic scrap. Accidental ingestion of hazardous substances can have severe health consequences.

- First Aid: Familiarize yourself with the location of the nearest first aid kit and ensure that it is well-stocked. In case of any chemical splashes, burns, or injuries, rinse affected areas with plenty of water and seek medical assistance if needed.

By following these safety precautions, you can minimize the risks associated with gold refining from electronic scrap. Remember that safety should always come first, and never hesitate to reach out for professional guidance or assistance if you are unsure about any aspect of the process. Taking the necessary steps to protect yourself and others will ensure a safer and more successful refining experience.

Gathering Electronic Scrap

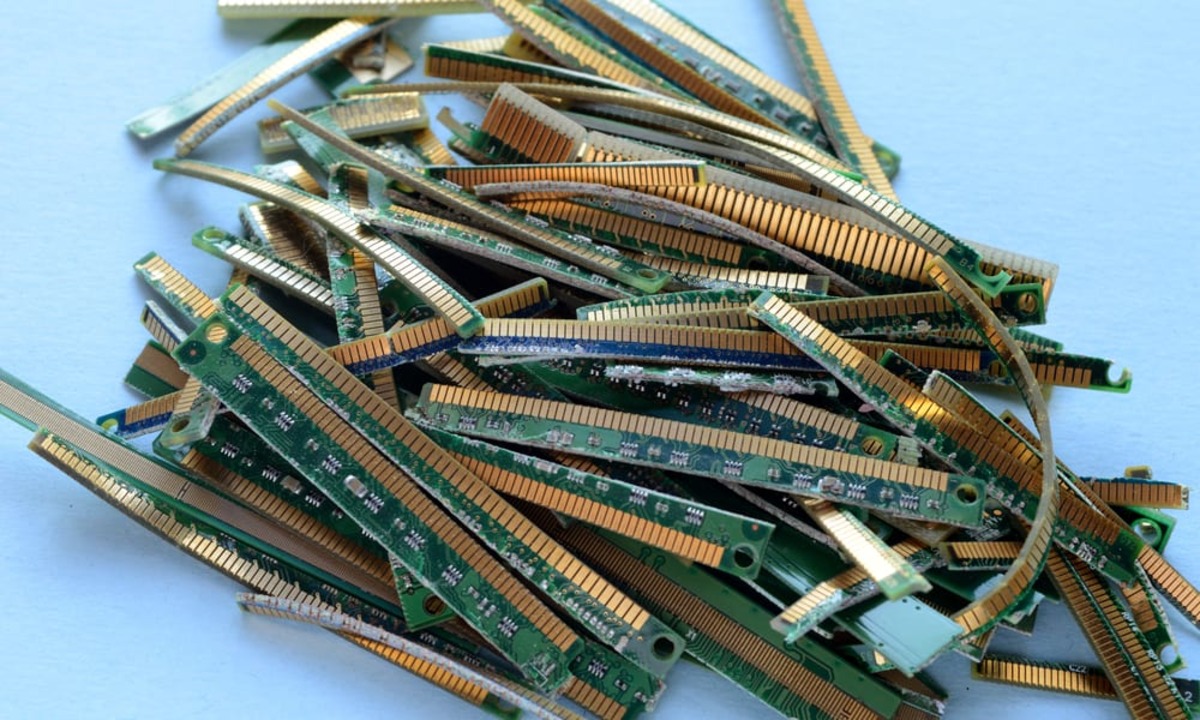

Gathering electronic scrap is the first step in the gold refining process. Electronic scrap refers to discarded electronic devices, such as old computers, cell phones, and circuit boards, which contain valuable metals like gold. Here’s how to effectively gather electronic scrap:

- Collections: Start by collecting electronic scrap from various sources, such as friends, family, local businesses, or electronic recycling centers. Reach out to local computer repair shops or companies that deal with electronic waste for potential sources.

- Assess Value: Once you have collected the electronic scrap, assess the devices to determine which components are likely to contain gold. Look for items like circuit boards, connectors, and pins that may have gold-plated surfaces.

- Separation: Separate the electronic scrap into different categories based on the types of devices and components. This will make it easier to process and extract the gold later on.

- Storage: Store the electronic scrap in a secure and dry area. Make sure to keep it away from moisture, extreme temperatures, and direct sunlight, as these factors can cause damage to the components or affect the effectiveness of the refining process.

