History of Silver in Electronics

Silver has played a significant role in the development of electronic devices throughout history. Its remarkable conductivity and corrosion resistance have made it a preferred choice for various applications in the electronics industry.

The use of silver in electronics can be traced back to the early 20th century when it was first introduced in the form of silver wires to connect components in radio and telegraph systems. The high conductivity of silver allowed for efficient signal transmission, revolutionizing communication technology.

In the 1950s, the invention of the transistor brought about a new era of electronics. Silver’s conductive properties made it an essential component in the manufacturing of transistors, enabling smaller and more efficient devices.

With the advent of printed circuit boards (PCBs) in the 1960s, silver found its way onto these boards as conductive traces. The ability to print intricate circuitry on a single board revolutionized the electronics industry, and silver became instrumental in the development of smaller and more powerful devices.

As technology continued to advance, the demand for silver in electronics increased. In the 1980s, the demand for silver in the production of electrical contacts skyrocketed with the growing popularity of consumer electronics such as televisions, computers, and mobile phones.

Another significant milestone in the history of silver in electronics was the introduction of surface mount technology (SMT) in the 1990s. This technology allowed for smaller and more densely packed components on PCBs, and silver was used as a conductive material in these components.

Silver’s versatility in electronics extends beyond traditional circuitry. It is also widely used in connectors, switches, and contacts due to its low resistance and reliable performance. Additionally, silver is used in batteries and energy storage, displays and screens, sensors and detectors, photovoltaic cells, antennas, and even printed electronics.

Overall, the history of silver in electronics is a testament to its exceptional conductivity and adaptability. As technology continues to advance, silver will likely remain a vital material in the development of futuristic electronic devices.

Conductivity of Silver

Silver is renowned for its exceptional conductivity, making it one of the most sought-after materials in the electronics industry. Its ability to efficiently transmit electrical signals has made silver an integral component in various electronic devices and applications.

The conductivity of silver is attributed to its atomic and crystal structure. Silver has a relatively high number of free electrons, which are responsible for conducting electricity. These free electrons can move easily through the silver lattice, facilitating the flow of electric current.

Compared to other metals, silver possesses the highest electrical conductivity, with only copper coming close. In fact, silver has an electrical conductivity that is approximately 6% higher than copper, making it an ideal choice for applications that require the highest level of conductivity.

Furthermore, silver maintains its excellent conductivity even at high frequencies. This property is crucial in electronic devices that operate in the radio frequency range, such as antennas and wireless communication systems.

The low resistivity of silver contributes to the efficient transmission of electronic signals. It minimizes energy loss during transmission, ensuring that the intended signals reach their destination without significant degradation.

In addition to its outstanding electrical conductivity, silver also exhibits remarkable thermal conductivity. This property allows silver to effectively dissipate heat generated by electronic components, preventing overheating and ensuring device reliability.

Despite its exceptional conductivity, there are some limitations to silver usage in electronics. The main challenge is its high cost compared to other conductive materials such as copper or aluminum. This has led to the development of alternative materials and techniques to meet the demands of cost-effective manufacturing.

