What Is a Digital Caliper?

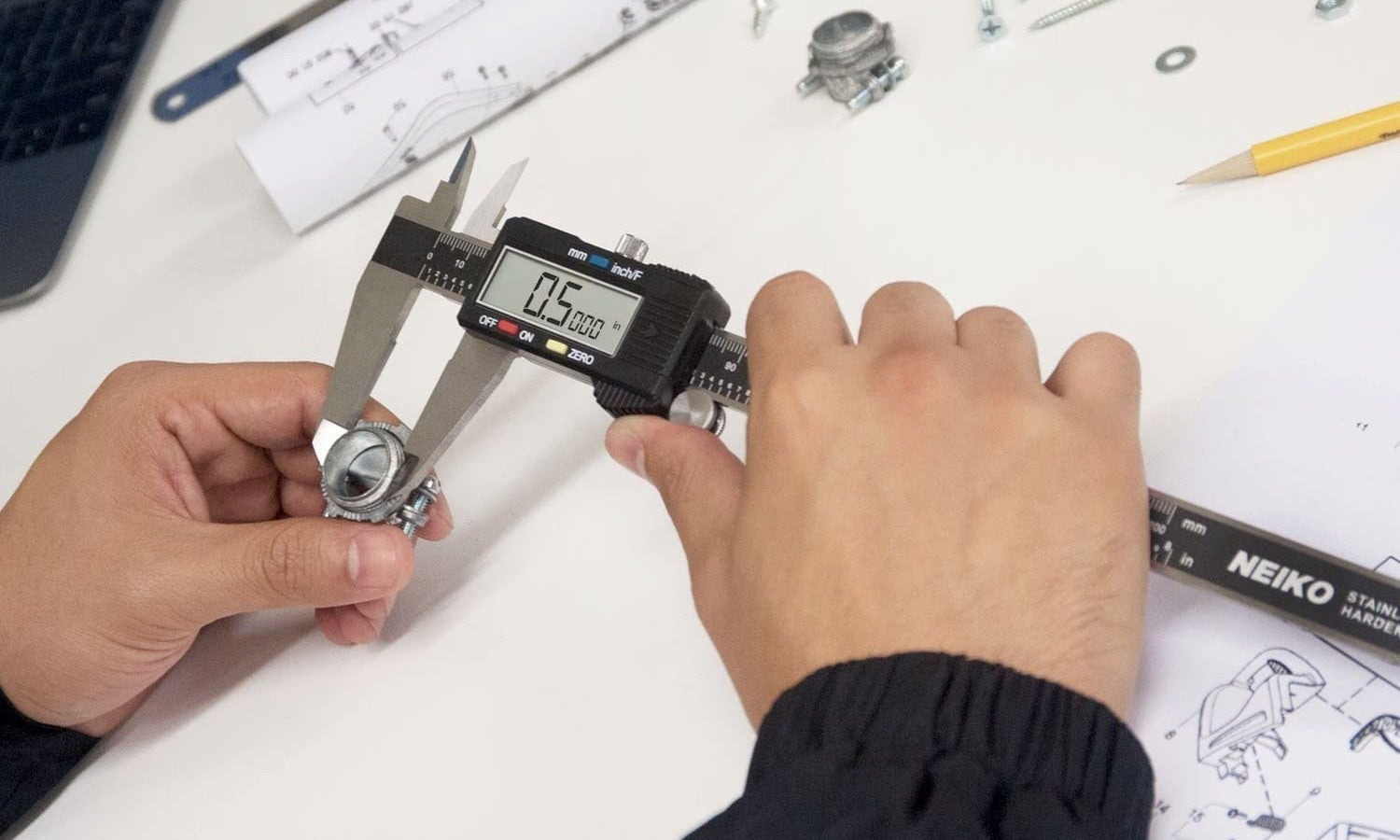

A digital caliper is a precision measuring tool used to accurately measure the length, width, depth, and diameter of various objects. It is an advanced version of the traditional Vernier caliper, with the added feature of a digital display that provides a direct reading of the measurements. This eliminates the need for manually reading and interpreting the scale markings, resulting in faster and more accurate measurements.

