Increase in Productivity

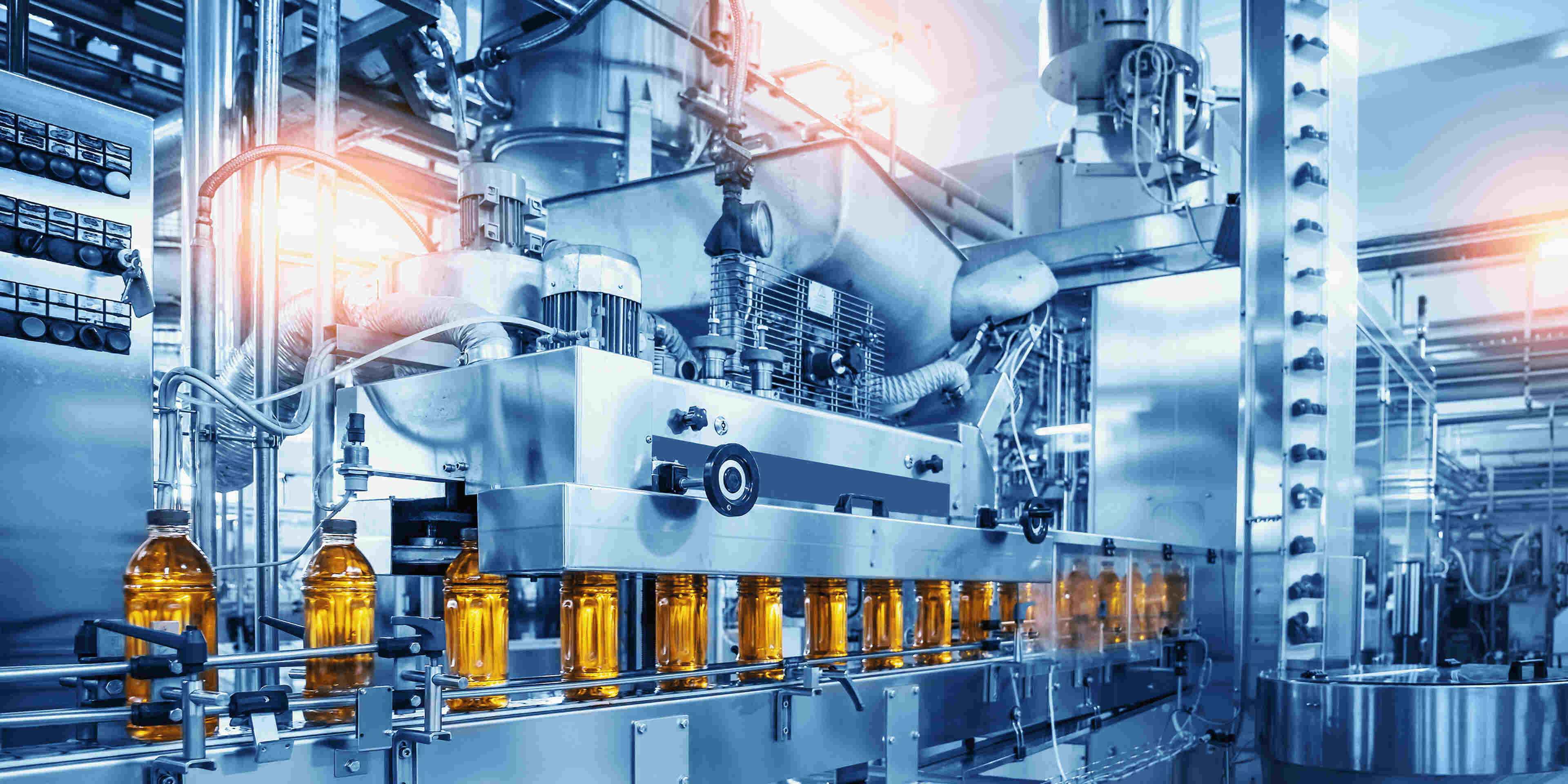

One of the major benefits that producers gain from the use of new technology in the industry is a significant increase in productivity. With the introduction of advanced machinery and automation systems, tasks that previously required significant manual labor can now be completed in a fraction of the time. This not only enhances efficiency but also allows producers to meet higher demand and scale their operations.