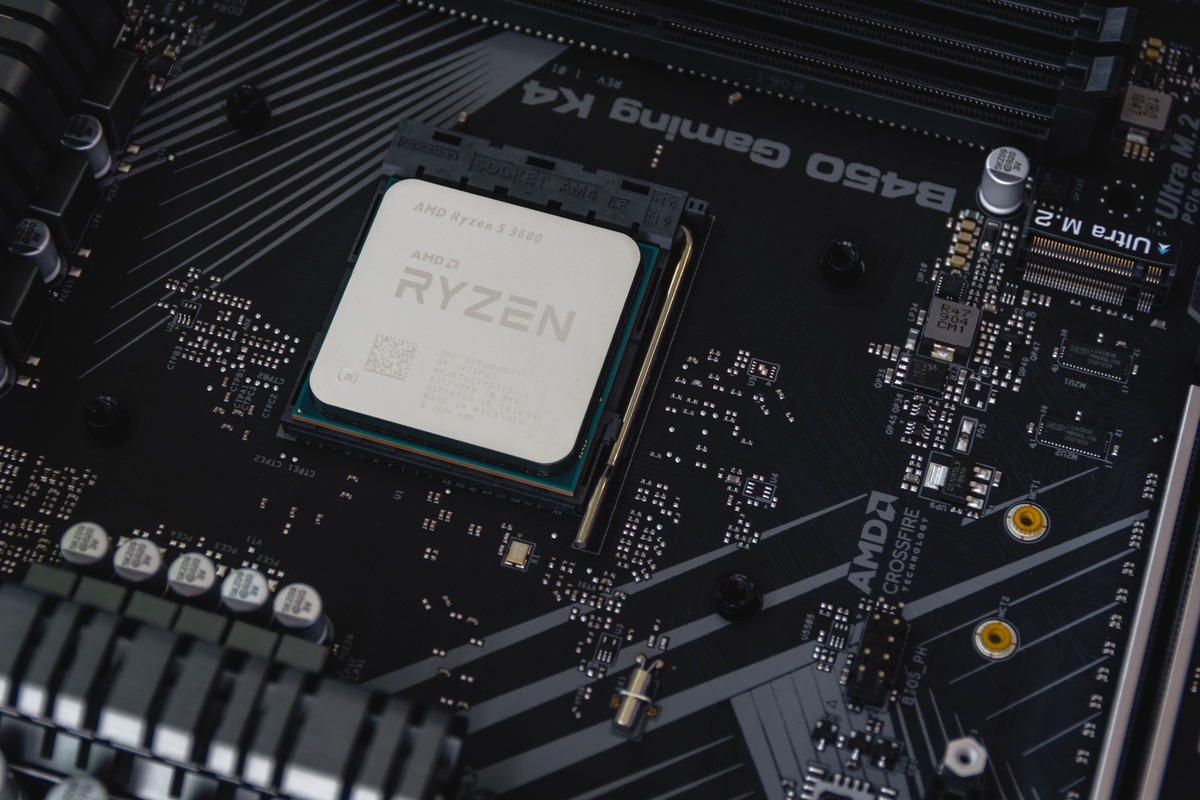

Silver in Circuit Boards

Circuit boards, also known as printed circuit boards (PCBs), are the backbone of electronic devices. Silver plays a crucial role in the production of circuit boards, enabling the efficient flow of electrical signals and facilitating the interconnection of electronic components.

Silver is primarily used in PCBs as conductive traces that connect various components and circuitry on the board. These traces are printed onto the board’s surface using specialized techniques such as screen printing or lithography.

One of the main advantages of using silver in circuit boards is its exceptional conductivity. The high conductivity of silver ensures minimal signal loss during transmission, allowing for accurate and reliable electronic communication.

Moreover, silver’s resistivity is lower than many other materials, which means it offers lower resistance to the flow of electric current. This translates to reduced power consumption and increased efficiency in electronic devices.

Another benefit of using silver in circuit boards is its superior corrosion resistance. Silver resists oxidation and tarnishing, which helps maintain the integrity of the conductive traces over time. This is particularly important in applications where the circuit boards are exposed to harsh environmental conditions or prolonged use.

Silver is also highly compatible with other materials commonly used in circuit boards, such as solder and protective coatings. This compatibility ensures strong and reliable connections between silver traces and other components, enhancing the overall durability and lifespan of the circuit board.

However, it is worth noting that the cost of using silver in circuit boards is relatively higher compared to alternative materials like copper or aluminum. This has led to developments in alternative techniques, such as silver-plated copper traces, to strike a balance between cost-effectiveness and performance.

Despite the challenges, silver remains a popular choice for high-end circuit boards where superior conductivity and reliability are crucial. Its exceptional properties make it an ideal material for applications such as aerospace and defense, telecommunications, and high-performance computing.

Silver in Electrical Contacts

Electrical contacts are the crucial components that enable the flow of electricity between different parts of an electrical circuit. Silver is widely used in electrical contacts due to its excellent conductivity, durability, and resistance to corrosion.

Silver exhibits one of the highest electrical conductivities among all metals, making it an ideal material for electrical contacts. The high conductivity of silver ensures efficient and reliable transmission of electrical signals, minimizing power loss and heat generation.

In addition to its exceptional conductivity, silver has a low contact resistance. This means that when two silver contacts come into contact with each other, the resistance between them is minimized, resulting in a more efficient flow of current.