The digital caliper consists of two jaws – an upper jaw and a lower jaw – that can be adjusted to fit the object being measured. The upper jaw is attached to the digital display unit, which shows the measurement in either metric or imperial units. The lower jaw is movable and can slide along the main body of the caliper, allowing for precise measurements to be taken.

One of the key advantages of a digital caliper is its ability to measure both inside and outside dimensions, as well as depth. This makes it a versatile tool used in a wide range of applications, such as woodworking, metalworking, machining, and engineering. Digital calipers are commonly used by professionals in various industries, as well as hobbyists and DIY enthusiasts who require accurate measurements in their projects.

In addition to its measurement capabilities, a digital caliper often comes with additional features like a locking screw, which allows the user to lock the jaws in place for consistent measurements. It also typically has a zero reset button, which allows the user to reset the measurement to zero, ensuring accurate readings and easy comparison between multiple measurements.

Overall, a digital caliper offers convenience, accuracy, and ease of use, making it an essential tool for anyone who needs precise measurements in their work or hobbies. Its digital display and various features are designed to simplify the measuring process and provide reliable results.

How Does a Digital Caliper Measure Length?

A digital caliper measures length by utilizing a precision scale and an electronic sensor. When the jaws of the caliper are adjusted to fit the object being measured, the sensor detects the distance between the jaws and converts it into a digital reading displayed on the screen.

To measure length, the user first opens the caliper jaws and places the object between them. The jaws are then gently closed until they securely grip the object. As the jaws close, the sensor detects the distance between them and sends this information to the digital display.

The digital display shows the measurement in either metric or imperial units, depending on the user’s preference. It typically provides readings up to two decimal places for precise measurements. The user can easily read and record the measurement without the need for manual interpretation of scale markings, as is required with traditional calipers.

It’s important to ensure that the object is placed firmly and securely between the jaws to obtain accurate measurements. Any misalignment or slippage may result in an incorrect reading. Additionally, it’s crucial to grasp the caliper properly and avoid exerting excessive pressure, as this can affect the accuracy of the measurement.

Overall, the digital caliper’s ability to measure length with speed and accuracy makes it an indispensable tool in fields that require precise measurements, such as engineering, manufacturing, and scientific research. Its digital display provides clear and easy-to-read measurements, eliminating the potential for human error when interpreting traditional scale markings. With a digital caliper, obtaining accurate length measurements has never been easier or more efficient.

Understanding the Digital Display of a Caliper

The digital display of a caliper plays a crucial role in providing precise and easy-to-read measurements. It consists of a numeric screen where the measurement is displayed in either metric or imperial units, depending on the user’s preference.

The digital display typically offers readings up to two decimal places, enabling highly accurate measurements. It eliminates the need for manual interpretation of scale markings, as required by traditional calipers, reducing the potential for human error.

When taking measurements, it’s important to ensure that the display is easy to read and properly calibrated. To ensure readability, most digital displays are equipped with a backlight or high-contrast screen, making it easier to view measurements in various lighting conditions.

To ensure the accuracy of the display, it’s essential to calibrate the caliper regularly. Calibration involves comparing the digital display reading against a known reference standard to ensure that it is accurate and within the acceptable range. If any discrepancies are detected, adjustments can be made to align the display with the correct measurements.

Additionally, the digital display may have additional features such as a hold function, which freezes the measurement on the screen. This is particularly useful when taking measurements in tight spaces where it may be difficult to see the display while holding the caliper in position.

Understanding the digital display of a caliper allows users to obtain accurate and reliable measurements. By ensuring proper calibration and utilizing the various features available, users can maximize the functionality and usability of the digital display, making their measuring tasks more efficient and precise.

How Does a Digital Caliper Measure Inside Dimensions?