- Record Keeping: Maintain a record of the quantity and types of electronic scrap that you have gathered. This will help you in tracking your progress and assessing the overall value of the materials you have collected.

- Sustainability Considerations: Be mindful of the environmental impact of your activities. Whenever possible, prioritize recycling and responsible disposal of electronic waste to minimize the amount of scrap that goes to landfill.

Gathering electronic scrap is a crucial step in refining gold. It is important to approach this process with care and diligence. Remember to respect any local laws or regulations regarding the collection and processing of electronic waste. By being mindful of the value of the materials and their impact on the environment, you can contribute to a more sustainable and efficient refining process.

Dismantling Electronic Scrap

Dismantling electronic scrap is the next step in the gold refining process. This involves carefully taking apart electronic devices to access the components that may contain gold. Follow these steps to effectively dismantle electronic scrap:

- Prepare Tools: Start by gathering the necessary tools, such as screwdrivers, pliers, wire cutters, and a heat gun. These tools will help you disassemble the devices without causing damage to the valuable components.

- Identify Components: Carefully examine the electronic devices to identify components that are most likely to contain gold. Focus on circuit boards, connectors, and pins, as they often have gold-plated surfaces. Refer to online resources or seek professional guidance to identify specific components.

- Disconnect Power: Before beginning any disassembly, ensure that the electronic device is completely powered off and disconnected from any power source. This will minimize the risk of electric shock or other accidents during the dismantling process.

- Safe Handling: Handle the electronic devices with care to prevent breakage or damage to the valuable components. Avoid applying excessive force or pulling on delicate wires. Be mindful of any sharp edges or protruding parts that could potentially cause injuries.

- Remove Components: Use your tools to remove the identified components from the electronic devices. Take your time and be patient to avoid damaging the components or the surrounding areas. Place the removed components in a safe and organized manner for further processing.

- Separate Plastic and Metal: Separate the plastic parts from the valuable metal components. Plastic parts can often be recycled separately, while the metal components will be further processed to extract the gold.

Dismantling electronic scrap requires careful attention to detail and a systematic approach. Take your time to ensure that valuable components are removed intact and undamaged. Remember to handle electronic waste responsibly and dispose of any non-valuable or hazardous materials properly. By following these steps, you will be one step closer to refining the gold from your electronic scrap.

Removing Non-Gold Components

After dismantling electronic scrap and separating the valuable components, the next step in the gold refining process is to remove non-gold components. These components can include plastics, ceramics, and other materials that do not contain any significant amount of gold. Here’s how to effectively remove non-gold components:

- Sorting: Sort through the collected components and separate them based on their material composition. Group together items that are primarily made of plastic, ceramic, or other non-metallic materials.

- Plastic Removal: Use pliers or wire cutters to carefully remove plastic parts from metal components. This can include cases, covers, and any plastic housing surrounding the valuable components. Be cautious not to damage or lose any small metal parts that may be attached to the plastic.

- Ceramic Removal: Ceramics are commonly found in electronic components like capacitors and resistors. To remove ceramics, gently pry or cut them away from the metal leads or connectors using appropriate tools. Take care not to damage any adjacent metal parts.

- Separation Techniques: Depending on the type and size of the non-gold components, you may need to employ different separation techniques. This could involve using sieves, magnets, or hand sorting to separate smaller metal components from non-metallic materials.

- Recycling Non-Gold Materials: Dispose of the non-gold components responsibly by recycling them where possible. Look for local recycling facilities or electronic waste management programs that can handle these materials properly and minimize environmental impact.

Removing non-gold components is crucial to isolate the valuable precious metal. By separating plastics, ceramics, and other non-metallic materials, you can focus on the gold-rich components and proceed with the refining process more efficiently.

Separating Gold-Plated Components

Once the non-gold components have been removed, the next step in the gold refining process is to separate the gold-plated components from the rest of the materials. Gold-plated components typically have a thin layer of gold applied to their surfaces. Here’s how to effectively separate gold-plated components:

- Visual Inspection: Thoroughly inspect the components to identify those that are gold-plated. Look for components with a distinct yellowish or golden color, as this indicates the presence of a gold layer.

- Magnetic Test: Conduct a magnetic test to further confirm the presence of gold plating. Gold is not magnetic, so if a component is attracted to a magnet, it likely does not contain a substantial amount of gold.

