Basics of Transformers

A transformer is an essential device used in electrical and electronic systems for various applications. It plays a crucial role in transferring electrical energy from one circuit to another without any direct electrical connection. Understanding the fundamentals of transformers is crucial to comprehend the working of electronic transformers.

At its core, a transformer consists of two or more coils of wire wound around a magnetic core. The primary coil receives electrical energy from a power source, while the secondary coil delivers the transformed energy to the load. These coils are extensively insulated and tightly wound to minimize leakage of energy and enhance efficiency.

The principle behind transformers is based on electromagnetic induction. As per Faraday’s law of electromagnetic induction, when an alternating current (AC) flows through the primary coil, it produces a fluctuating magnetic field. This changing magnetic field induces a voltage in the secondary coil, resulting in the transfer of electrical energy.

The transfer of energy in transformers relies on the concept of mutual inductance. When AC passes through the primary coil, it oscillates at a specific frequency. This oscillating current generates a changing magnetic field around the coil. The secondary coil, placed in close proximity, experiences this changing magnetic field, inducing a voltage in it according to Faraday’s law.

It is essential to note that transformers function efficiently when working with AC power. Direct current (DC) cannot be used directly with transformers as it does not produce the alternating magnetic field required for the operation of the transformer.

What is an Electronic Transformer?

An electronic transformer is a type of transformer that operates using solid-state electronic components rather than traditional electromagnetic transformers. It is commonly used in various applications, including lighting systems, power supplies, and electronic devices.

Unlike traditional transformers, which often use bulky iron cores and rely on electromagnetic induction, electronic transformers utilize advanced electronic circuitry to step up or step down the voltage levels. This makes them more compact, lightweight, and efficient compared to their electromagnetic counterparts.

Electronic transformers are designed to convert the input voltage to a higher or lower voltage level, as required by the specific application. This voltage conversion can be achieved through several electronic techniques, such as switching and frequency modulation.

One of the main advantages of electronic transformers is their ability to provide precise and stable voltage regulation. They can maintain a constant output voltage even when there are fluctuations or variations in the input voltage. This feature makes them highly suitable for use in sensitive electronic devices that require stable power supply.

Another notable characteristic of electronic transformers is their ability to provide fast response times. Unlike traditional transformers that may have a delay in voltage regulation, electronic transformers can quickly adjust to changes in the input voltage, ensuring a constant and stable output voltage.

Additionally, electronic transformers offer improved energy efficiency compared to electromagnetic transformers. Their solid-state design and advanced circuitry help minimize energy losses during the voltage conversion process, resulting in reduced power consumption and lower heat generation.

Furthermore, electronic transformers often have built-in protection mechanisms such as overload and short-circuit protection. These safety features help safeguard the transformer and connected devices from damage in case of sudden voltage surges or faults.

AC to AC Conversion

AC to AC conversion is a fundamental process in electronic transformers, allowing the transformation of one alternating current (AC) voltage level to another. This conversion is essential in various applications where specific voltage levels are required for efficient operation.

In electronic transformers, AC to AC conversion is accomplished through techniques such as voltage regulation, frequency modulation, and waveform shaping.

Voltage regulation is the process of maintaining a constant output voltage level despite fluctuations or variations in the input voltage. Electronic transformers achieve voltage regulation by using feedback control systems that continuously monitor the output voltage and adjust the primary circuit accordingly. This ensures a stable and reliable output voltage, which is crucial for powering sensitive electronic devices.

Frequency modulation is another technique used in AC to AC conversion. It involves adjusting the output frequency of the transformer to match the desired frequency level. This is particularly useful in applications such as motor control, where different devices may require different operating frequencies. Electronic transformers can easily modify the output frequency, allowing them to cater to different equipment requirements efficiently.

Waveform shaping is also employed to achieve specific AC to AC conversion. This technique involves modifying the shape of the AC waveform, typically by altering its amplitude, frequency, or phase. By manipulating the waveform, electronic transformers can tailor the output voltage to match the desired requirements of the load. This is particularly useful in applications where precise waveform control is necessary, such as in audio amplifiers or power conditioning systems.

Overall, AC to AC conversion plays a vital role in electronic transformers, ensuring that the output voltage matches the requirements of the connected load. Through voltage regulation, frequency modulation, and waveform shaping techniques, electronic transformers provide efficient and reliable power conversion for a wide range of applications.

How an Electronic Transformer Works

Electronic transformers operate on the principles of solid-state electronics to efficiently transfer electrical energy from one circuit to another. They employ advanced electronic components and techniques to step up or step down voltage levels and provide a stable power supply for various applications.