Measuring inside dimensions with a digital caliper is a simple and precise process. The caliper is designed with special jaws that allow for accurate measurement of the internal dimensions of objects such as holes, cylinders, and pipes.

To measure inside dimensions, the user first needs to select the appropriate jaws on the caliper. These jaws are slightly curved and tapered, allowing them to fit into narrow spaces. The caliper’s upper and lower jaws are adjusted to the desired position and then inserted into the opening being measured. The user gently applies pressure to the caliper, ensuring a snug fit against the walls of the opening.

As the caliper jaws are closed, the internal dimensions are captured by the sensor and displayed on the digital screen. The digital display provides accurate and precise readings in either metric or imperial units, depending on the user’s preference. It is important to maintain a steady hand and apply gentle pressure to avoid distorting the shape of the opening being measured.

With a digital caliper, measuring inside dimensions becomes hassle-free and eliminates the need for complex calculations. The user can easily obtain accurate readings for various applications such as determining the inner diameter of a pipe or measuring the depth of a hole.

It is worth mentioning that when measuring inside dimensions, it is essential to ensure that the caliper jaws are inserted perpendicular to the surface being measured. Any tilting or skewing of the caliper can result in inaccurate measurements. Care should also be taken to avoid scratching or damaging delicate surfaces while taking the measurements.

Overall, a digital caliper provides a reliable and efficient method for measuring inside dimensions. Its specially designed jaws and digital display make it an indispensable tool for professionals who need accurate measurements for engineering, machining, and other applications that require precise internal measurements.

Measuring Outside Dimensions with a Digital Caliper

Measuring outside dimensions with a digital caliper is a straightforward and accurate process. The caliper is designed with jaws that allow for precise measurement of the external dimensions of objects such as length, width, and diameter.

To measure outside dimensions, the user first needs to open the caliper jaws and place the object between them. The jaws are then gently closed until they securely grip the object. As the jaws close, the sensor detects the distance between them and displays the measurement on the digital screen.

The digital screen provides clear and easy-to-read measurements in either metric or imperial units, depending on the user’s preference. It typically offers readings up to two decimal places, providing precise measurements for various applications.

When measuring outside dimensions, it’s important to ensure that the caliper jaws are properly aligned with the object being measured. It’s recommended to grasp the caliper firmly and apply gentle pressure to ensure accurate and consistent measurements. Care should be taken to avoid excessive force that could distort the shape of the object or damage delicate surfaces.

A digital caliper’s ability to measure outside dimensions with speed and accuracy makes it an invaluable tool in various industries. Whether measuring the length of a board, the width of a sheet of metal, or the diameter of a pipe, a digital caliper simplifies the process and provides reliable measurements.

Furthermore, the digital caliper often comes with additional features such as a locking screw, which allows the user to lock the jaws in place for consistent measurements. This ensures that the caliper remains securely in position and prevents any slippage during the measurement process.

By utilizing a digital caliper for measuring outside dimensions, professionals and hobbyists alike can rely on its precise readings, enhancing accuracy and efficiency in their work. Its digital display, ease of use, and versatility make it an essential tool for anyone who needs accurate measurements of external dimensions.

How Does a Digital Caliper Measure Depth?

A digital caliper is not only capable of measuring length, width, and outside dimensions, but it can also measure depth with accuracy and precision. Measuring depth with a digital caliper involves utilizing the depth rod or probe that is attached to the caliper.

To measure depth, the user first needs to locate the depth rod on the caliper. The depth rod is a slender extension that protrudes from the main body of the caliper. It is used to extend the measuring range of the caliper and allows for precise depth measurements.

By gently sliding the depth rod into the object being measured, the user can accurately determine the depth. The depth rod extends below the bottom of the caliper jaws, allowing for measurements beyond the range of the jaws themselves.

As the depth rod is pushed into the object, the sensor in the caliper detects the distance and displays the measurement on the digital screen. The digital display provides clear and precise readings, making it easy to obtain accurate depth measurements.