By implementing modern technology, producers can streamline their production processes and eliminate various bottlenecks. For instance, the use of robotics and artificial intelligence (AI) allows for precise and rapid assembly, reducing human error and time-consuming manual tasks. This leads to faster production cycles and increased output.

Furthermore, the integration of advanced software and analytics tools enables producers to optimize their production lines. Real-time monitoring and predictive maintenance systems help identify and resolve issues before they cause disruptions, minimizing downtime. Additionally, data-driven insights allow for better planning and resource allocation, maximizing efficiency and reducing wastage.

Moreover, new technology facilitates communication and collaboration among team members and departments. Cloud-based platforms and project management tools enable real-time sharing of information, improving coordination and enabling teams to work together seamlessly. This helps in reducing delays and ensuring smooth workflow throughout the production process.

The use of advanced technology also empowers producers to improve the skills and knowledge of their workforce. Training programs on new equipment and software help employees adapt to the changing technological landscape and perform their tasks more efficiently. This further enhances productivity by leveraging the capabilities of both technology and human resources.

Cost Reduction

The adoption of new technology in the industry offers significant cost reduction opportunities for producers. By implementing modern solutions, producers can automate repetitive tasks, reduce labor costs, and optimize resource allocation.

Automation plays a crucial role in cost reduction. With the use of advanced machinery and robotics, producers can minimize the need for manual labor in certain processes. This not only reduces labor costs but also improves efficiency and accuracy, as machines can perform tasks faster and with fewer errors.

Furthermore, new technology enables producers to optimize resource allocation. Through the use of data analytics and real-time monitoring systems, producers can identify areas of inefficiency and eliminate wastage. This includes optimizing energy consumption, reducing material waste, and improving inventory management. By streamlining these processes, producers can significantly reduce their operational expenses.

In addition to reducing labor and operational costs, technology also enables better cost control and forecasting. Advanced software and analytics tools provide producers with real-time data and insights into various aspects of their business, including production costs, supply chain management, and pricing strategies. This allows producers to make informed decisions and take proactive measures to minimize costs and maximize profitability.

Another cost-saving benefit of new technology is the ability to leverage remote work capabilities. With the advancements in communication tools and remote collaboration platforms, producers can employ remote workers and reduce the need for physical office spaces. This not only cuts down on overhead costs but also provides opportunities to tap into a global talent pool.

Overall, the integration of new technology in the industry presents producers with numerous avenues to reduce costs. From automating processes and optimizing resource allocation to leveraging data analytics for better cost control, technology offers a range of cost-saving benefits that can positively impact a producer’s bottom line.

Improved Efficiency

The use of new technology in the industry brings about a significant improvement in efficiency for producers. By leveraging innovative solutions, producers can optimize workflows, reduce manual errors, and enhance overall operational efficiency.

One of the key drivers of improved efficiency is automation. With the help of advanced machinery and robotics, producers can automate repetitive tasks and streamline their production processes. This not only saves time but also reduces the risk of errors, resulting in higher quality output and a smoother workflow.

Furthermore, the integration of software and analytics tools enables producers to gain valuable insights into their operations. Real-time monitoring allows for proactive identification of issues and bottlenecks, enabling prompt resolution and minimizing downtime. Data analytics helps in better forecasting, resource planning, and inventory management, optimizing the use of resources and improving overall efficiency.

Additionally, new technology facilitates better communication and collaboration between different teams and departments within a producer’s organization. Cloud-based platforms and project management tools enable seamless sharing of information and enable real-time collaboration, leading to faster decision-making and improved efficiency.

Moreover, the use of technology enables producers to improve their quality control processes. Advanced sensors, AI-powered algorithms, and machine learning capabilities can detect defects, anomalies, and deviations in real-time, allowing for immediate corrective actions. This not only reduces waste and rework but also ensures that only products of the highest quality reach the market.

Another aspect of improved efficiency is the ability to adapt quickly to changing market demands. By utilizing new technology, producers can be more agile and responsive to customer needs. For example, flexible manufacturing systems and customization capabilities allow for rapid adjustments in production to meet specific customer requirements. This leads to increased customer satisfaction and a competitive edge in the market.

Streamlined Processes

The use of new technology in the industry brings about streamlined processes for producers, resulting in improved productivity and efficiency. By leveraging innovative solutions, producers can automate tasks, reduce complexity, and optimize their workflows.