Furthermore, silver’s resistance to corrosion makes it an excellent choice for electrical contacts that are exposed to harsh environments or frequent switching. Unlike other metals, silver does not easily oxidize or form a high-resistance layer on its surface, ensuring a stable and long-lasting electrical connection.

Silver contacts are commonly used in various electrical devices and equipment, including switches, relays, connectors, and circuit breakers. These components require reliable and low-resistance connections to ensure efficient and safe operation.

Although silver is an excellent choice for electrical contacts, its cost can be higher compared to alternative materials. To address this, manufacturers often use a silver alloy or silver-plated contacts, which offer a balance between performance and cost-effectiveness.

It is also worth mentioning that in some cases, silver contacts may experience a phenomenon called “silver migration.” This occurs when silver ions migrate across the contact surface, leading to a short circuit or malfunction. However, advancements in contact design and materials have significantly reduced the occurrence of silver migration.

Overall, silver’s superior conductivity, low contact resistance, and corrosion resistance make it an ideal material for electrical contacts. Its reliability and long-term performance make it a popular choice in a wide range of applications where efficient electrical connections are essential.

Silver in Connectors and Switches

Silver plays a vital role in the construction of connectors and switches, which are essential components in electrical and electronic systems. The exceptional conductivity and low resistance of silver make it an ideal material for ensuring reliable and efficient connections in these devices.

Connectors serve as the interface between different electrical or electronic components, allowing for the transfer of signals or power. Silver is commonly used in connector pins and sockets due to its excellent electrical conductivity. The high conductivity of silver ensures minimal signal loss and maximum efficiency in signal transmission.

Furthermore, silver’s corrosion resistance enhances the durability and longevity of connectors. It prevents the formation of tarnish or oxide layers on the contact surfaces, which can impair the electrical connection. This resistance to corrosion is particularly important for connectors exposed to moist or harsh environments.

In switches, silver is used in contact points that open or close the circuit. Silver’s conductivity and low resistance enable efficient current flow when the switch is in the closed position, ensuring minimal power loss. Additionally, silver’s low contact resistance ensures reliable operation even during repeated switching cycles.

Silver’s compatibility with other materials commonly used in connectors and switches, such as plastics and metals, simplifies the manufacturing process and ensures excellent mechanical stability and connection integrity.

Despite its numerous benefits, silver’s higher cost compared to alternative materials can be a limiting factor. To address this, manufacturers often use silver-plated contacts or silver alloys that offer a balance between cost-effectiveness and performance.

It is worth mentioning that silver’s exceptional properties go beyond standard connectors and switches. Silver is also used in high-frequency coaxial connectors, RF switches, and other specialized connectors that require superior signal integrity and performance.

Silver in Batteries and Energy Storage

Silver’s unique properties make it a valuable component in batteries and energy storage systems. Its high electrical conductivity, low resistance, and excellent chemical stability contribute to efficient energy storage and discharge.

One of the primary applications of silver in batteries is in the form of silver oxide. Silver oxide batteries, also known as silver-zinc batteries, are commonly used in small portable devices such as hearing aids and cameras. Silver oxide electrodes offer high energy density and long runtime, making them an ideal choice for these applications.

Another application of silver in energy storage is the use of silver in supercapacitors. Supercapacitors, also known as ultracapacitors, are energy storage devices that can deliver high power quickly. Silver electrodes in supercapacitors provide high conductivity and capacitance, enabling rapid charge and discharge cycles.

Silver is also utilized in the construction of silver-cadmium (Ag-Cd) batteries. These batteries offer high energy density, long cycle life, and stable performance, making them suitable for applications that require reliable and long-lasting power sources.

In addition to batteries, silver has shown potential in emerging energy storage technologies such as solid-state batteries and silver-based hybrid systems. Solid-state batteries, which use solid electrolytes, can benefit from silver’s high ionic conductivity, leading to improved energy storage and higher power output.

Silver’s chemical stability is a significant advantage in energy storage systems. It resists oxidation and corrosion, ensuring the electrode’s integrity and longevity. This stability allows for extended battery life and reduced maintenance requirements.