- Weight Comparison: Compare the weight of suspected gold-plated components to similar components without gold plating. Gold is much denser than most other metals used in electronic devices, so a significant weight difference can indicate the presence of gold.

- Acid Test: Perform an acid test to verify the gold-plated components. This involves applying a small amount of nitric acid on the component and observing the reaction. A greenish color or lack of reaction suggests gold-plating, as gold is resistant to most acids.

- Separation Techniques: Use appropriate tools to carefully separate the gold-plated components from the rest of the materials. These can include pliers, wire cutters, or special tools designed for delicate component removal.

- Storage: Store the separated gold-plated components in a designated container or pouch to prevent any contamination or loss. Label and keep them separate from other materials for further processing.

Separating gold-plated components is a critical step in refining gold from electronic scrap. By accurately identifying and isolating these components, you can extract the valuable gold for further processing in the refining journey.

Crushing and Grinding

After separating the gold-plated components, the next step in the gold refining process is to crush and grind the materials. This step helps to further break down the components into smaller pieces, increasing the surface area for chemical reactions. Follow these guidelines for effective crushing and grinding:

- Cutting and Breaking: Use appropriate tools, such as pliers, wire cutters, or a mortar and pestle, to cut or break the components into smaller pieces. Ensure that the tools are clean and free from any contaminants that could interfere with the refining process.

- Size Reduction: Aim to achieve a consistent particle size by further crushing and grinding the materials. The goal is to reduce the components to a fine powder or small particles that are more easily processed in subsequent steps.

- Equipment: Consider using a ball mill, hammer mill, or other suitable equipment for grinding the materials. These machines can efficiently break down the components into smaller sizes while ensuring uniformity and consistency.

- Safety Measures: Always prioritize safety when operating crushing and grinding equipment. Wear appropriate protective gear, such as safety goggles and gloves, to protect yourself from any potential hazards. Follow the manufacturer’s instructions for safe and proper use of the equipment.

- Batching: It’s helpful to work in batches when crushing and grinding the materials. This allows for better control and monitoring of the process, ensuring that the materials are processed evenly and thoroughly.

- Cleanliness: Keep the crushing and grinding equipment clean and free from any contaminants. Regularly clean the equipment between batches to prevent cross-contamination and maintain the purity of the gold-rich materials.

Crushing and grinding the materials is a vital step in the gold refining process. It helps to break down the components into a manageable size for further processing, enabling efficient extraction of the gold. By following the proper techniques and safety measures, you can ensure the success of this crucial step in the refining journey.

Chemical Bath

After crushing and grinding the materials, the next step in the gold refining process is to immerse them in a chemical bath. This chemical bath helps to dissolve certain non-gold components, leaving behind the precious gold particles. Here’s how to perform the chemical bath step:

- Container Selection: Choose a suitable container that is chemically resistant and large enough to hold the materials. Glass or plastic containers are commonly used for this purpose.

- Chemical Solution: Prepare a chemical solution, typically a mixture of water and an appropriate gold-dissolving agent, which can vary depending on the refining method being used. Commonly used chemicals include aqua regia or a cyanide-based solution. Be sure to follow safety guidelines and local regulations when working with these chemicals.

- Immerse the Materials: Place the crushed and ground materials into the container, ensuring that they are fully submerged in the chemical solution. Allow the materials to soak in the solution for a specific period, which can vary depending on the refining method and the manufacturer’s instructions.

- Agitation: Agitate the container periodically to enhance the dissolution process. This can be done by stirring the solution gently or using mechanical agitation methods, such as a magnetic stirrer or a shaker table. Agitation helps to promote the mixing and interaction between the gold particles and the chemical solution.

- Monitoring: Monitor the progress of the chemical reaction by observing any visible changes in the solution. This can include color changes or the formation of precipitates. Keep track of the reaction time to ensure that it aligns with the recommended refining process guidelines.

- Neutralization: Once the desired reaction has taken place, it may be necessary to neutralize the chemical solution before proceeding to the next step. This can be done by adding specific compounds or following the recommended neutralization process outlined in the refining instructions.

The chemical bath step is a critical part of the gold refining process, as it helps to dissolve non-gold components and separate them from the valuable gold particles. Proper selection of chemicals, appropriate immersion time, and monitoring are essential for effective results. Exercise caution and follow safety guidelines when working with chemicals to ensure a safe and successful refining process.