One of the key benefits of technology is the automation of repetitive and time-consuming tasks. With the help of advanced machinery and software, producers can automate various processes, such as inventory management, order processing, and data entry. This not only saves valuable time but also reduces the risk of errors that can occur in manual tasks.

Furthermore, technology allows producers to integrate different stages of their production process seamlessly. For example, through the use of enterprise resource planning (ERP) systems, producers can connect various departments, such as manufacturing, inventory, and sales, on a single platform. This integration enables real-time sharing of information, improves communication, and eliminates the need for manual data transfer between different systems.

Additionally, new technology enables producers to implement lean manufacturing principles, resulting in streamlined processes. By eliminating waste and minimizing non-value-added activities, producers can optimize their production flows and reduce cycle times. This leads to increased efficiency and cost savings.

Moreover, technology facilitates better tracking and monitoring of processes. With the use of sensors and Internet of Things (IoT) devices, producers can gather real-time data on machine performance, energy consumption, and product quality. This data allows for proactive maintenance, timely adjustments, and continuous improvement of processes.

Another aspect of streamlined processes is the integration of supply chain management. Through technology, producers can collaborate with suppliers and customers, ensuring a smooth flow of materials and information throughout the supply chain. This integration enables just-in-time inventory management, reduces lead times, and improves overall process efficiency.

Enhanced Quality Control

The use of new technology in the industry offers producers enhanced quality control capabilities, ensuring that the products they deliver meet the highest standards. By leveraging advanced tools and systems, producers can detect defects, reduce errors, and uphold consistent quality throughout their production processes.

One of the key benefits of technology in quality control is the use of advanced sensors and imaging systems. These technologies can detect even the smallest deviations from the desired specifications, helping to identify defects and potential issues early on. By preventing defective products from reaching the market, producers can uphold their reputation for delivering high-quality goods.

Moreover, technology enables real-time monitoring and data analysis to ensure quality control. Through the use of IoT devices and connected systems, producers can track critical parameters during the production process, such as temperature, pressure, and humidity. Any deviations or abnormalities can be immediately detected, allowing for swift corrective actions.

The integration of AI and machine learning algorithms further enhances quality control processes. By analyzing vast amounts of data, these technologies can identify patterns and anomalies that might be overlooked by human inspectors. This enables producers to predict and prevent potential quality issues, resulting in improved product consistency.

Furthermore, technology provides tools for comprehensive traceability and documentation. Through barcode systems, RFID tags, and digital record-keeping, producers can track the entire production process, from raw materials to the final product. This allows for quick identification of any quality-related issues and facilitates efficient recall processes if necessary.

Another aspect of enhanced quality control is the integration of customer feedback and real-time data analysis. Through online platforms, producers can gather feedback and insights from customers, enabling them to make continuous improvements to their products. By leveraging data analytics, producers can identify trends and patterns to further enhance product quality and customer satisfaction.

Customization and Personalization

The use of new technology in the industry allows producers to offer greater customization and personalization options to their customers. By leveraging advanced software, data analytics, and flexible manufacturing processes, producers can create unique and tailored products that meet the specific needs and preferences of individual customers.

One of the key benefits of technology in customization is the ability to efficiently handle complex product configurations. Through the use of configurator software, producers can offer a wide range of options and features for customers to choose from. This enables customers to create a product that aligns perfectly with their requirements, resulting in higher customer satisfaction.

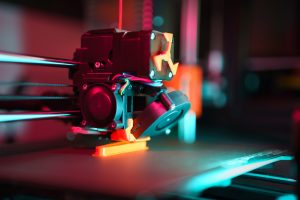

Moreover, technology enables mass customization, where producers can efficiently produce customized products at scale. Flexible manufacturing processes, such as 3D printing, allow for on-demand production of personalized items without the need for large upfront investments or excessive lead times. This enables producers to offer unique products without compromising on efficiency.

The integration of data analytics and customer insights plays a crucial role in customization and personalization. By gathering and analyzing data on customer preferences, behavior, and buying patterns, producers can understand their customers better and offer personalized recommendations and product suggestions. This not only enhances the customer experience but also increases the likelihood of repeat purchases and customer loyalty.

Furthermore, technology allows producers to leverage augmented reality (AR) and virtual reality (VR) technologies to enhance the customization experience. Customers can visualize and interact with virtual versions of the product, making informed decisions about customization options and personalizing their products in real-time.