Despite its advantages, the cost of silver remains a limiting factor in large-scale energy storage applications. However, ongoing research and development efforts are focused on finding alternative materials or methods to lower the cost while maintaining or enhancing silver’s performance in energy storage systems.

Overall, silver’s unique combination of conductivity, stability, and energy storage capabilities make it a valuable component in various battery technologies, offering efficient and reliable energy storage solutions.

Silver in Displays and Screens

Silver plays a crucial role in the manufacturing of displays and screens, contributing to their exceptional clarity, conductivity, and durability. Whether it’s in LCD, OLED, or other advanced display technologies, silver is utilized for various purposes to ensure optimal performance.

In LCD (Liquid Crystal Display) screens, silver is commonly used as a transparent electrode material. This transparent conductive layer allows electrical current to pass through while allowing light to transmit. Silver’s high electrical conductivity and excellent transparency make it an ideal material for this application, ensuring efficient signal transmission and vibrant display quality.

Furthermore, silver has excellent reflectivity properties, enabling it to enhance the brightness and overall visual experience of displays. It is often used as a reflective layer in LCD panels, functioning to redirect and amplify the light emitted by the backlight to improve brightness and image clarity.

OLED (Organic Light Emitting Diode) displays also benefit from silver’s exceptional properties. In OLED screens, silver is used as the cathode material, responsible for injecting electrons into the organic layers to emit light. Silver’s high electrical conductivity and low resistance enable efficient electron injection, resulting in brighter and more vibrant OLED displays.

Silver’s superior durability and corrosion resistance make it an excellent choice for screen coatings and protective layers. It helps prevent damage caused by scratches, moisture, or other environmental factors, ensuring the longevity and reliability of the display.

Moreover, silver nanoparticles have gained attention for their use in touchscreens, providing enhancements in conductivity and touch sensitivity. The incorporation of silver nanoparticles into touchscreen displays improves responsiveness, accuracy, and usability.

While silver offers numerous advantages in display and screen technologies, it is important to note that there are ongoing efforts to reduce the use of silver due to its cost. Alternative materials and techniques are being explored to achieve similar or even better performance while minimizing production expenses.

Overall, silver’s properties make it an essential component in the creation of high-quality displays and screens. Its conductivity, reflectivity, and durability contribute to the production of visually stunning and reliable display technologies.

Silver in Sensors and Detectors

Silver plays a vital role in the development of sensors and detectors, enabling precise and accurate measurement of various physical and chemical phenomena. Its exceptional conductivity, sensitivity, and stability make it an ideal material for a wide range of sensing applications.

One of the key applications of silver in sensors is its use as a sensing element in electrical and electronic sensors. Silver-based sensors can detect changes in electrical resistance, capacitance, or impedance in response to environmental variables such as temperature, pressure, or humidity.

Silver is also utilized in gas sensors, where it acts as a catalyst for gas reactions. Certain gases, such as carbon monoxide or hydrogen sulfide, can cause a change in the electrical properties of silver, allowing for the detection and measurement of these gases in various applications such as industrial safety and environmental monitoring.

In addition to its electrical properties, silver’s high reflectivity and surface plasmon resonance (SPR) characteristics make it suitable for optical sensors. SPR-based sensors are used in applications such as biosensing, where the interaction between biological molecules and silver-coated surfaces can be detected and analyzed.

Silver nanoparticles are widely used in chemical and biosensors due to their unique properties. The large surface area of silver nanoparticles allows for enhanced sensitivity and improved detection limits, making them valuable in medical diagnostics, environmental monitoring, and food safety applications.

The stability and corrosion resistance of silver make it an excellent choice for long-term and reliable sensing. It can withstand harsh environmental conditions without significant degradation, ensuring consistent sensing performance.

Despite silver’s favorable characteristics, cost can be a limiting factor in some sensing applications. Researchers are continuously exploring alternative materials or hybrid approaches to reduce costs while maintaining or improving sensing performance.

Silver in Photovoltaic Cells

Silver plays a crucial role in photovoltaic cells, commonly known as solar cells, which convert sunlight into electricity. It is used in various components of the cell to enhance conductivity, reflectivity, and durability, ultimately improving the efficiency and performance of solar energy conversion.