Filtering the Solution

After the chemical bath step, the next crucial step in the gold refining process is filtering the solution. Filtering helps to separate any remaining solid particles or undesired materials from the dissolved gold solution, preparing it for further processing. Follow these steps to effectively filter the solution:

- Filtration Equipment: Select a suitable filtration apparatus, such as filter paper, filter flask, or a filter funnel, depending on the volume and nature of the solution. Ensure that the chosen equipment is chemically resistant, capable of handling the solution, and provides adequate filtration capabilities.

- Preparation: Set up the filtration apparatus as per the manufacturer’s instructions. If using filter paper, ensure it is properly fitted within the filter funnel or in a separate filtration setup. Pre-wet the filter paper with distilled water to prevent any loss of the dissolved gold solution during the filtration process.

- Pouring the Solution: Carefully transfer the solution from the container into the filtration apparatus. Work slowly and avoid splashes to minimize any potential loss or contamination of the precious gold solution. Ensure that the solution is pouring only through the filter medium, allowing the unwanted particles to be trapped while the gold solution passes through.

- Collecting the Filtrate: Use an appropriate collection container, such as a beaker or a flask, to collect the filtrate that passes through the filter paper. This filtrate contains the dissolved gold solution, while the trapped particles remain on the filter paper.

- Washing the Residue: Rinse any residue left on the filter paper with a suitable solvent or distilled water to recover any remaining gold particles. Carefully collect and combine these washings with the main filtrate to ensure maximum recovery of the dissolved gold.

- Disposal of Filtered Material: Dispose of the filtered material properly, following local regulations for the disposal of chemical waste. Consider recycling or appropriate methods of waste management for any remaining solids or undesired components.

Filtering the solution is a critical step in the gold refining process, as it helps to separate the dissolved gold from any residues or unwanted particles. Ensure proper filtration techniques, adequate equipment, and careful handling to achieve effective separation and maximize the recovery of the precious gold solution.

Adding Chemicals for Precipitation

After filtering the solution, the next step in the gold refining process is to add specific chemicals to induce the precipitation of the gold from the dissolved solution. This precipitation process helps to separate the gold from other impurities, further purifying the precious metal. Follow these steps to effectively add chemicals for precipitation:

- Chemical Selection: Choose the appropriate precipitation agent based on the specific refining method and the composition of the dissolved gold solution. Common chemicals used for gold precipitation include sodium metabisulfite, ferrous sulfate, or zinc dust. Refer to the refining instructions or seek expert advice to determine the suitable chemical for your refining process.

- Preparation: Prepare the chemical solution according to the recommended concentration. Dissolve the desired amount of the precipitation agent in a separate container, following the manufacturer’s instructions and safety guidelines. Ensure thorough mixing to ensure uniformity of the solution.

- Gradual Addition: Slowly pour the prepared chemical solution into the filtered gold solution while stirring gently. It is crucial to add the precipitation agent gradually to avoid sudden reactions or excessive frothing, which can lead to loss of gold and impurities remaining in the final product.

- Stirring and Reaction Time: Continue stirring the solution gently after the addition of the precipitation agent to promote efficient mixing and reaction. The required reaction time can vary depending on the specific refining method and the instructions provided. Follow the recommended reaction time to ensure optimal precipitation of the gold.

- Observation: Observe any changes in the solution during the reaction. These changes can include color variations, appearance of solids, or formation of a precipitate. These observations indicate that the gold is being separated from the solution and forming a solid mass that can be further processed.

Adding chemicals for precipitation is a critical step in refining gold as it facilitates the separation of gold from other impurities. By following the recommended chemical selection, gradual addition, and proper reaction time, you can effectively induce the precipitation of gold and purify the precious metal in the refining process.

Precipitating Gold

Precipitating gold is a crucial step in the gold refining process, as it allows the gold to separate from the solution and form a solid mass that can be further processed. The precipitation process helps to purify the gold and remove any remaining impurities. Here’s how to effectively precipitate gold:

- Reaction Completion: After adding the appropriate chemicals for precipitation, allow the reaction to reach completion according to the recommended reaction time provided in the refining instructions. This ensures that the maximum amount of gold is separated and precipitated.