Electronic transformers consist of several key components, including a solid-state switching device, a high-frequency inverter, a transformer core, and control circuitry.

The switching device, usually a high-power transistor or MOSFET, controls the flow of current by rapidly turning on and off. This switching action is typically performed at a high frequency, often in the kHz or MHz range.

The high-frequency inverter takes the low-voltage DC input from the power source and converts it into high-frequency AC voltage. This AC voltage is then fed into the primary winding of the transformer.

The transformer core, typically made of ferrite or other magnetic materials, efficiently transfers the high-frequency AC voltage from the primary winding to the secondary winding. The primary winding is connected to the switching device and receives the high-frequency AC voltage, while the secondary winding is connected to the load and delivers the transformed voltage.

The control circuitry is responsible for regulating the voltage output and maintaining a stable power supply. It continuously monitors the output voltage and adjusts the switching device’s frequency and duty cycle to ensure it matches the desired voltage level.

During operation, the switching device rapidly turns on and off, creating a pulsating current in the primary winding. This generates a rapidly changing magnetic field in the transformer core, which induces a corresponding voltage in the secondary winding.

By controlling the switching frequency and duty cycle, electronic transformers can efficiently step up or step down the voltage according to the desired requirements. This allows them to provide the necessary power supply for various electronic devices and systems.

Overall, the working principle of an electronic transformer involves the use of solid-state switching devices, high-frequency inverters, transformer cores, and control circuitry to achieve efficient electrical energy transfer and voltage transformation.

Primary and Secondary Coils

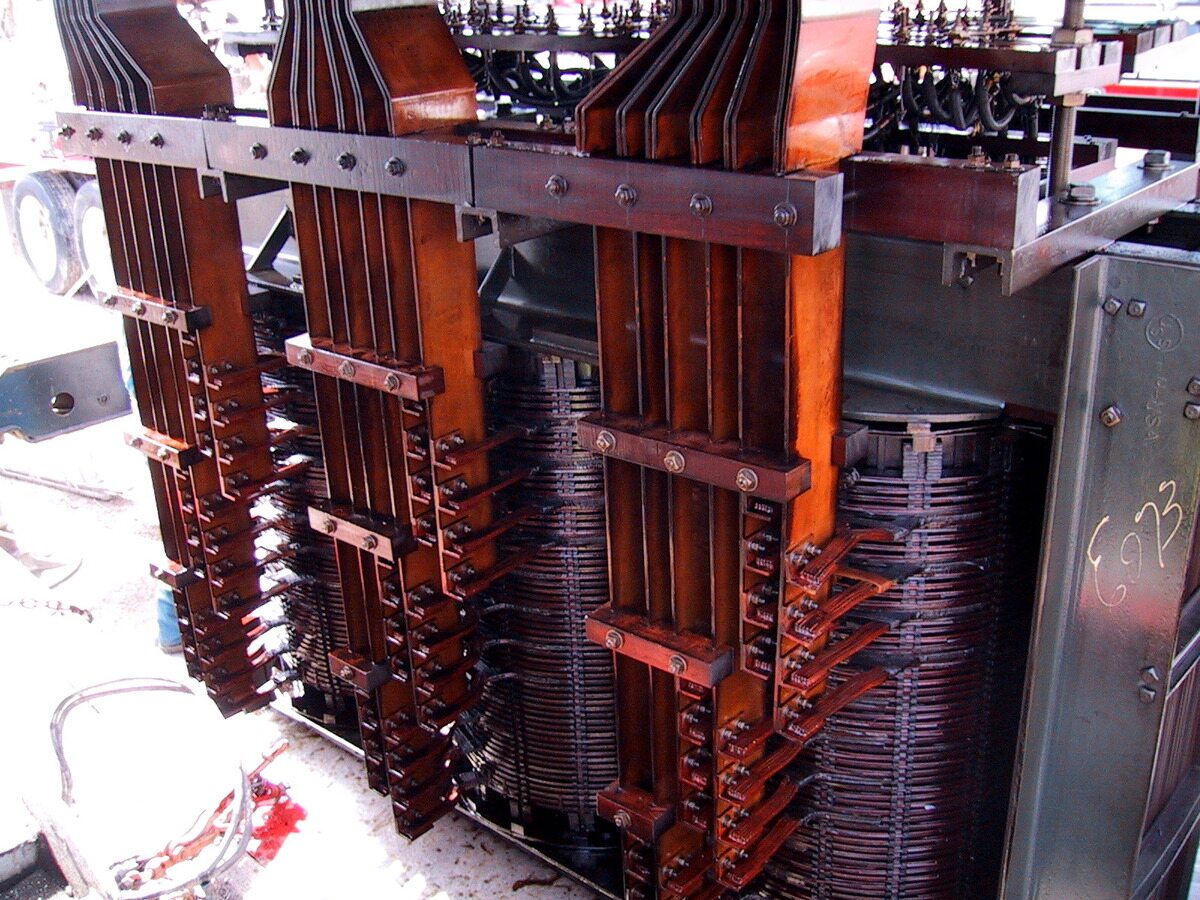

Primary and secondary coils are essential components of an electronic transformer. They play a crucial role in the transfer of electrical energy and voltage transformation.