One of the primary applications of silver in photovoltaic cells is as a conductive material. It is commonly used as the contact electrodes in the cell structure, facilitating the efficient flow of current within the device. Silver’s high electrical conductivity ensures minimal power loss during the conversion process.

In addition to its conductivity, silver’s exceptional reflectivity is advantageous in photovoltaic cells. It helps to maximize the absorption of sunlight by reflecting the incident light back into the active layer of the cell, ensuring more efficient utilization of solar energy.

Silver is also utilized in the production of busbars and interconnects, which play a crucial role in connecting multiple solar cells within a module or solar panel. Silver’s high conductivity and low resistance enable efficient current extraction and transfer, minimizing power losses.

Moreover, silver’s stability and corrosion resistance make it an ideal material for encapsulation and backside contact layers in photovoltaic cells. It protects the cell from environmental factors and prevents degradation, ensuring the longevity and reliability of the solar panel.

Silver paste, a mixture of silver particles and other additives, is commonly used for screen-printing the front and back contacts of photovoltaic cells. This paste enables precise and efficient deposition of silver onto the cell, enhancing electrical conductivity and contact quality.

Although silver offers numerous benefits in photovoltaic cells, its cost can be relatively high. As a result, researchers are continuously exploring alternative materials or techniques to reduce the cost while maintaining or improving the performance of solar cells.

Overall, silver’s conductivity, reflectivity, and stability make it an essential component in the development of efficient and reliable photovoltaic cells. Its role in enhancing electrical performance and mitigating losses contributes to the advancement of solar energy as a sustainable power source.

Silver in Antennas and RFID Technology

Silver plays a significant role in the construction of antennas and RFID (Radio Frequency Identification) technology, enabling efficient wireless communication and identification. Its exceptional conductivity, low resistance, and stability make it a preferred material for these applications.

Antennas are essential components in wireless communication systems, transmitting and receiving electromagnetic signals. Silver’s high electrical conductivity makes it an excellent choice for antenna construction. It allows for efficient signal transmission and reception, maximizing the range and reliability of wireless communication.

In applications where high-frequency signals are used, such as in mobile devices or wireless networks, silver is particularly advantageous. It offers low signal losses and reduced impedance, ensuring optimal performance and uninterrupted connectivity.

RFID technology relies on silver for its antennas to enable wireless identification and tracking. In RFID systems, silver-based antennas are used to wirelessly capture and transmit data stored on RFID tags. The high conductivity of silver ensures efficient energy transfer and reliable data transmission.

Silver’s stability and resistance to corrosion are important in both antennas and RFID technology. It ensures that the performance of the antenna or the readability of RFID tags remains consistent over time, even in various environmental conditions or prolonged usage.

Furthermore, silver nanoparticles have gained attention in RFID technology due to their unique properties. They enable the miniaturization of antennas and RFID tags, making them suitable for smaller and more compact devices. Additionally, silver nanoparticles enhance the sensitivity and range of RFID systems, improving overall performance.

Despite its excellent properties, the cost of silver can sometimes be a limiting factor in large-scale antenna and RFID applications. To address this, alternative materials or hybrid approaches may be adopted to strike a balance between cost-effectiveness and performance.

Silver in Printed Electronics

Silver plays a vital role in the field of printed electronics, a technology that revolves around the printing of electronic components onto various substrates. Its excellent electrical conductivity, compatibility with printing processes, and versatility make it an ideal material for the fabrication of flexible and cost-effective electronic devices.

One of the key applications of silver in printed electronics is its use as conductive ink or paste. Silver-based inks can be printed onto substrates using techniques such as screen printing, inkjet printing, or flexography. The ink’s silver particles provide the necessary electrical conductivity for printed circuits, sensors, and other electronic components.

The exceptional conductivity of silver allows for the creation of intricate and highly functional printed circuits. These circuits can be used in various electronic devices, such as touch panels, smart labels, wearable sensors, and flexible displays.

Moreover, silver’s compatibility with different substrates makes it suitable for a wide range of printed electronics applications. It can be printed onto flexible materials like plastic films, enabling the fabrication of bendable and stretchable electronic devices.

Silver’s thermal stability is also crucial in printed electronics. The printed silver circuits or traces must withstand high-temperature processes, such as curing or sintering, without deteriorating or losing their electrical conductivity.