- Observation and Settling: Observe the solution and look for signs of gold precipitation. Depending on the refining method, the solution may appear cloudy or a solid mass may form at the bottom of the container. Allow the solution to settle undisturbed to allow the gold precipitate to fully separate and settle at the bottom.

- Decantation: Carefully pour off the supernatant liquid, which contains the majority of the remaining solution and impurities, leaving behind the settled gold precipitate at the bottom of the container. Take caution not to disturb or lose any of the precious gold particles during decantation.

- Washing the Precipitate: Rinse the gold precipitate with distilled water or a suitable solvent to remove any residual impurities and chemicals from the refining process. This helps to further purify the gold and improve the quality of the final product. Repeat the washing process several times to ensure thorough cleaning of the precipitate.

- Filtering or Drying: Depending on the refining method and the desired consistency of the gold, you may choose to filter the washed gold precipitate or allow it to air dry. Filtering can help to remove any remaining particles or impurities, while air drying allows the gold to reach a solid state.

- Collecting and Storing: Collect the precipitated and dried gold and store it in a secure and labeled container. Take care to prevent contamination or loss of the precious metal. Store the gold in a safe and dry place until the final refining steps can be carried out.

Precipitating gold is a crucial stage in the gold refining process, as it allows the separation of the precious metal from the solution and further purification. By following the recommended steps and monitoring the process carefully, you can ensure a successful precipitation of gold and obtain a high-quality final product.

Filtering and Washing the Precipitate

After precipitating the gold, the next step in the gold refining process is to filter and wash the gold precipitate. This helps to remove any remaining impurities, chemicals, or residual solutions from the precipitated gold, ensuring a purer and higher-quality final product. Follow these steps to effectively filter and wash the gold precipitate:

- Filtering: Set up a suitable filtration apparatus, such as a filter paper, filter flask, or a funnel, to separate the gold precipitate from any remaining liquid or impurities. Ensure the filtration apparatus is clean and properly assembled, and that it can accommodate the volume of the precipitate.

- Pouring the Precipitate: Carefully pour the gold precipitate into the filtration apparatus, allowing any excess liquid to pass through the filter medium. Take precautions to prevent the loss of any gold particles during this process, as they are valuable and should be retained for further refining.

- Rinsing: Once the gold precipitate is in the filtration apparatus, carefully rinse it with distilled water or a suitable solvent to remove any residual chemicals or impurities. Gently pour the rinse liquid over the precipitate, allowing it to wash away any contaminants. Repeat the rinsing process several times to ensure thorough cleaning.

- Drying the Precipitate: After rinsing, transfer the washed gold precipitate to a clean container. Allow the precipitate to dry either by air drying or by using a suitable drying method, such as a gentle heat source. Ensure that the drying process is carried out safely and does not compromise the quality or integrity of the gold precipitate.

- Collecting and Storing: Once the gold precipitate is fully dry, collect it and store it in a secure, labeled container. Take precautions to prevent contamination or loss of the precious metal. Store the gold in a safe and dry place until the final refining steps can be undertaken.

Filtering and washing the gold precipitate is an important step in the gold refining process to remove any remaining impurities and improve the purity of the final product. By following proper filtration techniques, thorough rinsing, and careful drying, you can ensure a cleaner and higher-quality gold precipitate for further processing and refining.

Melting the Gold

After filtering and washing the gold precipitate, the next crucial step in the gold refining process is to melt the gold. Melting the gold converts it from a solid state into a molten form, allowing for further purification and shaping. Follow these steps to effectively melt the gold:

- Preparation: Prepare a suitable crucible, which is a heat-resistant container used for melting metals. The crucible should be clean and free from any impurities or contaminants that could affect the quality of the melted gold. Also, ensure that you are working in a well-ventilated and safe environment.

- Crucible Placement: Place the crucible on a heat-resistant surface, such as a firebrick or a crucible holder, ensuring stability during the melting process. Position the crucible in a way that allows for easy access and handling while ensuring safety precautions are in place.

- Applying Heat: Use a suitable heat source, such as a torch or a furnace, to apply heat to the crucible. Gradually and evenly heat the crucible to reach the melting point of gold, which is approximately 1,064 degrees Celsius (1,947 degrees Fahrenheit).