The primary coil is the input winding of the transformer, and it receives the electrical energy from the power source. This coil is typically made of a larger gauge wire and has a significant number of turns compared to the secondary coil. The primary coil is connected to the high-frequency inverter and receives the high-frequency AC voltage.

The secondary coil, on the other hand, is the output winding of the transformer. It delivers the transformed voltage to the load. The secondary coil is made of a finer gauge wire with fewer turns compared to the primary coil. The number of turns in the secondary coil determines the voltage transformation ratio. For example, if the secondary coil has half the number of turns as the primary coil, it will step down the voltage by a factor of two.

The primary and secondary coils are wound around the transformer core. The core material, typically made of ferrite or other magnetic materials, guides the magnetic flux generated by the alternating current in the primary coil to the secondary coil. It ensures efficient energy transfer and minimizes energy losses.

The ratio of the number of turns in the primary coil to the number of turns in the secondary coil determines the transformer’s voltage transformation ratio. For example, if the primary coil has 100 turns and the secondary coil has 50 turns, the transformer will step down the voltage by a factor of two. This means that if the input voltage is 100V, the output voltage will be 50V.

It is crucial to have proper insulation between the primary and secondary coils to prevent electrical arcing and ensure safety. Transformers are designed with layers of insulation to withstand the high voltages present in the primary coil and prevent any electrical contact between the windings.

Overall, the primary and secondary coils are fundamental components of an electronic transformer. They work together with the transformer core to efficiently transfer electrical energy and achieve the desired voltage transformation. The proper design and construction of these coils are essential to ensure optimal performance and reliability of the electronic transformer.

Core Material

The core material is a crucial component of an electronic transformer. It serves as a pathway for the magnetic flux generated by the alternating current in the primary coil to link with the secondary coil. The properties of the core material have a significant impact on the transformer’s performance, efficiency, and overall functionality.

Commonly used core materials in electronic transformers include ferrite, laminated iron, and powdered iron. Each material has unique characteristics that make it suitable for different applications.

Ferrite is a type of ceramic material with high magnetic permeability and low electrical conductivity. It is widely used in electronic transformers due to its excellent high-frequency performance and low losses. Ferrite cores offer high saturation flux density, allowing for efficient energy transfer at high frequencies. Additionally, ferrite cores provide good temperature stability and can handle high operating temperatures.

Laminated iron cores consist of layers of thin iron sheets, also known as laminations, that are insulated from each other. These laminations reduce the eddy current losses in the core, improving the transformer’s efficiency. Laminated cores are commonly used in low-frequency transformers, where high efficiency and low losses are crucial.

Powdered iron cores are made by compressing iron powder into a desired shape. They offer a good balance between magnetic performance and cost-effectiveness. Powdered iron cores provide high magnetic permeability, allowing for efficient energy transfer. They are commonly used in medium-frequency applications.

The choice of core material depends on various factors, including the frequency of operation, power requirements, and cost considerations. Different applications may require specific core materials to achieve the desired performance and efficiency.

It is also important to note that the core material should possess high resistivity to minimize eddy current losses and hysteresis losses. These losses can result in reduced efficiency, increased heat generation, and overall deterioration of transformer performance.

Additionally, proper design and construction techniques, such as careful winding of the coils and adequate insulation, are crucial to ensure optimal utilization of the core material and maximize the performance of the electronic transformer.

Saturation and Hysteresis

Saturation and hysteresis are two important phenomena that occur in transformer cores and have a significant impact on the performance and efficiency of electronic transformers.

Saturation refers to the point at which the magnetic flux in the core reaches its maximum value. At saturation, further increasing the current in the primary coil does not result in a proportional increase in the magnetic flux. This occurs because the core material has limited magnetic permeability, beyond which it cannot handle any additional magnetic flux. Saturation leads to distortion in the transformer’s output waveform and can cause excessive heat generation and reduced efficiency.