When using the depth rod, it’s important to ensure that it is properly aligned with the object being measured. This ensures that the depth measurement is accurate and consistent. It’s also crucial to avoid applying excessive force when inserting the depth rod to prevent damage to delicate surfaces.

The ability of a digital caliper to measure depth adds to its versatility and makes it a valuable tool in various industries. Whether measuring the depth of a hole, the thickness of a material, or the depth of a recess, a digital caliper ensures precise and reliable measurements.

Additionally, some digital calipers come with a locking screw that allows the user to secure the depth rod in place once the desired depth measurement has been obtained. This ensures that the depth rod remains fixed during the reading, providing consistent and accurate depth measurements.

In summary, a digital caliper can accurately measure depth by utilizing the depth rod or probe. Its ability to measure depth adds to its usefulness in a wide range of applications, making it an indispensable tool for professionals and enthusiasts who require precise depth measurements in their work.

The Importance of Zeroing Out a Digital Caliper

Zeroing out a digital caliper is a crucial step that ensures accurate and reliable measurements. It involves resetting the measurement reading to zero when the jaws are closed, allowing for precise comparisons and eliminating any potential measurement errors.

When the digital caliper is turned on or the jaws are opened, the measurement reading may not always be at zero. This is due to factors such as manufacturing tolerances or slight variations in the caliper’s components. By zeroing out the caliper, these variations are accounted for and the measurement readings are adjusted accordingly.

Zeroing out the digital caliper is a simple process. With the caliper jaws closed, the user needs to press the zero reset button or turn a zero adjustment wheel until the display reads zero. This establishes a reference point for subsequent measurements.

The importance of zeroing out a digital caliper lies in its ability to provide accurate relative measurements. For example, in woodworking or machining applications, where precise measurements or fitment are critical, zeroing out the caliper allows for precise comparisons between measurements and eliminates the need for complex calculations.

Moreover, zeroing out the digital caliper is particularly beneficial when measuring objects with varying thicknesses. By zeroing out the caliper on a reference surface, subsequent measurements can be taken directly from that zero point, making it easier to compare and record measurements accurately.

It is important to note that zeroing out the caliper should be done whenever there is a change in the measurement reference point. This could be due to a different object being measured or a change in the zero reference surface. By regularly zeroing out the caliper, the accuracy and reliability of measurements are maintained.

In summary, zeroing out a digital caliper is a fundamental step that ensures accurate and consistent measurements. By establishing a clear reference point, it allows for precise relative measurements and eliminates any potential errors resulting from variations in the caliper. Incorporating this practice into your measurement routine will greatly enhance the reliability and usefulness of your digital caliper.

Using the Locking Screw on a Digital Caliper

The locking screw on a digital caliper is a valuable feature that allows the user to secure the caliper jaws in place, ensuring consistent and accurate measurements. It is particularly useful when measuring objects that require a steady grip or when taking measurements in tight spaces.

To utilize the locking screw, the user first adjusts the caliper jaws to fit the object being measured. Once the jaws are in position, the locking screw, usually located near the base of the caliper, is tightened to secure the jaws in place. This prevents any movement or unintended adjustment of the jaws during the measurement process.

The locking screw provides several benefits when using a digital caliper. First, it allows for consistent measurements. By locking the jaws in position, any potential slippage or movement of the object being measured is minimized. This ensures that subsequent measurements taken with the caliper will be reliable and consistent.

Furthermore, the locking screw helps maintain the measurement integrity when working in tight or awkward spaces. It allows the user to lock the jaws in position and then remove the caliper from the object for easier readjustment or viewing of the digital display. This is particularly beneficial when taking measurements in areas where the caliper jaws may obstruct the view of the screen.

Using the locking screw also reduces the risk of accidental adjustments during handling or transportation. By securely locking the jaws, the user can confidently move the caliper without fear of changing the measurement position or altering the integrity of the measurement.

It’s important to note that the locking screw should not be overtightened, as excessive force can damage the caliper or affect the accuracy of the measurement. A firm but gentle tightening of the locking screw is usually sufficient to hold the jaws in place without causing any harm.