- Melting Process: Once the crucible reaches the desired temperature, carefully add the gold precipitate into the crucible. Observe the melting process and ensure that all the gold precipitate is completely melted. Stir the molten gold gently, if necessary, to promote uniformity.

- Skim Off Impurities: As the gold melts, impurities or dross may rise to the surface. Use a suitable tool, such as a graphite rod or a skimming spoon, to remove any impurities or floating particles from the surface of the molten gold. This helps to improve the purity of the final product.

- Pouring or Casting: Once the molten gold is free from impurities, you can pour it into a suitable mold or container for further shaping or use. Ensure that the mold is clean and well-prepared to achieve the desired shape or form for the refined gold.

- Cooling and Solidification: Allow the poured or cast gold to cool and solidify naturally at room temperature or use a cooling method if necessary. Avoid sudden temperature changes, as they can introduce stress or cracks in the solidified gold. Once cooled, carefully remove the refined gold from the mold for further processing or storage.

Melting the gold is a critical step in the gold refining process as it transforms the gold into a molten state, allowing for further purification and shaping. By following proper preparation, heating techniques, impurity removal, and handling, you can successfully melt the gold and obtain a refined, high-quality final product.

Final Refining Process

After melting the gold and obtaining a molten state, the final refining process focuses on further purifying the gold to achieve the highest possible quality. This step involves various techniques to remove any remaining impurities and obtain a refined gold product. Follow these steps to effectively carry out the final refining process:

- Chemical Treatment: Depending on the refining method used, chemical treatments such as cupellation or electrolysis may be employed to remove remaining impurities from the molten gold. These processes further purify the gold by separating it from other metals or elements that may still be present in the molten state.

- Dross Removal: During the final refining process, any remaining dross or impurities that rise to the surface of the molten gold can be carefully skimmed off using appropriate tools. Skimming helps to enhance the purity of the gold by eliminating unwanted elements or substances.

- Assaying: Assaying is the process of analyzing the gold sample to determine its precise composition and purity. This step involves various tests, such as fire assay or spectroscopy, to accurately assess the gold content and identify any remaining impurities or traces of other metals.

- Adjustment: Based on the results of the assaying process, adjustments can be made to further refine the gold. This can involve adding certain chemicals or processes to eliminate any remaining impurities or to achieve a specific purity level, such as 24 karat or higher.

- Granulation or Casting: After achieving the desired purity, the refined gold can be further processed into the desired form, such as granules or cast bars. This step involves carefully pouring the purified gold into a mold or using specialized equipment to create consistent shapes and sizes.

- Quality Control: As a final step in the refining process, quality control measures are implemented to ensure that the refined gold meets industry standards and customer requirements. This can involve verifying the weight and purity of the gold, conducting additional testing, and adhering to established quality control protocols.

The final refining process is a crucial stage that focuses on achieving the highest quality and purity in the gold before it is ready for use or sale. By following the proper techniques, implementing quality control measures, and ensuring compliance with industry standards, you can obtain a refined gold product that meets the desired specifications and requirements.

Final Thoughts

Refining gold from electronic scrap is a complex process that requires careful attention to detail, proper equipment, and knowledge of refining techniques. While the steps outlined in this guide provide a general overview, it is important to note that the refining process can vary depending on the specific methods, equipment, and materials used.

Throughout the refining process, it is crucial to prioritize safety and adhere to proper handling procedures for chemicals, equipment, and electronic waste. Always wear appropriate protective gear, work in a well-ventilated area, and follow local regulations for the disposal of hazardous materials.

Additionally, it is worth mentioning that refining gold from electronic scrap can be a rewarding endeavor both financially and environmentally. By extracting valuable metals like gold from electronic waste, you are contributing to resource conservation and reducing the need for new mining operations.

However, refining gold from electronic scrap requires expertise and experience. If you are unsure of any aspect of the process, it is advisable to consult with professionals or seek out specialized refining services to ensure the best results and maximum recovery of the precious metal.

Lastly, refining gold from electronic scrap can be a time-consuming process that requires patience and careful monitoring. It is important to set realistic expectations and be prepared for potential challenges that may arise during the refining process.

With proper knowledge, safety measures, and dedication, refining gold from electronic scrap can be a rewarding and sustainable venture. By reclaiming precious metals and responsibly managing electronic waste, you are making a positive contribution to both the environment and your own financial goals.