Hysteresis is the phenomenon where the magnetization of the core material lags behind the applied magnetic field. This lag is due to the magnetic domains in the core material aligning and realigning themselves as the alternating current flows through the primary coil. Hysteresis results in energy losses in the form of heat due to the constant reversal of magnetic field direction during each AC cycle.

To minimize the effects of saturation and hysteresis, transformer cores are often made from materials with high magnetic permeability and low coercivity. Coercivity refers to the resistance of a material to change its magnetization state. By selecting core materials with low coercivity, the hysteresis losses can be reduced.

Additionally, laminated cores are commonly used in transformers to mitigate eddy current losses caused by the alternating magnetic fields. Laminations help to confine the flow of eddy currents, which would otherwise circulate within the core material, resulting in inefficient energy transfer and increased heat generation.

Proper design and construction techniques, along with careful selection of core materials, are crucial to minimize the effects of saturation and hysteresis. This includes selecting core materials with appropriate magnetic characteristics, such as high saturation flux density and low coercivity, and ensuring proper insulation and laminations to reduce eddy current losses and magnetic hysteresis.

By mitigating saturation and hysteresis effects, electronic transformers can operate more efficiently, reduce energy losses, and provide stable and reliable voltage transformation for various applications.

Voltage Regulation

Voltage regulation is a critical aspect of electronic transformers. It refers to the ability of a transformer to maintain a constant output voltage despite variations or fluctuations in the input voltage.

Electronic transformers achieve voltage regulation through various control mechanisms, such as feedback control systems and constant voltage control circuits.

In a feedback control system, the output voltage of the transformer is continuously monitored and compared to a reference voltage. Any deviation from the desired output voltage triggers appropriate adjustments in the primary circuit. These adjustments may include changing the switching frequency, duty cycle, or other parameters to regulate the output voltage.

The constant voltage control circuits are designed to automatically adjust the primary circuit based on changes in the load. These circuits ensure that the output voltage remains stable even when the load varies. They are particularly useful in applications where the connected devices have different power requirements and can change dynamically.

Voltage regulation is vital in electronic transformers, especially in applications where stable and precise voltage levels are crucial. For example, in lighting systems, consistent voltage regulation ensures a steady and reliable illumination level. In electronic devices, voltage regulation helps protect sensitive components from damage and ensures their proper functioning.

Poor voltage regulation can result in undesirable effects such as voltage sag or voltage swell. Voltage sag refers to a temporary drop in voltage below the desired level, usually caused by sudden load changes or faults in the power supply. Voltage swell, on the other hand, is a temporary increase in voltage above the desired level. These fluctuations can disrupt the operation of connected devices and potentially damage them.

Electronic transformers employ various techniques to improve voltage regulation. These include the use of control circuits, voltage feedback loops, and compensation techniques to adjust for variations in the input voltage and load conditions. By maintaining a stable output voltage, electronic transformers ensure the reliable operation of connected devices and enhance overall system performance.

Efficiency of Electronic Transformers

Efficiency is a critical factor to consider when evaluating the performance of electronic transformers. It refers to the ratio of output power to input power, indicating how effectively the transformer converts electrical energy.

Electronic transformers are designed to operate with high efficiency, minimizing energy losses and maximizing the utilization of electrical power. Unlike traditional electromagnetic transformers, which can have significant energy losses due to core losses and other factors, electronic transformers employ solid-state electronics to achieve improved efficiency.

One of the main factors contributing to the high efficiency of electronic transformers is the use of advanced switching and control circuitry. These circuits allow for precise control of the power transfer process, reducing energy losses and optimizing the transformer’s performance. By rapidly switching the high-frequency inverter and efficiently controlling the switching device’s conduction, electronic transformers can minimize power dissipation and improve overall energy conversion efficiency.

Moreover, electronic transformers often incorporate techniques such as soft-switching and zero-voltage switching. These techniques reduce switching losses by minimizing power dissipation during the rapid switching cycles, further enhancing efficiency.

Another aspect that contributes to the efficiency of electronic transformers is the core material selection. By using high-quality core materials with low magnetic losses and optimizing core design, electronic transformers can minimize eddy current losses and hysteresis losses, which can otherwise contribute to energy wastage.

Furthermore, electronic transformers provide voltage regulation, which helps maintain a stable output voltage despite variations in the input voltage. This stability ensures that the transformer operates at its optimal efficiency, delivering consistent energy conversion.

Efficient electronic transformers have several benefits, including reduced power consumption, lower operating costs, and less heat generation. Minimizing energy losses not only helps conserve energy resources but also contributes to environmental sustainability.

Efficiency ratings for electronic transformers can vary depending on factors such as design, load conditions, and component quality. It is essential to select quality transformers with high efficiency ratings to optimize energy usage and promote overall system performance.