In summary, the locking screw on a digital caliper is a valuable feature that enhances the accuracy and usability of the tool. By securing the jaws in place, it ensures consistent measurements and reduces the risk of accidental adjustments. Understanding how to use the locking screw properly will greatly improve the efficiency and reliability of your digital caliper measurements.

How Does a Digital Caliper Switch Between Metric and Imperial Units?

One of the key features of a digital caliper is its ability to switch between metric and imperial units of measurement. This flexibility allows users to work with either system depending on their specific needs and preferences.

To switch between metric and imperial units on a digital caliper, there are usually buttons or switches on the caliper itself. These buttons or switches are labeled with the respective unit symbols, such as “mm” for millimeters and “in” for inches.

When the caliper is powered on, pressing the unit button or moving the switch to the desired unit setting will initiate the switch. The digital display will then update to show the measurement readings in the selected unit.

It’s important to note that when switching between metric and imperial units, the caliper does not convert the previous measurements to the new unit. Instead, it only displays the measurements in the newly selected unit going forward. If you need to convert existing measurements, manual calculations or conversion methods should be applied.

Some digital calipers also offer the option to display both metric and imperial units simultaneously on the screen. This feature can be particularly useful for users who work with both systems or need to make quick conversions between the two.

Switching between metric and imperial units on a digital caliper provides versatility and compatibility with various measurement systems. Whether working on international projects or simply choosing the unit system that best suits the task at hand, this feature allows for seamless transitions and accurate measurements.

It’s essential to ensure that the selected unit is appropriate for the intended application. Using the wrong unit of measurement can lead to confusion, errors, and inaccuracies in the final results.

In summary, a digital caliper offers the flexibility to switch between metric and imperial units of measurement. By using the dedicated buttons or switches on the caliper, users can easily switch to their preferred unit system, providing convenience and accuracy in their measurements.

Maintaining and Calibrating a Digital Caliper

Maintaining and calibrating a digital caliper are essential practices to ensure accurate and reliable measurements over time. By properly caring for the caliper and periodically calibrating it, users can maintain the tool’s functionality and maximize its performance.

To maintain a digital caliper, it’s important to keep it clean and free from debris. After each use, wipe the caliper with a soft, lint-free cloth to remove any dust or particles. Avoid using solvents or harsh cleaners, as they may damage the caliper’s components. It’s also important to store the caliper in a protective case or in a clean and dry environment to prevent any damage or contamination.

Calibration is a process that ensures the accuracy of the caliper by comparing its measurement readings against a known reference standard. It’s recommended to calibrate a digital caliper at regular intervals or whenever there is a suspicion of inaccuracy. Calibration can be done using calibration blocks, gauge blocks, or other certified measuring instruments.

To calibrate a digital caliper, first, verify that the reference standard is properly calibrated and traceable to a recognized national or international standard. Then, zero out the caliper to establish a starting point. Next, compare the caliper’s measurement readings with the reference standard at various points along the measurement range. Take note of any discrepancies and make necessary adjustments to align the caliper’s readings with the reference standard.

It’s important to follow the manufacturer’s instructions for calibration, as different models may have specific calibration procedures. Some digital calipers have calibration features built-in, allowing for easy adjustment of the measurement readings.

Regular calibration ensures that a digital caliper remains accurate and reliable. It helps identify any drift or deviation in measurements and allows for corrective action to be taken. Additionally, it may be necessary to recalibrate the digital caliper if it undergoes any significant physical impact, such as dropping or being exposed to extreme temperatures or humidity.

Lastly, it’s a good practice to periodically check the battery life of the digital caliper and replace the batteries as needed. Low battery power can affect the performance and accuracy of the caliper.

In summary, maintaining and calibrating a digital caliper are crucial steps in ensuring accurate measurements. By keeping the caliper clean, storing it properly, and regularly calibrating it against reference standards, users can rely on their digital caliper to provide precise and reliable measurements for a long time.