Another aspect of customization and personalization is the integration of smart devices and Internet of Things (IoT) technologies. Through connected devices, producers can gather real-time data on customer usage and preferences, enabling them to offer personalized features and recommendations. For example, smart home appliances can learn from user behavior and automatically adjust settings to meet individual needs.

Overall, the use of new technology empowers producers to offer a higher degree of customization and personalization to their customers. By leveraging advanced software, data analytics, flexible manufacturing processes, and emerging technologies, producers can create unique, tailored products that cater to individual preferences and enhance the overall customer experience.

Access to a Wider Market

The use of new technology in the industry provides producers with enhanced opportunities to access a wider market and reach a larger customer base. By leveraging digital platforms, e-commerce, and online marketing strategies, producers can overcome geographical limitations and tap into global markets.

One of the key benefits of technology is the ability to establish an online presence and conduct e-commerce. With the help of websites, e-commerce platforms, and online marketplaces, producers can showcase their products to a global audience. This eliminates the need for physical stores and allows producers to reach customers beyond their local market.

Technology also enables producers to implement targeted digital marketing strategies. Through search engine optimization (SEO), social media marketing, and online advertising, producers can increase their online visibility and attract potential customers. This targeted approach allows for effective marketing campaigns that reach specific demographics and geographic areas.

Furthermore, technology facilitates seamless international transactions and logistics. With the integration of online payment gateways, producers can securely process payments from customers worldwide. In addition, advanced supply chain and logistics management systems enable efficient shipping and delivery, ensuring that products can be delivered to customers across different regions.

Additionally, technology provides valuable data and insights on market trends and customer preferences. Through analytics tools and data tracking, producers can gain a better understanding of their target market’s needs and adapt their products and marketing strategies accordingly. This enables producers to align their offerings with market demands and maximize their reach.

Another aspect of accessing a wider market is the ability to offer multilingual and localized support. Through technology, producers can provide translated product descriptions, customer service, and support in various languages. This enhances the customer experience and removes language barriers, allowing producers to connect with a more diverse customer base.

Moreover, technology enables producers to engage with customers in real-time and build meaningful relationships. Through social media platforms, live chats, and online communities, producers can foster direct communication with their target audience. This not only helps in understanding customer needs but also enables producers to provide personalized assistance and support.

Overall, the use of new technology opens up opportunities for producers to access a wider market. By leveraging digital platforms, online marketing strategies, and data-driven insights, producers can expand their reach, overcome geographical limitations, and connect with customers around the world.

Real-time Data and Analytics

The use of new technology in the industry provides producers with access to real-time data and analytics, empowering them to make informed decisions and optimize their operations. By leveraging advanced software, sensors, and data analytics tools, producers can gain valuable insights into their processes, performance, and customer behavior.

One of the key benefits of technology is the ability to gather real-time data from various sources. Through the integration of sensors and IoT devices, producers can collect data on machine performance, environmental conditions, and product quality in real time. This enables proactive monitoring and allows for immediate action to be taken in case of deviations or issues.

Furthermore, technology enables the consolidation and analysis of large volumes of data. With the help of data analytics tools and algorithms, producers can extract valuable insights from their data sets. From identifying trends and patterns to predicting future outcomes, data analytics allows producers to make data-driven decisions and optimize their processes.

Real-time data and analytics also facilitate continuous improvement and optimization of production processes. By monitoring key performance indicators (KPIs) in real time, producers can identify areas of inefficiency or performance gaps. This enables them to implement necessary changes and improvements to enhance their operational efficiency and overall performance.

In addition, technology provides producers with valuable insights into customer behavior and preferences. By analyzing customer data, producers can gain a deep understanding of their target audience, their buying patterns, and their preferences. This allows for more effective marketing strategies, personalized recommendations, and the development of products that align with customer needs.

Moreover, technology enables producers to optimize their supply chain through real-time data and analytics. By gathering and analyzing supply chain data, producers can improve inventory management, predict demand fluctuations, and identify bottlenecks or inefficiencies. This allows for better resource planning and ensures the smooth flow of materials throughout the supply chain.

Another aspect of real-time data and analytics is the ability to monitor and analyze the performance of marketing campaigns. Through digital marketing analytics, producers can track the effectiveness of their marketing strategies, measure key metrics such as click-through rates and conversion rates, and make data-driven adjustments to optimize their marketing efforts.