Additionally, silver is used as an electrode material in printed sensors. Whether it’s temperature sensors, strain sensors, or gas sensors, silver electrodes offer high signal quality and reliability, enabling accurate and sensitive detection.

Despite the advantages of using silver in printed electronics, it is worth noting that cost can be a factor to consider. Silver is generally more expensive than other conductive materials, such as copper or aluminum. Researchers and manufacturers are continuously exploring alternative materials and techniques to achieve cost-effective solutions without compromising performance.

Overall, silver’s exceptional conductivity, compatibility with printing processes, and versatility make it an essential material in the field of printed electronics. It enables the fabrication of flexible, lightweight, and cost-effective electronic devices that are increasingly prevalent in various industries.

Challenges and Alternatives to Silver Usage

While silver offers numerous advantages in various electronic applications, there are challenges associated with its usage, primarily related to cost and availability. These challenges have led to the exploration of alternative materials and techniques that aim to provide comparable performance while addressing these issues.

One of the main challenges with using silver is its relatively high cost compared to other conductive materials, such as copper or aluminum. The cost of silver can significantly impact the overall production cost of electronic devices, especially in high-volume manufacturing. This has prompted the development of cost-effective alternatives that provide similar electrical properties.

One alternative to silver is copper, which is a widely available and more cost-effective option. Copper has excellent electrical conductivity and lower cost compared to silver. It is commonly used in high-conductivity applications that require a balance between performance and cost, such as in power distribution systems and high-speed data transmission.

Another alternative to silver is aluminum, which is even more cost-effective than copper. While aluminum has lower electrical conductivity than silver or copper, it can still be suitable for certain applications, especially when weight reduction is a priority. Aluminum is commonly used in electronic components like heat sinks and interconnects.

In addition to alternative materials, advances in technology have led to the development of techniques that reduce the amount of silver used in electronic devices. For example, silver-plated copper or silver alloy coatings can be used instead of pure silver to achieve a balance between performance and cost.

Furthermore, researchers are exploring the use of nanomaterials and nanotechnology to enhance the efficiency and performance of alternatives to silver. Graphene, carbon nanotubes, and conductive polymers are among the nanomaterials being investigated for their conductivity and suitability in various electronic applications.

It is important to note that while challenges exist, silver continues to be the material of choice for applications that require the highest level of conductivity and stability. Advances in silver recycling and recovery techniques are also being explored to mitigate the environmental impact and cost associated with its usage.

Future of Silver in Electronics

The future of silver in electronics looks promising, as it continues to be a key material in various applications and emerging technologies. Advancements in materials science and the increasing demand for efficient and sustainable electronic devices are driving the exploration and development of silver-based solutions.

One area where silver is expected to play a significant role is in the field of advanced electronics, such as flexible and wearable devices. The exceptional conductivity and flexibility of silver make it an ideal candidate for printed electronics, enabling the creation of lightweight, bendable, and stretchable electronic devices.

Furthermore, the rise of Internet of Things (IoT) devices and applications is expected to boost the demand for silver in electronics. IoT devices rely on efficient wireless communication and reliable sensing capabilities, where silver’s conductivity, stability, and compatibility come into play.

As energy efficiency becomes a critical factor in electronic devices, silver’s superior conductivity and low resistance make it a valuable component in emerging energy-saving technologies. From energy storage to power electronics, silver’s properties contribute to improved efficiency and reduced power consumption.

The development of alternative energy sources, such as solar power, also relies on silver. Silver is crucial for efficient photovoltaic cells, helping drive the adoption of solar energy as a sustainable and renewable power source.

Additionally, advancements in nanotechnology and nanomaterials are expected to influence the future of silver in electronics. Nanostructured silver materials, such as nanoparticles or nanowires, offer enhanced properties and performance in various applications, including sensors, displays, and energy storage.

Despite the promising future, it is important to address the challenges associated with silver usage, such as cost and availability. Research efforts continue to focus on finding cost-effective alternatives to silver while maintaining or even surpassing its performance.

Overall, the future of silver in electronics is shaped by its unique properties, adaptability, and ongoing innovation. As the demand for more efficient, sustainable, and advanced electronic devices continues to grow, silver is expected to play a pivotal role in shaping the electronics industry for years to come.