Advantages and Disadvantages of Electronic Transformers

Electronic transformers offer several advantages over traditional electromagnetic transformers, but they also come with a few disadvantages that should be considered when choosing the right transformer for a particular application.

Advantages:

1. Size and Weight: Electronic transformers are generally smaller and lighter compared to electromagnetic transformers. This makes them ideal for applications where space is limited or weight constraints are a concern, such as in portable electronic devices or compact lighting fixtures.

2. Efficiency: Electronic transformers are designed to operate with high efficiency, minimizing energy losses during the power conversion process. This results in reduced power consumption, lower operating costs, and less heat generation. Improved efficiency also contributes to environmental sustainability by conserving energy resources.

3. Voltage Regulation: Electronic transformers provide precise and stable voltage regulation, ensuring a consistent output voltage even in the presence of input voltage fluctuations. This is particularly important in applications that require a steady and reliable power supply, such as sensitive electronic devices and lighting systems.

4. Fast Response Time: Electronic transformers can quickly respond to changes in input voltage or load conditions. They can adjust the output voltage and power accordingly, providing fast and efficient power delivery. This is advantageous in applications where dynamic load variations occur or when a rapid voltage adjustment is required.

Disadvantages:

1. Cost: Electronic transformers can be more expensive compared to traditional electromagnetic transformers. The advanced electronic components and circuitry involved in their design contribute to the higher cost. However, the long-term energy savings and other advantages might outweigh the initial investment.

2. Sensitivity to Line Disturbances: Electronic transformers can be sensitive to certain line disturbances, such as voltage spikes, harmonics, or frequency variations. These disturbances can affect the performance and efficiency of electronic transformers. Adequate protection mechanisms and proper design considerations are necessary to mitigate the impact of such disturbances.

3. Compatibility: In some cases, electronic transformers might not be compatible with all types of loads. Certain devices, such as those with high inrush currents or specific voltage requirements, may not be suitable for use with electronic transformers. Careful consideration of the load characteristics and compatibility is essential when choosing the type of transformer.

4. Complexity: Electronic transformers involve more complex circuitry and control mechanisms compared to traditional transformers. This complexity can make their design, installation, and maintenance more challenging. Proper understanding, expertise, and technical support may be required to ensure optimal performance and operation.

Despite the disadvantages, the advantages offered by electronic transformers, such as smaller size, higher efficiency, voltage regulation, and fast response time, make them a preferred choice in many applications where space, energy efficiency, and stable power supply are essential.

Applications of Electronic Transformers

Electronic transformers find a wide range of applications in various industries and technologies. Their compact size, high efficiency, and precise voltage regulation make them well-suited for numerous electrical and electronic systems. Here are several common applications where electronic transformers are utilized:

1. Lighting Systems:

Electronic transformers are extensively used in lighting applications such as halogen lamps, LEDs, and fluorescent lights. They provide consistent voltage regulation to ensure stable illumination and optimal performance. Additionally, electronic transformers can be designed to accommodate different types of lighting fixtures and voltage requirements.

2. Power Supplies:

Electronic transformers are utilized in power supply units for electronic devices, computers, and telecommunications equipment. They help convert and regulate AC voltages to match the required input voltage levels. The high efficiency and fast response time of electronic transformers are valuable in ensuring reliable and uninterrupted power supply to sensitive electronic components.

3. Audio Equipment:

Electronic transformers play a vital role in audio amplifiers, audio interface devices, and other audio equipment. They provide impedance matching and voltage transformation between different components, helping to enhance audio signal quality and ensure compatibility between devices.

4. Industrial Automation:

In industrial automation processes, electronic transformers are used in motor control systems, power distribution units, and various control panels. They provide voltage regulation and isolation, ensuring safe and efficient operation of machinery and equipment.

5. Renewable Energy Systems:

Electronic transformers are often utilized in renewable energy systems, such as solar power inverters and wind power converters. They convert the generated DC power from solar panels or wind turbines into AC power for use in homes, businesses, and grid integration. The efficiency and voltage regulation capabilities of electronic transformers are crucial for maximizing the energy output from renewable sources.

6. Electric Vehicles:

Electronic transformers are used in electric vehicle charging stations to convert and regulate AC power from the electrical grid to the required voltage and current levels for charging the vehicle’s battery. They provide efficient and reliable power conversion, ensuring fast and safe charging of electric vehicles.

These are just a few examples of the broad range of applications where electronic transformers are utilized. Their versatility and ability to provide efficient voltage conversion and regulation make them essential components in various electrical and electronic systems, contributing to improved performance, energy efficiency, and overall functionality.