Overall, the use of real-time data and analytics empowers producers to make informed decisions, optimize their processes, and deliver better products and services. By leveraging advanced software, sensors, and data analytics tools, producers can gain valuable insights that drive continuous improvement and success in the industry.

Reduced Environmental Impact

The use of new technology in the industry brings about reduced environmental impact, allowing producers to operate in a more sustainable and eco-friendly manner. By leveraging innovative solutions and adopting green practices, producers can minimize their carbon footprint and contribute to environmental conservation.

One of the key ways technology reduces environmental impact is through improved energy efficiency. The integration of energy-efficient equipment, smart sensors, and automation systems helps optimize energy consumption and reduce wastage. This leads to significant energy savings, lower greenhouse gas emissions, and a smaller ecological footprint.

Furthermore, technology enables producers to implement waste reduction and recycling initiatives. Through advanced sorting and recycling systems, producers can segregate different types of waste and maximize the recycling potential. This reduces the amount of waste sent to landfills and promotes the reuse of valuable resources.

The use of technology also facilitates better water management and conservation. Through sensors and monitoring systems, producers can track water usage in real time and detect leaks or areas of excessive consumption. This enables prompt identification and resolution of water-related issues, resulting in significant water conservation efforts.

Moreover, technology allows for the adoption of sustainable materials and production processes. With the help of advanced research and development, producers can explore alternative materials and manufacturing methods that have a lower environmental impact. This includes the use of bio-based materials, eco-friendly packaging, and the reduction of harmful chemicals in production processes.

Another aspect of reduced environmental impact is the integration of remote work and virtual meetings. With the advancements in communication technology, producers can reduce the need for frequent business travel, leading to lower carbon emissions from transportation. Remote work also promotes work-life balance and reduces the need for physical office spaces, further contributing to a greener business model.

Furthermore, technology enables producers to monitor and reduce their carbon footprint throughout the entire supply chain. By integrating suppliers, transportation logistics, and distribution processes, producers can identify areas of inefficiency and implement measures to minimize carbon emissions associated with their products.

Overall, the use of new technology in the industry plays a significant role in reducing the environmental impact of producers. By implementing energy-efficient practices, waste reduction initiatives, sustainable materials and processes, and promoting remote work, producers can operate in a more environmentally conscious and sustainable manner.

Competitive Advantage

The use of new technology in the industry provides producers with a competitive advantage in the market. By leveraging innovative solutions, producers can differentiate themselves from competitors, enhance customer satisfaction, and stay ahead of the competition.

One of the key ways technology offers a competitive advantage is through improved efficiency and productivity. By automating processes, streamlining workflows, and leveraging data analytics, producers can optimize their operations and deliver products more efficiently. This leads to shorter lead times, faster delivery, and higher customer satisfaction, giving them an edge over competitors.

Furthermore, technology enables producers to offer a higher level of customization and personalization. By leveraging advanced software, flexible manufacturing processes, and data-driven insights, producers can create unique products tailored to meet individual customer needs. This customization capability sets them apart in the market and attracts customers looking for personalized solutions.

The integration of advanced technology also enables producers to enhance their product quality and reliability. Through improved quality control systems, real-time monitoring, and data analytics, producers can consistently deliver products of superior quality. This builds trust and confidence in their brand, providing a competitive advantage over competitors who may struggle with quality issues.

Moreover, technology provides producers with valuable customer insights and a deeper understanding of market trends. By leveraging data analytics and digital marketing tools, producers can identify customer preferences, market demands, and emerging trends. This enables them to develop and launch new products or services that align with customer needs, giving them a competitive edge in the market.

Another aspect of gaining a competitive advantage through technology is the ability to provide exceptional customer experiences. By utilizing advanced customer relationship management (CRM) systems, chatbots, and personalized communication channels, producers can deliver excellent customer service and support. This leads to higher customer satisfaction, loyalty, and ultimately, a competitive advantage.

Furthermore, technology allows producers to tap into new markets and expand their customer base. Through digital marketing strategies, online platforms, and e-commerce capabilities, producers can reach customers beyond their traditional boundaries. This widens their market reach and increases their potential customer base, giving them an advantage over competitors with limited market presence.

Overall, the use of new technology provides producers with a competitive advantage by improving efficiency, offering customization, enhancing product quality, providing valuable customer insights, delivering exceptional customer experiences, and expanding market reach. By leveraging innovative solutions, producers can differentiate themselves and stay ahead of the competition in today’s fast-paced business landscape.